EFA EFA Z27 Guide

Schmid & Wezel

D 75433 Maulbronn

Ausführung/ Execution

05.2004

Wichtige Informationen:

Diese Anleitung unbedingt dem Bedienpersonal aushändigen!

Important Informations:

Please forward these operating instructions to your operating

personell!

Betriebsanleitung/ Operating instructions

Wartungsanleitung/ Maintenance instructions

Ersatzteilliste/ Sparepart list

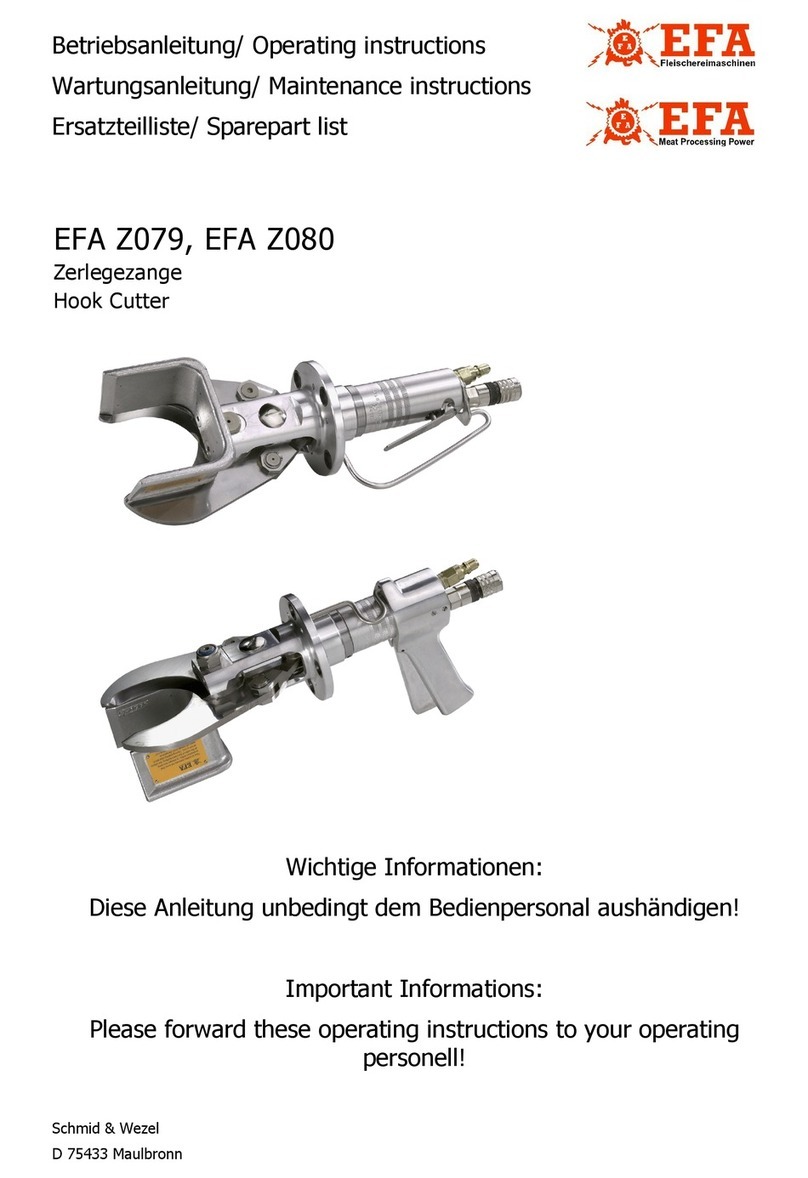

