Microprocessor control

Wall mounted

16 zone protection (across 2 zones)

4 - 20mA signal input

Measuring range 0 - 20% L.E.L. /

0 - 300ppm

IP55 protective rating

EN50194 for explosive gases

EN50291 for toxic gases

3 year guarantee

Application

Duomo is recognised within the gas industry for

providing a comprehensive range of low cost, high

reliability gas detection for many applications. We have

installed and commissioned natural gas and carbon

monoxide sensors in applications such as boiler rooms,

kitchens, car parks, aircraft hangers, factories and

shopping centres.The BX116 is the command centre for

the complete range of Duomo gas sensors. All Duomo

products are manufactured to meet relevant European

Normatives and proposals for explosive and toxic gases.

Features

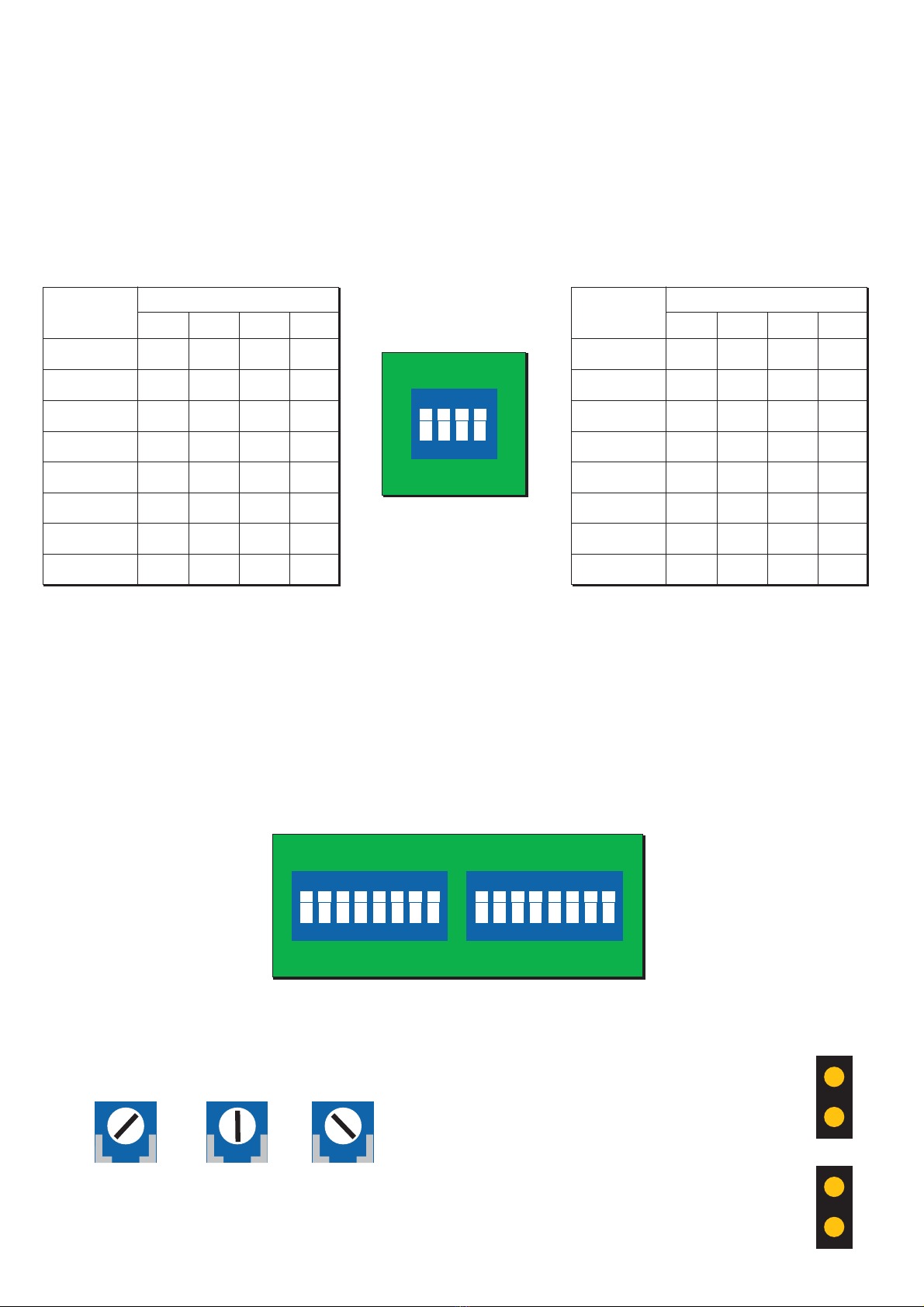

The BX116 is a wall mounted microprocessor based gas

detector control unit. It can be configured to meet

customer requirements. The following parameters can

be changed using on board DIP switches:

Number of sensors from 1 to 16

Type of gas to be sensed (explosive or toxic)

Main alarm delay period (3 or 20 seconds)

Main alarm relay action (latching or auto-reset)

