4Eastwood Technical Assistance: 800.544.5118 >> techelp@eastwood.com

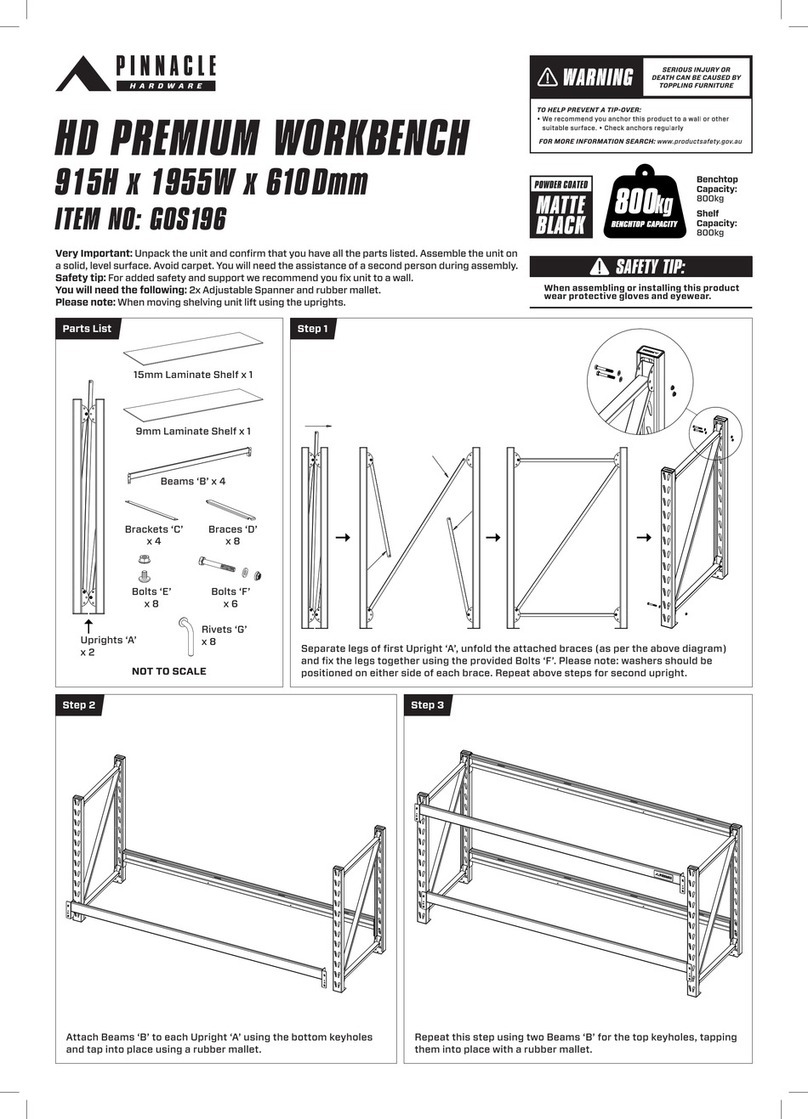

FIG. 3

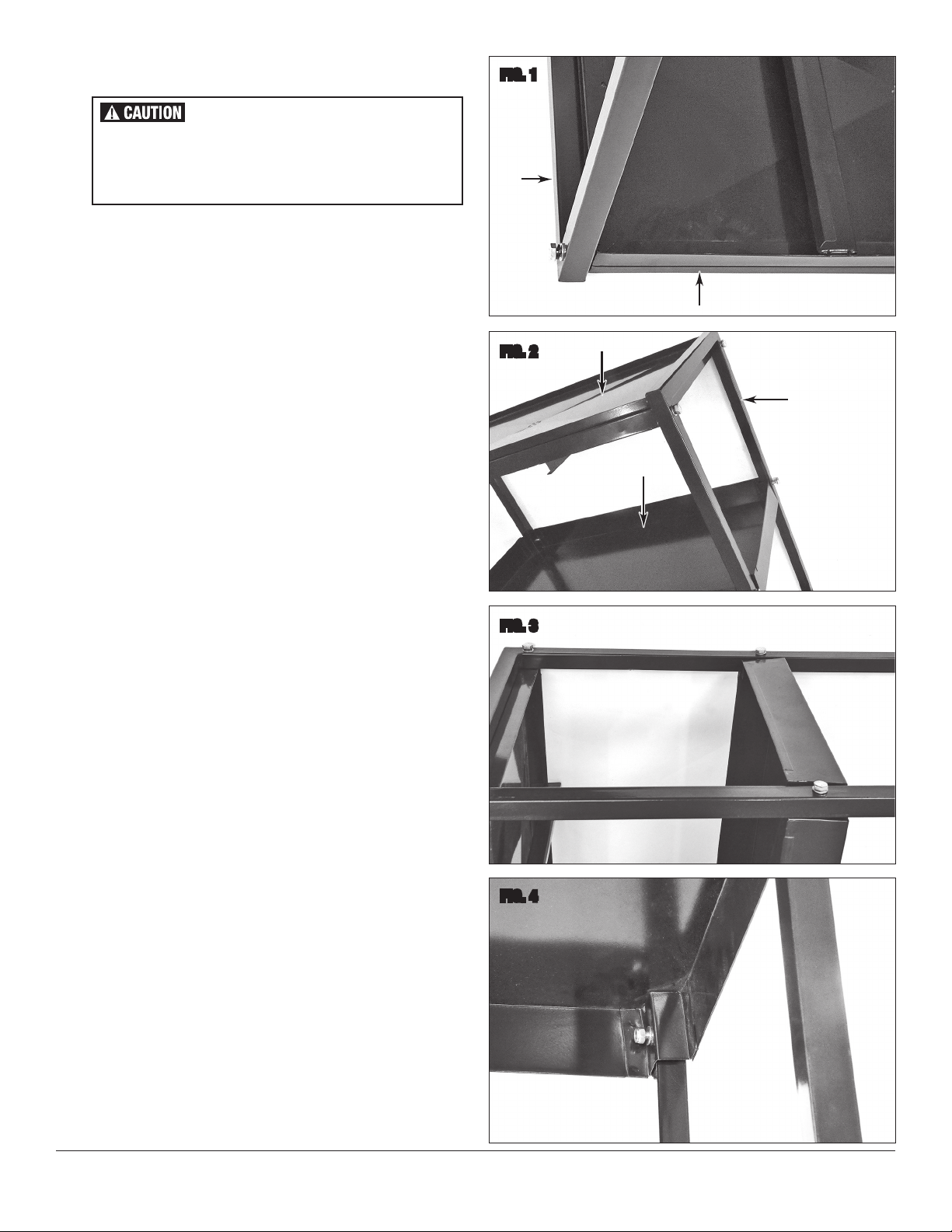

FIG. 4

ASSEMBLY

• Begin by placing the Drain Work Top [A] upside down on a soft surface.

