DURKOPP ADLER H-TYPE Series Operating manual

Other DURKOPP ADLER Sewing Machine Accessories manuals

DURKOPP ADLER

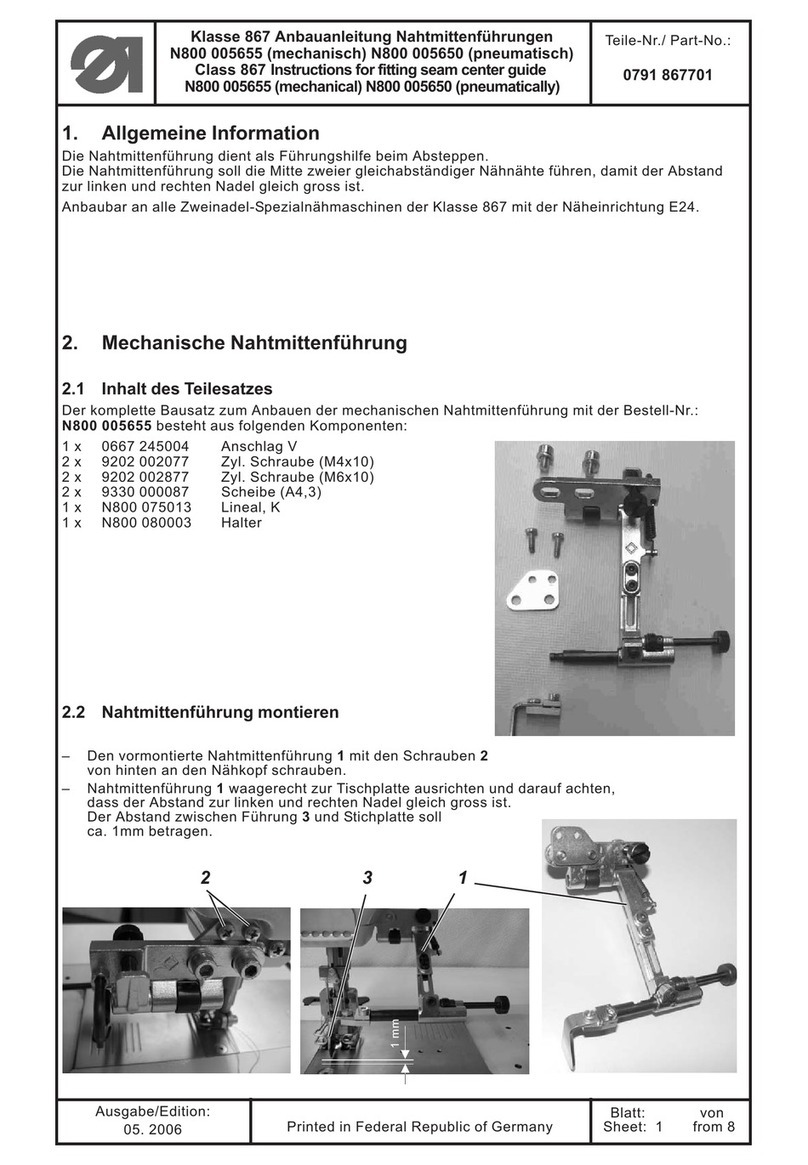

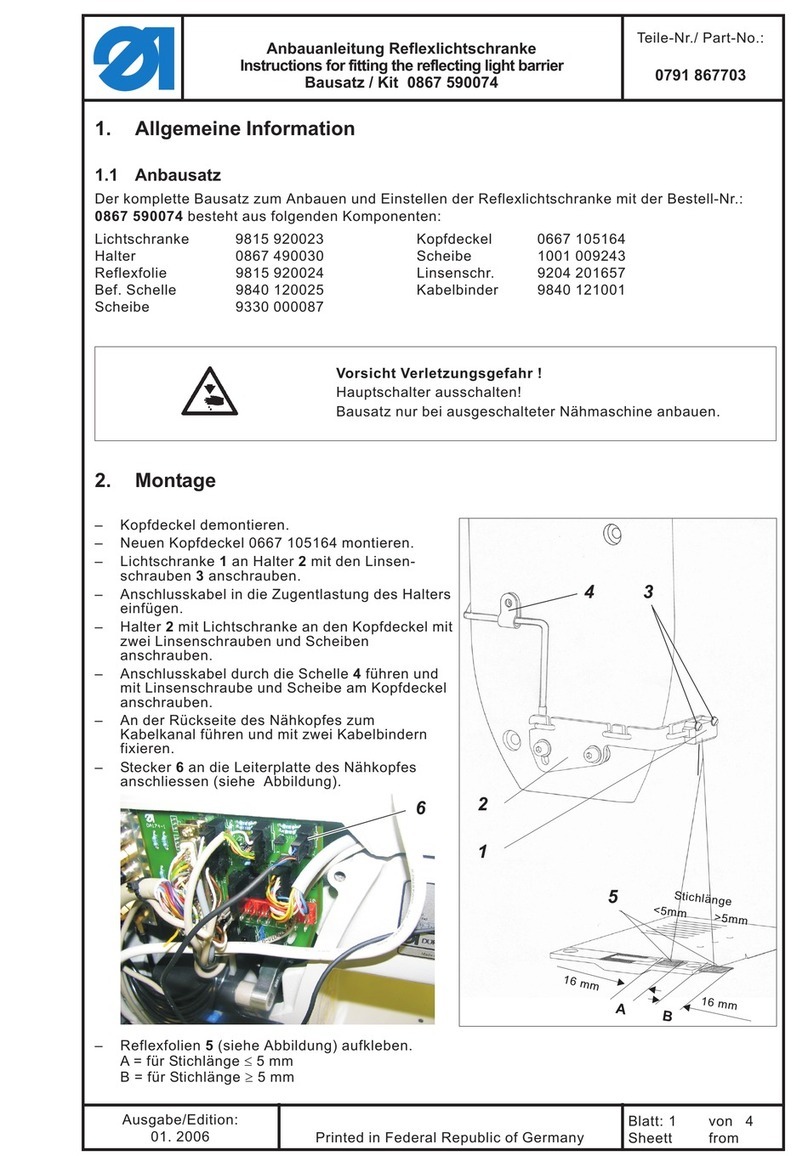

DURKOPP ADLER 867 User manual

DURKOPP ADLER

