Edgetech 4200-FS User manual

USER’S HARDWARE MANUAL

Revision: 1.2 / May, 2005

Email: [email protected]

Web: http://www.edgetech.com

4 Little brook Rd.

West Wareham, MA. 02576

Tel: (508) 291-0057

Fax: (508) 291-2492

1141 Holland Drive, Suite 1

Boca Raton, FL 33487

Tel: (561) 995-7767

Fax: (561) 995-7761

4

42

20

00

0-

-F

FS

S

High Definition, Multi-Pulse, Dual

Frequency Side Scan System

i

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

FORWARD

This manual is intended to provide the user with an understanding of the operation and care of

the 4200-FS side scan towfish. Although this manual covers the latest operational features of the

4200-FS, some features may be periodically upgraded. Also, certain hardware may be changed

per customer requirements. Therefore, portions of this manual such as parts lists, and test

features are subject to change. Such sections should be used for reference only. When changes

are made that affect system operation, they will be explicitly noted. Also, some options and

features may not be active in your unit at time of delivery. Upgrades will be made available

when these features are implemented.

A 4200 System consists of two hardware components plus an installed software sub-component.

The hardware components are the Model 566, or 566P, topside processor with its color video

monitor and the EdgeTech 4200-FS towfish. Information relating to the 4200-FS towfish is

included in this manual. Information relating to the Model 566 and 566P and instructions

pertaining to the installed sonar processor are included in their own individual manuals.

EdgeTech has made every effort to document this product accurately and completely. However,

EdgeTech assumes no liability for errors or for any damages that result from use of this manual

or the equipment it accompanies. EdgeTech reserves the right to upgrade features of this

equipment and to make changes to this manual without notice at any time.

Since clear and concise documentation is inherent for proper operation and understanding of the

equipment, we solicit you to contact us with any questions or comments so that we may enhance

this manual.

EdgeTech

4 Little Brook Road

West Wareham, MA 02576

Tel: (508) 291-0057

Fax: (508) 291-2491

ii

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

WARRANTY STATEMENT

All equipment manufactured by EdgeTech is warranted against defective components and

workmanship for repair at their plant in West Wareham, Massachusetts, free of charge, for a

period of one year. Shipping costs are to be borne by the customer. Malfunction due to improper

use is not covered in this warranty and EdgeTech disclaims any liability for consequential

damage resulting from defects in the performance of the equipment. No product is warranted as

being fit for a particular purpose and there is no warranty of merchantability. This warranty

applies only if:

(i) the items are used solely under the operating conditions and in the

manner recommended in the instruction manual, specifications, or

other literature;

(ii) the items have not been misused or abused in any manner or repairs

attempted thereon;

(iii) written notice of the failure within the warranty period is forwarded

to EdgeTech and the directions received for properly identifying

items returned under warranty are followed;

and (iv) the return notice authorizes EdgeTech to examine and disassemble

returned products to the extent EdgeTech deems necessary to

ascertain the cause for failure.

The warranties expressed herein are exclusive. There are no other warranties, either expressed or

implied, beyond those set forth herein, and EdgeTech does not assume any other obligation or

liability in connection with the sale or use of said products.

Equipment not manufactured by EdgeTech is supported only to the extent of the original

manufacturer's warranty.

iii

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

WARNING

THIS EQUIPMENT CONTAINS STATIC SENSITIVE DEVICES

These devices are extremely sensitive to static electrical charges which may be developed on the

body and clothing. Extreme care should be taken when handling these devices both in and out of

the circuit board. Normal handling precautions involve the use of anti-static protection materials

and grounding straps for personnel.

WARNING

This equipment generates, uses, and can radiate radio frequency energy, and if not installed

properly may cause interference to radio communications. It has not been tested for compliance

to the appropriate FCC or EC rules designed to provide reasonable protection against such

interference when operated in a commercial environment. Operation of this equipment in a

residential area may cause interference, in which case the user, at his own expense, will be

required to take whatever measures may be needed to correct the interference. It is the user's

responsibility to verify that his system complies with the applicable emission limits.

iv

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

HARDWARE VARIATIONS & COMPATIBILITY

The 4200-FS towfish contains both standard PC and proprietary hardware. At times EdgeTech

may change these standard components due to their availability or performance improvements.