NOTE: The cardboard carton provides an excellent scratch-resistant

work surface.

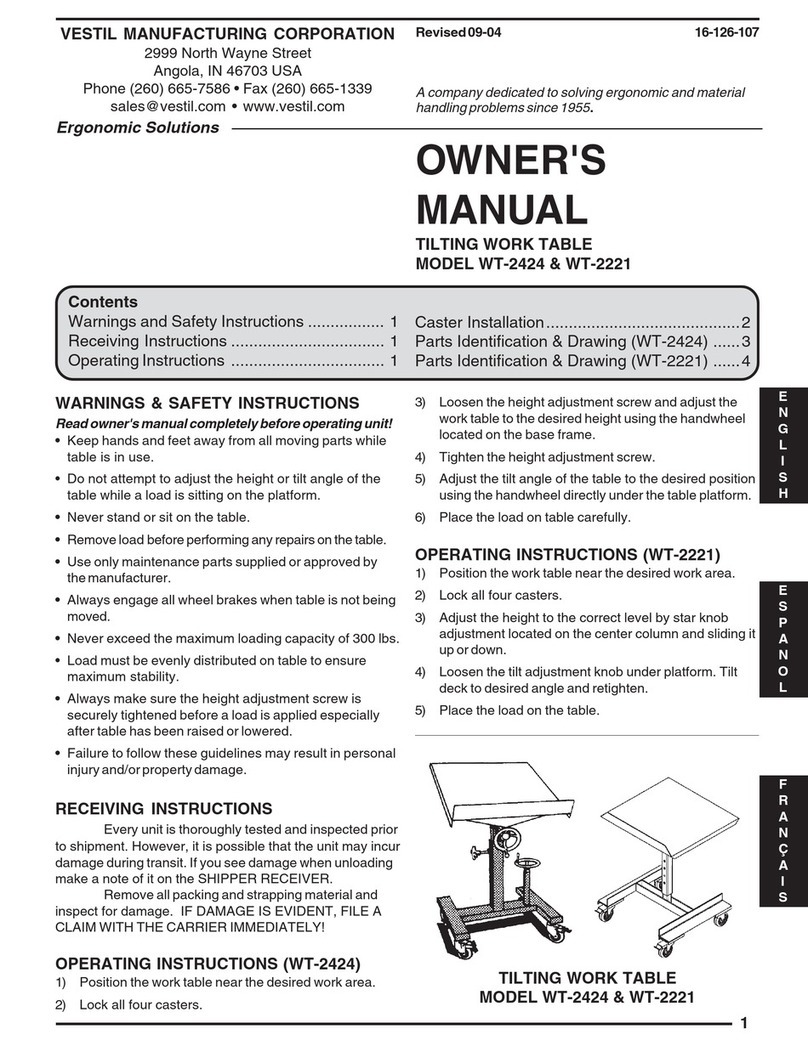

• Set the “U” section of a Side Frame [B] with the punched corner holes

aligned with the threaded holes in the ends of the Drain Work Top [A].

