5 … 6

Heizungsanlagen

Es

besteht die Notwendig-

keit sicherheitsrelevante

Komponenten nach Er-

reichen ihrer Nutzungs-

dauer auszutauschen.

Diese Empfehlung gilt

nur für Heizungsanla-

gen und nicht für Ther-

mprozessanwendungen.

DUNGS empehlt den

Austausch gemäss fol-

gender Tabelle:

heating applianc-

es

It is necessary

to replace safety-rele-

vant components after

they have reached the

end of their useful life.

This recommendation

applies only to heating

appliances and not to

industrial heating proc-

esses. DUNGS recom-

mends replacing such

components according

to the following table:

Il est

nécessaire de remplacer les

composants relatifs à la sé-

curité lorsqu‘ils ont atteint

la n de leur vie utile. Cette

recommandation ne s‘ap-

plique qu‘aux installations

de chauffage et non aux

applications de processus

thermique. DUNGS recom-

mande le remplacement,

conformément au tableau

qui suit :

Ciò rende

necessaria la sostituzione

di componenti rilevanti dal

punto di vista della sicu-

rezza alla scadenza della

loro durata di utilizzazione.

Questo suggerimento vale

solo per impianti di riscal-

damento e non per impie-

ghi per processi termici.

DUNGS consiglia detta

sostituzione in conformità

alla sottostante tabella:

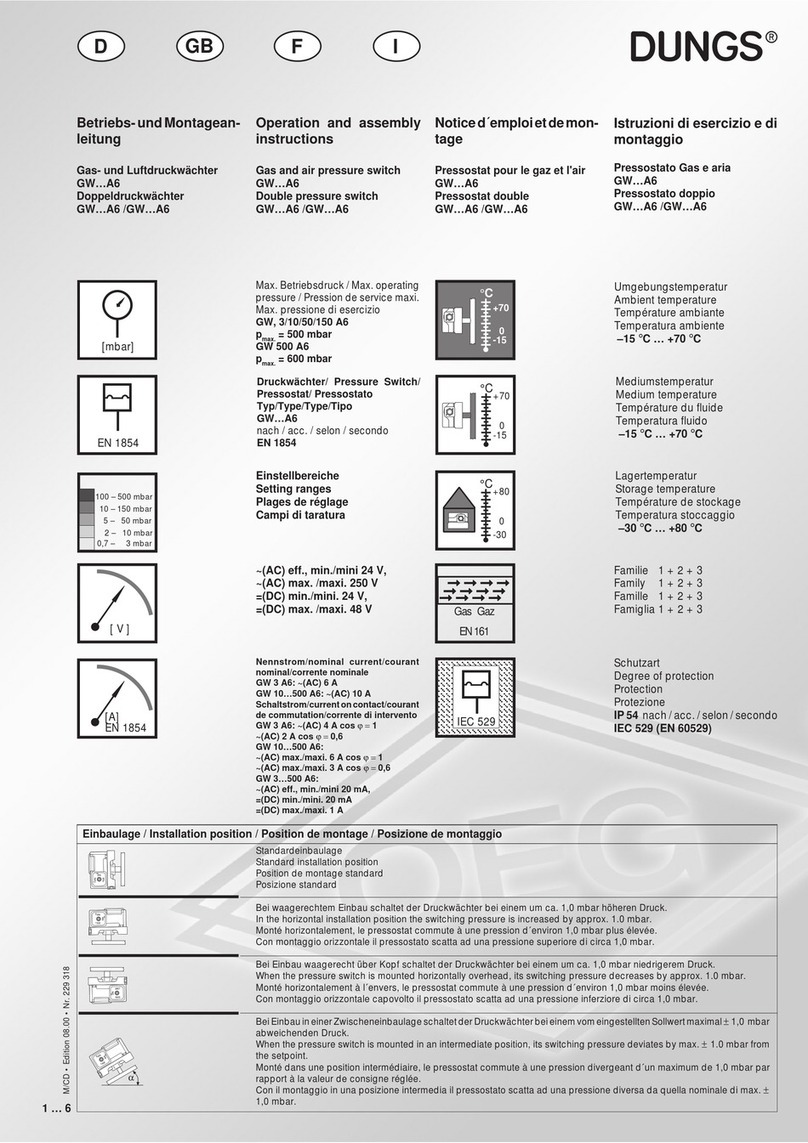

Sicherheitsrelevante Komponente

Safety relevant component

Composant relatif à la sécurité

Componenti rilevanti dal punto di vista della sicurezza

NUTZUNGSDAUER

DUNGS empehlt den Austausch nach:

USEFUL LIFE

DUNGS recommends replacement after:

VIE UTILE

DUNGS recommande le

remplacement au bout de :

DURATA DI UTILIZZAZIONE

DUNGS consiglia la sostituzione dopo:

Schaltspiele

Operating cycles

Cycles de manoeuvres

Cicli di comando

/ 10 Jahre/years/ans/anni

/ 10 Jahre/years/ans/anni

10 Jahre/years/ans/anni

10.000 h

Betriebsstunden / Operating hours

Heures de service / Ore di esercizio

15 Jahre/years/ans/anni

nach erkanntem Fehler / after error detection

après détection du défaut / dopo il rilevamento di errori

10 Jahre/years/ans/anni

10 Jahre/years/ans/anni

10 Jahre/years/ans/anni

10 Jahre/years/ans/anni

Karl Dungs GmbH & Co. KG

Postfach 12 29

D-73602 Schorndorf

e-mail info@dungs.com

Internet www.dungs.com

Karl Dungs GmbH & Co. KG

Siemensstr. 6-10

D-73660 Urbach, Germany

Telefon +49 (0)7181-804-0

Telefax +49 (0)7181-804-166

Hausadresse

Head Oces and Factory

Usine et Services Administratifs

Amministrazione e Stabilimento

Briefadresse

Postal address

Adresse postale

Indirizzare la corrispondenza a