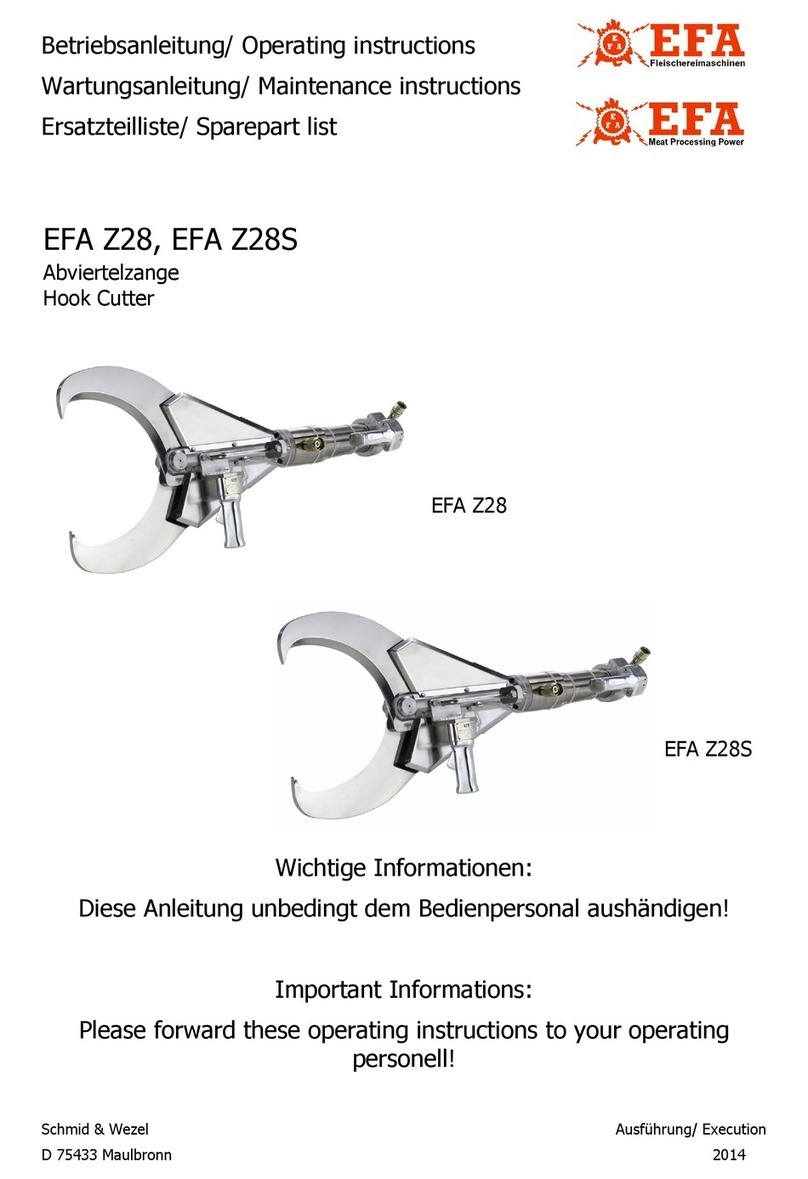

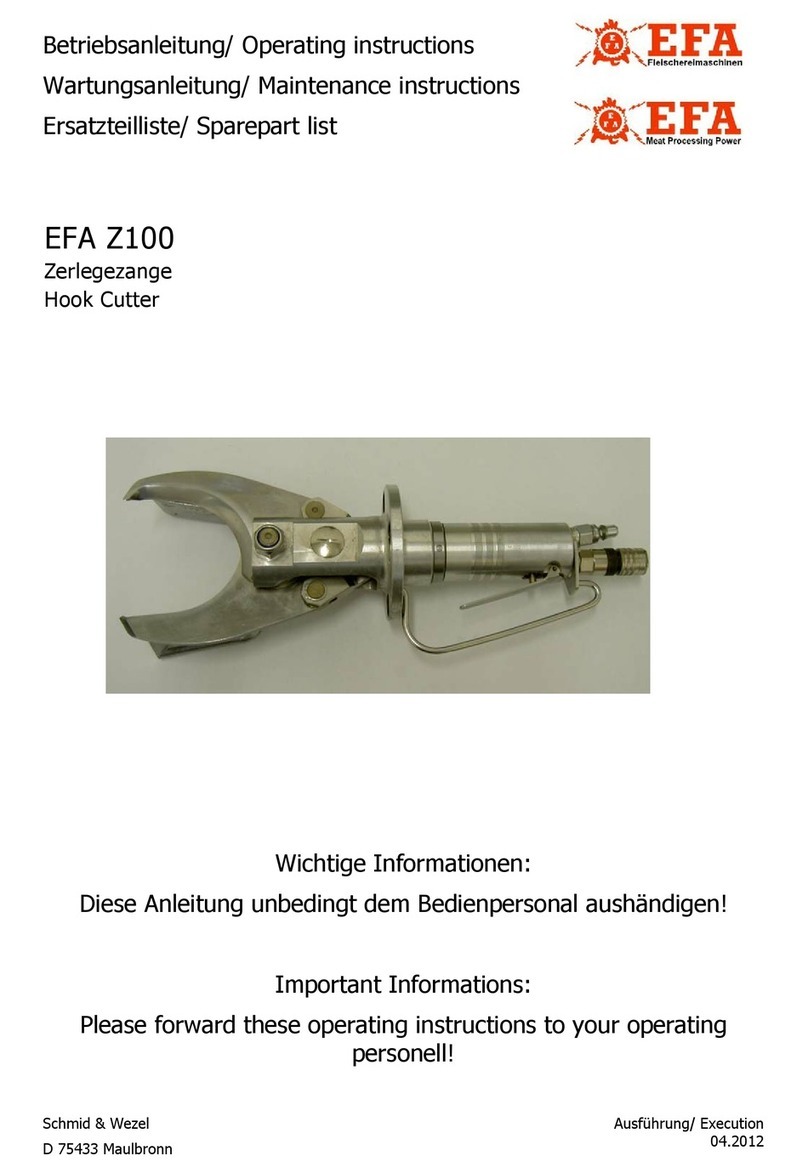

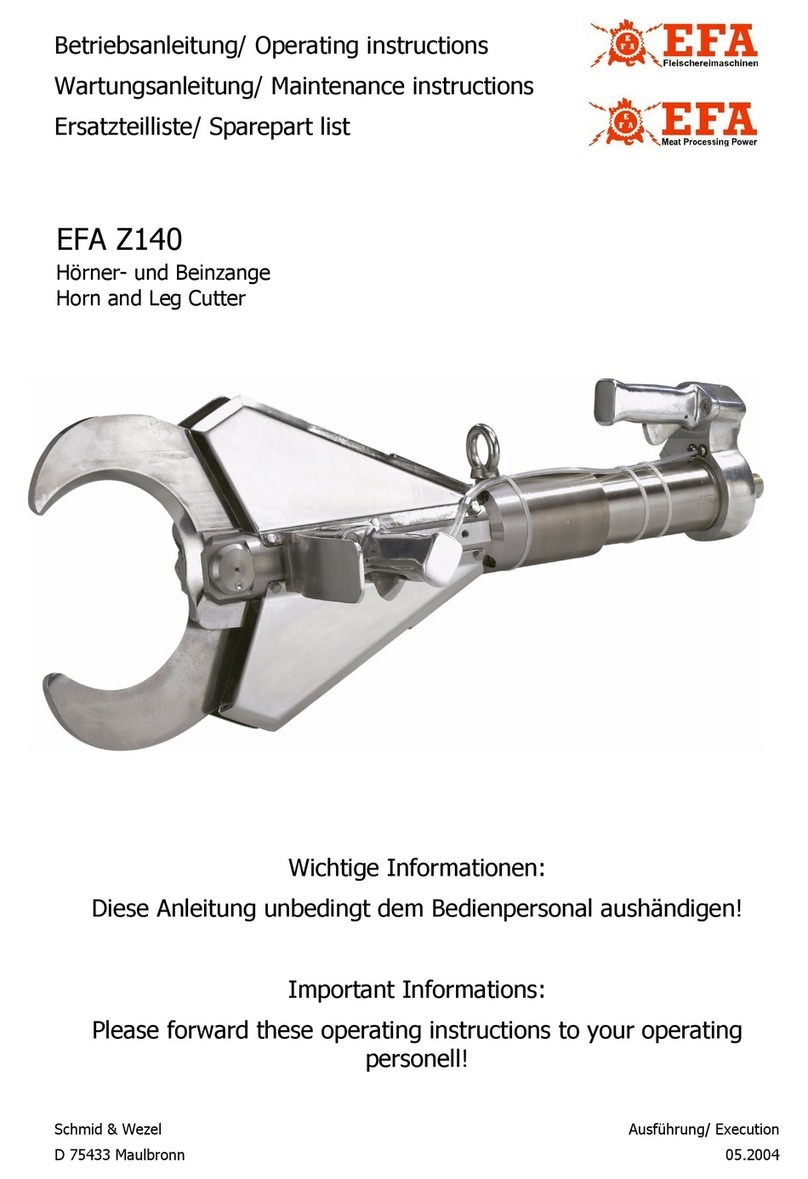

EFA Z27, EFA Z27S

Abviertelzange

Hook Cutter

EFA Z27

EFA Z27S

Schmid & Wezel

D 75433 Maulbronn

Ausführung/ Execution

05.2004

CONTENT

1. Operation, Scope of Supply, Accessories...............................................................................1