Although manufacturers, their models, and styles may change from unit to unit, replacement

components will generally be interchangeable.

EdgeTech will make all effort to see that replacement boards are interchangeable and use the

same software drivers. At times though, there may be instances where direct replacements do not

exist. When this happens, EdgeTech will provide the necessary drivers with the replacement part.

v

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

TABLE OF CONTENTS

1 INTRODUCTION ..................................................................................................................1

1.1 SPECIFICATIONS ....................................................................................................................................2

2 566 TOPSIDE PROCESSOR ..................................................................................................3

3 4200 TELEMETRY...............................................................................................................4

3.1 SPECIFICATIONS ....................................................................................................................................4

4 4200 TOWFISH....................................................................................................................5

5 TOW CABLE........................................................................................................................7

6 DEPLOYMENT.....................................................................................................................7

6.1 OPTION 1(KEVLAR TOW CABLE)...........................................................................................................7

6.1.1 Cable Attachment.............................................................................................................................8

6.1 OPTION 2(STEEL ARMORED TOW CABLE)...........................................................................................10

6.2.1 Cable Attachment...........................................................................................................................10

7 TROUBLESHOOTING &REPAIR .......................................................................................11

7.1 ACCESS/REMOVAL ..............................................................................................................................11

7.1.1 Tools..............................................................................................................................................11

7.1.2 Preliminary.....................................................................................................................................11

7.1.3 Electronics Assembly Removal.....................................................................................................12

7.1.4 Transducer Removal......................................................................................................................14

7.2 TROUBLESHOOTING.............................................................................................................................14

7.2.1 Equipment Required ......................................................................................................................14

7.2.2 General Troubleshooting ...............................................................................................................15

7.2.2.1 Transmission Verification....................................................................................................................15

7.2.2.2 Sonar Processor and Data Link............................................................................................................16

7.2.2.3 Topside Power Unit.............................................................................................................................16

7.2.2.4 Command and Data Link.....................................................................................................................16

7.2.2.5 Data link ..............................................................................................................................................17

7.2.2.6 Towfish................................................................................................................................................17

7.2.2.7 Tow Cables..........................................................................................................................................19

7.3 REPAIR ................................................................................................................................................21

7.3.1 Damaged Tail Fins.........................................................................................................................21

7.3.2 Transducers....................................................................................................................................21

7.3.3 Towfish Rearming .........................................................................................................................21

