Intended use.

This power tool is intended: for commercial applications in industry and trade, for cutting sheet-metal (the maximum cutting thicknesses

of the material are indicated in the Specifications), for use with dies and punches, which are indicated in these operating instructions or

recommended by DRÄCO.

Operating the power tool.

To ensure that the die and punch have a long service life, apply cutting paste or oil along the cutting path (on sheet steel), or petroleum

(on aluminium sheet).

Switching ON/OFF (1)

First check that the cable and plug are not damaged.

Switching the power tool ON:

nSlide switch (1) forward (I)

Switching the power tool OFF:

nSlide switch (1) backwards (0).

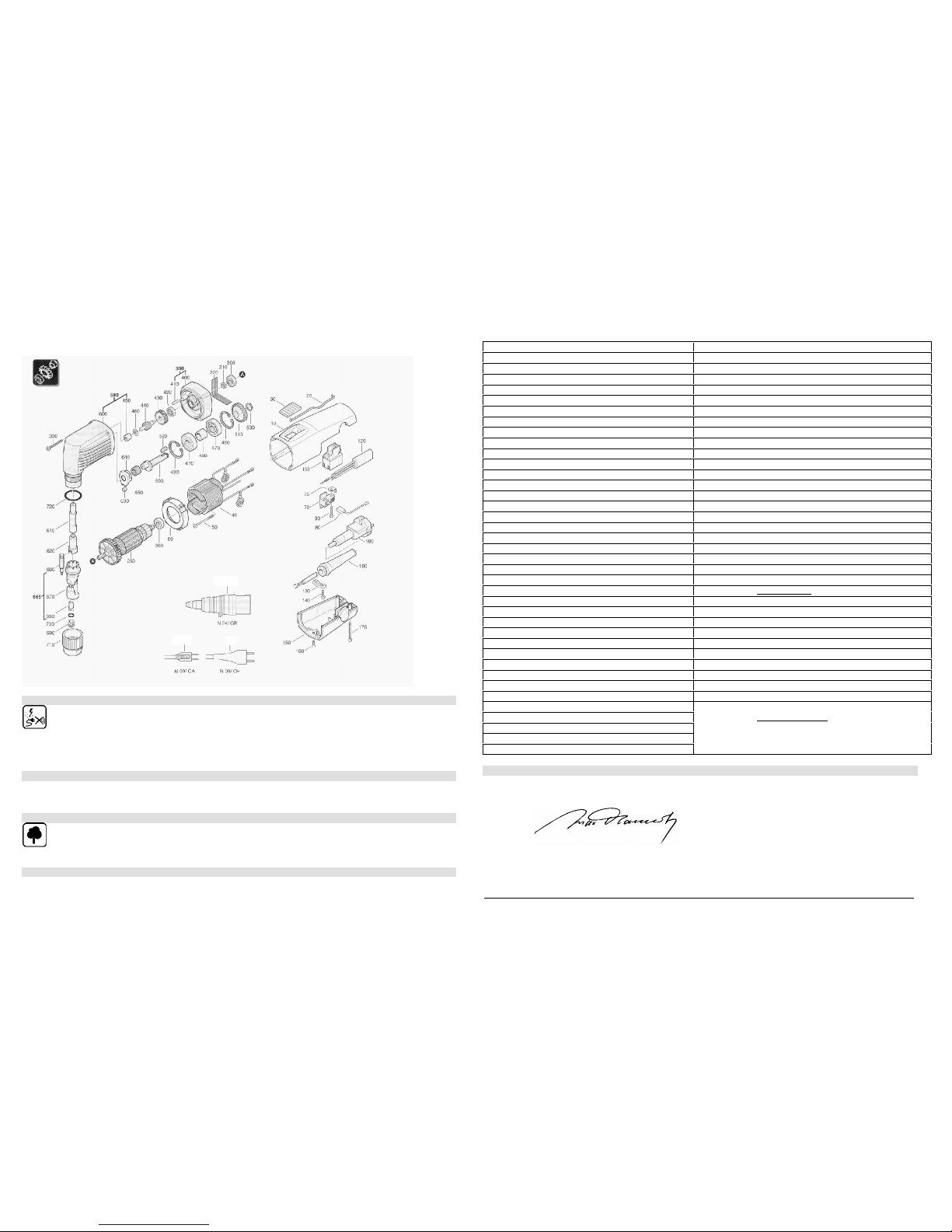

Adjusting the cutting direction (3)

nLoosen the union nut (7a) by approx. 3 revolutions.

nPull the die holder downwards.

nRotate the die holder in the cutting direction, push up and notch it

into the groove.

nTighten the union nut.

Changing the punch (5)

Risk of injury by switching the tool ON unintentionally. Before

changing the tool, pull out the mains plug.

Do not regrind the punch and dies. If increased feed is required to

guide the power tool or if no-load strokes or excessive burr formation

occur, the cutting tools are blunt.

For an optimum cut, change the die and punch at the same time!

nLoosen the union nut. (7a)

nRemove the die holder.

nChange the punch.

nRe-fit the die holder again.

nTighten the union nut.

Changing the die (6)

Risk of injury by switching the tool ON unintentionally.

Before changing the tool, pull out the mains plug. For an optimum cut,

change the die and the punch at the same time.

nUnscrew the screw (a).

nPress out and change the die.

nTighten the screw (a).

Assembling the profile set (7)

Risk of injury by switching the tool ON unintentionally.

Before changing the tool, pull out the mains plug.

Ideal for treating deep-profiled trapezoidal sheets.

Loosen the union nut (7a) and remove die holder and punch.

Pull the punch extension upwards a little out of the profile set and

insert it from the side into the groove.

Mount the profile set.

Tighten the union nut (7a).

For changing the punch pull it out completely, together with the punch

extension.

Attention! Put in the die in from the side (Die groove has to

match the groove at the wear plate).

1Safe operation of this machine is possible only when the

operating instructions and the safety precautions are read

completely and the instructions contained therein are strictly

observed.

2The machine must not be used when damp and must not be

operated in a wet environment.

3Always inspect cable and plug before using machine. Only have

damage repaired by a qualified professional. Put the plug into the

mains socket only when the machine is switched off.

4+5 Always wears protective goggles, protective gloves and heavy-

duty shoes when working.

lDo not carry the machine by the cable.

lAlways remove the plug from the power supply socket before

carrying out any work on the machine, when interrupting work

and when not using the machine.

lAlways place the cable to the rear away from the machine.

lApply the machine to the sheet metal only when switched on.

lAlways provide for secure footing when working.

lFirmly clamp the work piece if it dose not remain stationary

from its own weight.

lThe knife should not rub on the jaws: Possible danger of

cutting tool breakage.

lDo not exceed the maximum allowable material thickness

especially when cutting over doublers, folded joints or welded

seams.