3

Instruction Booklet IB157001EN

Effective May 2015

Fixed capacitor banks (Unipump, Unipak, and Unipak

detuned lter) low voltage (600 V and below), NEMA 1

NEMA 3R (outdoor) enclosed versions

EATON www.eaton.com

Receiving

Check the capacitor bank when receiving to verify that there is no

shipment or handling damage during transit. Minor damage such as

scratches or small dents to the outer enclosure will not inhibit the

capacitor’s performance, but units with large dents or leaks should

not be installed. In case of major damage, file a claim against the

carrier and also notify the nearest Eaton sales office for instructions

regarding the disposition of the capacitor bank.

Check the capacitor’s nameplate to verify that the nameplate voltage

rating matches the system and the applied voltage.

Installation

Install capacitor bank in accordance with all applicable local electrical

standards (NECTNFPA 70, etc.). Failure to properly install capacitor

bank in accordance with local electrical safety standards may cause

electrical shock, fire, and incorrect operation including reduction in

useful life of the capacitor bank.

Preparation for installation

The capacitor bank storage temperature range is –40 °C to +55°C,

and the operating temperature range is –40 °C to +46 °C. For

optimal equipment life, prepare to install the capacitor bank in an

area free of external heat sources, such as direct sunlight.

For optimal equipment life, a harmonic resonance evaluation

should be performed prior to installation, particularly if an unfiltered

capacitor bank is used.

Installation locations

Capacitor banks should be located in a well-ventilated area with a

minimum of 3 inches of clearance around all sides and top of the

enclosure to ensure good air circulation.

Equipment rated for indoor use should be installed indoors in a dry

environment. Outdoor rated units shall be shielded from the radiant

heat of direct sunlight by a canopy or a sunshade.

Both for indoor and outdoor installations, the maximum ambient

temperature should not exceed 40 °C (104 °F) and the annual average

temperature should not exceed 35 °C (95 °F). Higher location ambient

temperatures will cause capacitor failure and reduction in useful life of

the capacitor, including instantaneous failures.

Installation procedures

Mechanical installation

To open the capacitor bank enclosure, remove the screws holding

the top cover. Grasp the front cover and tilt it forward and down to

separate it from the base unit.

Inspect the internal capacitor cells to verify that no physical damage

has occurred during shipment or handling.

Inspect and ensure that the power conductors are secured and tight

in their terminals by applying a gentle tug on the wires on both ends.

Inspect the discharge resistors for any marks of damage or cracks

and that they are seated and intact in the terminal.

If any signs of loose or cracked discharge resistor is noticed, stop

and do not proceed with the installation and immediately notify your

nearest Eaton sales person for further instructions.

Mechanically secure the capacitor bank to either the wall or the floor

using anchor fasteners.

Electrical installation

In accordance with NECT460, conductors should be sized for at

least 135% of the nameplate full load amps of the capacitor unit.

NEC460 also requires that the power factor capacitors must be

provided with a disconnecting means and overcurrent protection.

When connecting the capacitor bank on the load side of a motor

starter overload relay, it is not necessary to provide additional

disconnecting or overcurrent protection devices.

Fuses should be rated at least 165% of rated capacitor current.

A circuit breaker should be rated at least 135% of the rated

capacitor current.

Eaton requires that all customer feeder supply wiring be 90 °C rated

stranded copper wire sized and used at its 75 °C ampacity rating.

Observe all torque requirements for electrical connections. When

making connection using crimp terminals, be sure to use the

crimping tool recommended by the terminal manufacturer. Wire and

cable connections having improper torque may cause loosening of

the electrical connections resulting in localized heating or fire. The

unit should be cleaned of any debris, metal shavings, insulation, and

conductor strippings before being put into service.

An appropriately sized ground conductor should always be

connected to the ground terminal. Lack of ground connection or

improper grounding may result in electric shock or fire or inability

of ground fault protection to operate.

