8DYMAX BlueWave®200 Version 2.0 UV Light-Curing Spot Lamp System

BRIGHT, VISIBLE LIGHT

The bright, visible light emitted by some UV light-curing systems can be objectionable to some workers and can

cause eyestrain. Tinted eye protection and/or opaque/tinted shielding can be utilized to address this concern.

SUMMARY

UV light sources can be more “worker friendly” than many commonly accepted industrial processes, provided the

potential concerns are addressed. Contact your DYMAX representative for information regarding the proper use

of DYMAX UV light-curing systems.

DESCRIPTION

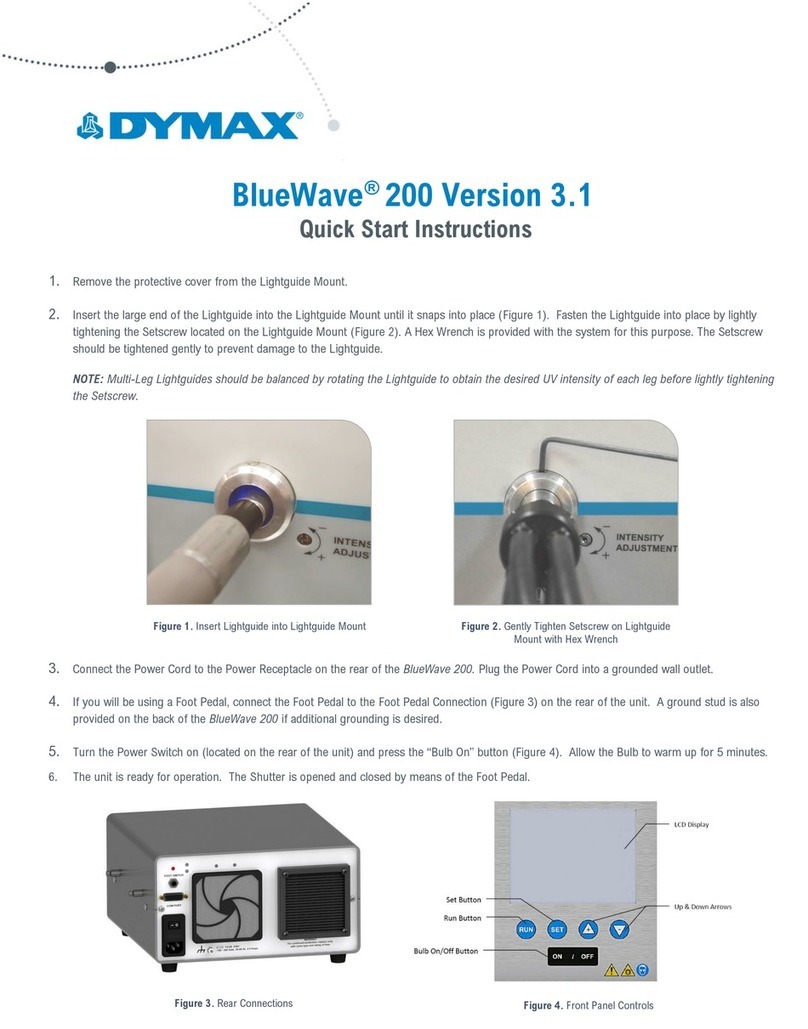

The BlueWave®200 is a high-intensity UV light-curing Spot Lamp System used for small area curing of

adhesives, coatings, and potting materials. It emits up to an 8-mm diameter spot of UV light from a liquid

Lightguide (sold separately). The Lightguide is hand-held for complete mobility or can be clamped into position

on assembly equipment or workstations for repetitive operations.

WARNING: Engage the Lightguide in the Bezel before the light is turned on, and remove the Lightguide from the

Bezel only after the light is turned off to avoid the possibility of exposure to the light. Lightly tighten the setscrew

for safety.

AVERTISSEMENT: Engager le guide de lumière dans le biseau avant la lumière est allumer, et enlève le guide

de lumière de le biseau seulement après la lumière est fermer pour éviter la possiblité d’exposition à la lumière.

Reserrer doucement la vis pour sécurité,

The system consists of an anodized aluminum housing containing an electronic Power Supply, Circuit Protection,

Bulb/Reflector Assembly, Internal Light Filter for extended Lightguide life, thermostatically-controlled Cooling Fan,

Lightguide Mount, Bulb and Unit Status Indicator Lights, combination resettable and non-resettable Hour-Meter,

and Shutter. The Shutter is supplied with a timed and manual operation mode.