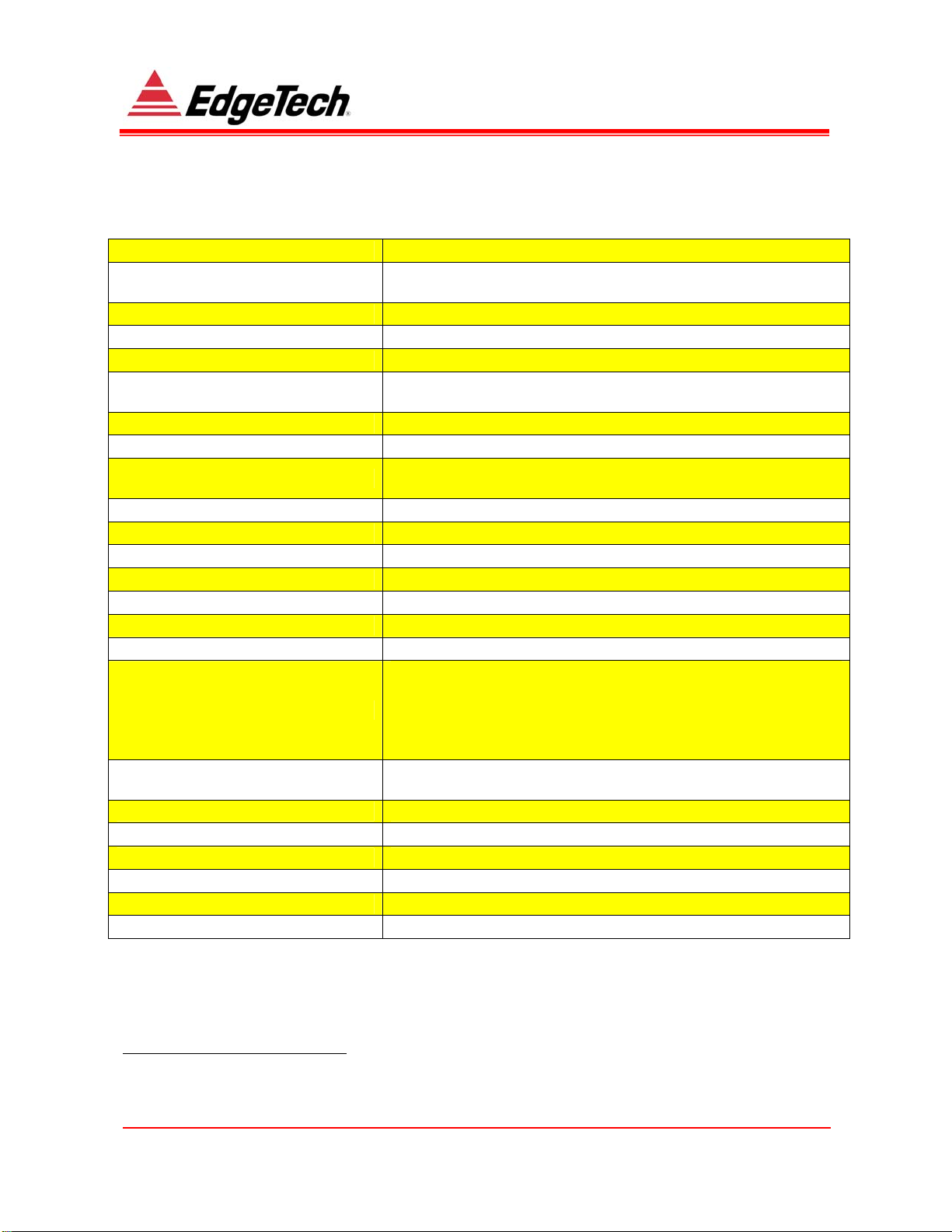

7.4 TROUBLESHOOTING GUIDE .................................................................................................................22

7.4.1 Non Deployment Tests ..................................................................................................................22

7.4.2 Pre-Deployment Rub Test..............................................................................................................25

7.4.3 Deployment Tests when Operational.............................................................................................26

8 TOW CABLES AND CONNECTIONS ...................................................................................30

8.1 4200 TELEMETRY................................................................................................................................30

8.2 ARMORED TOW CABLE TERMINATION.................................................................................................32

9 4200-FS TOWFISH PARTS LIST .......................................................................................33

10. RETURNED MATERIAL AUTHORIZATION........................................................................34

vi

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

TABLE OF FIGURES

FIGURE 6-1: SAFETY LINK.........................................................................................................7

FIGURE 6-2: SPARE SHEAR PINS................................................................................................8

FIGURE 6-3: TOW ARM -CABLE MOUNTING,LIGHTWEIGHT ...................................................8

FIGURE 6-4: TOW ARM AND FISH CONNECTION .......................................................................9

FIGURE 6-5: ARMORED CABLE ATTACHMENT........................................................................10

FIGURE 7-1: ELECTRONICS ASSEMBLY REMOVAL...............................................................13

FIGURE 7-2: ELECTRONICS ASSEMBLY REMOVAL...............................................................13

FIGURE 7-3: ELECTRONICS ASSEMBLY REMOVAL...............................................................13

FIGURE 7-4: TOWFISH COMPONENT LOCATIONS.................................................................27

FIGURE 7-5: TAIL FIN DIMENSIONS.......................................................................................28

FIGURE 7-6: END CAP TRANSDUCER CONNECTIONS..............................................................29

FIGURE 8-1: TOW CABLE WITH 566 TOPSIDE TERMINATION..................................................30

FIGURE 8-2: TOW CABLE WITH 566P TOPSIDE TERMINATION ...............................................31

FIGURE 8-3: ARMORED TOW CABLE TERMINATION..............................................................32

APPENDIX

Appendix A: Magnetometer Option - Document #: A958614

Document: 990-0000046-1000 Page 1

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

1 INTRODUCTION

The 4200-FS Side Scan Sonar combines EdgeTech’s Full Spectrum Chirp and Multi-Pulse

