Eaton Magnum MRR1000 User manual

Other Eaton Industrial Equipment manuals

Eaton

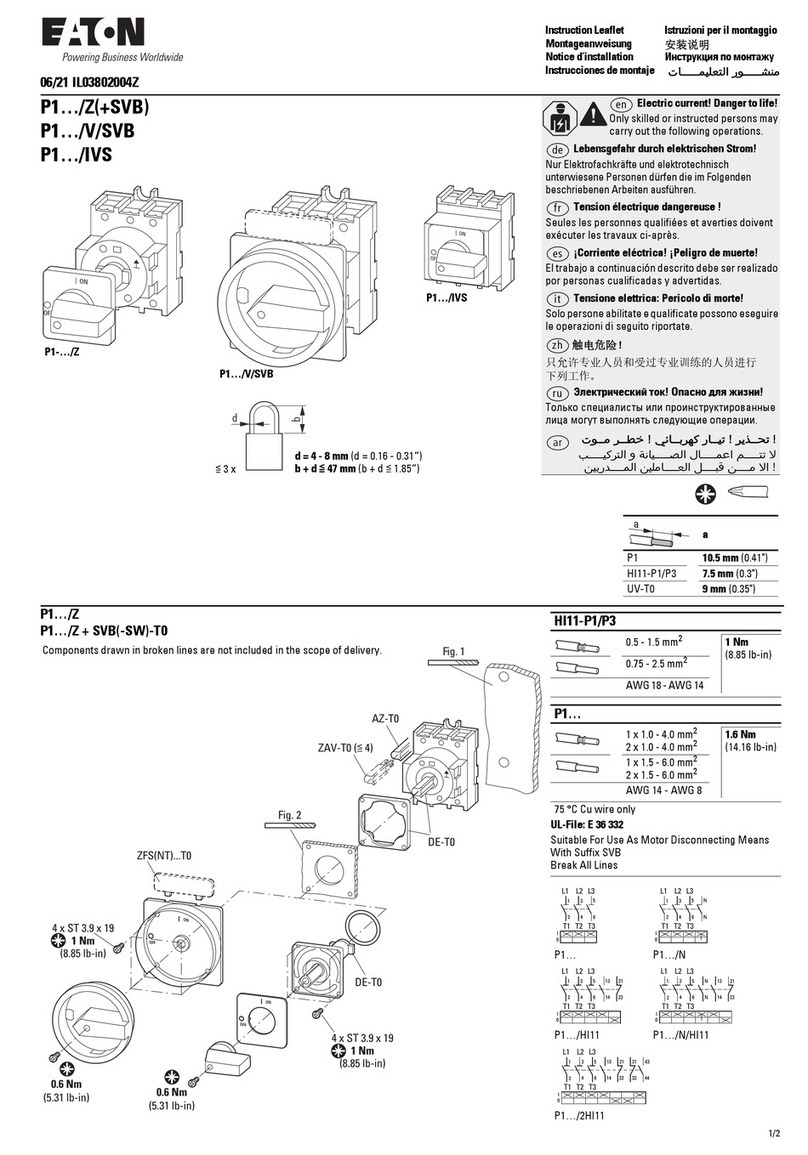

Eaton P1/Z Plus SVB Series Manual

Eaton

Eaton CODMV Series Manual

