CONTENTS

Safety Notices................................................................................................................................. 1

1. Technical description............................................................................................................ 5

2. Technical Features................................................................................................................. 5

3. Technical Data............................................................................................................................ 5

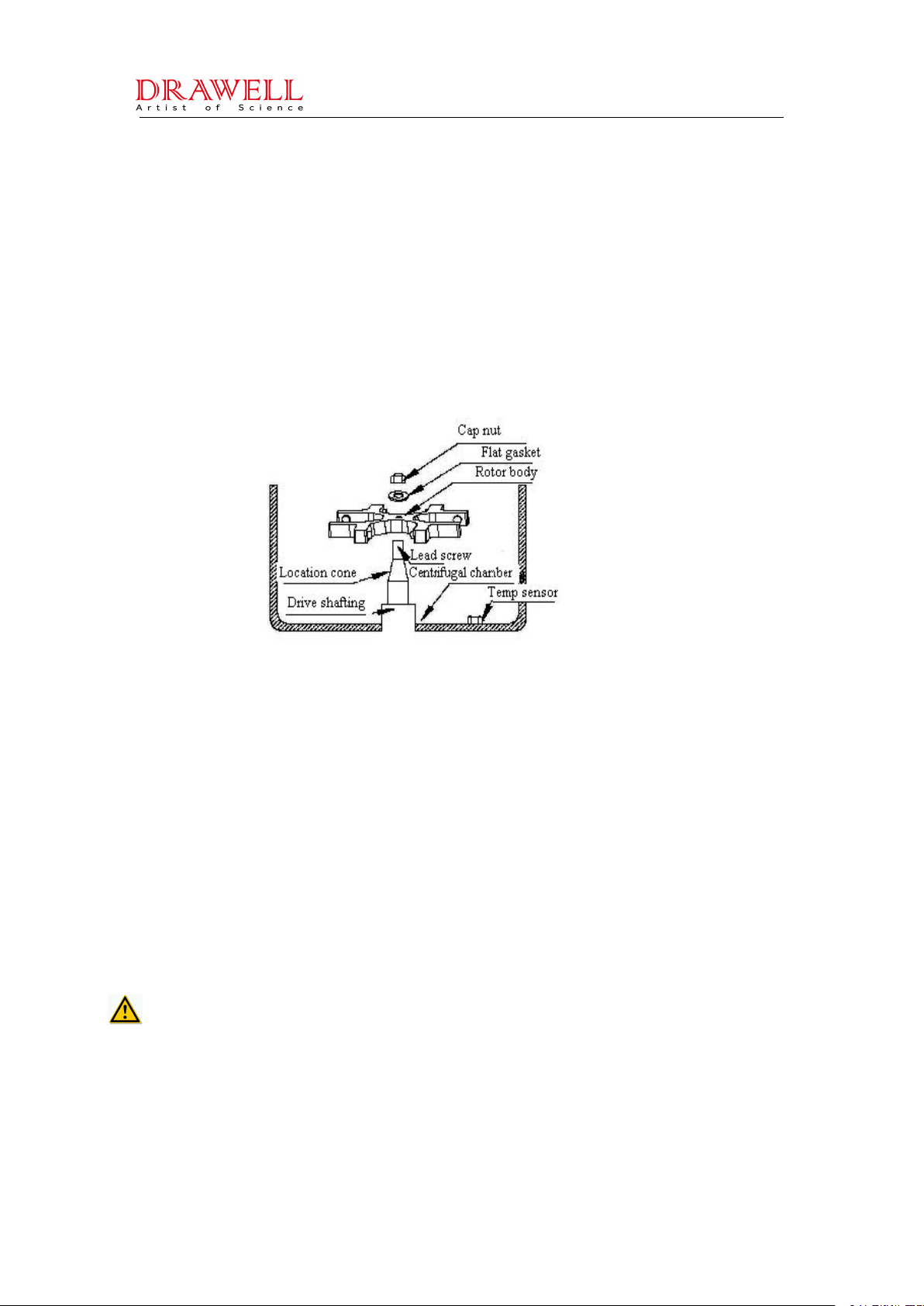

4. Structure Characteristics........................................................................................................ 6

4.1 Structure......................................................................................................................................6

4.2 Main Frame Shap................................................................................................................... 6

5. Installation................................................................................................................................... 6

5.1 Installation Requirement...........................................................................................................6

5.2 Adjusting Requirement..............................................................................................................7

6. operation...................................................................................................................................... 8

6.1 Safety Notice.............................................................................................................................. 8

6.2 How to Operate.....................................................................................................................10

6.2.1 Rotor Installation.................................................................................................................. 10

6.2.2 Tubes Installation................................................................................................................. 10

6.2.3 Preset..................................................................................................................................... 10

6.2.4. Parameter set...................................................................................................................... 11

6.2.5 Start........................................................................................................................................ 11

7. Safety Notice.............................................................................................................................11

8. Maintenance..............................................................................................................................12

9.Trouble Shooting...................................................................................................................... 12

10. Electrical Block...................................................................................................................... 13

Warranty......................................................................................................................................... 14

Quality Certificate........................................................................................................................ 15

Packing List................................................................................................................................... 16