RTK PEX7250 explosion proof annunciator

Operating instructions

June 2018

INS RTK PEX7250 Rev 8

Instruction sheet

MTL process alarm equipment

1

Eaton Electric Limited,

Great Marlings, Butterfield, Luton

Beds, LU2 8DL, UK.

Tel: + 44 (0)1582 723633 Fax: + 44 (0)1582 422283

www.mtl-inst.com

© 2019 Eaton

All Rights Reserved

Publication No. INS RTK PEX7250 Rev 8

June 2019

1

EUROPE (EMEA):

+44 (0)1582 723633

THE AMERICAS:

+1 800 835 7075

ASIA-PACIFIC:

+65 6 645 9888

The given data is only intended as a product

description and should not be regarded as a legal

warranty of properties or guarantee. In the interest

of further technical developments, we reserve the

right to make design changes.

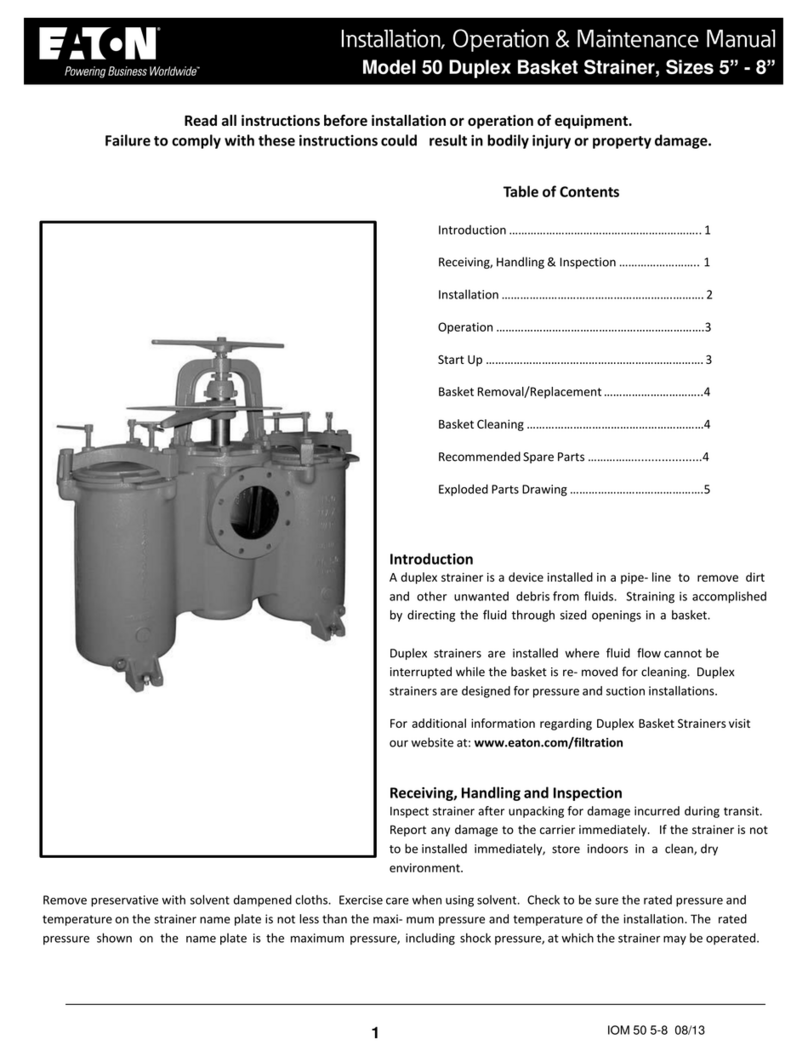

Introduction

This manual provides the information necessary to install, connect, test and maintain the RTK PEX7250 explosion proof

alarm annunciator.