technologies to provide a unique dual mode of operation system.

The surveyor may run the 4200-FS system in either of the following software selectable

modes:

•High Definition Mode (HDM): Conventional simultaneous dual frequency mode of

operation using extra long arrays for superior resolution.

•High Speed Mode (HSM): Dual pulse operation for speed up to 10 knots, while

meeting NOAA and IHO requirements for ‘hits on target’.

When operating at the High Speed Mode (HSM) the surveyor can select either of the

operational frequencies, namely 410 kHz for up to 200 meter per side coverage or 120 kHz

for up to 500 meter per side coverage.

The 4200-FS uses a variant of EdgeTech’s deep water proven StarMux® Digital Telemetry

System to link the topside to the towfish using a single coaxial cable up to 6000m long.

The 4200-FS system comprises the following major components:

•4200 Towfish

•Option 1: 4200-FS Processor (19" rack mount PC, - Model 566 processor)

•Option 2: 4200-FS Portable Processor (Waterproof carry case – Model 566P

processor)

•100 feet (30 m) Test Tow cable

•Tow cable (as per order)

Document: 990-0000046-1000 Page 2

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

1.1 SPECIFICATIONS

Frequency 120 / 410 kHz dual

Modulation Full Spectrum chirp frequency modulated pulse with amplitude

and phase weighting

Operating Range (max) 120 kHz 500 meters p/side; 410 kHz 200 meters p/side

Towing Speed (max safe) 12 knots

Towing Speed*4.8 knots in HDM, 9.6 knots in HSM

Output Energy (Power x pulse

length) 120 kHz 4 joules, 410 kHz 2 joules

Pulse Length 120 kHz up to 20 ms, 410 kHz up to 10 ms

Resolution Across Track 120 kHz 8 cm, 410 kHz 2 cm

Resolution Along Track 120 kHz: 2,5m @ 200 meters range, 410 kHz: 0,5m @ 100

meters range (HDM mode)

Horizontal Beam Width (HDM) 120 kHz - 0.64°, 410 kHz – 0.3°

Horizontal Beam Width (HSM) 120 kHz – 1.26°, 410 kHz – 0.4°

Digital Link 4 MBits/sec (typical), 4 channels of side scan data + sensor data

Vertical Beam Width 50°

Operating Depth (meters) 1000

Operating Temperature 0°C to 45°C

Optional Sensor Port (Mag) (1) Serial – RS 232C, 9600 Baud, Bi-directional

Heading/Pitch/Roll

Heading Accuracy: < 1.5° RMS

Heading Resolution: 0.1°

Roll, Pitch Angle Accuracy: ± 0.4°

Roll, Pitch Angle Repeatability: 0.2°

Roll, Pitch Angle Resolution: 0.1°

Options Pressure, Temperature, Magnetometer, USBL Acoustic Tracking

System, Acoustic Responder, and Custom Sensors

Diameter 11.4 cm (4.5 inches)

Length 125.6 cm (49.5 inches)

Towfish Material Stainless Steel, 316

Weight in Air/Saltwater 48 / 32 kg (105 / 70 pounds)

Tow cable Length 6,000 meters

Tow cable Type Co-axial

*3 hits on a 1 m target

Document: 990-0000046-1000 Page 3

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

2566 TOPSIDE PROCESSOR

The 566 processor is based on a 19" rack mount ruggedized PC, running Microsoft Windows

2000. Another choice is the 566P, portable topside housed in a rugged, waterproof case. The

user control and display interface is provided by EdgeTech’s Discover 4200-FS acquisition

software. This software package is optimized for real time data acquisition and logging using

the 4200-FS sonar. See the separate Discover 4200-FS Software User Manual, Document #:

990-0000047-1000.

