51

iiiii

TABLE OF CONTENTS

INTRODUCTION 1

CHAPTER 1: OVERVIEW 2

1 A: Glossary.............................................................2

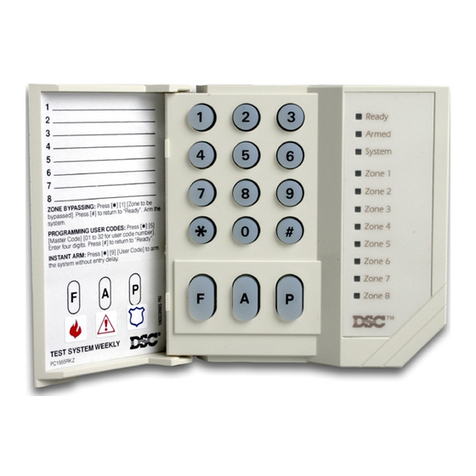

1 B: Components ......................................................3

CHAPTER 2: GETTING STARTED 5

2 A: Preparing for Installation ...................................5

2 B: Installing the Controller Battery .........................6

CHAPTER 3: ADDING COMPONENTS 7

3 A: Enrolling the First Keypad.................................7

3 B: Entering the Enrollment Mode...........................8

3 C: Enrolling Sounders............................................9

3 D: Enrolling Detection Devices ...........................10

3 E: Enrolling the Second Keypad .........................11

3 F: Reviewing the List of Enrolled Components ...12

3 G: Removing Components from the System.......13

CHAPTER 4: MODULE PLACEMENT AND TESTING

14

4 A: Locating the Controller and Sounders............14

4 B: Locating System Components........................14

4 C: Entering the Placement Test Mode.................15

4 D: A Note About WLS904 Wireless

Motion Detectors:.............................................16

CHAPTER 5: INSTALLER PROGRAMMING 17

5 A: How to Enter the Installer’s

Programming Mode .........................................17

5 B: Programming Data Entry Sections..................18

5 C: Programming System Option Sections...........19

5 D: Exiting Installer Programming.........................19

CHAPTER 6: ZONE LABELS 20

6 A: Editing Zone Labels ........................................20

6 B: Label Editing Options......................................21

CHAPTER 7: MOUNTINGTHE COMPONENTS 22

7 A: Controller .........................................................22

7 B: Sounder ...........................................................22

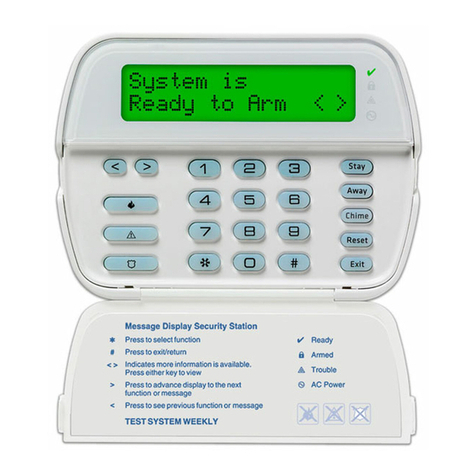

7 C: Keypad ............................................................23

7 D: Motion Detector...............................................23

7 E: Universal Transmitter .......................................23

7 F: Smoke Detector ...............................................23

CHAPTER 8: SYSTEM PROGRAMMING SECTIONS24

[00] Binary Programming ........................................24

[01] Zone Definitions ...............................................24

[02] System Times ...................................................26

[03] Installer’s Code ................................................26

[04] Master Code.....................................................26

[05] First System Options ........................................27

1 Quick-Exit Enable / Disable...........................27

2 Auto-Interior Enable / Disable .......................27

3 Door Chime Option Available / Not Available28

4 One-Time Use Code Option..........................28

5 Sounder Shutdown Enable / Disable ............28

6 Second Sounder Operation...........................28

7 Pre-Alert Volume Setting................................28

8 AC Trouble Indication ....................................28

[06] Second System Options ..................................29

1 [F] Key Disable / Enable................................29

2 [P] Key Disable / Enable ...............................29

3 [A] Key Disable / Enable ...............................29

4 [P] Key Audible / Silent..................................29

5 [F] Key Alarm Steady / Pulsed ......................29

6 Bypassing Disable / Enable ..........................29

7 Keypad Lockout Enable / Disable ................29

8 AC Frequency ................................................29

[07] Third System Options.......................................30

1 Entry Delay Off Arming Option ......................30

2 Silent Supervisory Fault .................................30

3 Tamper Faults Transmit Only while Armed....30

4 Interior Zone with Delay.................................30

5 Exit Delay Termination ...................................30

6 Audible Home Mode Arming .........................30

7 - 8 For Future Use ............................................30

CHAPTER 9: COMMUNICATIONS PROGRAMMING

SECTIONS 31

[20] First Monitoring Station Telephone Number....31

[21] Second Monitoring Station Telephone Number31

[22] Account Code ..................................................31

[23] - [38] Notes on Reporting Codes.....................31

[23] Alarm Reporting Codes, Zones 1 to 10...........32

[24] Restoral Reporting Codes, Zones 1 to 10.......32

[25] Closing (Arming) Reporting Codes, Access

Codes 0 to 9.............................................................32

[26] Opening (Disarming) Reporting Codes, Access

Codes 0 to 9.............................................................32

[27] Tamper Reporting Codes, Zones 1 to 10 ........32

[28] Tamper Restoral Reporting Codes,

Zones 1 to 10 ...................................................32

[29] Low Battery Reporting Codes, Zones 1 to 10.33

[30] Low Battery Restoral Reporting Codes,

Zones 1 to 10 ...................................................33

[31] Supervisory Reporting Codes, Zones 1 to 10.33

[32] Supervisory Restoral Reporting Codes,

Zones 1 to 10 ...................................................33

[33] Priority Alarms and Restorals: [F], [A], [P]

and Fire Zone Trouble......................................33

[34] System Trouble Reporting Codes....................34

[35] System Restoral Reporting Codes ..................34

[36] Keypad and Sounder Tamper

Reporting Codes..............................................34

[37] Keypad and Sounder Restoral

Reporting Codes..............................................35

[38] Additional System Reporting Codes. ..............35

[39] Communication Variables ................................36

[40] Test Transmission Time of Day ........................37

[41] Communicator Format Options .......................37

[42] First Communicator Options............................38

1 Communicator Disable / Enable ...................38

2 Dialing Format................................................38

3 Pulse Dialing Ratios.......................................38

4 Transmission Limit Setting .............................38

5 Telephone Line Monitor .................................38

6 Telephone Line Monitor Silent / Audible .......38

7 - 8 For Future Use ...........................................38