1.1 Symbols in this Manual................................................................................................................1

1.2 Intended Use..............................................................................................................................1

1.3 Scope of Delivery........................................................................................................................1

1.4 Accessories.................................................................................................................................1

2. Safety Precautions.................................................................................................................2

2.1 General Safety Precautions ..........................................................................................................2

2.2 Conduct at the Place of Work.......................................................................................................2

3. Commissioning and operational safety .................................................................................2

3.1 Initial Operation..........................................................................................................................2

3.2 Switch Operation.........................................................................................................................3

3.3 Working with the Hook Cutter......................................................................................................3

4. Assembly................................................................................................................................3

4.1 Changing Blades .........................................................................................................................4

4.2 Valve Replacement......................................................................................................................4

4.3 Changing Pistons ........................................................................................................................4

4.4 Hydraulic Power Unit...................................................................................................................4

4.5 Adjustment of the Spring Balancer ...............................................................................................4

5. Maintenance ..........................................................................................................................5

6. Cleaning and Maintenance ....................................................................................................6

6.1 Daily Cleaning After Completing Work...........................................................................................6

6.2 Daily Maintenance of Cutter.........................................................................................................6

6.3 Extended Maintenance (after approx. 100 operating hours)............................................................6

6.4 Repair by After-Sales Service .......................................................................................................7

7. Transport and Storage...........................................................................................................7

8. Returning Products................................................................................................................7

A. Annex.....................................................................................................................................8

A.1 Technical data ............................................................................................................................8

A.2 List of spare and wear parts ........................................................................................................8

A.3 Cutter sizes ..............................................................................................................................10

