Marquette Hellige GmbH MAC 1100/1200 V 1.1 Page 3

227 492 20 D - 0002

1 Device description_______________________________________________________7

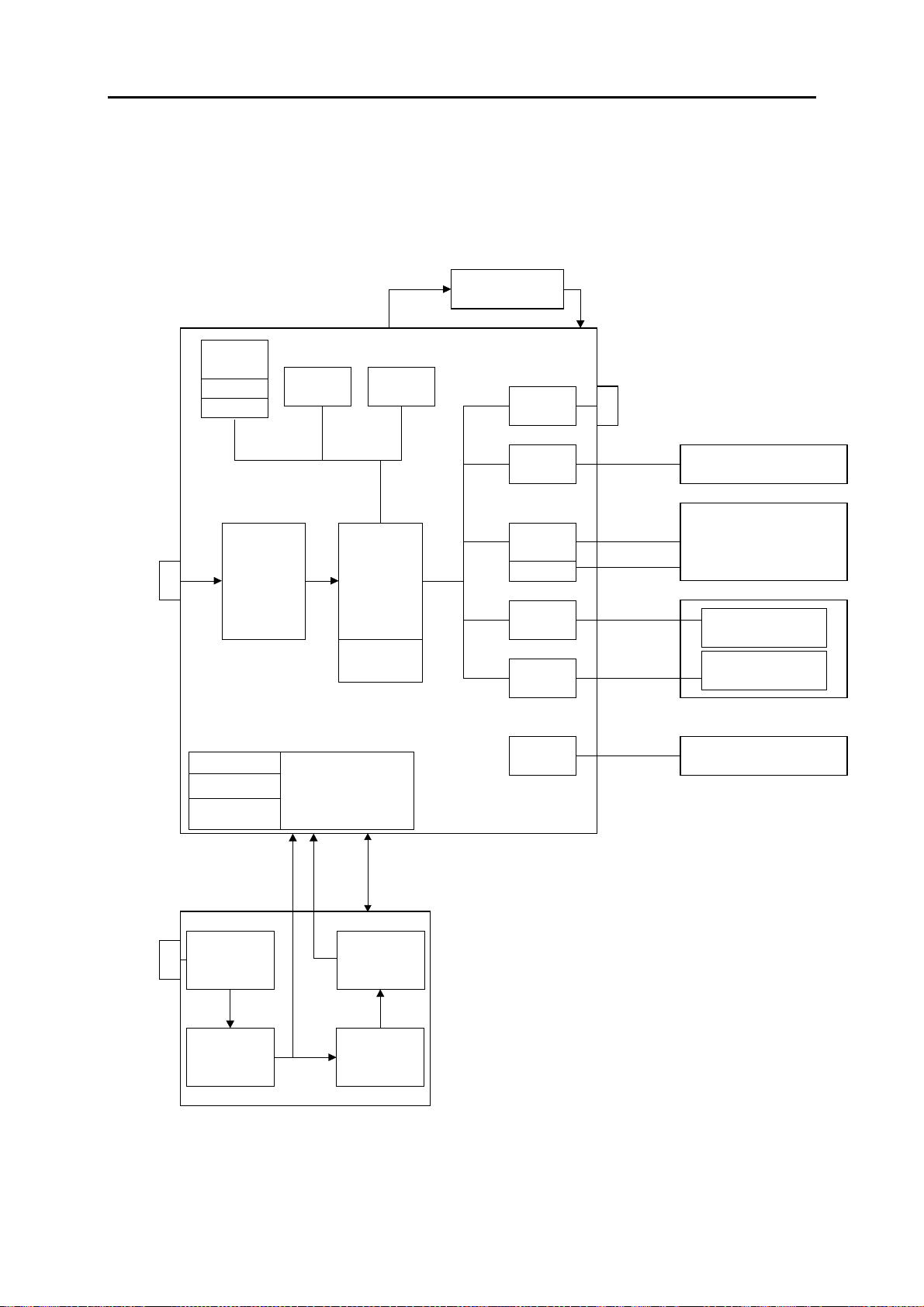

1.1 Block circuit diagram of entire instrument_______________________________________ 9

1.2 Mechanical components ___________________________________________________ 10

2 Functional description __________________________________________________11

2.1 Switching power supply ___________________________________________________ 11

2.2 PCB NC Battery Charge __________________________________________________ 11

2.2.1 Charging circuit for the NC battery _______________________________________________ 11

2.2.2 Device behavior depending on the state of battery charge______________________________ 12

2.3 PCB Control CS_CI ______________________________________________________ 12

2.3.1 Generation of internal power supplies _____________________________________________ 13

2.3.2 Switch On/Off circuit__________________________________________________________ 13

2.3.3 ECG recording and front-end processing___________________________________________ 14

2.3.4 Controller core_______________________________________________________________ 15

2.3.5 Real time clock ______________________________________________________________ 16

2.3.6 Memory ____________________________________________________________________ 16

2.3.7 LCD graphics display interface __________________________________________________ 17

2.3.8 Keypad interface _____________________________________________________________ 17

2.3.9 Printhead control _____________________________________________________________ 18

2.3.10 Motor control________________________________________________________________ 18

2.3.11 RS-232 interface _____________________________________________________________ 19

2.3.12 Buzzer _____________________________________________________________________ 19

2.4 PCB Modem Supply CS_M ________________________________________________ 19

2.5 Internal interfaces________________________________________________________ 19

2.5.1 Mechanical interfaces _________________________________________________________ 19

2.5.2 Electronic interfaces __________________________________________________________ 20

2.5.2.1 Interface to the switching power supply__________________________________________ 20

2.5.2.2 Interface to the PCB NC battery charge__________________________________________ 20

2.5.2.3 Interface to the LCD Graphics Display __________________________________________ 21

2.5.2.4 Interface to the keypad_______________________________________________________ 21

2.5.2.5 Interface to the printhead_____________________________________________________ 22

2.5.2.6 Interface to the motor________________________________________________________ 23

2.5.2.7 Interfaces for production tests _________________________________________________ 23

2.5.2.8 Interface to PCB Modem Supply CS_M _________________________________________ 24

2.6 Interfaces to peripherals___________________________________________________ 25

2.6.1 Electronic interfaces __________________________________________________________ 26

2.6.1.1 RS-232 interface ___________________________________________________________ 26

2.6.1.2 Patient input_______________________________________________________________ 27

2.7 Software Updates ________________________________________________________ 28

2.8 Limitations______________________________________________________________ 28

3 System test functions____________________________________________________29

3.1 General information ______________________________________________________ 29

3.2 Test start _______________________________________________________________ 29

3.3 Display test______________________________________________________________ 30

3.4 Keyboard test____________________________________________________________ 31

3.5 Motor test_______________________________________________________________ 31

3.6 Test results______________________________________________________________ 32