The Power Supply operates on line voltages between 100 and 240 VAC, and frequency between 50 and 60 Hz.

The Power Supply is auto-ranging and is specially designed to provide proper rated voltage and current to the

200 Watt Lamp.

A Cooling Fan with a control loop is provided to keep the Lamp Housing and internal components of the Power

Supply at the optimum operating temperature. The Cooling Fan must not be covered or otherwise blocked.

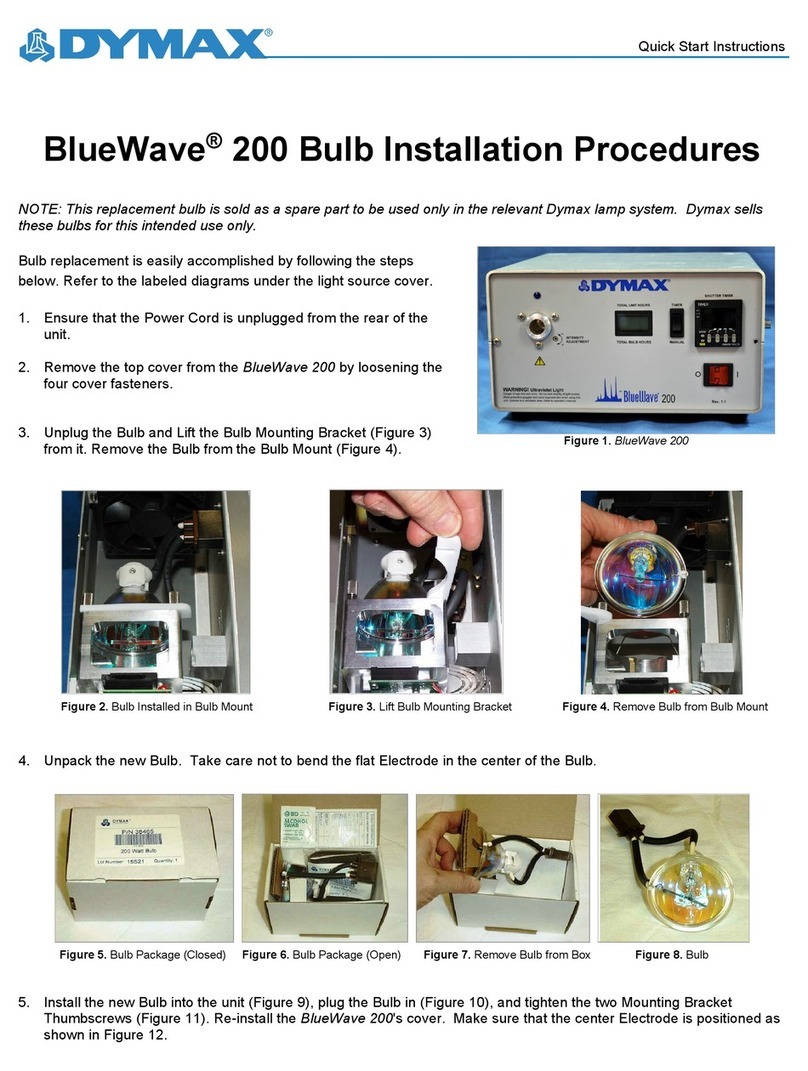

The UV source is a 200-Watt, medium-pressure arc metal halide Bulb mounted in a Reflector and focused to

provide optimum light output. The unit is rated for continuous operation. The Bulbs used to power all high-intensity

UV light-curing Spot Lamps degrade with use. Intensity, therefore, decreases as the Bulb ages. Using the Blue

Wave 200’s intensity control feature, users can eliminate this variation by manually increasing intensity to offset

this degradation. During operation a user can adjust the output intensity using a tool or removable knob. The

Blue Indicator Light, above the Bezel, lights when the Bulb is operating. If the Bulb extinguishes due to a

momentary power failure, the unit must be turned off, allowed to cool, and then restarted to re-ignite the Bulb. A

Change Bulb Indicating Light turns on when Bulb replacement is required.

A Thermal Shutdown Sensor is provided for internal temperature control of the unit. A Cover-Closed Switch and

Lightguide Sensing Switch add to the safety of the unit. Fan Filters should be changed or cleaned frequently to

prevent blockage and reduced ventilation airflow. Electric Shutters are supplied with timed and manual Shutter

operating modes.