61040-1 Gb - 1020-1.doc, , 7-12-2014

Operating Instructions

1. Intended use. This Power Tool is intended for

industrial applications, for cutting sheet metal

(maximum capacity is indicated in the

Specifications), for use with cutting jaws and cutting

blades which are indicated in these operating

instructions or recommended by DRÄCO

2. Initial Operation

Observe the rated voltage: The voltage of the power

source must match that given on the nameplate of the

machine. Machines for 230V can also be operated on

220 V power sources.

Switching ON and OFF

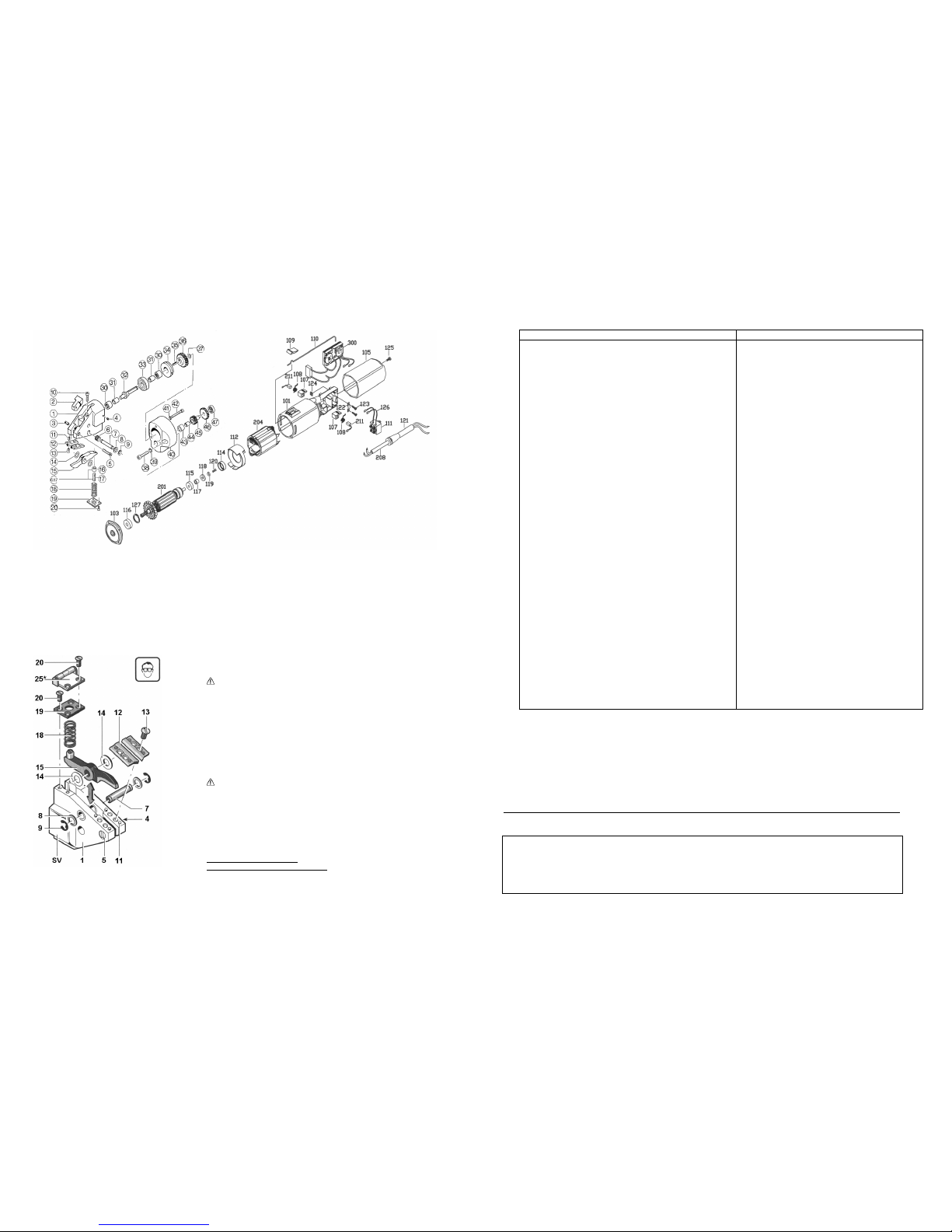

Switching ON: Slide the switch pad (109) forward

Switching OFF: Slide the switch pad (109) to the rear.

