Edwards nES Series User manual

This manual suits for next models

9

Table of contents

Other Edwards Water Pump manuals

Edwards

Edwards E2M28 User manual

Edwards

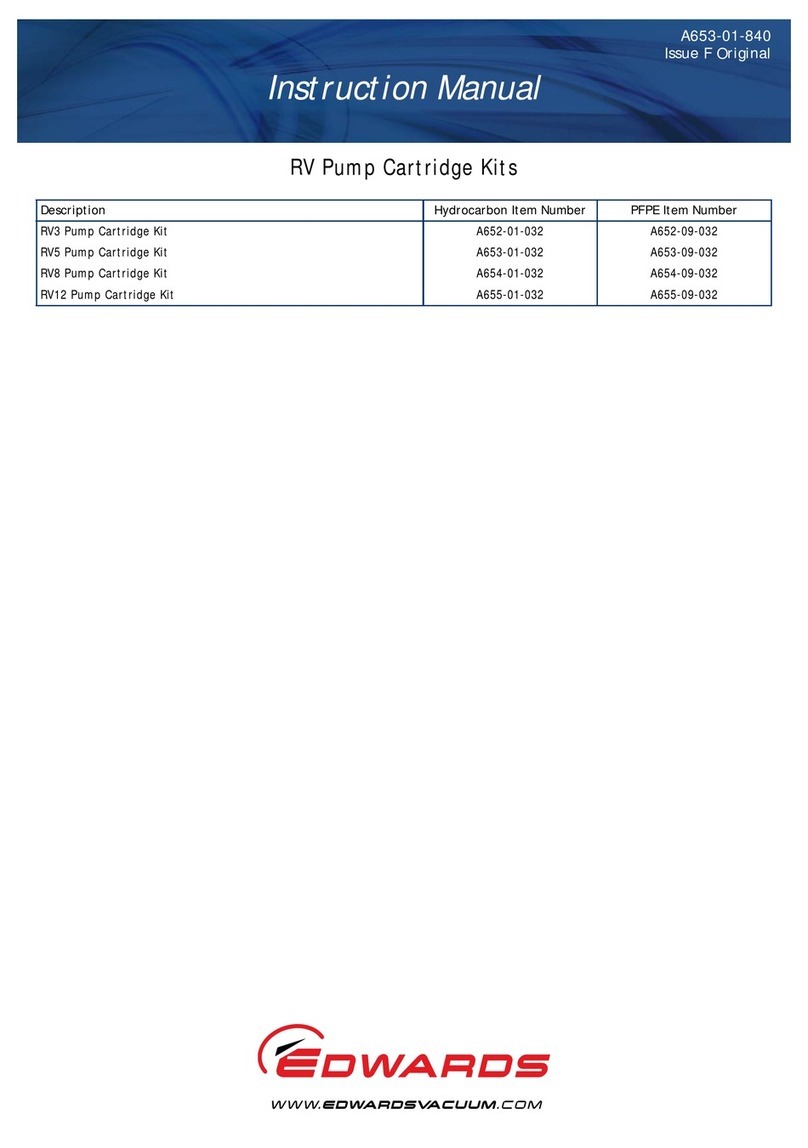

Edwards RV Series User manual

Edwards

Edwards EXT555H User manual

Edwards

Edwards STP-301 Series User manual

Edwards

Edwards EDS 200 User manual

Edwards

Edwards nXDS6i User manual

Edwards

Edwards Barocel 7025 User manual

Edwards

Edwards ATEX 1 EHR User manual

Edwards

Edwards RV3 User manual

Edwards

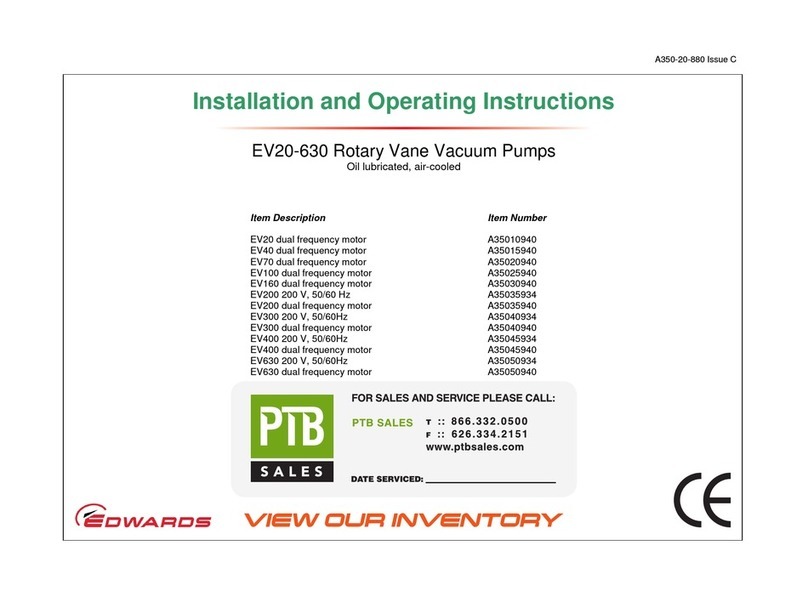

Edwards EV20 User manual