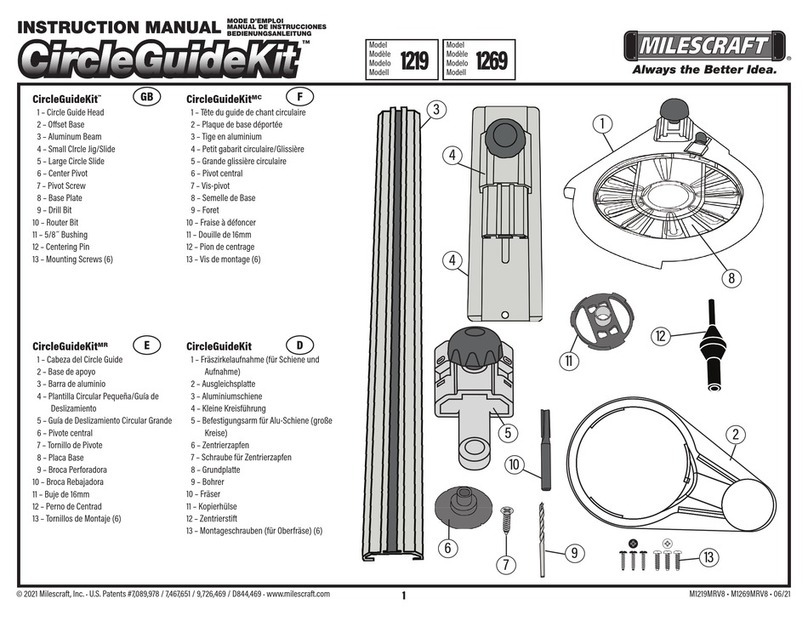

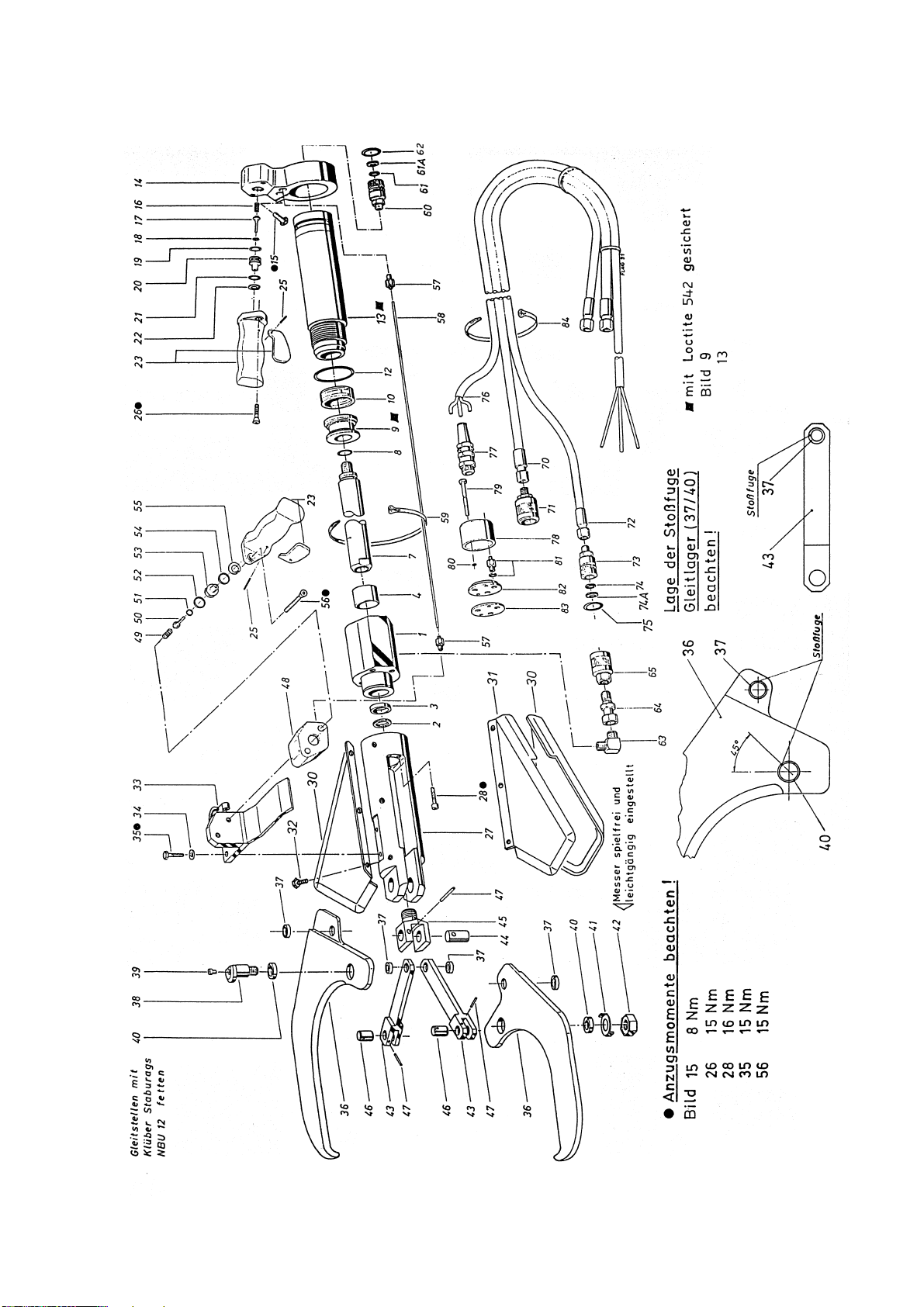

A.4 Exploded diagram, Z27/ Z27S....................................................................................................11

B. Declaration of Conformity ...................................................................................................12

Schmid & Wezel

D-75433 Maulbronn

Seite / Page

1/ 12

Ausführung / Execution

05.2004

1. Operation, Scope of Supply,

Accessories

Note, read carefully!

This manual is intended for the unit operator. Keep

it in a safe place!

The hook cutter may only be used:

In a technically safe condition, for its intended

use and in accordance with the applicable safety

and accident prevention regulations.

With all the safety devices attached.

In accordance with the safety precautions.

When the operating personnel has read and

understood this manual, in particular Chapter 2

"Safety Precautions" (pg. 2) and Chapter 3

"Commissioning and operational safety" (pg. 2)

Only in this way can incorrect operation be avoided

and hazard situations correctly assessed.

Never reach into the cutting area

of the cutter to avoid the risk of

cutting off limbs!

Wear eye protection or safety gog-

gles when completing work!

1.1 Symbols in this Manual

Hazard symbol:

The greatest care and attention must be

taken here. Lack of attention can result

in an immediate risk of injury for oper-

ating personnel or third parties. Further-

more, the machine may be damaged.

Information symbol:

Texts marked with this symbol contain

important information and useful tips.

1.2 Intended Use

The cutter is designed for cutting meat containing

bone in non-frozen or partially frozen state (from

approx. 5° C).

The cutter is suitable for dismembering and cutting

work in medium-sized and large plants, both in the

meat and poultry industries.

EFA Z27: For cutting cattle

EFA Z27S: For severing pigs' heads

The device is not equipped for any other form of

use. Should the operator wish to use the device in

some other way, please consult Schmid & Wezel

GmbH & Co. (S&W) beforehand.

Use in any other way may result in a risk of acci-

dents and increased wear. The user alone is liable

for the consequences of any other form of use.

1.2.1 Residual risks

Since the cutter is intended for industrial use on an-

imal carcasses, there is a risk of injuring yourself

and, in the case of extreme misuse, of fatally injur-

ing others. Since, due to the intended use, the size

of the opening between the cutter knives cannot be

reduced, there is a risk of the neck or upper arm or

even the shoulder joint coming between the cutting

knives and the cutter then being activated. Improp-

er use of the cutter could thus lead to instant death

or to death by bleeding. Therefore, be sure to al-

ways use the machine in the proper manner.

Manufacturer's declaration:

The machine itself cannot build up any pressure.

The pressure is only built up in when connected to

an upstream pressure generator and the corre-

sponding hoses. The machine may only be put into

operation when all the requirements of the Pressure

Equipment Directive applicable to this product have

been observed.

The machine is designed for a pressure of 200 bar.

A value of can be assumed for the

pressure volume in the hook cutter and in the pres-

sure generator and hoses. The Pressure Equipment

Directive97/23/ECwiththecorrespondingdiagrams

generally applies to these elements. In view of the

robust design in respect of strength, torsional rigid-

ity and stability under static and dynamic operating

loads, however, we would refer you to Article 1.3.10

of the Pressure Equipment Directive 97/23/EC:

As the pressure constitutes no significant factor for

the design, the EFA hook cutter is not subject to the

above directive.

1.3 Scope of Delivery

Hook cutter

Operating manual

1.4 Accessories

Spring balancer

Hose unit

Aggregate

pV 240>⋅

Schmid & Wezel

D-75433 Maulbronn

Seite / Page

2/ 12

Ausführung / Execution

05.2004

Hydraulic oil

The order numbers for both the parts contained in

the scope of supply and for accessories can be

found in Annex A.2 "List of spare and wear parts"

(pg. 8).

2. Safety Precautions

2.1 General Safety Precautions

Be sure to observe the following safety pre-

cautions when working with the hook cutter.

Always disconnect the equipment from the

power supply before changing the cutting

blades or starting any installation, maintenance

and repair work.

It is assumed that all work involving operation

of the hook cutter is always completed by ade-

quately skilled operating personnel.

Instruction is provided by our specialist person-

nel.

Installation, maintenance and repair work may

only be carried out by authorised and qualified

personnel.

Hook cutters from S&W conform to the relevant

safety regulations.

2.2 Conduct at the Place of Work

1. Keep your place of work tidy. Untidiness can

lead to accidents.

2. Give consideration to environmental influences.

Ensure good lighting (min. 500 lux).

3. Keep other people away from your place of

work. Work in a concentrated and sensible man-

ner. Do not use the hook cutter when you are

unconcentrated and/or tired.

4. Keep the hook cutter in a safe place. Store the

unit in a dry place when not in use.

5. Working clothes: Do not wear any baggy clothes

or jewellery because these could be caught by

moving parts. Wear solid shoes when working.

Wear a hair net as a general rule!

6. Avoid abnormal body postures. Ensure a safe

working position and keep your balance at all

times.