2. The material to be cut must always be free of oil or

grease. Always place the machines jaws flat on the work

piece.

3. Cut-outs: Drill a starting hole with a 12-14 mm diameter

drill. Circular cuts: Always cut counter clockwise and

from left to right.

4. Do NOT cut sheet metal along welding points. Do

NOT cut multi layer sheets, which exceed the

maximum cutting capacity.

5. For inside cutting, the shortest curve possible has

a radius of 200 mm (±8”). If cutting a radius with

the right hand, cut from right to left. The outside

radius is unlimited.

6. For cutting out curved or circular inside patterns,

a 14 mm (± 1/2 “) hole, or a punched slot should

be made to insert the centre cutter.

7. If after cutting, a small strip remains this can

easily be trimmed off to the exact measurement,

without leaving a burr or any distortion of the

material. Just one side of the power tools can be

used for cutting also (e.g. along a marked line).

Lift the power tools out of the shavings while the

motor is running. Cut off longer shavings.

8. Both knife and jaws can be sharpened. After

being sharpened or replaced, the knife at it’s

lowest point should protrude the jaws by

approximately 3 mm. The knife should have

approximately 0,05 mm (0,005”) play on each

side of the jaws, centring the cutter with spacing

shims supplied.

9. Every 200 operating ours have the cutting blade

and cutting jaws sharpened at a specialist

workshop.

10. Ensure that the material to be cut is free of oil

and grease.

Noise/vibration information

Recycling raw materials instead of waste

disposal. Machine, accessories and packaging should

be sorted for environment-friendly recycling.

These instructions are printed on recycling paper

manufactured without chlorine

Measured values determined according to EN 50 144.

Typically the A-weighted sound pressure level of the tool is

83 dB(A). The noise level when working can exceed 85 db

(A).

Wear ear protection!

The typical hand-arm vibration is below 2,5 m/s²

Before working on machine disconnect from power

supply by removing plug from socket.

Always keep the machine and the ventilation slots clean.

Oil the knife pin and knife at regular intervals.

If the machine should happen to fail despite the care

taken in manufacture and testing, repair should be

carried out by an authorised customer services agent for

DRÄCO power tools

DRÄCO tools carry a guarantee of 12 months from

date of delivery.

Damage attributable to normal wear and tear,

overload or improper handling will be excluded from

the guarantee. (e.g. blades/knifes and jaws)

In case of complaint please send the machine,

undismantled, to your dealer or the DRÄCO Service

Centre for electric power tools.

CE-Declaration of conformity

We declare under our sole responsibility that this product is in conformity with the following standards.

EG 98/37, EG 93/ 68 EWG, EG 04/108 EG und Normen DIN EN ISO 12100-1 , DIN EN ISO 12100-2 , EN 50 144, EN 55 014,

entspricht.

14 Susanne Draenert

Operating Instructions for the metal shear 1020-1

To avoid any disturbance please read the following instructions:

For your safety:

1 2 3 4 5

1 Safe operation of this machine is possible only

when the operating instructions and the safety

precautions are read completely and the

instructions contained therein are strictly

observed.

2The machine must not be used when damp and

must not be operated in a wet environment.

3Always inspect cable and plug before using

machine. Only have damage repaired by a qualified

professional. Put the plug into the mains socket only

when the machine is switched off.

4+5 Always wears protective goggles, protective

gloves and heavy-duty shoes when working.

lDo not carry the machine by the cable.

lAlways remove the plug from the power

supply socket before carrying out any work on

the machine, when interrupting work and when

not using the machine.

lAlways place the cable to the rear away

from the machine.

lApply the machine to the sheet metal only

when switched on.

lAlways provide for secure footing when

working.

lFirmly clamp the workpiece if it dose not

remain stationary from its own weight.

lThe knife should not rub on the jaws:

Possible danger of cutting tool breakage.

lDo not exceed the maximum allowable

material thickness especially when cutting over

doublers, folded joints or welded seams.

FFor further notes on safety refer to enclosed sheet