DURKOPP ADLER 867 User manual

DURKOPP ADLER

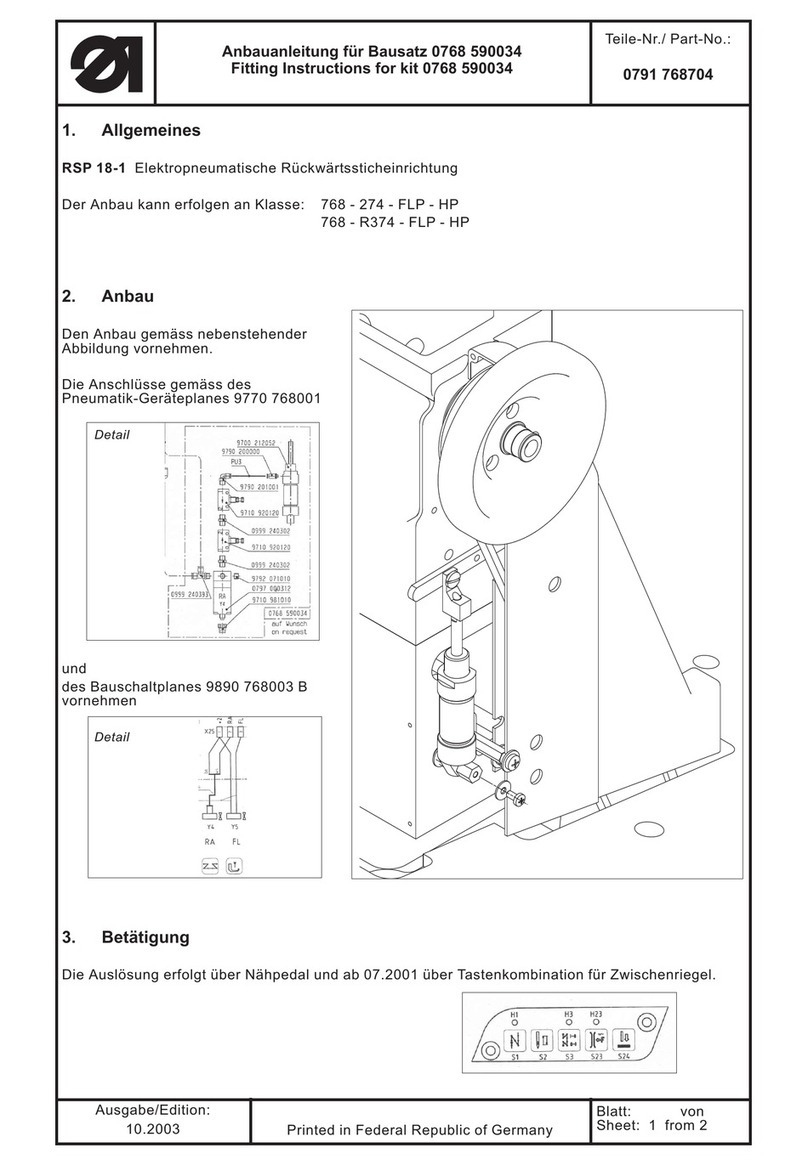

DURKOPP ADLER 768 User manual

DURKOPP ADLER

DURKOPP ADLER 550-867 Operating manual

DURKOPP ADLER

DURKOPP ADLER 867 User manual

DURKOPP ADLER

DURKOPP ADLER 767 - User manual