Edwards

Edwards STP-iXR1606 User manual

Edwards

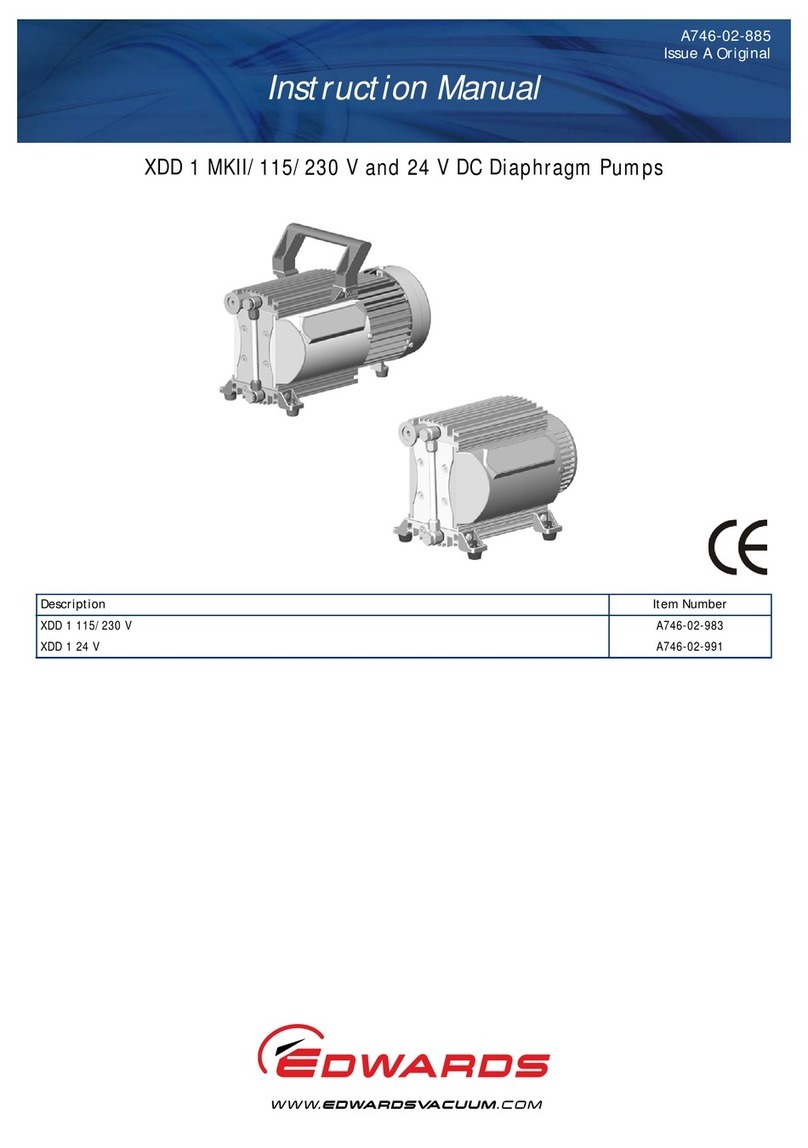

Edwards XDD 1 115/230 V User manual

Edwards

Edwards nEXT 240D User manual

Edwards

Edwards STP Series User manual

Edwards

Edwards CXS 160 User manual

Edwards

Edwards E-LAB 2 User manual

Edwards

Edwards nEXT85 User manual

Edwards

Edwards T-Station 300 User manual

Edwards

Edwards XDD1 115 V AC User manual

Edwards

Edwards HV8000 VF User manual

Popular Water Pump manuals by other brands

variolux

variolux V-GP 900 operating instructions

Graco

Graco Dura-Flo Instructions-parts list

