3 Safety

3.1 Intended Use

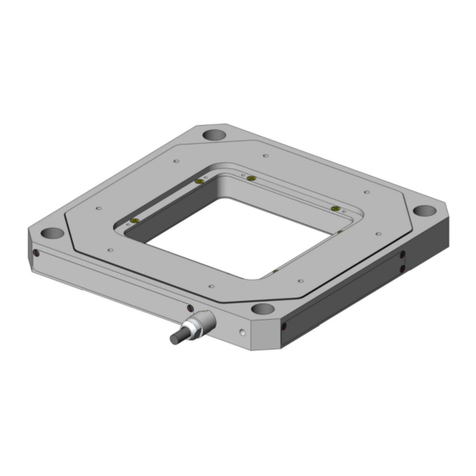

The V-412.xx6025E0 is a laboratory device as defined by DIN EN 61010-1. It is intended for

indoor use and use in an environment that is free of dirt, oil, lubricants, and liquids.

In accordance with its design, the V-412.xx6025E0 is intended for positioning, adjusting and

shifting loads in one axis at various velocities. The V-412.xx6025E0 is not intended for

applications in areas, in which a failure would present severe risks to human beings or the

environment.

The V-412.xx6025E0 is intended for operation with a horizontally aligned motion axis. A

vertically aligned motion axis may only be operated with suitable gravity compensation (not

in the scope of delivery).

The intended use of the V-412.xx6025E0 is only possible when completely mounted and

connected. The thermal protection sensor built into the V-412.xx6025E0's motor must be

evaluated and monitored. The V-412.xx6025E0 must be operated with suitable

electronics (p. 13). The electronics are not in the scope of delivery of the V-412.xx6025E0.

The V-412.xx6025E0 may not be used for purposes other than those stated in this user

manual. The V-412.xx6025E0 may only be used in compliance with the technical

specifications and instructions in this user manual.

3.2 General Safety Instructions

If the protective earth conductor is missing or not properly connected, risk of dangerous

touch voltages on the V-412.xx6025E0 in the event of malfunction or failure of the system. If

there are touch voltages, touching the V-412.xx6025E0 leads to serious injuries or death by

electric shock.

►Connect the V-412.xx6025E0 to a protective earth conductor before startup.

►Do not remove the protective earth conductor during operation.

►If the protective earth conductor has to be removed temporarily (e.g., for modification),

reconnect the V-412.xx6025E0 to the protective earth conductor before restarting.

The V-412.xx6025E0 contains permanent magnets that could impair the function of heart

pacemakers and electronic implants.

►Make sure that people with heart pacemakers and / or electronic implants do not have

access to the V-412.xx6025E0.

The magnets in the V-412.xx6025E0 can damage parts susceptible to magnetic influences,

e.g., magnetic data carriers and electronic devices.

►Make sure that there are no objects sensitive to magnets within a radius of at least 10 cm

around the V-412.xx6025E0.

The magnets in the V-412.xx6025E0 can attract magnetizable parts, e.g., loose screws.

Objects attracted can damage the V-412.xx6025E0.

►Make sure that there are no movable, magnetizable objects within a radius of at least

10 cm around the V-412.xx6025E0.

Mechanical forces can destroy the V-412.xx6025E0.

►Avoid knocks that affect the V-412.xx6025E0.

►Do not drop the V-412.xx6025E0.

The V-412.xx6025E0 is built according to state-of-the-art technology and recognized safety

standards. Improper use of the V-412.xx6025E0 may result in personal injury and/or damage

to the V-412.xx6025E0.

►Use the V-412.xx6025E0 only for its intended purpose and if it is in perfect condition.

►Read the user manual.

3 SAFETY V412M0008EN ‒ 5/11/2020

7MOTION | POSITIONING