7. Service your tools with care. Use only sharp and

undamaged blades so that you can work better

and safer.

8.

Use only original EFA blades. Follow the instruc-

tions given under "Changing the blades". See

also Chapter 4.1.1 "Changing the blades" (pg. 4)

.

9. Do not leave wrenches on the machine. Check

that all wrenches have been removed before

starting the equipment.

10.Use only original EFA accessories. Use of other

accessories will void the warranty. Use of other

tools or accessories may result in injury to your-

self.

11.Modifications and changes to the machine are

not permitted and exonerate S&W of any war-

ranty and liability.

3. Commissioning and opera-

tional safety

Place of work

The operator requires a working space of at least

1.5 sq. m. No other place of work should extend into

this area, as the movements with the cutter could

result in the risk of injury.

The illumination at the place of work must be at

least 500 lux.

3.1 Initial Operation

The hook cutter must be in an

"off" state when connected to the

works power network!

Important information, e.g. technical

data sheets, drawings and parts lists can

be found in Annex A.2 (pg. 8).

3.1.1 Spring balancer

The machine must always be operated in combina-

tion with a weight relief system (spring balancer).

Install this above the working area on an element

assembled higher or on the ceiling. Information on

fine adjustment of the spring balancer can be found

in Chapter 4.5 "Adjustment of the Spring Balancer"

(pg. 4).

Suspend the cutter so that it is as top-heavy as pos-

sible. The vertical position can be adjusted, if nec-

essary.

Due to the weight of approx. 24 kg, there is a risk

of injury through the unit slipping or falling down

when fixing or loosening the weight relief system.

Pay attention also that the machine does not jam

on the trigger snap or on the hook of the cutter.

Work cautiously!

When the cutter is not in use, store it so that there

is no risk of accidental contact with the blades as

Schmid & Wezel

D-75433 Maulbronn

Seite / Page

3/ 12

Ausführung / Execution

05.2004

they are sharp.

3.1.2 Hydraulic power unit

The cutting mechanism of the cutter functions hy-

draulically. Connect the cutter to an operational hy-

draulic power generator (see also the separate

operating manual for the hydraulic power unit), and

fill finely filtered hydraulic oil in the relevant

opening provided and

connect the generator unit via the terminal box

(Y-connection 3: 400 V ~, 50 Hz).

The hydraulic hoses to be used have threaded fit-

tings of different sizes and therefore cannot be con-

nected incorrectly.

3.1.3 Connecting and disconnecting the cut-

ter

The cutter is equipped with a plug connection return

flow and a coupling body feed flow. Proceed as fol-

lows:

Switch off the compressed air and actuate the

two-hand safety circuit (refer to Chapter 3.2.1

"Switching on" (pg. 3)) on the hook cutter once.

Disconnect the depressurised hydraulic hose

assembly (1 - 13), with feed flow closed, from

the hose unit.

To disconnect, release the safety locking ring on

the coupling body. To do this, turn the locking

ring until the lock is released.

The hydraulic couplers are self-locking so that no oil

escapes when they are disconnected.

Protect the coupling and plug parts

against soiling!

3.2 Switch Operation

The cutter may only be switched

on after reading this operating

manual and correct connection to

the power supply!

The hook cutter is equipped with a two-hand, safety

circuit.

3.2.1 Switching on

Hold the cutter firmly!

Actuate the front operating handle simultane-

ously with the rear operating handle to close the

cutter.

3.2.2 Switching off

Release the operating handles to open the cut-

ter

The cutting process can be interrupted or repeated

at any time.

3.3 Working with the Hook Cutter

Never reach into the cutting area

of the cutter to avoid the risk of

cutting off limbs!

Wear eye protection or safety gog-

gles when completing working!

3.3.1 Working process

The hydraulic power pack must be ready for

operation.

Hold the cutter firmly, position it correctly and

actuate the two-hand safety circuit (see Chapter

3.2 "Switch Operation" (pg. 3))

The cutting process can be carried out either with

the carcass/meat hanging or lying on the table. The

cutter operator selects the cutting area and per-

forms a quick cut by actuating the two-hand safety

circuit.

Always apply the cutter at right angles

and in the cutting area (not with the

blade tips). Otherwise the blades may

break due to overload.

Venting of the cutter is not necessary, as the air es-

capes from the venting filter of the hydraulic power

unit via the hydraulic hoses after a few actuations of

the cutter.

3.3.2 Operating safety

Hold the machine firmly with both handles.

Work very cautiously when cutting, the blades

close within 1.3 s.

Always apply the machine at right angles and in

the cutting area so that the blades do not break

in the event of overloading.

Suspend the cutter from a spring balances for

safe handling (guidance).

4. Assembly

Disconnect the machine from the

works mains power before start-

ing any assembly work!

The drawings necessary for assembly can be found

Schmid & Wezel

D-75433 Maulbronn

Seite / Page

4/ 12

Ausführung / Execution

05.2004

in Annex A.4 "Exploded diagram, Z27/ Z27S" (pg.

11)

4.1 Changing Blades

4.1.1 Changing the blades

Close the blades (36)

Switch off the hydraulic power pack and depres-

surise the system by actuating the two-hand

safety circuit once (see Annex 3.2.1 "Switching

on" (pg. 3))

Disconnect the cutter (see Chapter 3.1.3 "Con-

necting and disconnecting the cutter" (pg. 3))

Disassemble the taper sleeve (47) and force out

both bolts (44, 46) paying attention to a clean

contact of the fork (45).

Remove the hex. nut (42) with locking washer

(41) and threaded bolt (38).

Before assembling the cutter, clean the removed

parts, inspect them for wear and replace, if neces-

sary.

Grease all sliding points with EFA special grease.

4.1.2 Checking the blade clearance

In order to avoid breakage, the blades must always

be adjusted without clearance but with free move-

ment. The adjustment is made using the locking

washer (41) and hex. nut (42).

4.1.3 Blade installation

Before reassembling the cutter, clean the removed

parts, inspect them for wear and replace, if neces-

sary. Grease all sliding points with EFA special

grease.

Before securing in the forks (45), adjust the blades

(36) via the locking washer (41) and the self-locking

hex. nuts (42) so that they are clearance-free but

can move freely.

4.2 Valve Replacement

Replacing the valve parts

Remove screw (26) to release the handle (23).