Eaton

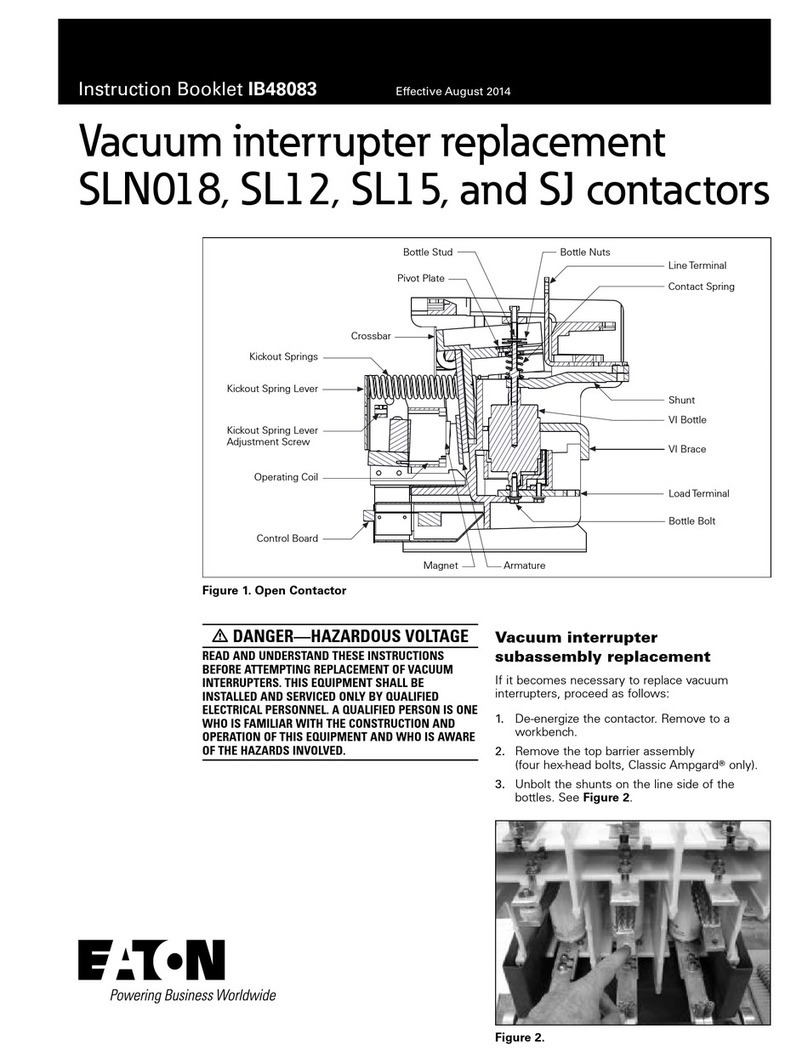

Eaton SLN018 User manual

Eaton

Eaton Airflex WCBD Series User manual

Eaton

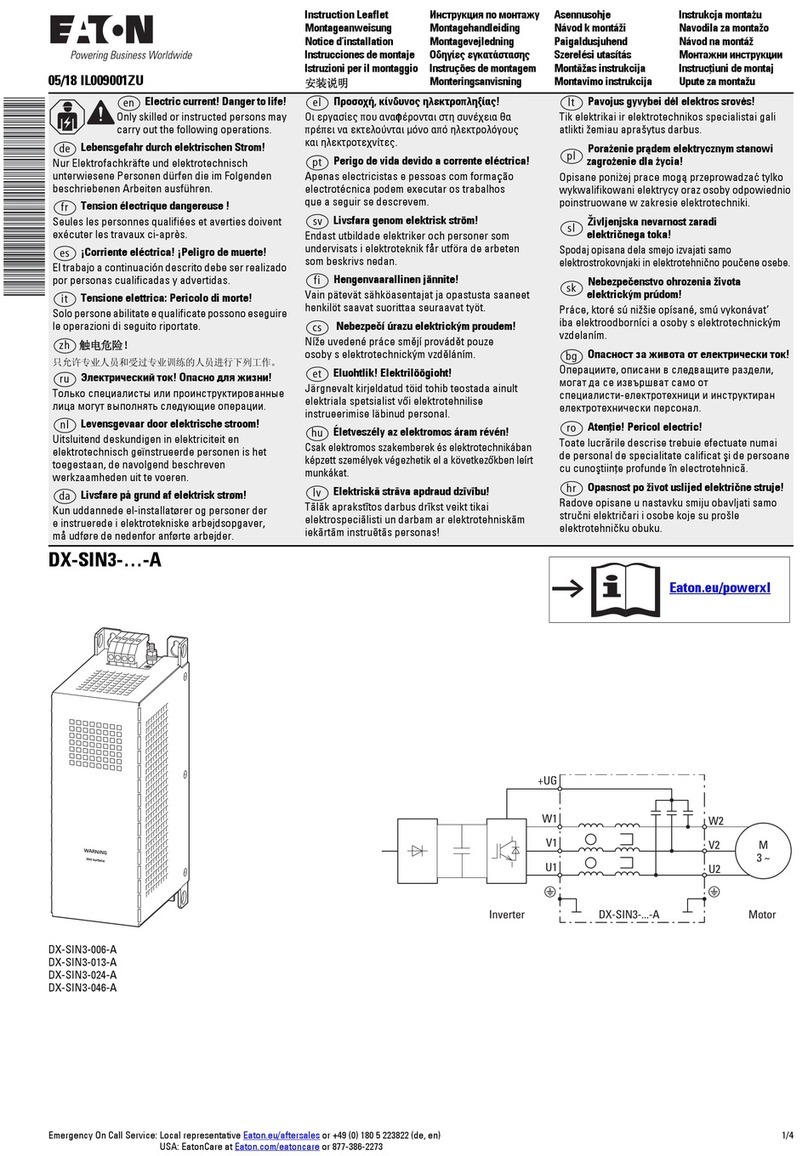

Eaton DX-SIN3-006-A Manual