DURKOPP ADLER

DURKOPP ADLER 806 Parts list manual

DURKOPP ADLER

DURKOPP ADLER 867 User manual

DURKOPP ADLER

DURKOPP ADLER 767 - User manual

DURKOPP ADLER

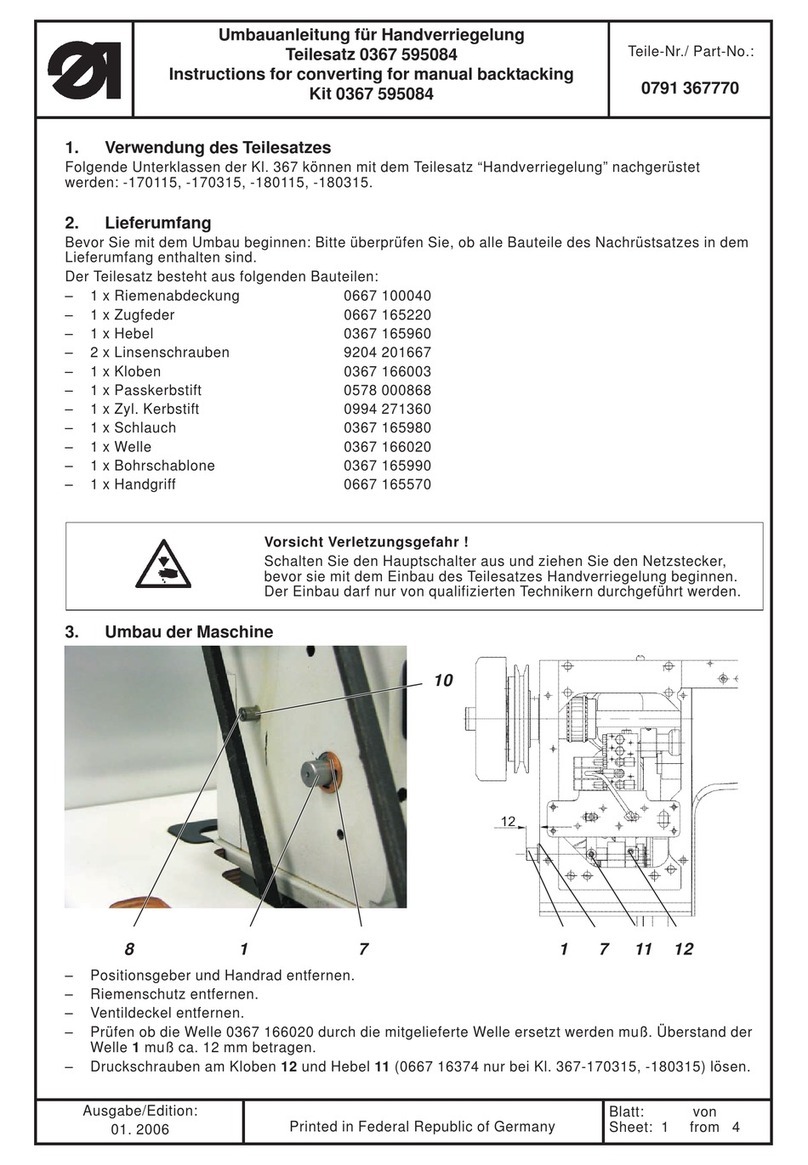

DURKOPP ADLER Kit 0367 595084 User manual