Contents

Contents................................................................................................................................... 1

Attention................................................................................................................................... 1

Attention for safety.................................................................................................................................. 1

Attention for fireproofing.........................................................................................................................2

Attention for safe operation................................................................................................................... 2

Attention for safety in chemistry and biology......................................................................................3

1. General introduction..............................................................................................5

1.1 Application and scope......................................................................................................................5

1.2 Name and Classify........................................................................................................................... 5

1.3. Centrifugation Theory..................................................................................................................... 5

2. Main technical parameters..............................................................................................5

2.1 Technical features............................................................................................................................ 5

2.2 Technical data................................................................................................................................... 6

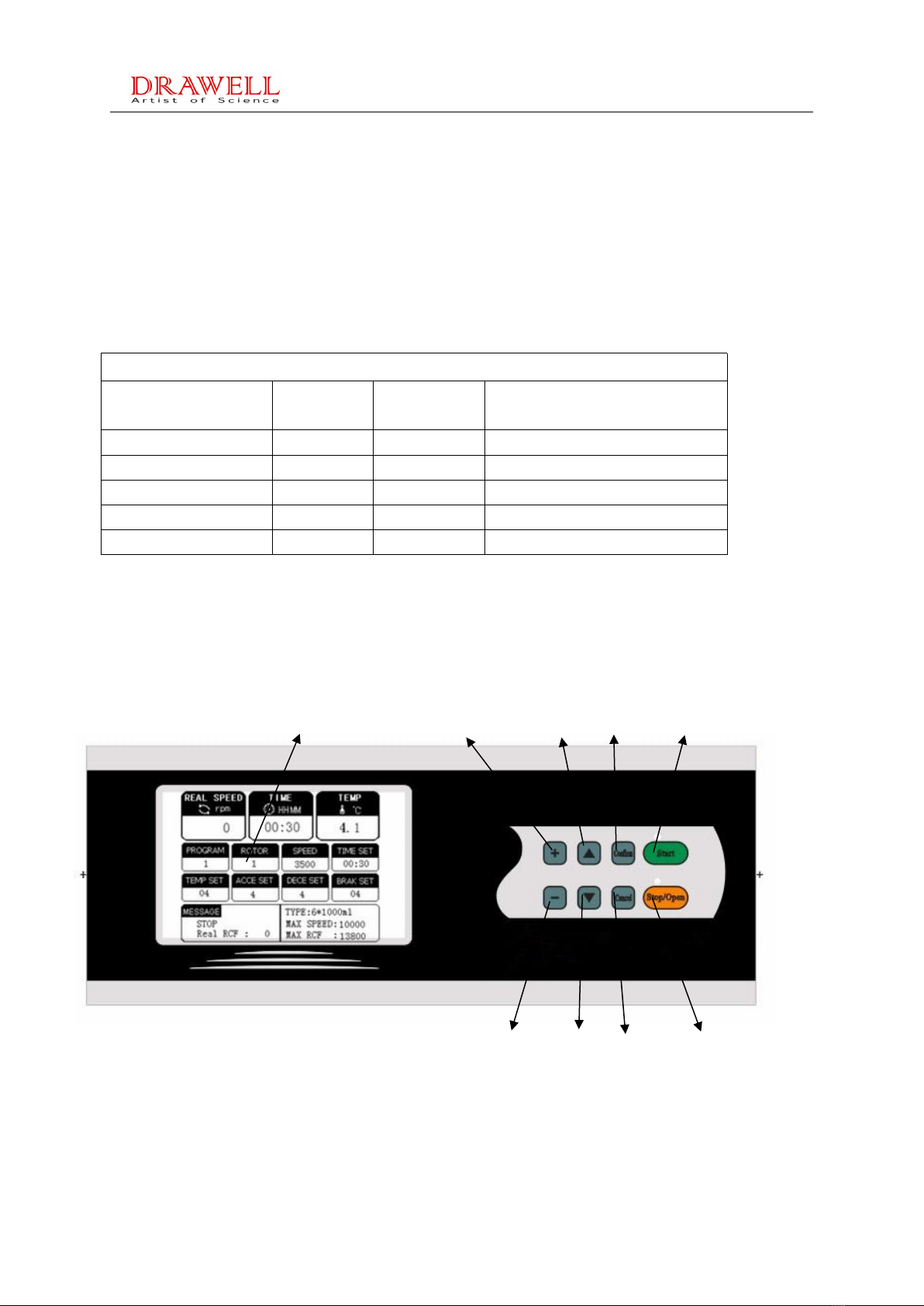

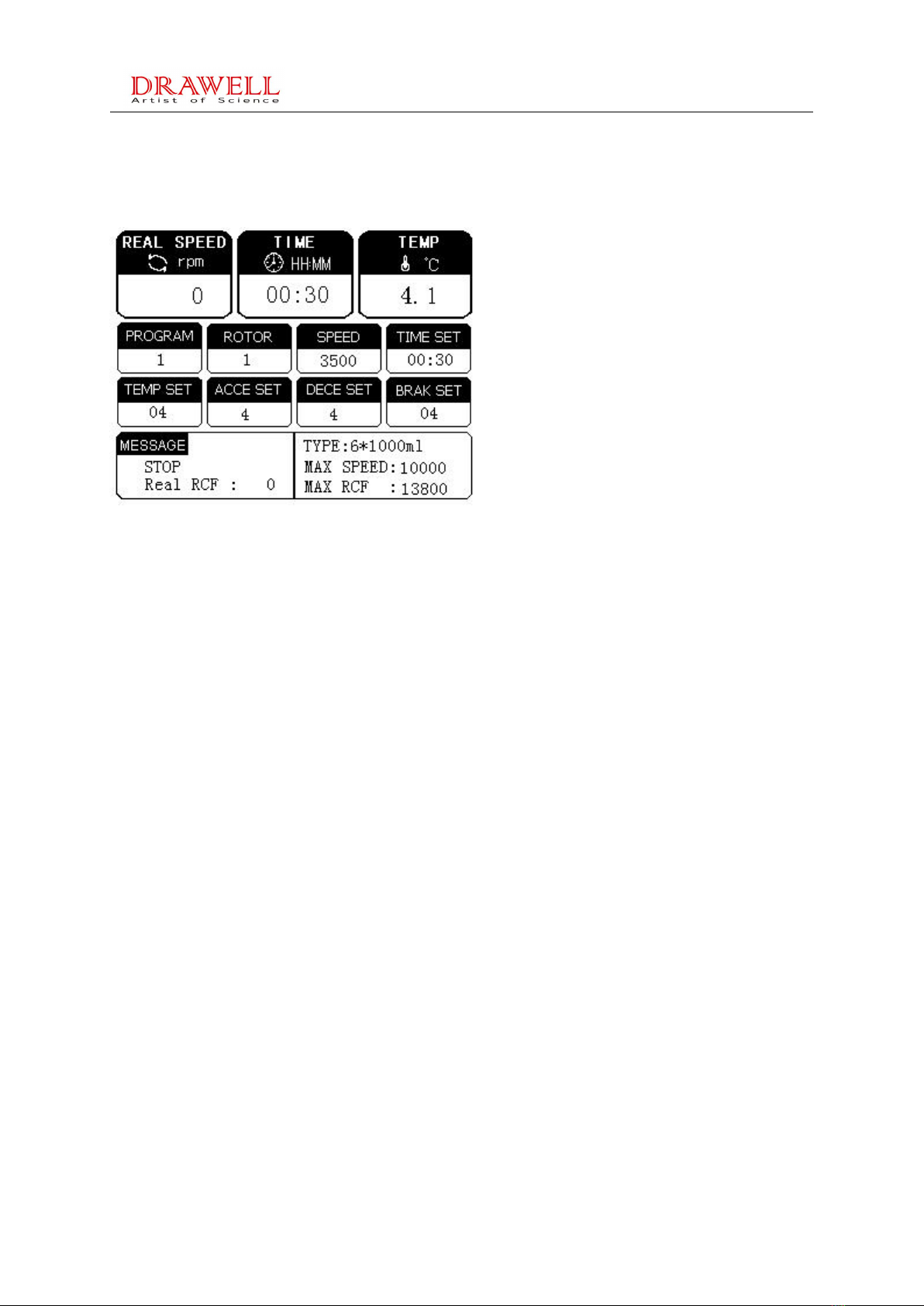

2.3 Control Display Panel...................................................................................................................... 6

3. Installation........................................................................................................................... 7

3.1 Installation Requirements............................................................................................................... 7

3.2 Normal Working Conditions.........................................................................................................7