Document: 990-0000046-1000 Page 4

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

34200 TELEMETRY

3.1 SPECIFICATIONS

Link

oTrigger TTL, for USBL or Fish external trigger

oTow cable co-axial

oTow cable length up to 6000m

Power

o566 Processor 115/230V AC, 50/60Hz Auto, @ 240watts

o566P Processor 115/230V AC, 50/60Hz Auto, or 24 VDC @ 200watts

Document: 990-0000046-1000 Page 5

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

44200 TOWFISH

The 4200 towfish is a hydro-dynamically stable towed body, which contains the transducers

and electronics necessary to generate and receive the side scan sonar signals, and

communicate with the topside unit. It is a compact stainless steel cylinder equipped with

stabilizing fins and lead nose weight for hydrodynamic balance. One person can handle it, but

it is recommended that 2 persons team up to carry the towfish.

Identical but separate, port and starboard transducers are mounted along the side of the

towfish. The whole length of the towfish is a watertight pressure vessel, housing the

electronics. The front and rear end caps are secured to the housing, and waterproofed using

double bore O ring seals. A guide pin is provided to ensure proper alignment.

The electronics chassis is connected to the rear end cap through a Delrin insulating plate.

The towfish was designed to only require a single tool for maintenance. A 4mm Allen key is

used to secure the arrays, the tail cone and accessing the electronics.

All connections to the arrays are terminated at the rear (aft) end cap.

The end caps are retained in the pressure housing by using nylon line in a shared end cap/tube

retention groove, minimizing the need for fine securing screws in the external assembly.

Document: 990-0000046-1000 Page 6

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

A rigid tow arm is mounted on the top of the towfish just ahead of the power and telemetry

connector. The tow arm provides a housing for the splice for the soft tow cable. The arm is

also configured with EdgeTech’s Saf-T-Link mechanical attachment to prevent towfish loss

due to snagging on the seafloor or moorings lines.

Note: The towfish assembly is made of high quality stainless steel 316L material, therefore

requires no cathodic protection.

The external hardware for the fish is all metric.

Document: 990-0000046-1000 Page 7

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

5TOW CABLE

The tow cable serves a dual purpose. It is the strength member used for towing and the

electrical conduit between the surface and sub-sea electronics. A single coax cable is

required. Most standard marine coax cables are adequate; the cable quality dictates maximum

cable length. Both lightweight Kevlar and armored tow cables are available depending on

survey speed and operating depth.

6DEPLOYMENT

The 4200-FS towfish may be deployed in two possible configurations depending on the users

tow and handling requirements.

Option 1: Standard, using a Kevlar tow cable for shallow surveys at speeds less than 8 knots.

Option 2: High Speed (8-10 knots) or deep surveys using armored tow cable.

6.1 OPTION 1(KEVLAR TOW CABLE)

A custom Edgetech tow arm with a Saf-T-Link feature is used.

The tow arm is built using two components, which are held together using a sacrificial shear

pin.

FIGURE 6-1: SAFETY LINK

Shear Pin

Document: 990-0000046-1000 Page 8

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

FIGURE 6-2: SPARE SHEAR PINS

The system is supplied with spare shear pins and retaining cotter pins.

Specifications:

Shear Pin: 8 mm (5/16") Delrin rod.