LEYBOLD

LEYBOLD TURBOVAC TW 250 S operating instructions

Marina

Marina 75 instruction manual

Maxspect

Maxspect Jump Series owner's manual

Pentair

Pentair AURORA 1070 Series INSTRUCTION, INSTALLATION, MAINTENANCE AND REPAIR MANUAL

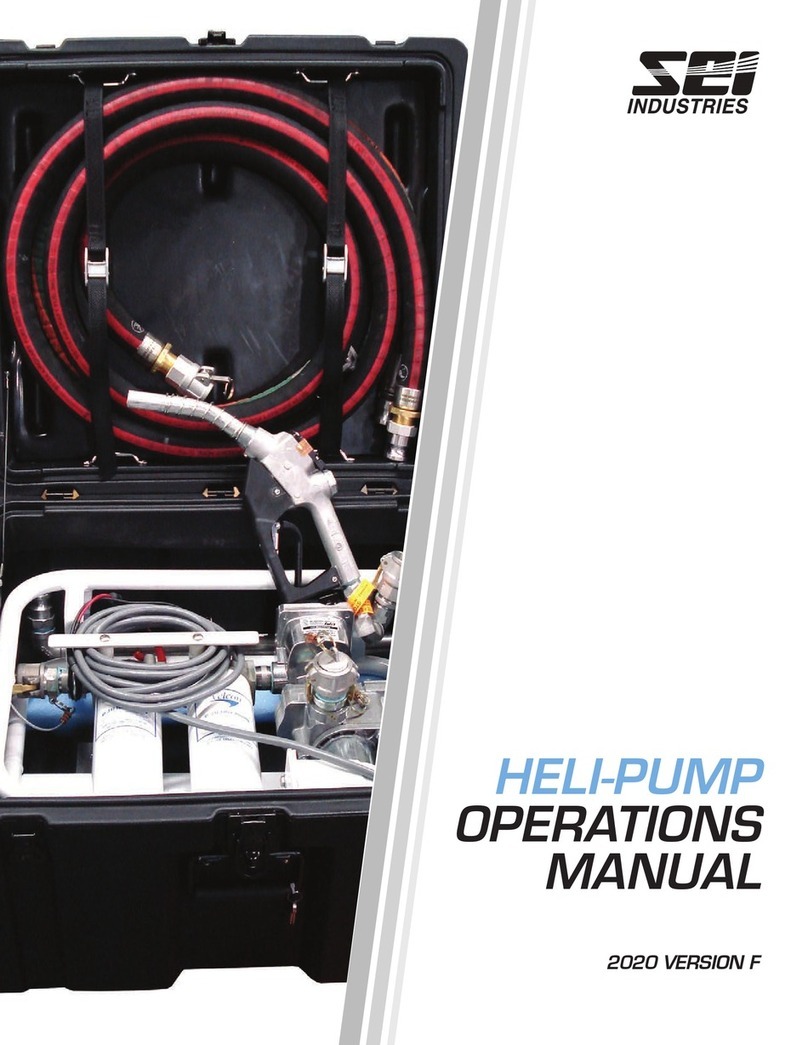

SEI Industries

SEI Industries HELI-PUMP Operation manual

STA-RITE

STA-RITE DB10018T-02 owner's manual

Sears

Sears Craftsman 390.2655 owner's manual

Daewoo

Daewoo DDP17000 user manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 80 Series Installation, operation, and maintenance manual with parts list