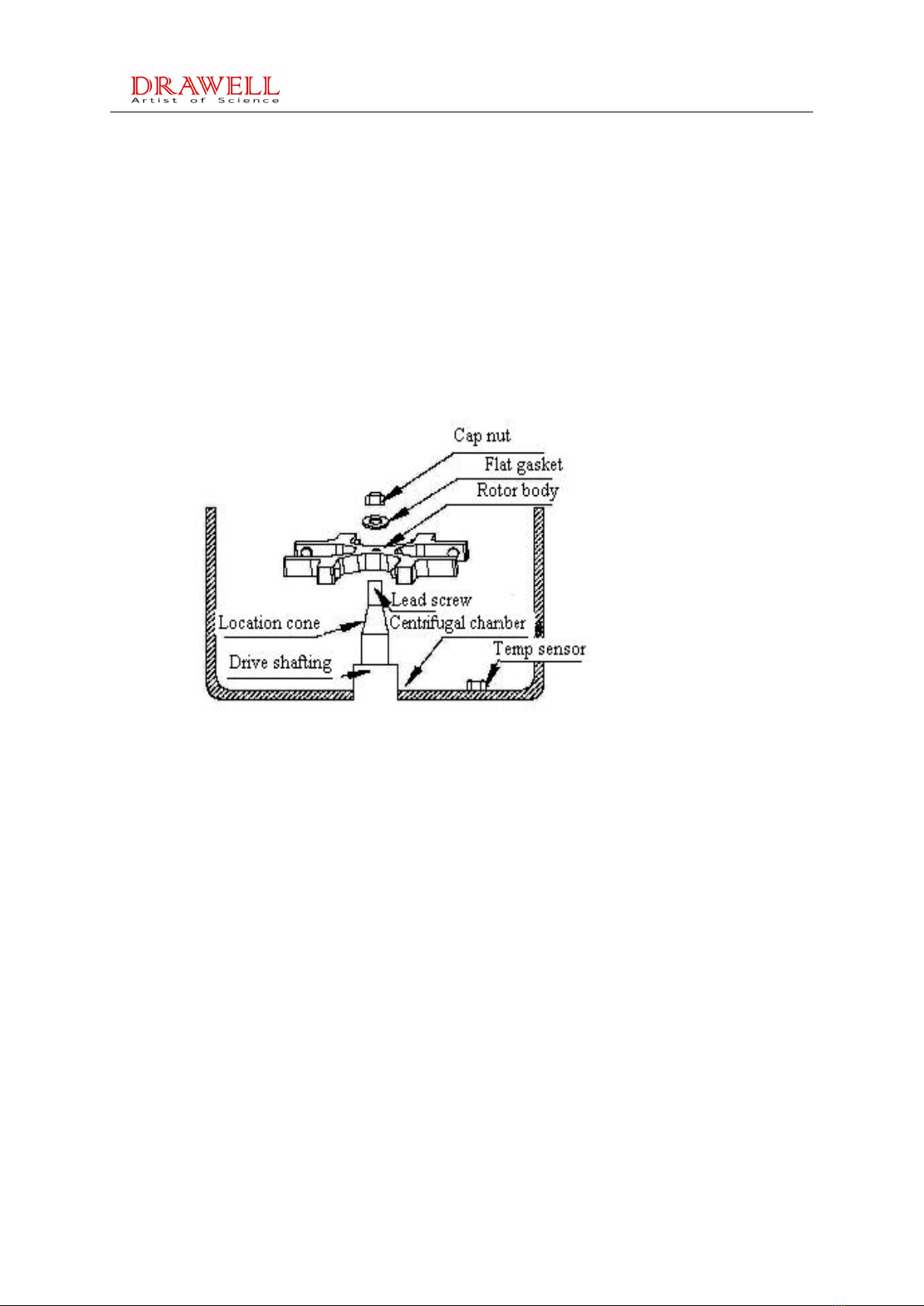

3.3 Rotor Installation............................................................................................................................8

3.4 Installation of Brackets and Tubes............................................................................................. 8

3.5 Operation Procedures & Directions...............................................................................................9

3.5.1 Power on................................................................................................................................ 9

3.5.2 Parameters setting................................................................................................................9

3.5.3 Closing the lid......................................................................................................................10

3.5.4 Start the machine................................................................................................................10

3.5.5 Stop the machine................................................................................................................10

3.5.6 Note....................................................................................................................................... 11

4. Maintenance......................................................................................................................11

5. Trouble Shooting............................................................................................................. 12

6. Instrument safety and protection................................................................................13

7. Electrical Block............................................................................................................. 14

8. Quality Warranty........................................................................................................... 14

Quality Certificate.....................................................................................................15

Packing List..............................................................................................................16

Warranty Card...........................................................................................................17

Service Records.......................................................................................................18

Service Manual.........................................................................................................19