Description

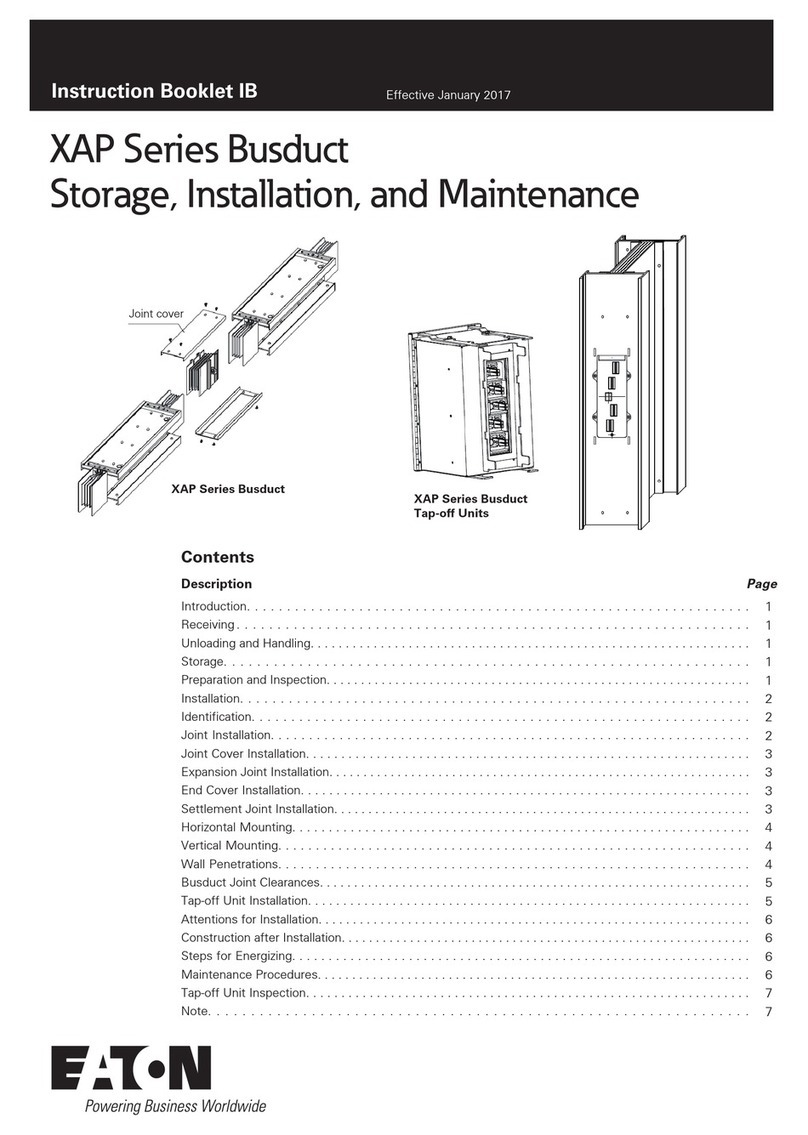

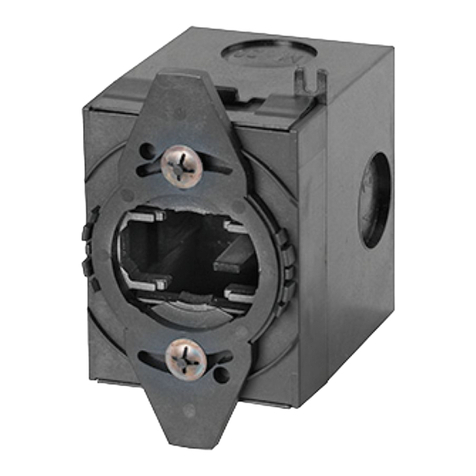

The RTK PEX7250 explosion proof annunciator is available with 1 of 3 of our established products fully integrated within the

enclosure. Option 1 = RTKP725, Option 2 = RTK725B/C and these versions are available using 30 x 30 mm, 30 x 60 mm or

60 x 60 mm window sizes. Option 3 = RTKSIL725 which is certified for SIL2 applications. This version is available in 30 x 60

mm or 60 x 60 mm window sizes.

The standard enclosure is copper free cast aluminium alloy and is finished in a light grey two-part epoxy paint, coloured

RAL7035, making it ideal for offshore applications. Systems are available in a range of formats and sizes and all carry the

same approval to internationally recognised Zone 1 standards.

