Dremel 200 series User manual

Other Dremel Tools manuals

Dremel

Dremel PC10 User manual

Dremel

Dremel 8300 User manual

Dremel

Dremel 8260 Assembly instructions

Dremel

Dremel 330 Assembly instructions

Dremel

Dremel 225 User manual

Dremel

Dremel 3000 Operating/s User manual

Dremel

Dremel LITE User manual

Dremel

Dremel 7350 Assembly instructions

Dremel

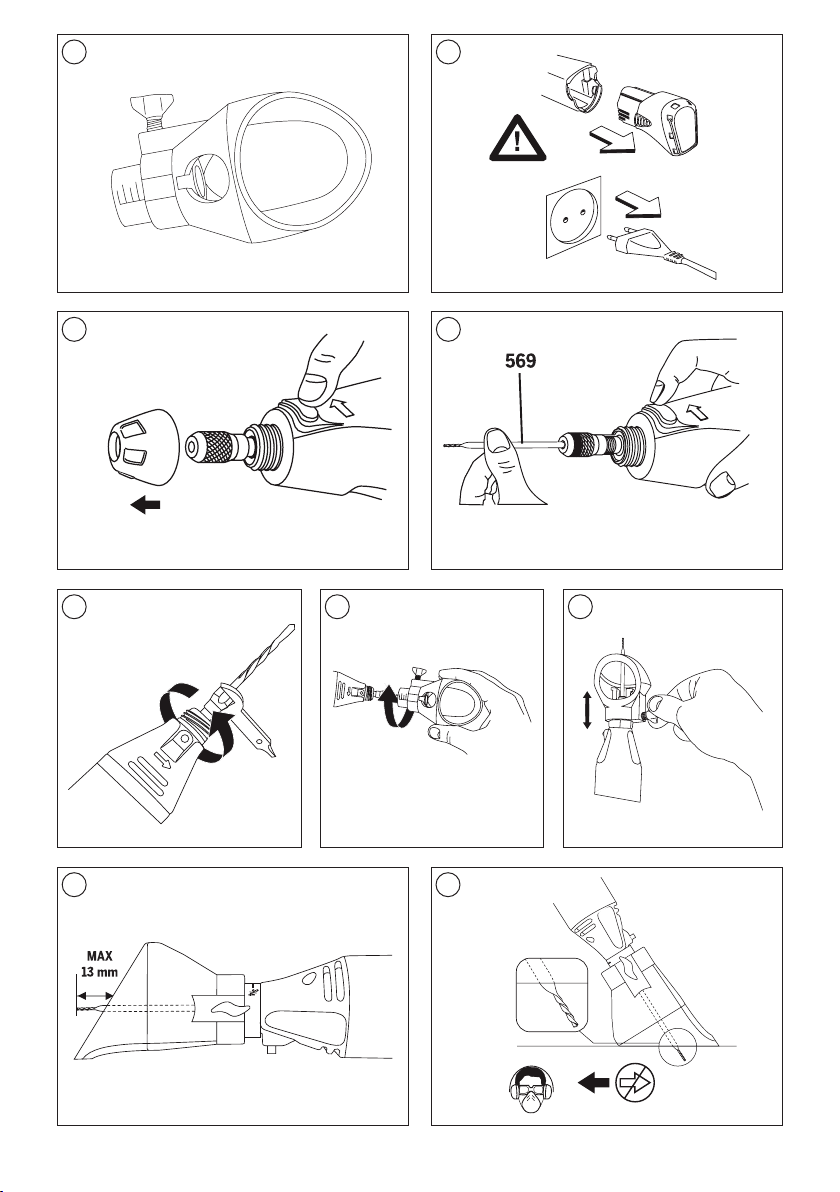

Dremel GO DRAFT Assembly instructions

Dremel

Dremel 4200 User manual