Remove the snap ring (22) and pull out the

valve (17 - 21), clean the removed parts,

inspect them for wear and install again in the

reverse order.

Always replace the valve (17 - 21) together with the

snap ring (22).

4.3 Changing Pistons

Replacing the piston parts

The assembly kit must be available for this repair.

See also Annex A.2 "List of spare and wear parts"

(pg. 8).

Remove the blades (36) (see Chapter 4.1.1

"Changing the blades" (pg. 4)).

Disassemble the cutter body (27).

Loosen the cylinder barrel (13) from the guide

(1) using the hook wrench (right-hand thread).

Unbolt the housing (1) and push piston rod (7)

with piston (10) in the direction of the guide (1).

Caution:

The cylinders (1, 13) must be secured with Loctite

542!

Install piston (10) only with mounting cone and

expander sleeve - removal is possible only after

heating to 150° C.

Screw the cylinder barrel into guide (1) and

secure with Loctite 542.

Clean all the parts, check Pos. 2, 3, 10 and 11

for signs of wear and reassemble in reverse

order.

Grease all sliding points and blades (36) with EFA

special grease .

4.4 Hydraulic Power Unit

At least once a year, drain the oil filling, inspect for

soiling and replace if necessary. (See also Annex

3.1.2 "Hydraulic power unit" (pg. 3) and separate

operating manual for the hydraulic power unit).

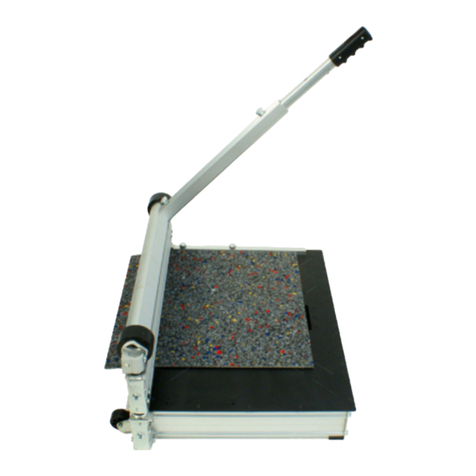

4.5 Adjustment of the Spring Bal-

ancer

The fine adjustment of the spring balancer is effect-

ed via the PLUS/MINUS screw on its housing (see

Fig. 1).

Figure 1:Spring balancer

Turn the screw in MINUS direction until the cut-

ter is hanging freely in equilibrium (with the

spring balancer) at working height.

Schmid & Wezel

D-75433 Maulbronn

Seite / Page

5/ 12

Ausführung / Execution

05.2004

If the cutter cannot be pulled out, the spring balanc-

er is jammed and a readjustment is necessary:

Turn the screw in PLUS direction until the cutter

can be pulled out and start the fine adjustment

again (see above).

5. Maintenance

Malfunctions may occur during operation, but these

are generally relatively simple to remedy. Table 1:

"Troubleshooting" lists these malfunctions with pos-

sible causes and resulting potential remedies.

Table 1: Troubleshooting

Malfunction Possible cause Remedy

When the trigger lever is pressed,

the pump does not run and the

cutter does not close

1. Unit is not switched on. Switch on power pack

2. Power supply is incorrect. Check the electric power supply

and remedy the fault

On actuating the trigger lever, the

pump starts up but the cutter

does not close.

3. Insufficient air pressure for

switching

Set the air pressure on the power

generator to at least 5 bar with 5

m hose length

4. Control line is defective Inspect the control line and

replace, if necessary

5. Two-hand safety block is

defective Inspect the safety block and

replace, if necessary

6. Coupling connector of the

hydraulic return flow hose is not

connected properly Connect the hose correctly

7. Gaskets defective Inspect the gaskets and replace,

if necessary

8. Oil level too low Refill oil (see Chapter 3.1.2

"Hydraulic power unit" (pg. 3)

When actuating the trigger lever,

the pump starts but the cutter

closes slowly

9. Oil filter on the pump clogged Change the oil filter and oil

10. Hose coupling is loose Check the proper connection of

the hoses

Hydraulic pump too hot 11. Gear pump is defective Replace gear pump

Pumps runs, but no hydraulic

pressure in the cutter 12. Defective seals in the hydrau-

lic pump cylinder Replace the seals, replace the

pump cylinder

Handle cannot be pressed 13. Defective valve Replace valve (see Chapter 4.2

"Valve Replacement" (pg. 4))

14. Valve blocked due to soiling Clean valve (see Chapter 4.2

"Valve Replacement" (pg. 4))

Cutter does not open when han-

dle is released

15. Refer to Point 10 Refer to Point 10

16. Valve pins block, do not

return to initial position or valve

spring is broken

Clean or replace the valve or (see

Chapter 4.2 "Valve Replacement"

(pg. 4))

17. Setting of timer valve in unit

not correct Adjust the setting (see separate

operating manual or unit)

Pump does not run 18. See separate operating man-

ual for pump See separate operating manual

for pump

Schmid & Wezel

D-75433 Maulbronn

Seite / Page

6/ 12

Ausführung / Execution

05.2004

6. Cleaning and Maintenance

Disconnect the machine from the

works mains before all cleaning

and maintenance work!

6.1 Daily Cleaning After Completing

Work

Trouble-free, continuous operation can be ensured

only if the hook cutter is permanently kept in a

clean, hygienic condition. The machine should nor-

mally be disinfected before each cleaning.

Observe the applicable safety and hygiene regula-

tions (EN 1672)!

Disinfectants must not be allowed to come into di-

rect or indirect contact with foodstuffs. Rinse the

machine with clear water after disinfection.

Donot useaggressivesolvents!Do

not use steam or high-pressure

cleaners! Do not immerse the unit

in water!

6.1.1 Disinfection

Disinfect the machine during operation after every

cut with hot water (82° C).

6.1.2 Cleaning the cutter

Clean the machine after use with a cloth, brush and

warm water (40 - 55° C). Stubborn or encrusted dirt

and residue must be soaked beforehand. Clean us-

ing a cleaning agent, preferably as a foam, that is

applied to the surface to be cleaned and allowed to

work in for 15 - 20 minutes. Subsequently wash off

the dissolved soiling manually with warm water.

Recommended cleaning agents

Diversey Lever Tego 2000: Surface-active disin-

fectant.

