GS920 SeismicactivityNaturalGas&L.P.G.Detector

t: 01905 797989

FEATURES

■Seismic Activity

■Natural Gas or Propane detection sensor

■230V AC 50Hz Power Supply

■12V DC Battery backup option

■Catalytic Sensor Technology

■-10°C to +40°C Operating temperture

■IP42 Protective Rating

■CE Certied and approved to EN50194 & EN61779

■6 Year sensor lifespan

(in clean air and within operating temperature)

■2 Year Guarantee - 3 Year by Registering at duomo.co.uk

APPLICATION

The GS920 is a stand alone gas detector for detcting methane

or LPG sensor (specify at order stage) with an integrated seismic

detector that will shut o o a gas valve in the event of seismic

activity making it an ideal sensor in areas prone to earthquakes.

With a built-in relay the GS920 can be used to shut o a gas valve

in the event of a leak, or operate remote sirens and beacons to alert

those nearby of a potential hazard.

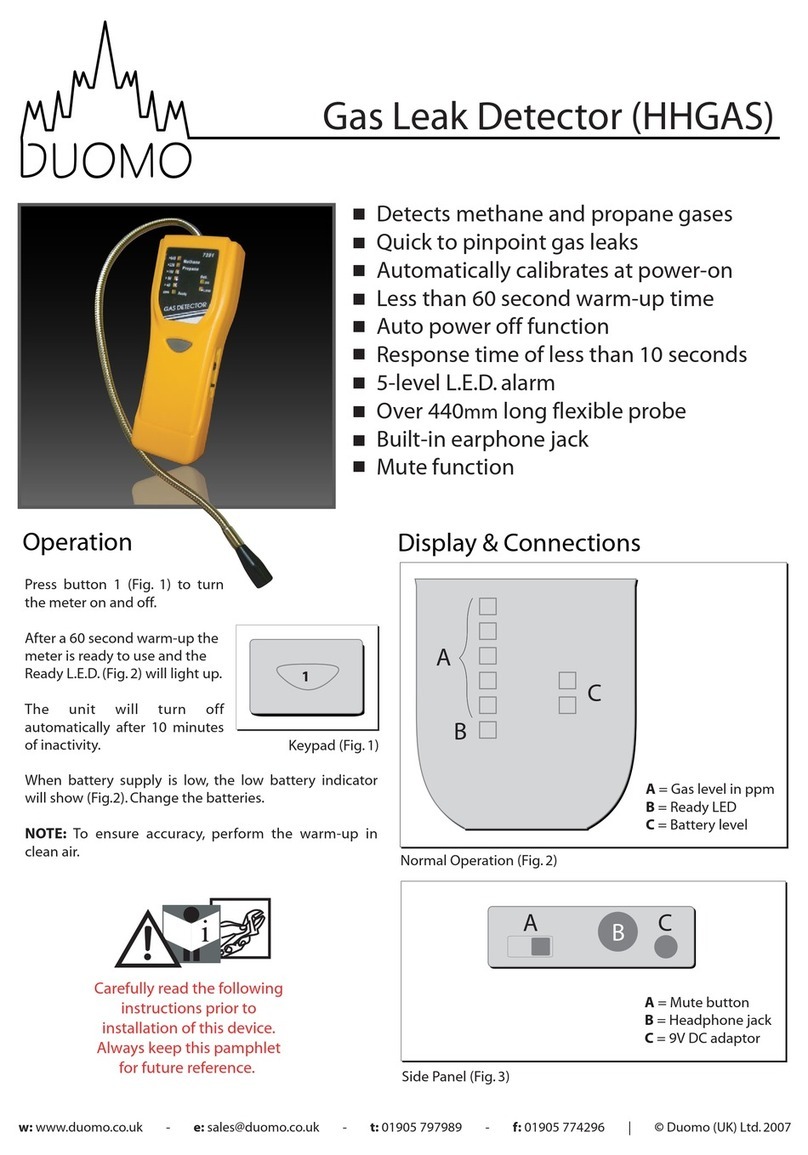

OPERATION

As gas concentrations exceed 10%LEL the relay on the unit will

actuate into an alarm state. Using a built-in 3-axis accelerometer,

the GS920 will shut o a gas valve and halt the gas supply when

seismic activity reaches 6 on the Modied Mercalli scale (or 60

-70cm/s2).

Stopping the gas supply in a building at this time is a valuable, and

potentially life-saving, exercise. Ruptured pipework due to buildings

shifting can cause undetected leaks and an increased risk of

explosion.

A further relay on the unit is pre-set to actuate at 10% LEL of either

methane or LPG. This relay can break the electrical connection to a

gas valve, or make a connection to an external waring device such

as an audible alarm or ashing beacon.

BATTERY CONNECTION

It is possible to connect this unit to a 12V DC battery to perform two

functions:

Firstly, It can be used to power the unit itself for up to one hour in the

events of mains failure.

Secondly, the battery can power a remote 12V DC manual reset

solenoid valve or siren, over 300mA.

GS920 Seismic Activity Natural Gas / Propane Sensor

SPECIFICATION

Power

Power Supply 230V AC 50Hz +/- 10%

Secondary Battery 12V DC - 1.2Ah +/- 10%

Current Consumption 2W @ 230V

Technical Specication

Earthquake Proof Sensor 6th degree of Mecalli scale

Gas(es) Detected L.P.G or Natural Gas

Sensor Technology Catalytic

Dimensions Width 115mm |Height 150mm |Depth 45mm

LED indicator Green: Power ON

Yellow: Fault

Red: Alarm

Mounting Wall Mounted or Embedded box

Alarm Threshold 10% of LEL

Working Temperature -10°C to 40°C

Functioning Humidity 0-90% Relative Humidity

Body Material ABS Self Extinguishing

Protective Rating IP42

Compatibility

Calibration Gas Compatibility Duomo Nat Gas / L.P.G Test Gases

Approvals, Certications and Guarantee

Approvals CE Certication: No.96125

Guarantee 2 Year as Standard

3 Year by Registering at www.duomo.co.uk

IP42

LPG

Natural

Gas

Seismic

activity