Shear Force: 6.2 to 6.4 kN (1400-1500 lbf)

6.1.1 CABLE ATTACHMENT

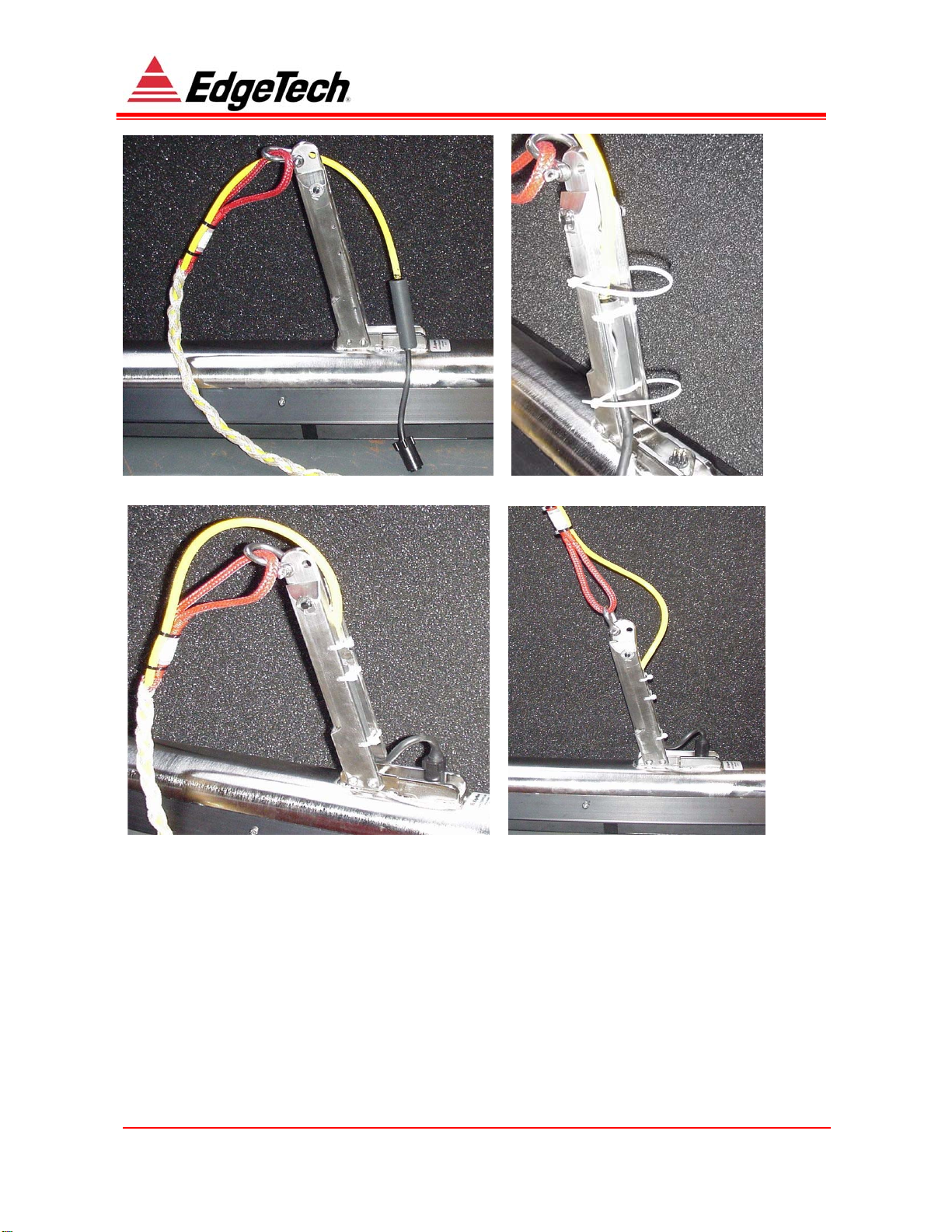

The tow arm and tow cable attachments are shown below.

FIGURE 6-3: TOW ARM - CABLE MOUNTING, LIGHTWEIGHT

The safety release catch cable should be attached ahead and below the tow point. This keeps

the catch cable clear of the tow cable entry.

SafeT release catch

cable

Shear Pin

Document: 990-0000046-1000 Page 9

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

12

3 4

FIGURE 6-4: TOW ARM AND FISH CONNECTION

The Kevlar tow cable is terminated in a customized splice, which incorporates the 6 pin

female mating connector. This splice/connector combination is mated to the towfish (3 & 4),

and the splice is stored in the tow-arm cavity (2, 3 & 4). The cable is retained in the tow arm

using tie wraps (2 & 3)

Note: The maximum recommended tow speed using the supplied Edgetech coaxial

Kevlar cable is 8 knots.