Thread in two M8 x 40mm Bolts with four M8 Lock washers

and secure with a 14mm wrench (FIG 1).

• Repeat for 2nd Side Frame [B].

• Lie the Drain Top and Side Frames assembly [A & B] over on one side.

• Place eight M8 Flat Washers under the heads of the eight M8 x 40mm

Bolts.

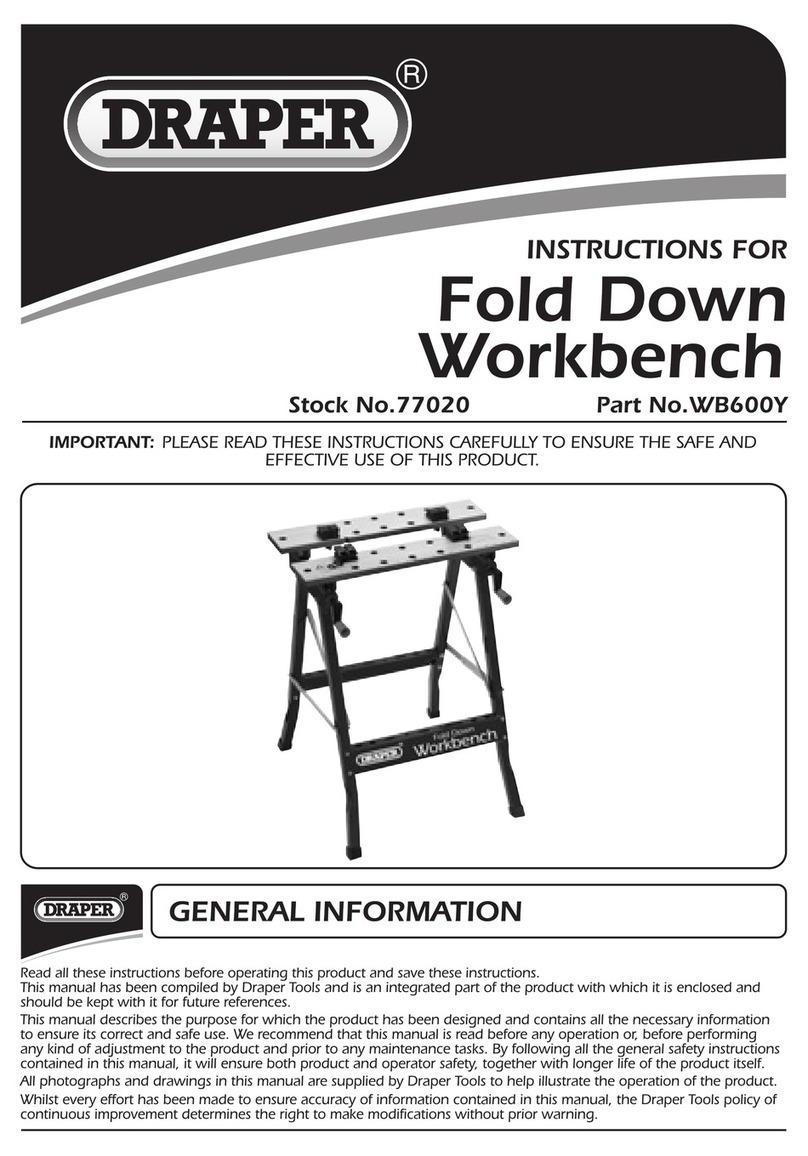

• Drop in one of the two identical Shelf Trays [C] with the open side up,

then align the four punched holes in the corner notches with those in

the middle of the Side Frames (FIG 2).

• With threads facing inward, insert four of the eight M8 x 40mm Bolts

with Washers into the open holes of the Side Frames and Shelf Tray

(FIG 3).

• In this sequence, place four more M8 Flat Washers over the threads

of M8 x 40mm Bolts, then thread on the M8 Nuts (FIG 4). Tighten all

hardware with 14mm & 13 mm wrenches.

• Repeat with the remaining Shelf Tray and hardware [C].

• Once again turn the assembly upside down for caster installation

(FIG 6).

The Eastwood Tear Down Table consists of cumbersome

metal components. Avoid pinching hands while han-

dling parts during assembly. Obtaining the assistance

of a helper during assembly is recommended.

FIG. 1

FIG. 2

A

B

A

B

C