Introduction

Welcome ................................................................................................................... 6

System Overview....................................................................................................... 7

Important Safety Notes.............................................................................................. 8

Non-ionising Radiation.......................................................................................................8

Risk of Electric Shock ........................................................................................................8

Isolating the Sensor ...........................................................................................................8

Lifting the Sensor...............................................................................................................9

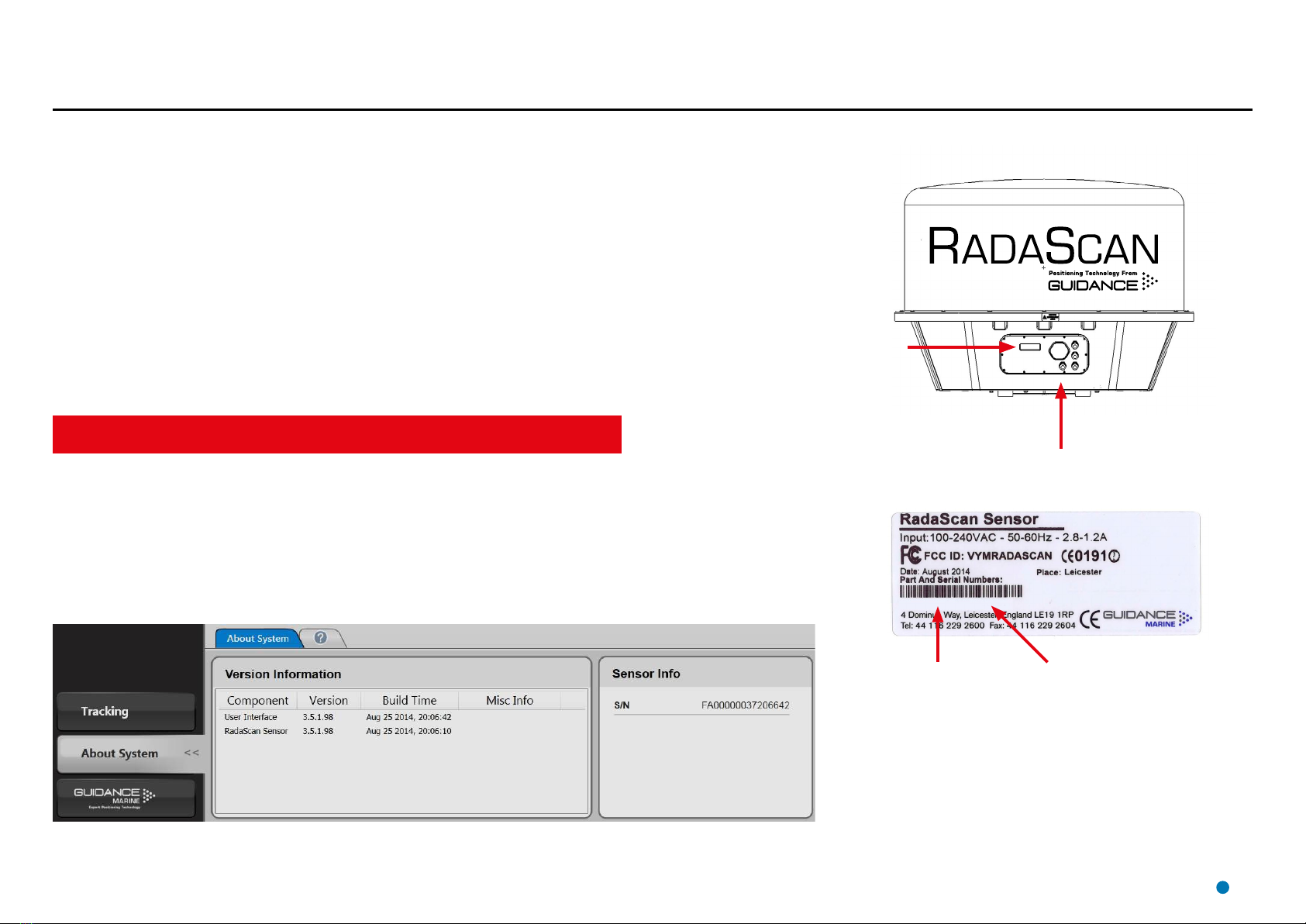

Serial Numbers and Software Versions .................................................................... 10

Product Labels ................................................................................................................10

Software Version Information ...........................................................................................10

To Display the About System Pane ..................................................................................10

Installing the Sensor Hardware and Software

Mounting the Sensor ............................................................................................... 12

Avoiding Other Sources of Radiation................................................................................13

Operating Area Astern (e.g. PSV) .....................................................................................14

Operating Area Forward (e.g. Shuttle Tanker) ...................................................................15

Operating Area to Port or Starboard (e.g. Track and Follow).............................................16

Sensor Dimensions.................................................................................................. 17

Mounting Template .................................................................................................. 18

Standard Sensor Connections - Direct..................................................................... 19

Low Temperature Sensor Connections - Direct........................................................ 20

Sensor Connections - Separate Ethernet Connection Box (3 Glands) ...................... 21

Sensor Connections—Separate Ethernet Connection Box (4 Glands)...................... 22

Cable Routing Diagram - Direct Connection ............................................................ 23

Cable Routing Diagram - Separate Connection Box ................................................ 24

Cable Routing Diagrams - Processor and Monitor Options ...................................... 25

Sensor Information Display ...................................................................................... 26

Installing the Sensor Software.................................................................................. 28

Installing the Type 2 Marine Processor

Type 2 Marine Processor Dimensions ...................................................................... 30

Plan view .........................................................................................................................30

Type 2 Marine Processor Connections..................................................................... 31

Installing the Dashboard Software onto a Type 2 Marine Processor ......................... 32

Installing the Dashboard Software onto a Hatteland Panel PC ................................. 33

Changing the Sensor IP Address Setting ................................................................. 34

Conguring the RadaScan Dashboard

Start Up and Shut Down ......................................................................................... 36

Start Up...........................................................................................................................36

Shut Down ......................................................................................................................36

Setting the Date and Time ....................................................................................... 37

Using the On-Screen Keyboard ............................................................................... 38

Entering Service Access Mode ................................................................................ 39

Conguration Settings ............................................................................................. 40

DP Message Format and Feed Behaviour................................................................ 41

Display Options ....................................................................................................... 43

Vessel Parameters ................................................................................................... 44

Bow and Starboard Offsets..............................................................................................45

Bearing Offset..................................................................................................................46

Blanking Zone ......................................................................................................... 47

Installing Responders

Responder Overview ............................................................................................... 49

Positioning Responders........................................................................................... 51

Mounting Responders ............................................................................................. 52

Charging Responders.............................................................................................. 54

Operating Responders ............................................................................................ 55

Appendices

International Standards Compliance ........................................................................ 57

RadaScan Transceiver .....................................................................................................57

RadaScan Responders ....................................................................................................57

Part Numbers.......................................................................................................... 58

DP Message Types.................................................................................................. 59

UPS and Cable Specications ................................................................................. 63

Network Connection Troubleshooting ...................................................................... 64

Installation Checklist ................................................................................................ 65

Index ....................................................................................................................... 67

Table of Contents

4