404LXR Series Product Manual

3

404LXR Series Product Manual

Table of Contents

REVISION NOTES.............................................................................................................................................................. 4

CHAPTER 1 - INTRODUCTION ......................................................................................................................................... 5

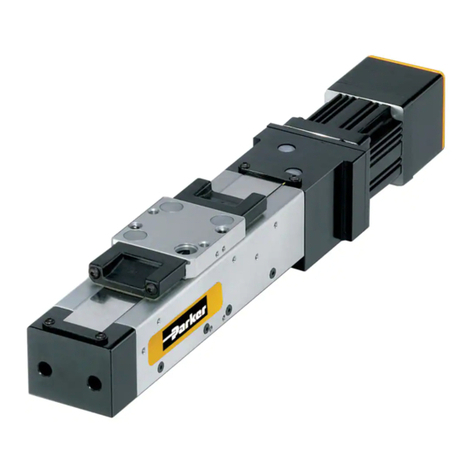

PRODUCT DESCRIPTION...................................................................................................................................................... 5

UNPACKING ....................................................................................................................................................................... 5

RETURN INFORMATION........................................................................................................................................................ 6

REPAIR INFORMATION ......................................................................................................................................................... 6

WARNINGS AND PRECAUTIONS ............................................................................................................................................ 6

SPECIFICATION CONDITIONS AND CONVERSIONS ................................................................................................................... 7

ASSEMBLY DIAGRAMS ........................................................................................................................................................ 8

Strip Seal Version............................................................................................................................................................................8

Hardcover Version...........................................................................................................................................................................9

CHAPTER 2 - 404LXR SERIES TABLE SPECIFICATIONS............................................................................................ 10

ORDER NUMBER NOMENCLATURE ..................................................................................................................................... 10

DIMENSIONAL DRAWINGS.................................................................................................................................................. 11

GENERAL TABLE SPECIFICATIONS...................................................................................................................................... 12

404LXR SERIES TECHNICAL DATA .................................................................................................................................... 17

Force/Speed Charts.......................................................................................................................................................................17

Clean Room Preparation ...............................................................................................................................................................18

ELECTRICAL SPECIFICATIONS ............................................................................................................................................ 19

CABLING AND WIRING DIAGRAMS....................................................................................................................................... 21

Connector Pin Out and Extension Cable Wire Color Codes ...........................................................................................................21

CHAPTER 3 - HOW TO USE THE 404LXR ..................................................................................................................... 24

MOUNTING SURFACE REQUIREMENTS ................................................................................................................................ 24

MOUNTING METHODS ....................................................................................................................................................... 24

SIDE AND INVERTED MOUNTING CONCERNS........................................................................................................................ 25

SETTING TRAVEL LIMIT SENSORS ...................................................................................................................................... 25

SETTING HOME SENSOR ................................................................................................................................................... 26

Z CHANNEL POSITION REFERENCE .................................................................................................................................... 26

GROUNDING / SHIELDING .................................................................................................................................................. 26

CABLING ......................................................................................................................................................................... 27

CHAPTER 4 - PERFORMANCE....................................................................................................................................... 28

ACCELERATION LIMITS ...................................................................................................................................................... 28

SPEED LIMITS .................................................................................................................................................................. 29

ENCODER ACCURACY AND SLOPE CORRECTION.................................................................................................................. 29

THERMAL EFFECTS ON ACCURACY..................................................................................................................................... 31

THERMAL EFFECTS ON REPEATABILITY............................................................................................................................... 32

CAUSES OF TEMPERATURE INCREASES .............................................................................................................................. 32

COMPENSATING FOR THERMAL EFFECTS ............................................................................................................................ 33

CHAPTER 5 - CONNECTING THE GEMINI AMPLIFIER................................................................................................. 34

CHAPTER 6 - MAINTENANCE AND LUBRICATION ...................................................................................................... 37

INTERNAL ACCESS PROCEDURE ........................................................................................................................................ 37

SQUARE RAIL BEARING LUBRICATION................................................................................................................................. 39

CABLE MANAGEMENT MODULE REPLACEMENT.................................................................................................................... 39

LIMIT AND HOME SENSOR MODULE ADJUSTMENT ................................................................................................................ 41

LIMIT AND HOME SENSOR MODULE REPLACEMENT.............................................................................................................. 42

APPENDIX A – UNDERSTANDING LINEAR MOTORS.................................................................................................. 43

THE LINEAR MOTOR CONCEPT .......................................................................................................................................... 43

LINEAR MOTOR BENEFITS ................................................................................................................................................. 43

SLOTLESS LINEAR MOTOR DESIGN .................................................................................................................................... 43

ADVANTAGES/DISADVANTAGES OF SLOTLESS LINEAR MOTORS ............................................................................................ 44

APPENDIX B - INTERNAL PROTECTION....................................................................................................................... 45

INDEX ............................................................................................................................................................................... 47