Page

2

A WARNING

TYPE DSll AND

DSLll

BREAKERS ARE PROTEC-

TIVE DEVICES.

AS

SUCH, THEY

ARE

MAXIMUM

CURRENT RATED DEVICES. THEREFORE, THEY

SHOULD NOT UNDER

ANY

CIRCUMSTANCES

BE

APPLIED OUTSIDE THEIR NAMEPLATE RATINGS.

OPERATION OUTSIDE OF THESE RATINGS COULD

RESULT IN DEATH, BODILY INJURY OR PROPERTY

DAMAGE.

1-2 SAFETY FEATURES

Types DSll and DSLll Circuit Breakers and associated

drawout equipment are manufactured with built-in inter-

locks and safety related features. They are provided to

reduce hazards to operating personnel and provide

proper operating sequences.

A WARNING

TYPES DSll AND

DSLll

CIRCUIT

BREAKERS

ARE

STRONGLY

BUil

T AND PROVIDED WITH SAFETY

FEATURES. NEVERTHELESS, THE VOLTAGES,

Table

1.1

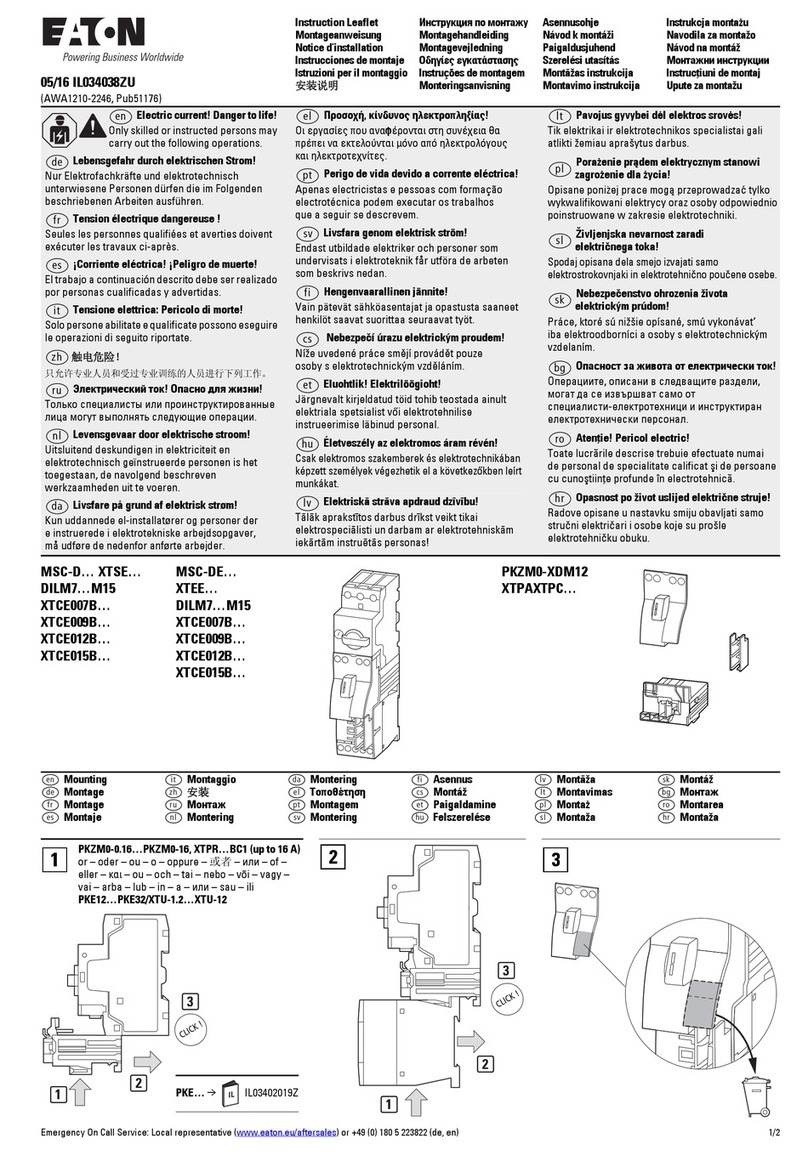

Type OSI/ BreakerRatings

. . .,

I:

'I

J

:1

DSll-308 800 42,000 30,000

DSll-508 800 65,000 50,000

DSll-608 800 65,000 65,000

DSll-516 1600 65,000 50,000

DSll-616 1600 65,000 65,000

DSll-620 2000 65,000 65,000

DSll-632 3200 85,000 65,000

DSll-840 4000 130,000 85,000

DSll-850 5000 130,000 85,000

©

MBXlmum

voltages at which the interrupting ratings apply are:

System Voltage Maximum Voltage

208 or 240 254

480 508

600 635

® Also short-time ratings.

l.B.

694C694-02

CURRENTS AND POWER LEVELS

AVAILABLE

IN

AND AROUND THIS EQUIPMENT WHEN

IT

IS IN

OPERATION ARE EXTREMELY DANGEROUS AND

COULD

BE

FATAL

UNDER NO CIRCUMSTANCES

SHOULD INTERLOCKS AND OTHER SAFETY FEA-

TURES

BE

MADE INOPERATIVE,

AS

THIS

MAY

RESULT IN DEATH, BODILY INJURY OR PROPERTY

DAMAGE.

1-3 SAFETY PRACTICES

To

pro~ect

personnel associated with the installation,

operation and maintenance of this equipment, the fol-

lowing practices must be followed:

1.

Only qualified electrical personnel familiar with the

equipment, its operation and the associated hazards

should be permitted to work on the equipment.

Additionally, only qualified personnel should be per-

mitted to install or operate the equipment.

2. Always be certain that the primary and secondary cir-

cuits are de-energized or the circuit breaker is

removed to a safe work location before attempting

any maintenance.

3. For maximum safety, only insert a completely assem-

bled breaker into an energized cell.

I I • • I • j 1 • •

I

I·'

.11

I:

JI

:.

: I

600

v

30,000 30,000 30,000 30,000

42,000 50,000 50,000 42,000

50,000 65,000 65,000 50,000

42,000 50,000 50,000 42,000

50,000 65,000 65,000 50,000

50,000 65,000 65,000 50,000

65,000 65,000 65,000 65,000

85,000 85,000 85,000 85,000

85,000 85,000 85,000 85,000

@ Short circuit ratings of non-automatic breakers except the DSll-840/850 which is 65,000.

Effective

07

/97

Courtesy of NationalSwitchgear.com