Drawell Scientific

Precautions on Safe Operation

Precaution:

♦For your safety and to operate the instrument properly, please read this operation instruction

carefully before using and operate the following requirements in this manual.Where you violate

the instruction of manufacturer in this manual, it is possible to damage the protection of this

instrument.

♦This instrument shall not be used for purposes other than sterilization,drying,and it shall also

not be used for sterilizing the flammable, explosive and readily oxidizable products or strong acid,

alkali and saline solutions to avoid explosionand corruption of sterilizer chamber or pipelines.

♦The power supply of sterilizer should be properly connected according to nameplate on the

instrument. In case of excessive voltage fluctuation, the regulated power supply shall be used to

ensure optimum performance of the instrument. IF you are using other types of voltage, a

transformer must be used to prevent the instrument from being damaged.

♦It is necessary to ground the instrument properly, and never connect the ground wire to

plastic pipeline, gas pipe, telephone ground wire and lightning rod.

♦Never block the steam exhaust hole on the safety valve with articles, so that the safety valve

may work properly under abnormal conditions.

♦Always ensure that the reading of pressure gauge is "OMpa" before opening the chamber

cover. Never attempt to open the chamber cover and drainage valve, or draw out the steam

trapping bottle when the pressure inside the sterilizer chamber is over "OMpa" to avoid injury

from ejected pressurized steam.

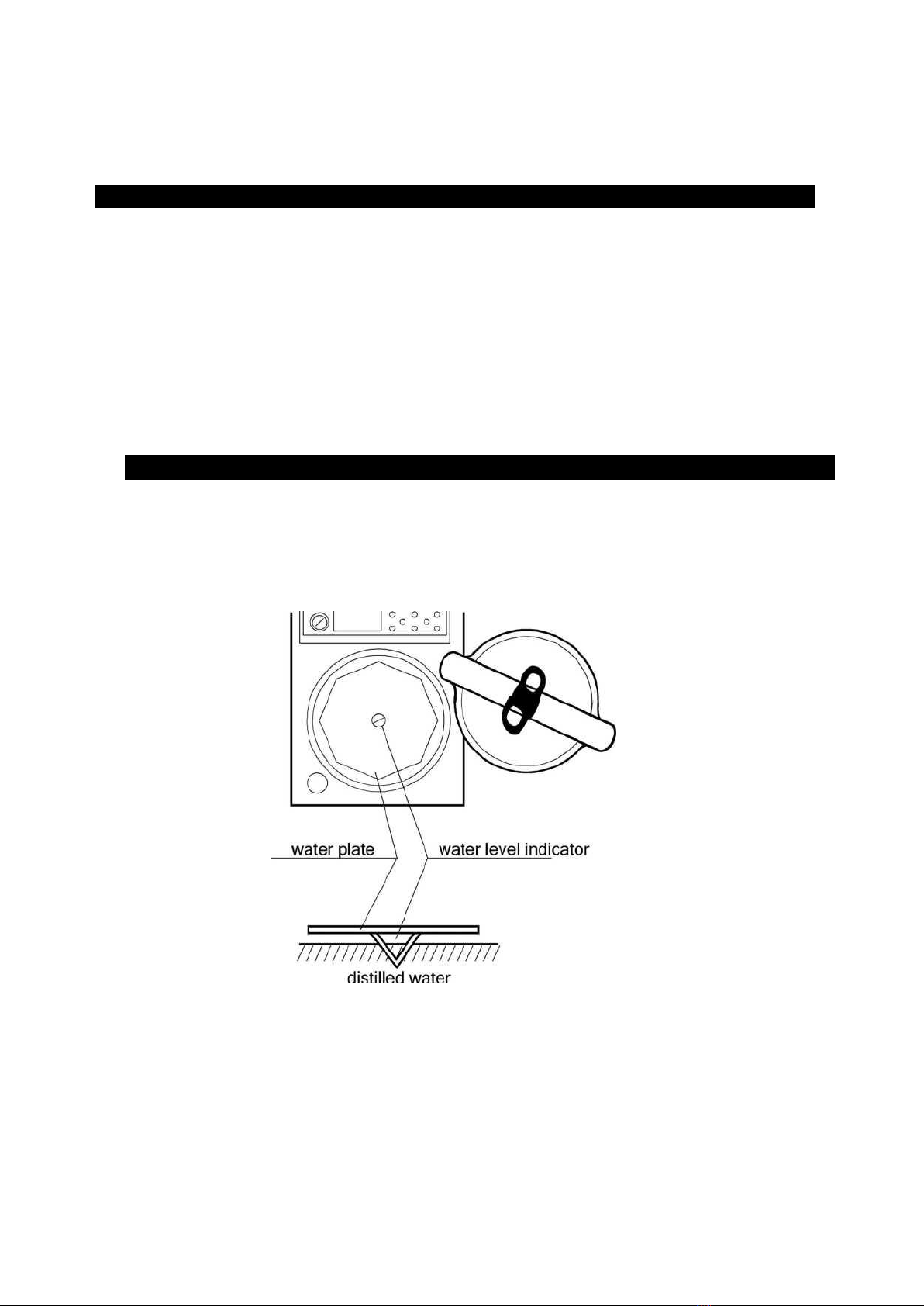

♦Avoid dripping water to the control circuit when adding distilled water to the sterilizer

chamber to against electric shock or other faults.

♦When using waste processing bags or other type of bags, please put the bags into the

stainless steel basket before put into the sterilizer chamber to avoid affecting the precision of

temperature.

♦If the handle is turned by mistake during sterilization, it will not continue turning as it has

been locked by the interlocking device, and there will be a little steam exhausted to release. In this

case, press the"STOP" button to stop the instrument immediately. When opening the chamber

cover, turn the handle slightly toward the opposition direction that it is wrongly operated, and

then turn the handle counter-clockwise until the cover is released.

♦Observe the temperature variation inside the sterilizer chamber. The temperature is relatively

high when operation has been finished, keep the face and hands away from the sterilizer chamber

when opening the cover to avoid injury from ejected pressurized steam. Gloves must be used

when taking articles out of the sterilizer chamber.

♦Liquid does take some time to get cooling, verify whether the temperature is low enough or

not, when taking the liquid after sterilization out of the chamber to avoid scalding.