Eaton

Eaton Power Xpert C445 User manual

Eaton

Eaton Fuller FTS 108LL Series Installation and operation manual

Eaton

Eaton DX-BR Series Manual

Eaton

Eaton ET5050 User manual

Eaton

Eaton DILMS7-DILMS12 Series Manual

Eaton

Eaton MEMSHIELD 4 User manual

Eaton

Eaton KLV-UP-F Series Manual

Eaton

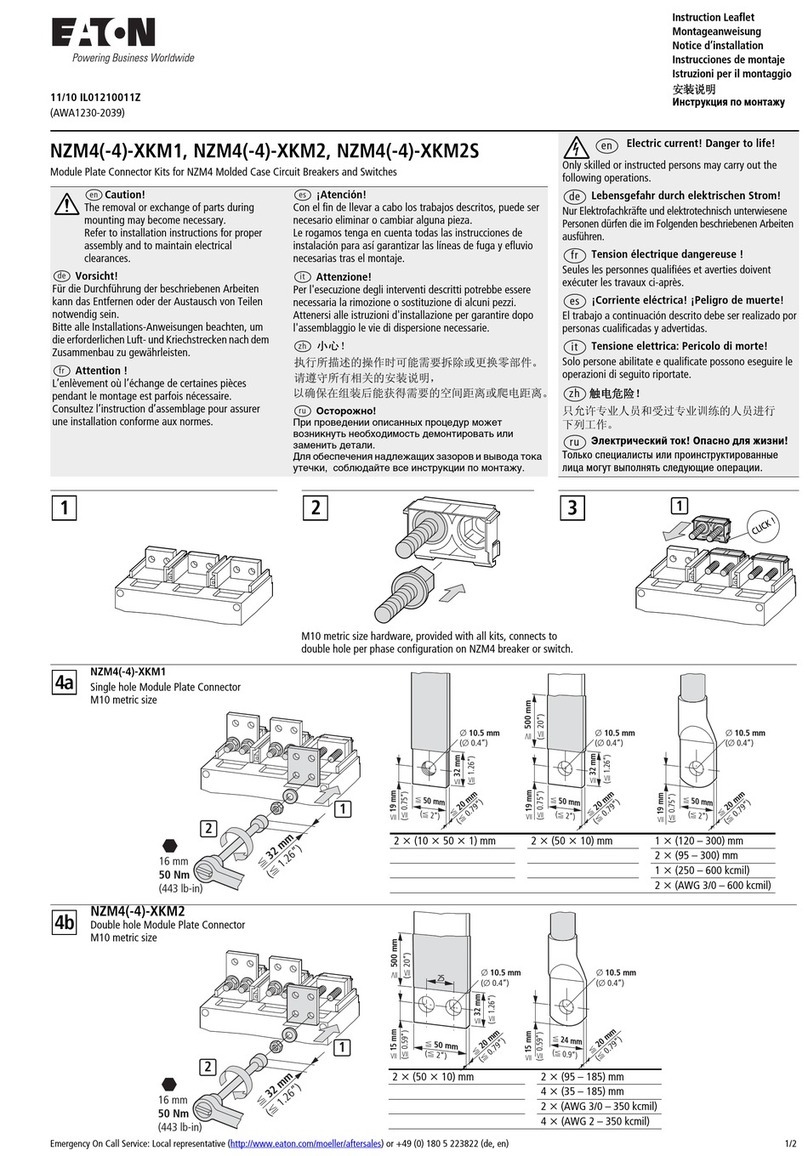

Eaton NZM4-4-XKM1 Manual

Eaton

Eaton NZM1-4-XIPKA Manual