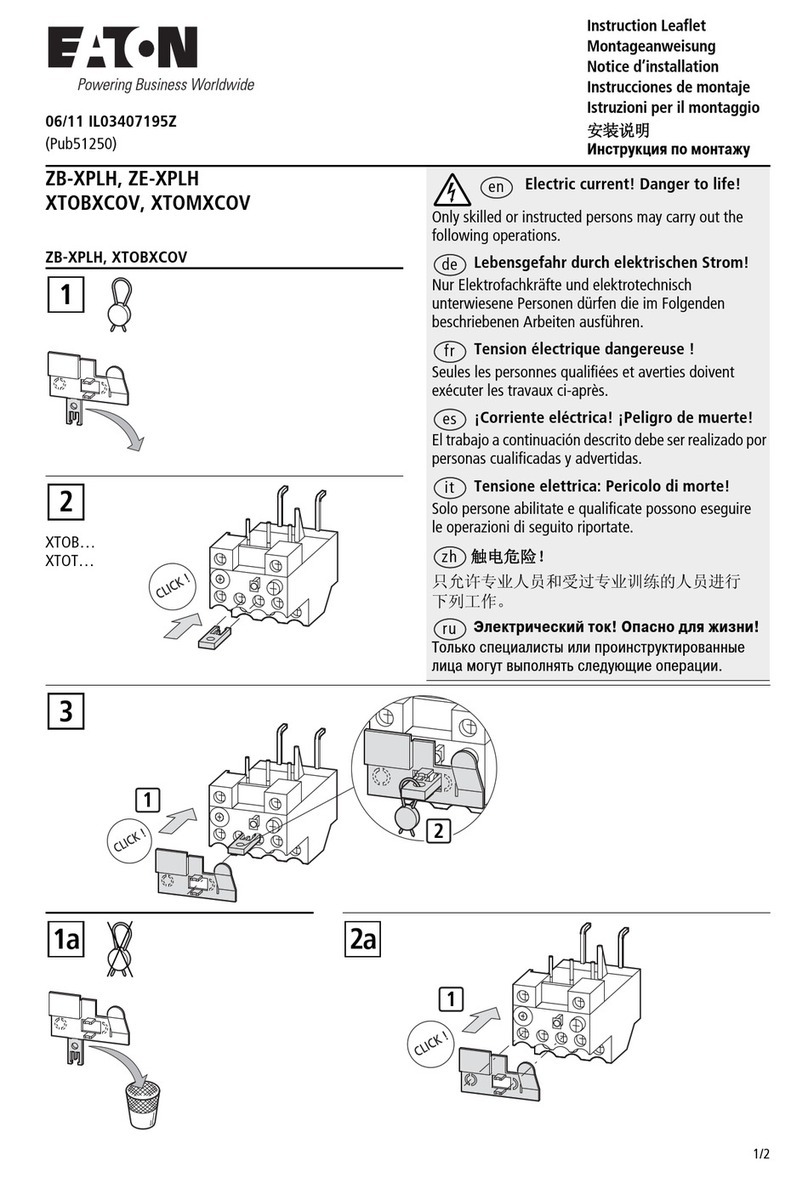

Installation

This product has been certified to be mounted in

Zone 1,2,21 or 22 hazardous areas. Equipment must be

installed in accordance to IEC60079-14 (Electrical installation

in hazardous areas) or alternative national standards.

Manual Handling

Below are basic methods which should be observed while

handling the equipment.

• Assess the load (size, shape and weight). Is mechanical

or human assistance is required?

• Assess where the unit will be placed. Make sure there

are no obstructions, and the route is clear.

• Stand as close to the load as possible, with your feet

shoulder width apart.

• Bend your knees and try to keep the back’s natural,

upright posture.

• Grasp the load firmly as close to the body as you can.

• Use the legs to lift the load in a smooth motion as this

offers more leverage reducing the strain on your back.

• Carry the load close to the body with the elbows tucked

into the body.