Diversey Lever GmbH

Mallaufstr. 50-56, 68219 Mannheim

P3-topax 91: Surface-active disinfectant

Henkel-Ecolab Deutschland GmbH

Postfach 13 04 06, 40554 Düsseldorf

A cleaning plan and further details can be obtained

from the above addresses.

The above cleaning agents are only a recommenda-

tion; if other cleaning agents are used, the customer

should examine the material compatibility and com-

pliance with the hygiene regulations.

6.1.3 Lubricants and hydraulic oil

The lubricant and the hydraulic oil have to meet the

regulations for the foodstuffs sector (DIN 1672).

Recommended lubricating grease

Klübersynth UH1 14-22 (1 kg special grease in can)

Quality: H1 approval

Order No.001 365 621

Recommended hydraulic oil

Shell Risella D15 (ISO VG 10 - ISO VG 68 to DIN

51519)

Quality: H1 approval

Order No.001 365 614

6.2 Daily Maintenance of Cutter

6.2.1 Lubrication

After every cleaning, grease the pivot and sliding

points and the blades lightly with EFA Special

Grease.

6.2.2 Blade clearance

Check the blade clearance at regular intervals. In or-

der to avoid breakage, the blades must always be

adjustedwithoutclearance but withfreemovement.

If the self-locking effect of the hex. nut is no longer

assured, it must be replaced without delay. See also

Chapter 4.1 "Changing Blades" (pg. 4).

6.3 Extended Maintenance (after

approx. 100 operating hours)

6.3.1 Hydraulic power unit

Check the oil level at regular intervals and top up, if

necessary. See also Chapter 3.1.2 "Hydraulic power

unit" (pg. 3) and the separate operating manual for

the hydraulic power pack.

CAUTION! Food grade: H1 approval. Pay attention

to cleanliness! Use a filler funnel with a fine-mesh

screen (mesh width approx. 0.4 mm).

At least once a year, drain the oil filling, inspect for

soiling and replace if necessary.

The hydraulic oil is classified as a hazardous sub-

stance and must be used and disposed of according-

ly. On no account may hydraulic oil drain into the

sewage system or escape into the atmosphere.

Schmid & Wezel

D-75433 Maulbronn

Seite / Page

7/ 12

Ausführung / Execution

05.2004

6.3.2 Sharpening the blades

Incorrectly sharpened blades impair productivity

and also represent considerable risks for the user.

We have set up a sharpening service for

you in our Service department. In this

case, please contact your nearest con-

tract workshop or our parent company

directly.

If the machine is used correctly, resharpening of the

blades is not generally necessary.

If required, the blades can also be resharpened with

minimum material removal using commercially

available grinders.

Do not use force as parts could be

damaged! Only use original EFA

spare parts!

6.4 Repair by After-Sales Service

Disconnect the machine from the

works mains before starting any

repair work!

Repairs may only be carried out by specialist

personnel.

Our Service department is at your disposal for

all repair work. In the event of a repair, please

contact your nearest contract workshop or our

parent company directly.

On request, spare parts lists can be supplied to

the repair workshop with qualified specialist

staff.

After every repair, the gear units must be

repacked with grease!

7. Transport and Storage

The unit must be stored in a dry, well-ventilated

room.

The machine must be cleaned as described in Chap-

ter 6.1.2 "Cleaning the cutter" (pg. 6) and transport-

ed in dry condition.

Ensure that the unit is not damaged during trans-

port.

8. Returning Products

At the end of their useful service life, return old units

to the parent company for disposal.

Schmid & Wezel

D-75433 Maulbronn

Seite / Page

8/ 12

Ausführung / Execution

05.2004

A. Annex

A.1 Technical data

A.2 List of spare and wear parts

EFA Z27 EFA Z27S

Operating pressure 200 bar 200 bar

Closing force 26.5 kN 26.5 kN

Closing time of the jaws 1.5 s 1.5 s

Cutter opening 260 mm 186 mm

Sound pressure level (EN ISO 11688-1) < 85 dB(A) < 85 dB(A)

Hand-arm vibration (EN 28662) < 2.5 m/s2< 2.5 m/s2

Weight 24 kg 22,5 kg

Load capacity of the spring balancer 200 - 300 N 200 - 300 N

Hose length 5 m 5 m

Z27 Z27S

Fig. No. Qty. Designation Order No.

