Contents

Introduction....................................................................................................................................................4

Introduction to the User Guide ....................................................................................................................................... 4

Where to Get Help .......................................................................................................................................................... 4

Safety..............................................................................................................................................................4

General Safety Considerations ........................................................................................................................................ 4

Specific Safety Considerations......................................................................................................................................... 4

Personal Protective Equipment....................................................................................................................................... 5

Product Overview ...........................................................................................................................................5

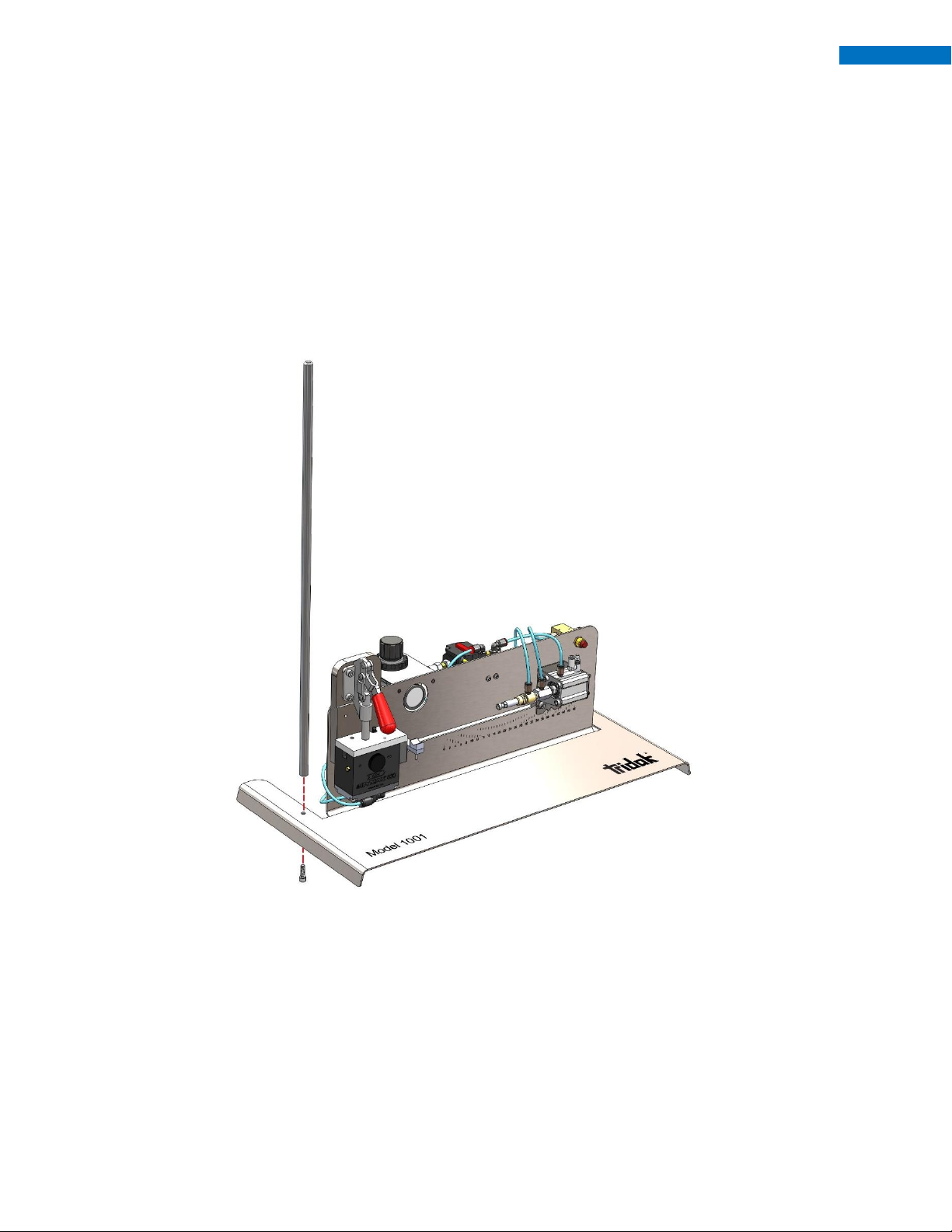

Description of the Model 1001 Syringe Filling System .................................................................................................... 5

Special Features and Benefits of the Model 1001........................................................................................................... 5

Description of Main Components.................................................................................................................................... 6

Assembly and Setup........................................................................................................................................7

Unpacking and Inspecting Your Shipment....................................................................................................................... 8

Parts Included in the Model 1001 Syringe Filling System ................................................................................................ 8

Utilities Required............................................................................................................................................................. 8

Preparing the System for Use..........................................................................................................................9

Installing the Reservoir Support ...................................................................................................................................... 9

Installing the Material Reservoir ..................................................................................................................................... 9

Connecting the Material Reservoir Pressure Supply Tube ............................................................................................ 10

Operation ..................................................................................................................................................... 10

Preparing the Cartridge................................................................................................................................................. 11

Loading the System ....................................................................................................................................................... 12

Pressurizing the System................................................................................................................................................. 14

Depressurizing the System ............................................................................................................................................ 15

Adjusting the Syringe Rest............................................................................................................................................. 15

Setting the Fill Amount for the Syringe Size .................................................................................................................. 15

Priming the System........................................................................................................................................................ 16

Preparing the Syringes................................................................................................................................................... 16

Filling the Syringe .......................................................................................................................................................... 17

Model 830 Valve Adjustments ...................................................................................................................................... 17

Cleaning and Maintenance ........................................................................................................................... 18

System Cleaning ............................................................................................................................................................ 18

Spare Parts and Accessories.......................................................................................................................... 18

Replacement Parts/Accessories ........................................................................................Error! Bookmark not defined.

Specifications................................................................................................................................................19

System Specifications .................................................................................................................................................... 19

Index....................................................................................................................Error! Bookmark not defined.