iii

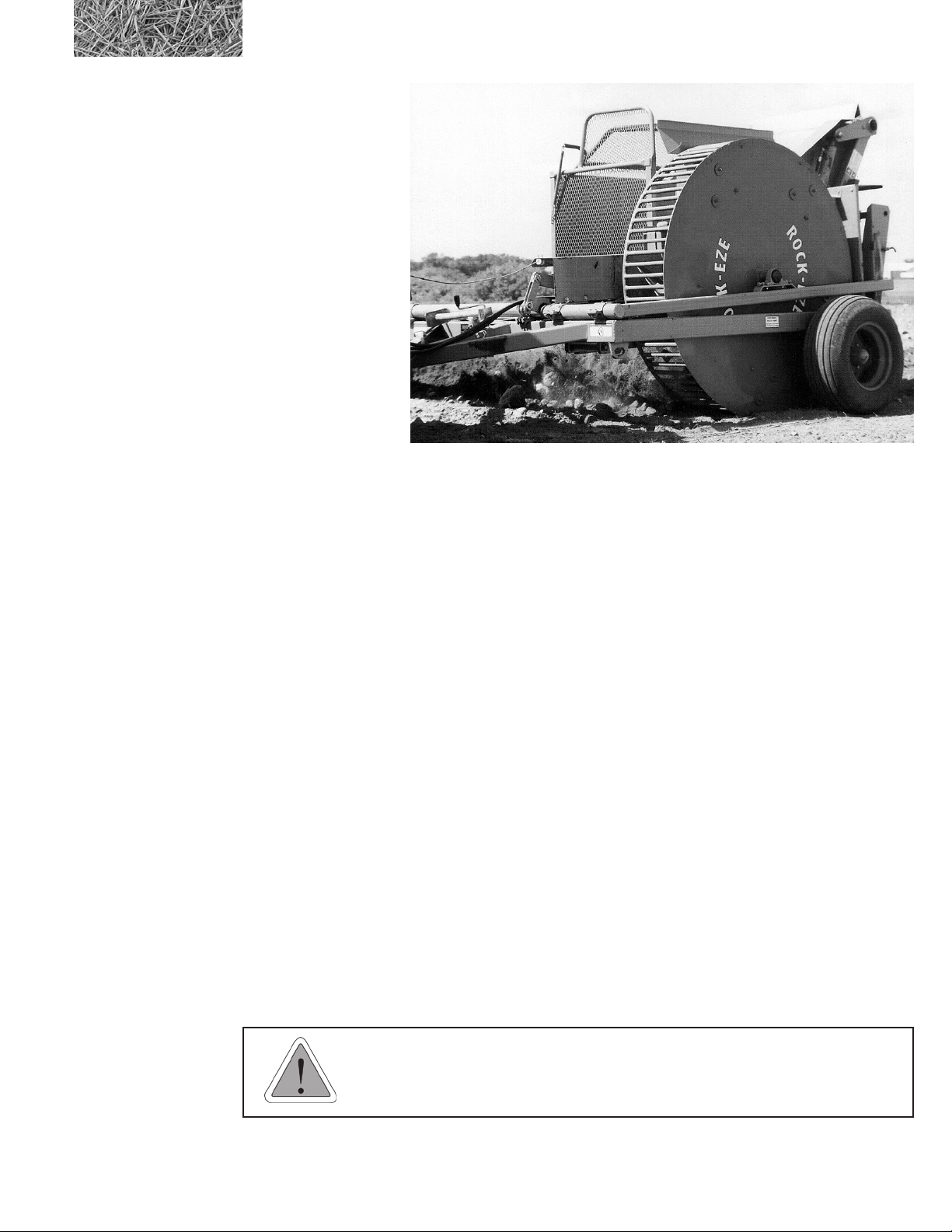

H-106 ROCK-EZE OPERATING INSTRUCTIONS

TABLE OF CONTENTS

Part 1: Operating Instruction ...........................................1

Introduction ................................................................................. 2

Purpose ........................................................................................ 2

Section 1: Safety.......................................................................... 5

1.1 Safety-alert symbols.......................................................................................... 5

1.2 Operator - personal equipment.......................................................................... 7

1.3 Machine safety labels ........................................................................................ 8

1.4 Safety review Section ....................................................................................... 9

1.5 Towing/road transport ..................................................................................... 10

Section 2: Dealer preparation ................................................... 11

2.1 ASSEMBLY .................................................................................................... 11

2.2 ADJUSTMENTS.............................................................................................. 19

Section 3: Operation .................................................................. 20

3.1 Pre-operation inspection.................................................................................. 20

3.2 Normal shutdown procedure ............................................................................ 21

3.3 3106 ROCK-EZE hydraulic system.............................................................. 21

3.3.1 Using the3106 ROCK-EZE with a tractor that has triple hydraulic

outlets............................................................................................................. 21

3.32 Hose Torquing Procedure .................................................................... 21

3.4 Operating Tips ................................................................................................ 24

3.5 Storage........................................................................................................... 25

3.5.1 Preparing the machine for storage:...................................................... 25

3.5.2 Removing the machine from storage.................................................... 25

Section 4: General maintenance .......................................... 26

4.1 Lubrication ...................................................................................................... 26

4.2 Axle, wheels, tires ........................................................................................... 31

4.3 General appearance ......................................................................................... 31

Appendix A: Warranty ................................................................ 32

Appendix B: General specications .......................................... 33

Appendix C: Required for operation .......................................... 34

Part 2: Parts Reference........................................................ 35

MAIN FRAME ASSEMBLY............................................................................................ 36

MAIN FRAME ASSEMBLY - DETAIL A....................................................................... 38

MAIN FRAME ASSEMBLY - DETAIL B ....................................................................... 40

MAIN FRAME ASSEMBLY - DETAIL C ....................................................................... 42

MAIN FRAME ASSEMBLY - DETAIL D....................................................................... 44

WHEELS AND HUBS...................................................................................................... 46

ROCK BOX ASSEMBLY ................................................................................................ 48

lIFT/ROCKWHEEL ASSEMBLY .................................................................................... 50

LIFT/ROCKWHEEL ASSEMBLY DETAIL A ................................................................ 52

LIFT/ROCKWHEEL ASSEMBLY DETAIL B ................................................................ 54

LIFT/ROCKWHEEL ASSEMBLY DETAIL C ................................................................ 56

WINDROWER ASSEMBLY - CHAIN DRIVEN END................................................... 58

WINDROWER ASSEMBLY - UNDRIVEN END........................................................... 60

HYDRAULIC ASSEMBLY 1........................................................................................... 62

HYDRAULIC ASSEMBLY 2 .......................................................................................... 64

DRAG PLATE (OPTION) ................................................................................................ 66

TAIL LIGHT ASSEMBLY................................................................................................ 68

TAIL LIGHT WIRING HARNESS .................................................................................. 71

DECALS ........................................................................................................................... 72

3106 ROCK-EZE DOCUMENTATION COMMENT FORM.................... 76