BRINKMANN PUMPS

BRINKMANN PUMPS SXC2824-R operating instructions

Levitronix

Levitronix BPS-i600 user manual

Industrial Gold

Industrial Gold G43 owner's manual

Einhell Royal

Einhell Royal HWA 810 operating instructions

Lavor

Lavor EDS-PM 12500 instruction manual

Franklin Electric

Franklin Electric Little Giant BE Series instruction manual

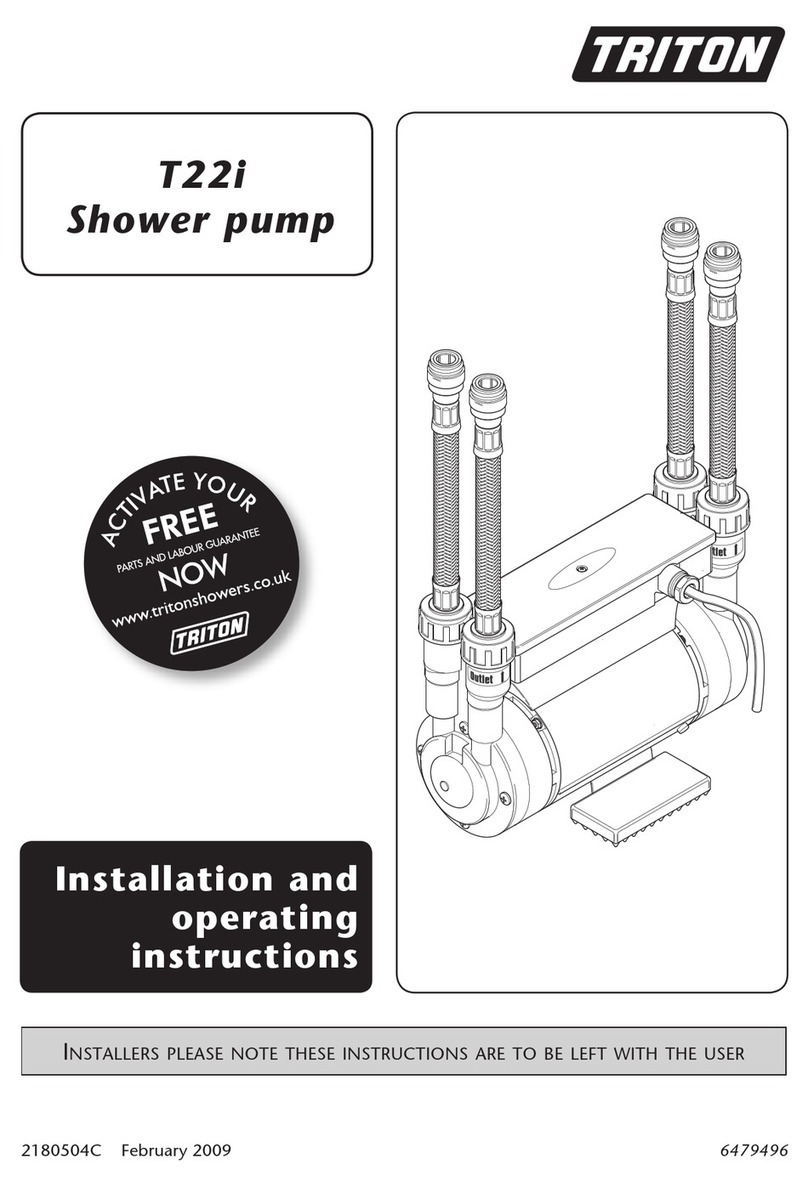

Triton

Triton T22i Installation and operating instructions