Model 50 Duplex Basket Strainer, Sizes 5” - 8”

Operation

The chamber in operation can be determined by observing

the position of the valve handle. The

handle is on the same side of the center line as

the chamber in operation (see Figure 4).

Start up

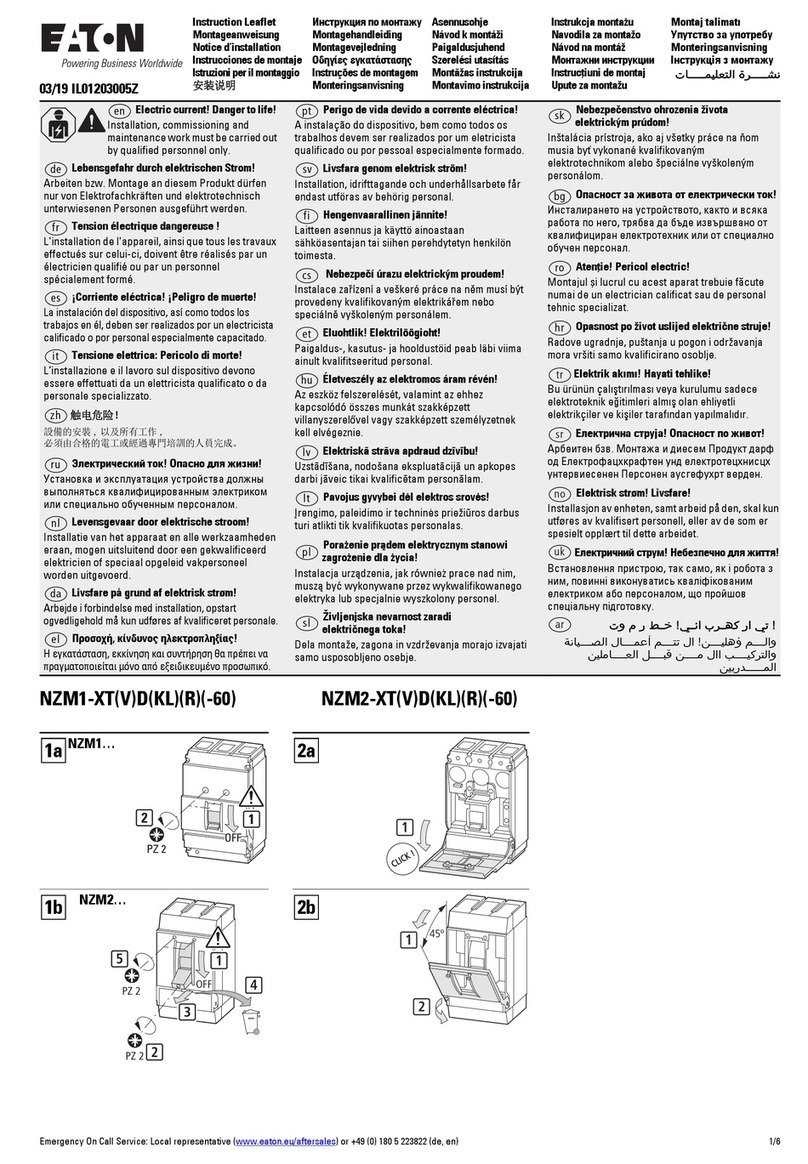

Open both chamber vents, if strainer is so equipped (see

figure 3), to expel air from the

strainer.

Position valve handle in the center to allow both chambers

to fill and close the equalizer valve, if strainer is so

equipped (see figure 2).

Slowly allow fluid to enter strainer by opening OUTLET

valve first, then followed by opening the INLET valve.

CAUTION: Start system GRADUALLY. This

eliminates sudden shock to strainer and

other equipment in the line.

Close vents when air is expelled and fluid begins to leak out

vent.

Move valve handle to extreme travel position over one

clean basket. DO NOT leave valve handle in the center

position as both baskets will become dirty. This would

require interrupting flow to clean them.

Seat valve plug lightly by turning valve yoke clockwise. To

avoid excessive stresses, stuck valve plugs etc. when

operating at temperatures above 120°F use only

minimum hand pressure on the valve yoke to position the

valve plug against the seat.

The valve plug should be firmly seated during basket

cleaning to prevent excessive leakage into the opened

chamber.

Start up, Continued

NOTE: The strainer valve plug is intended to

divert flow. It is not designed to provide

absolute tight shut off. Product design

criteria requires valve plug seepage to be low

enough to provide time for basket cleaning only.

Shut Down

Tightly close pipeline valve on inlet and outlet connections

of the strainer. Open vents, (see

figure 3), to relieve liquid pressure in the strainer.

CAUTION: DO NOT loosen body covers

while there is liquid or air flow from the

vent.

Switching Flow

Without Equalizer

Turn lifting handle counterclockwise to lift valve plug

and position turning handle (to extreme travel position)

over clean basket. Seat valve plug slightly by turning

lifting handle clockwise.

With Equalizer

Open pressure equalizer valve and turn lifting handle

counterclockwise to lift valve plug.

Position turning handle (to extreme travel posi- tion) over

clean basket and seat valve plug tightly by turning lifting

handle clockwise.

Close equalizer valves.

Basket Removal (Yoke Cover)

Transfer flow from dirty to clean chamber (see Switching

Flow) and open vents, and/or drain valve to relieve liquid

pressure in dirty chamber.

When pressure is relieved, loosen, but do not remove, T-

bolt. Then drain fluid away through the chamber drain

connection to a level below the basket seat. This

prevents by-pass of dirty fluids.

Swing yoke away from body yoke stud and clear of body

cover. Remove cover.

Remove dirty basket.