For speeds in excess of 8 knots up to 12 knots we recommend the use of steel armored

cable, See Section 6.1.

Document: 990-0000046-1000 Page 10

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

6.1 OPTION 2(STEEL ARMORED TOW CABLE)

This option is used with the standard Edgetech tow-arm, as in Section 6.1

Higher speeds and depths maybe achieved using an armored tow cable.

6.2.1 CABLE ATTACHMENT

Tow cable attachment arrangements as follows.

FIGURE 6-5: ARMORED CABLE ATTACHMENT

The armored cable termination should be in accordance with the drawing in Section 8.

Document: 990-0000046-1000 Page 11

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

7TROUBLESHOOTING & REPAIR

This section provides information on isolating problems to the major component or subassembly

level. Once the problem area is isolated, the defective item should be replaced and returned to

EdgeTech for disposition. It is recommended that a complete set of spare boards and replaceable

subassemblies be kept onboard or at a readily accessible service center or depot facility.

The circuit boards contain static-sensitive devices. These devices are extremely sensitive to

static electrical charges that may develop on the body and clothing. Extreme care should be

taken when handling these components. Use anti-static protection materials and personnel

grounding straps during handling.

It is recommended that all attempts be made to see if a problem is external to the towfish

before opening it. Only open the towfish body as a last resort when it has been established

that the problem is internal to the towfish.

7.1 ACCESS/REMOVAL

Follow the procedures below to gain access to the internal components. Reverse the order to

reassemble. Note: Except for the transducers, all external hardware is mounted to the towfish

body with 4mm socket hex bolts.

Warning

Potentially Lethal Voltages Are Present in the Instrument

when it is powered from the topside or any other power unit.

7.1.1 TOOLS

Tools for access and service include:

•Phillips-head screw driver #2 (1)

•Flat-blade screw driver 1/8

•Socket driver 8mm (1)

•Allen key 4mm (1)

•Needle-nose pliers (1)

•Silicone grease (1)

•O-ring 2-154 N1470-70 (1)

Note: (1)These items are included in spares kit

7.1.2 PRELIMINARY

Prior to servicing the towfish, disconnect the mechanical and electrical connections to the tow

cable. Protect all disconnected underwater connectors. Ensure that they are kept clean and

Document: 990-0000046-1000 Page 12

4

42

20

00

0-

-F

FS

S

S

Si

id

de

e

S

Sc

ca

an

n

S

So

on

na

ar

r

lightly coated with silicone grease. Do not pack female connectors with grease unless the system

is to be put in long term storage.

7.1.3 ELECTRONICS ASSEMBLY REMOVAL

The electronics assembly is accessed from the aft section of the towfish body. This should be

done only in a clean, dry location. Proceed as follows to remove the electronics section.

1. Towfish electronics chassis is removed from the tail. There is no reason to remove the

nose section.

2. Remove tail fins (4mm Allen key) Fig 7-1

3. Remove the 4 bolts holding the plastic tail cone to the towfish (4mm Allen key) and

withdraw the tail cone from the end cap.

4. Attach handle (spares kit) to the end cap at the tail-cone bolt holes using two of the

removed bolts. Bolts do not have to be tight. See Figure 7-2

5. Carefully disconnect the four transducer connections on the end cap. Tag their ends as

to their placement.

6. Remove the screw securing a small metal block ( retention washer) located on the

topmost position near the rear end cap, see Figure 7-3

7. Remove the retention washer from the recess

8. Pull out the colored nylon retaining line with a pair of needle-nose pliers.

Note: If there is no exposed retaining line or the retaining line is cut and all the pieces

do not come out, pass a spare retaining line into the opposite end to expose and force

out any remaining pieces.

9. Pull on the handle and slide out the electronics to about 13 cm (5 inches) maximum.

Note: If there is a vacuum build up within the electronics housing that hinders removal,

remove the pressure relief port located between the 2 top connectors on the end cap to

relieve the pressure.

