Texsteam Pumps Multipoint Installation Manual 7

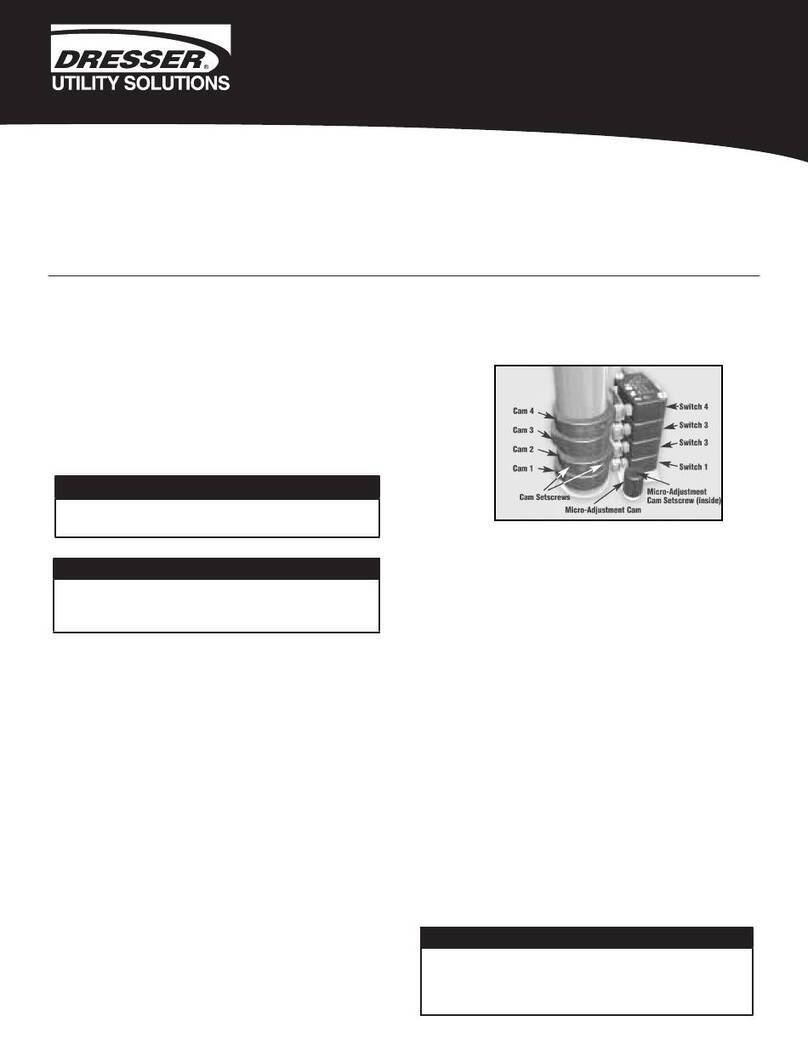

Multipoint Injection Controller

Servicing & Troubleshooting

WARNING

- EXPLOSION HAZARD -

SUBSTITUTION OF COMPONENTS MAY IMPAIR

SUITABILITY FOR CLASS 1, DIVISION 2.

WARNING

- EXPLOSION HAZARD -

DO NOT DISCONNECT EQUIPMENT UNLESS POWER

HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN

TO BE NON-HAZARDOUS.

WARNING

Beware of potentially harmful chemicals ejecting from

the pump head when you are opening the priming valve.

Take appropriate precautions to protect your self from high

temperature and/or harmful chemical exposure.

WARNING

This equipment can be installed in areas that

may contain gases or vapors which can lead to

oxygen depletion and/or personnel asphyxiation. Additional

protection and warnings should be

followed and posted in such installations.

IMPORTANT

Read this instruction document with special attention

to warnings, cautions and safety concerns.

FAILURE TO ADHERE TO THESE INSTRUCTIONS

COULD RESULT IN SAFETY HAZARDS WHICH MAY

RESULT INJURY TO PERSONNEL, MOTOR/CONTROLLER

DAMAGE OR OTHER ELECTRICAL EQUIPMENT.

Doubts or reservations with regards to installations

or maintenance with reference to connecting your

“Solar Powered” Chemical Injection Pump system should

refer to the detailed sections supplied in this manual.

For additional instruction, classication or assistance,

contact an authorized Service Center.

WARNING

Avoid personnel injury involving equipment that is in motion.

Always remove or disconnect power prior to service to

the motor, motor controller, batteries, charge controller,

solar panels.

For uid leaks check all ttings make sure there are no loose

connections, and tight ttings.

For solenoids valve not operating, check electrical connections.

The following spare parts are available if replacements are need

it:

Part # Description

SP2216 RELAY MODULE, DIN-RAIL MNTD

TERMNL BLCK,12VDC 6AMP

TB 1774 MANIFOLD VALVE ASSY, 4 STATION

TA 1773 MANIFOLD VALVE ASSY, 3 STATION

TA 1772 MANIFOLD VALVE ASSY, 2 STATION

TC 2400-KIT KH401XF02J1BF5 - Solenoid Repair Kit

Emergency eld repairs by authorized service technicians are

strongly advisable. Repairs made by un-authorized technicians

will void any warranty. To assure safety of equipment and

personnel, only Dresser recommended replacement parts

shall be installed. And above all, disconnect power from the

iCIP® pump before servicing. Damage to wiring and operating

equipment may be avoided with careful reviewing the

operating and installation procedures document by qualied

personnel. At all times, operating safety of electrical equipment

is imperative to avoid injury to personnel.