• Avoid twisting the body as much as possible by turning

your feet to position yourself with the load

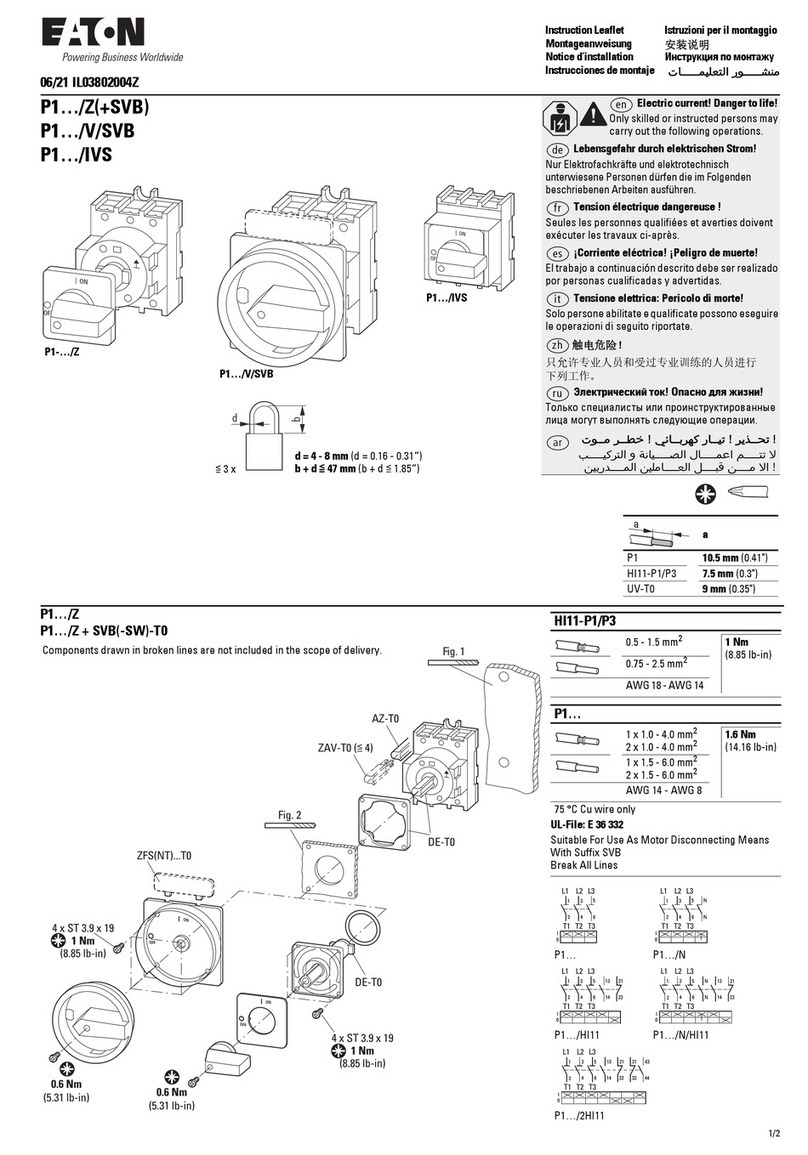

Mounting

Unit is supplied with mounting brackets for vertical or

horizontal mounting.

Connection detail

Refer to wiring diagram supplied for terminal connections. All

wiring inside the box must be carried out in compliance with

the characteristics of the components.

Use and Service

All the operations of installation and service will be carried out

when the circuit is not powered. Take care in not damaging

the coupling joints; always reapply the silicone grease to

the flanges before re-closing the box, and ensure all closing

screws have been returned and fully tightened. Use screws

of quality A2-70 according UNI 7323 with ultimate tensile

strength of at least 700N/mm²

Cable Entries

Refer to the General Arrangement drawing supplied with the

unit for details on cable entries fitted to the RTK PEX7250

Annunciator.

WARNING:

Ensure only correctly sized cable glands are used and

that any threaded hole within the lid or the body not

being used is closed with certified blanking plugs.

Cable entries shall also be suitably sealed if the enclosure

is to be used in dust atmospheres.

Specific Conditions of Use

1. It is the responsibility of the installation engineer to ensure

that suitably ATEX equipment certified Ex db IIB+H2 cable

glands and blanking plugs are installed to ensure that the IP

rating of IP66/67 is maintained on the Ex d enclosure.

2. When the enclosure is fitted with an MTL5521, the

enclosure must be mounted vertically.