Eaton

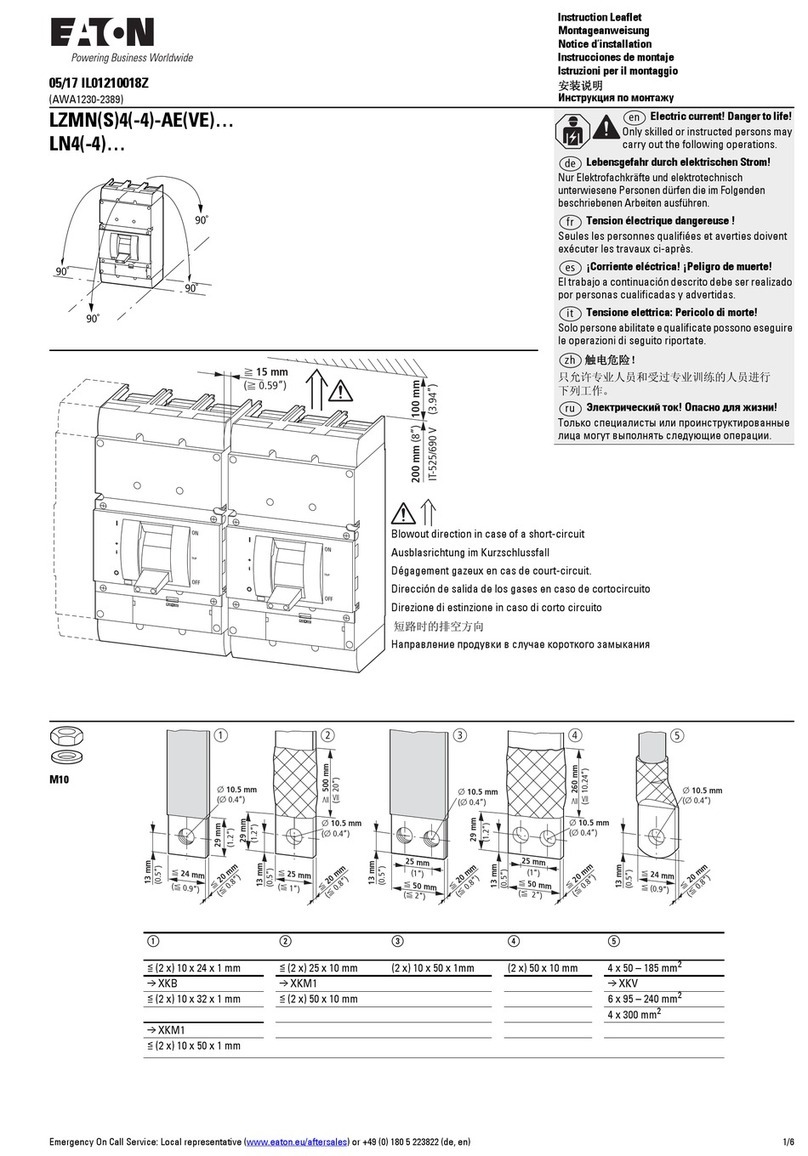

Eaton LZMNS4-AE Series Manual

Eaton

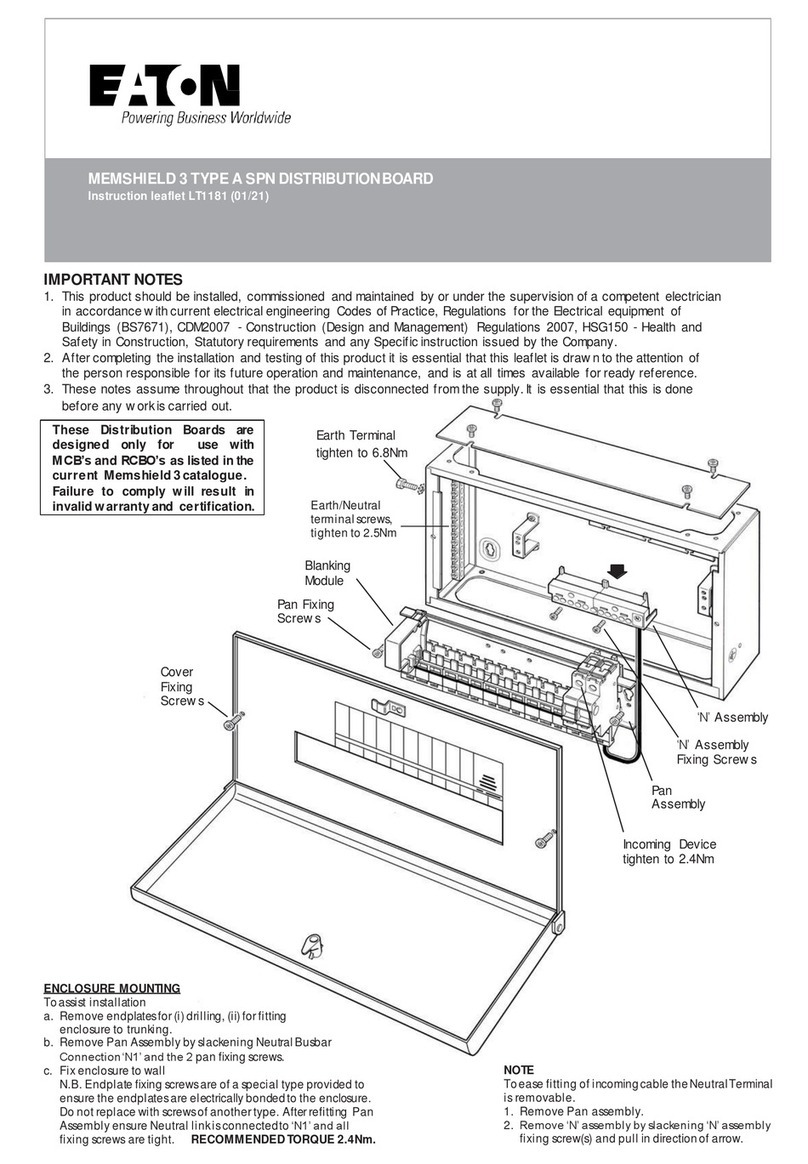

Eaton MEMSHIELD 3 Manual

Eaton

Eaton RS2 Series Manual