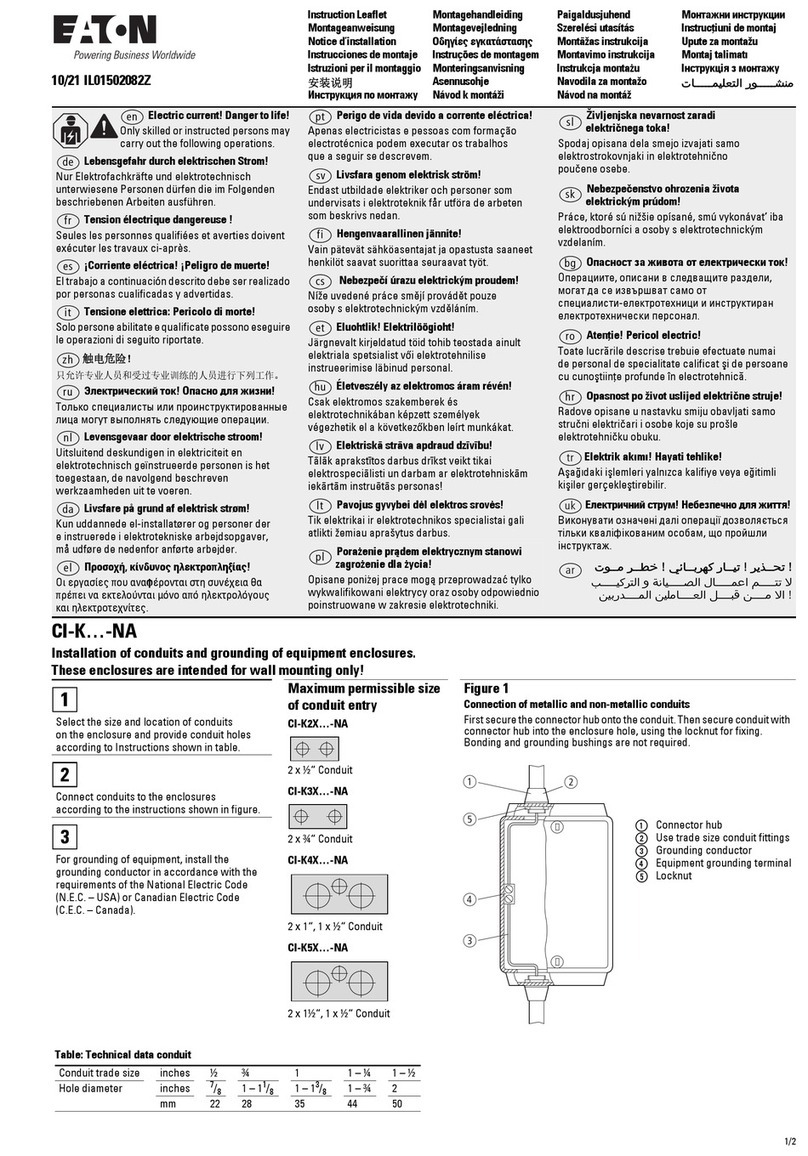

Conduit entry location should be selected so as to allow the

straightest connection to the provided mechanical lugs without

compromising the conductors’ bending radii. Connect the capacitor

bank by securing power conductors into the provided mechanical

lugs and tighten to the torque provided in Table 3. Connect ground

conductor into grounding lug and secure by tightening per torque

requirements below.

Conduit sizes, tray sizes, and cable ampacity must be according

to the National Electrical Code or applicable electrical codes in the

customer’s area.

Proceed to connect the feeder cables to the disconnecting switch/

circuit breaker. This operation must be performed with the

equipment completely de-energized.

Table 3. Recommended torque

Torque based on conductor size Torque based on bolt size

AWG Pound-inch Inches Pound-inch

30–10 80 1/8 45

8 80 5/32 100

6–4 165 3/16 120

3 275 7/32 150

2 275 1/4 200

1 275 5/16 275

1/0–2/0 385 3/8 375

3/0–4/0 500 1/2 500

250–350 650 9/16 600

400 825

500 825

600–750 1000

ote:N Follow the lower torque value between the conductor size

and the bolt size.