10. Disconnect the two inline connections for the power & telemetry cables near the end

cap.

11. Pull out the remaining electronics.

Table of contents

Other Edgetech Marine Equipment manuals

Edgetech

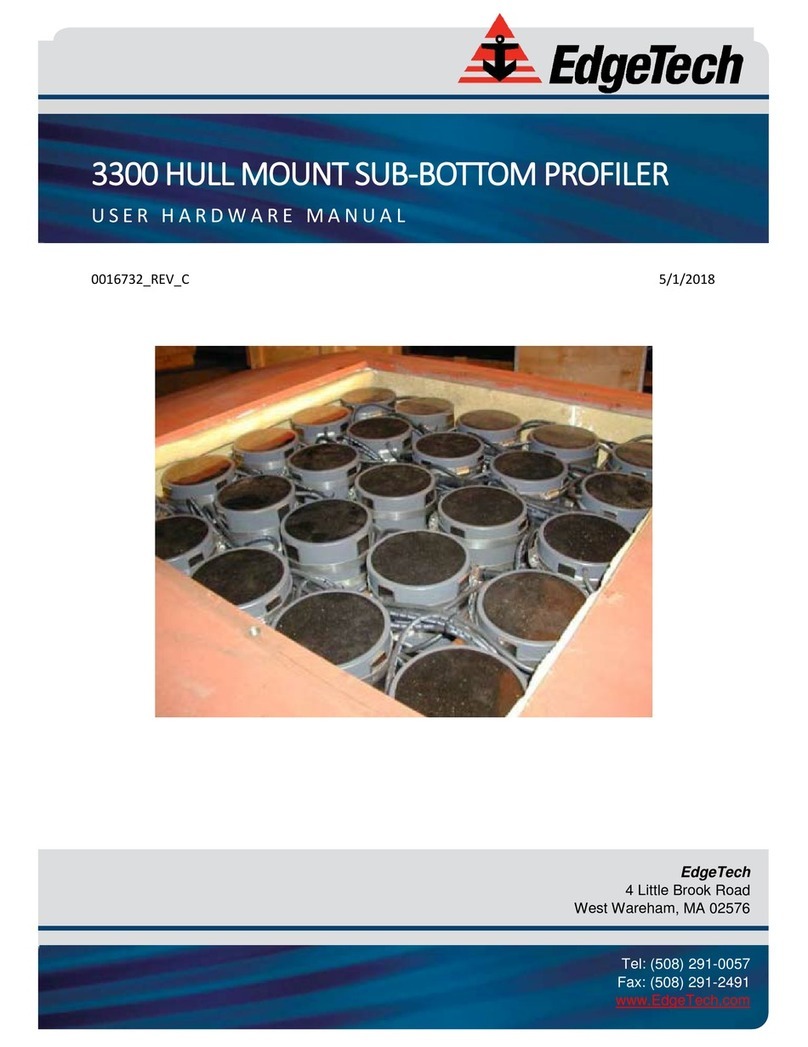

Edgetech 3300 User manual

Edgetech

Edgetech 3100 User manual

Edgetech

Edgetech 3400 User manual

Edgetech

Edgetech STARMUX IV User manual

Edgetech

Edgetech 2300 User manual

Edgetech

Edgetech 8242XS User manual

Edgetech

Edgetech 3200-XS User manual

Edgetech

Edgetech 3400 User manual

Edgetech

Edgetech 2050-DSS User manual

Edgetech

Edgetech 4380 MULTIBEACON User manual

Edgetech

Edgetech STARMUX IV User manual

Edgetech

Edgetech 3200-XS User manual

Edgetech

Edgetech 701 DIGITAL LINK User manual

Edgetech

Edgetech 8011M User manual

Edgetech

Edgetech 6205S2 User manual

Edgetech

Edgetech 4125I User manual

Edgetech

Edgetech Model 3100P Sub-bottom Sonar System User manual

Edgetech

Edgetech Port Pop-Up User manual