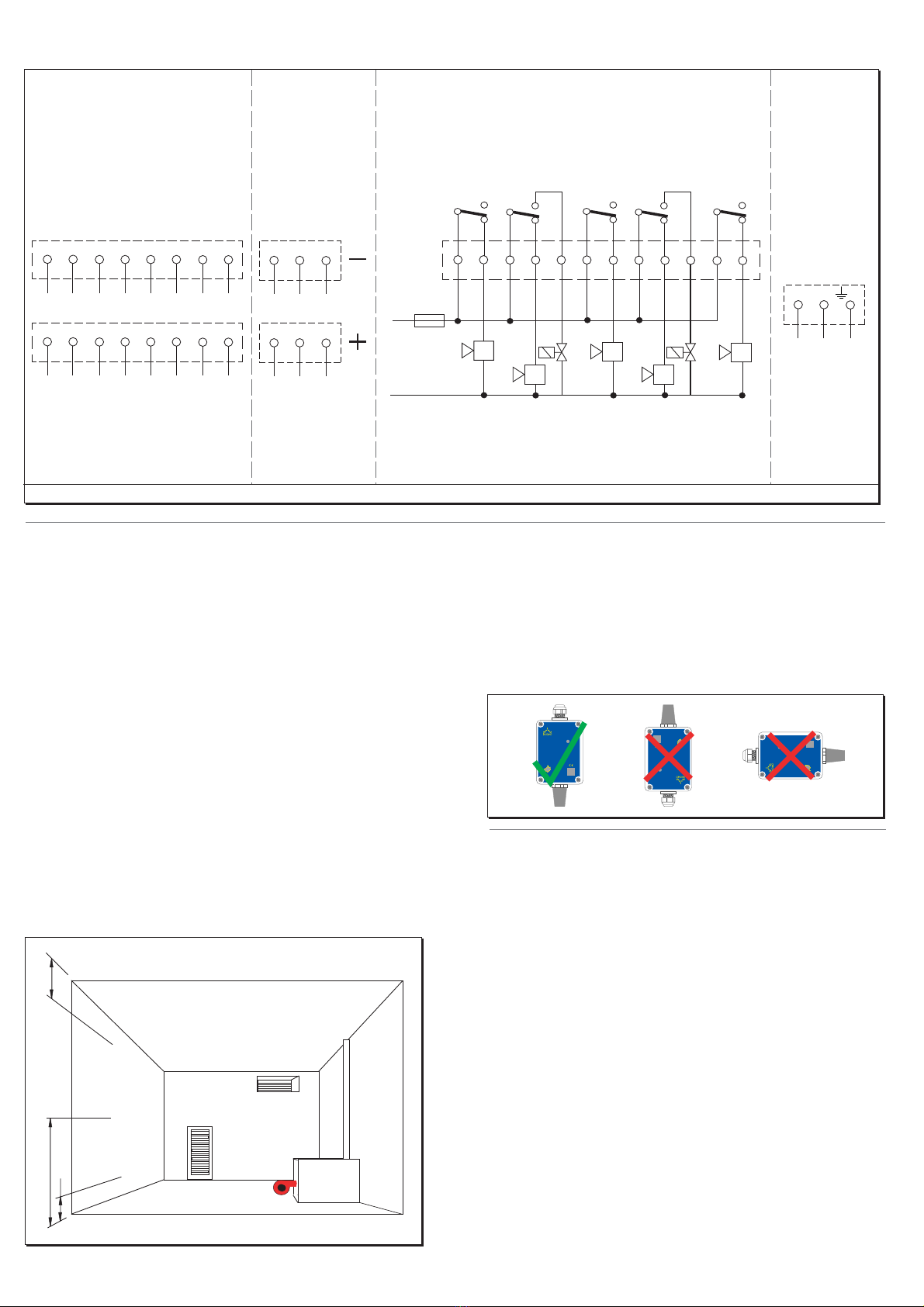

The BX116 has two plug in terminal blocks. One is for

the incoming mains supply and alarm circuit wiring and

the second is for connecting the sensor wiring. This

reduces the chance of incorrect site wiring. The front

panel has two banks of eight lights indicating, in

rotation, which probe is currently monitoring and a

bright display showing the LEL or PPM gas

concentration measured.

Operation

When the remote sensor detects the presence of the

targetgasa4-20mA signal is sent to the detector,

proportional to the level of gas. The BX116 then

operates a pre-alarm relay - used for remote sirens or

visual indicators. If the level of gas continues to rise then

the second pre-alarm is actuated. In the case of

explosive gases, when the level of gas reaches 20%

L.E.L., the main alarm relay is activated to break the

electrical supply to the gas safety shut-off valve (SSOV).

The BX116 also has a separate volt-free sensor fault relay

that actuates if the correct return signal is not sensed by

the detector. The BX116 can detect both explosive and

toxic gases.

CAUTION!

Carefully read the following instructions prior to

installation of this device. Always keep this pamphlet for

future reference.Ensure that the gas detection system is

wired correctly and is only used for the purpose for

which it is intended.

Duomo gas proving systems - Duomo gas detection - Duomo carbon dioxide sensors - Duomo ventilation interlocks - Are available direct or from all major stockists

BX116 Gas Detector

i