Eaton

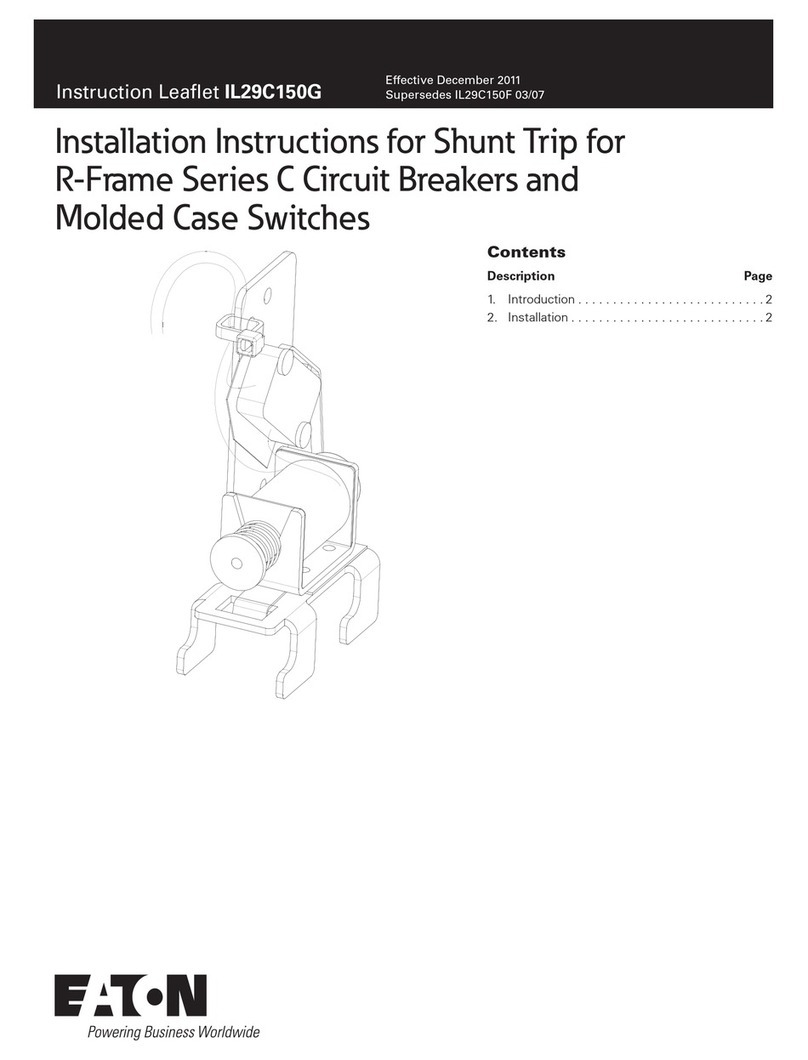

Eaton R-Frame Series User manual

Eaton

Eaton NZM-XSWD-704 Manual

Eaton

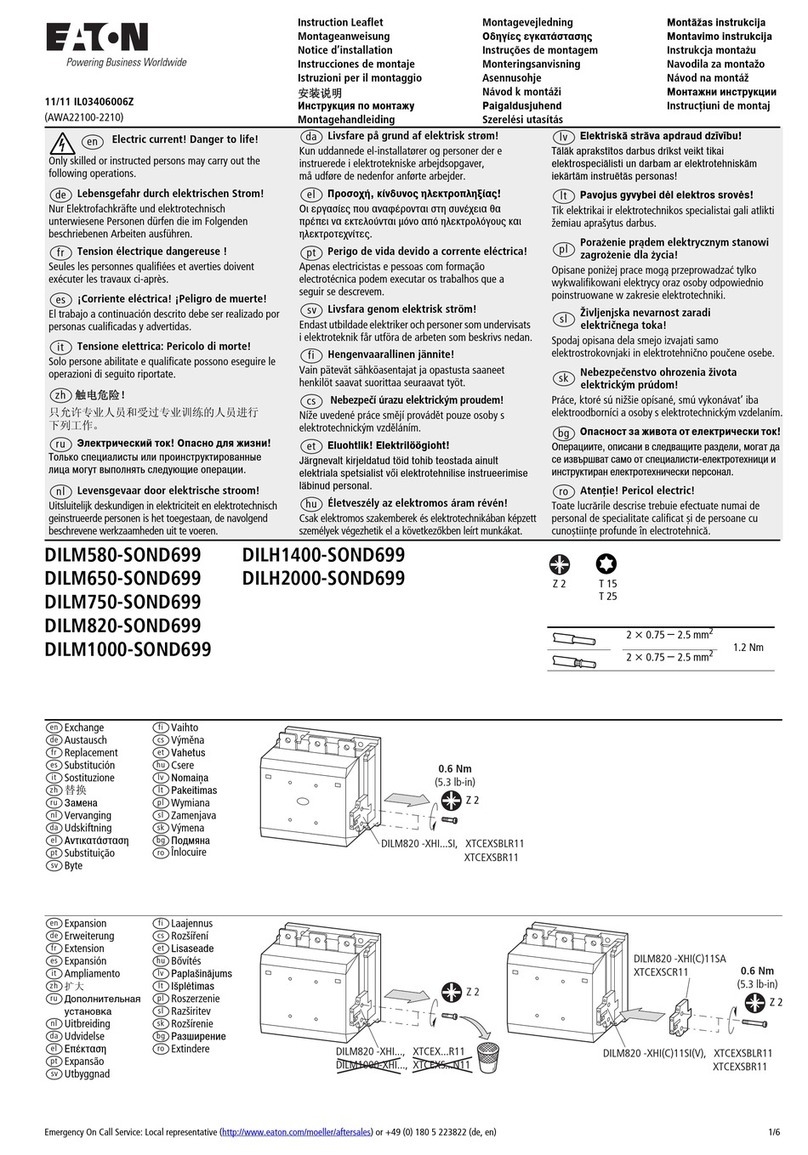

Eaton DILM580-SOND699 Manual