Hook cutter, ass'y. 008 008 535 008 010 524

Hydraulic cylinder assy. (1 - 13) 001 964 050

1 1 Guide, complete (with 2 - 4, 12) 001 964 046

2 1 Stripper 001 964 041

3 1 Grooved ring 001 964 039

4 1 Bushing 001 964 038

7 1 Piston rod 001 964 034

8 1 O-ring 17x2 001 312 649

9 1 Piston 001 964 032

10 1 Piston seal 001 964 040

12 1 O-ring 46x2 001 312 669

13 1

1Cylindrical tube with end section

Bracket assy. (14 - 22) 001 964 045

008 005 279

14 1 Bracket 007 005 281

15 2 Hex. head bolt 001 325 904

16 1 Pressure spring 003 003 932

17 1 Valve pin 003 005 063

18 1 O-ring 001 312 620

19 1 O-ring 001 312 627

20 1 Valve insert 003 005 055

21 1 O-ring 001 312 636

22 1 Snap ring 001 312 313

23 2 Handle assy. (with 25) 008 005 278

25 2 Taper sleeve 001 307 008

26 2 Countersunk screw 001 326 508

Schmid & Wezel

D-75433 Maulbronn

Seite / Page

9/ 12

Ausführung / Execution

05.2004

27 1 Cutter body 003 008 536

28 4 Hexagon socket head screw 002 000 275

30 2 Cover (right) 003 008 741

31 2 Cover (left) 003 008 742

32 12 Hex. head bolt 001 325 921

33 1 Bracket 003 008 526

34 2 Spring washer 001 317 003

35 2 Hex. head bolt 001 325 908

36 2 Blade complete (each with 1 piece 37 +

40) 007 008 542 007 009 046

37 4 Slide bearing 001 346 002

38 1 Stud bolt (with 39) 007 008 540

39 1 Grease nipple 001 305 802

40 2 Slide bearing 001 346 003

41 1 Washer with external tab 001 311 515

42 1 Hex. nut 001 304 630

43 2 Fork complete (each with 1 piece 37) 007 008 543

44 1 Bolt 003 008 541

45 1 Yoke 003 008 539

46 2 Bolt 003 005 083

47 3 Taper sleeve 001 307 009

Flange assy. (48 - 55) 008 005 277

48 1 Flange 003 005 056

49 1 Pressure spring 003 003 932

50 1 Valve pin 003 005 063

51 1 O-ring 001 312 620

52 1 O-ring 001 312 627

53 1 Valve insert 003 005 055

54 1 O-ring 001 312 636

55 1 Snap ring 001 312 313

56 2 Flat-head socket head cap screw 001 326 515

57 4 Male fitting 001 610 601

58 2 Flexible Rilsan hose 001 610 658

59 3 Cable tie 001 371 916

60 1 Coupling socket (with 61-62) 001 606 590

61 1 O-ring (inner) 001 312 649

61A 1 Back-up ring (inner) 001 317 801

62 1 O-ring (outer) 001 312 670

63 1 Elbow male fitting 001 606 597

64 1 Straight male fitting with shaft 001 606 598

65 1 Plug connector 001 606 591

Wear set for cutter (2 - 4, 8, 10, 12, 16,

18, 37, 40, 49, 007 899 488

Hose unit assy. (70 - 84) 008 005 181

Flow Hydraulic hose ass'y. (70 - 71) 001 606 577

70 1 Hydraulic hose 001 606 582

71 1 Plug connector 001 606 578

Return flow Hydraulic hose ass'y. (72 - 75) 001 606 579

72 1 Hydraulic hose 001 606 583

73 1 Coupling socket (74-75) 001 606 580

Schmid & Wezel

D-75433 Maulbronn

Seite / Page

10/ 12

Ausführung / Execution

05.2004

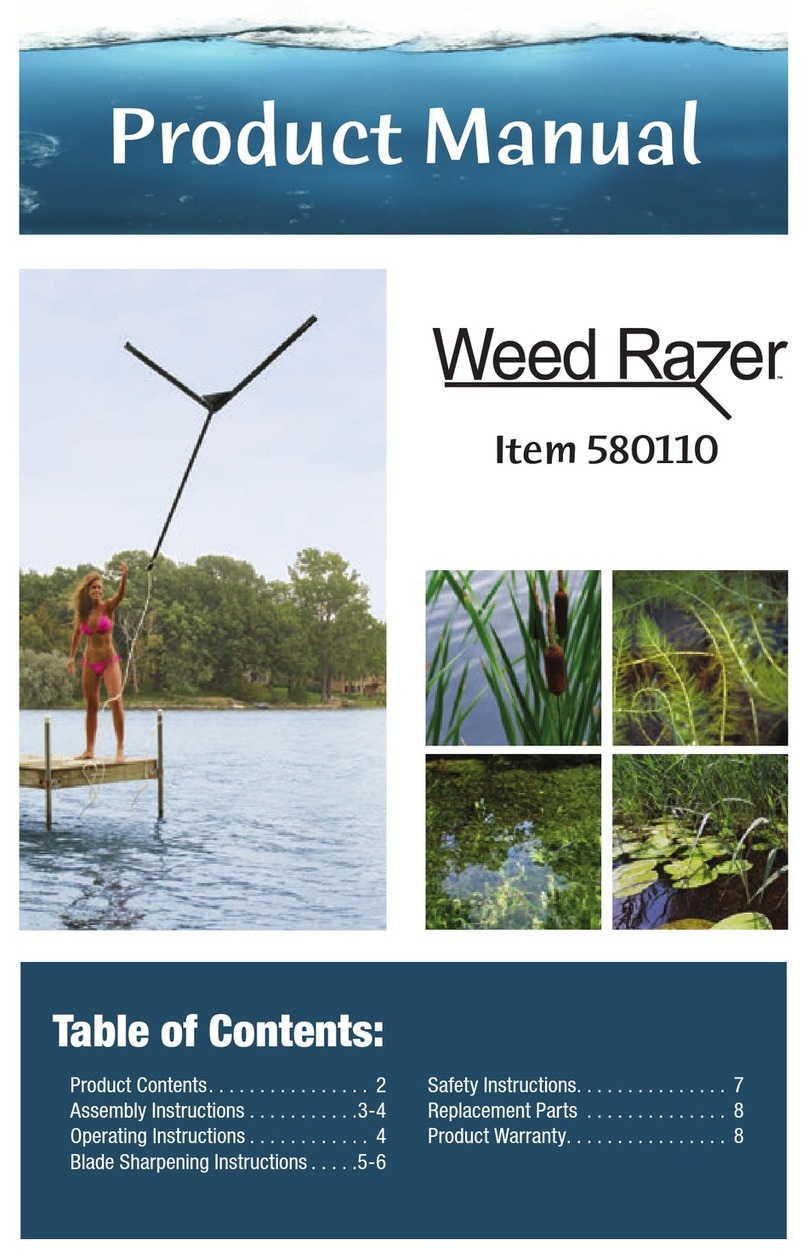

A.3 Cutter sizes

74 1 O-ring (inner) 001 312 649

74A 1 Back-up ring (inner) 001 317 801

75 1 O-ring (outer) 001 312 670

76 1 Multi-strand cable 001 610 605

77 1 Cable gland 001 325 525

78 1 Housing 003 005 068

79 2 Hex. head bolt 002 000 234

80 2 O-ring 001 312 656

81 3 Male fitting 001 610 601

82 1 Bracket 003 005 067

83 1 Gasket 003 005 396

84 5 Cable tie 001 371 913

Special Accessories

2 Hydraulic oil 20 l 001 365 614

1 Spring balancer 001 620 025

1 Grease gun 001 365 403

1 Special grease 001 365 621

1Assembly kit 007 899 668 007 899 668

1 Hook wrench 001 370 205 001 370 205

1 Face pin wrench 001 369 705 001 369 705

1 Rotating pin 001 366 005 001 366 005

1 Assembly cone 003 006 661 003 006 661

1 Expanding sleeve 003 006 662 003 006 662

Type A B C D E F

Z27 410 260 340 345 520 980

Z27S 342 186 160 165 335 795

Schmid & Wezel

D-75433 Maulbronn

Seite / Page

11/ 12

Ausführung / Execution

05.2004

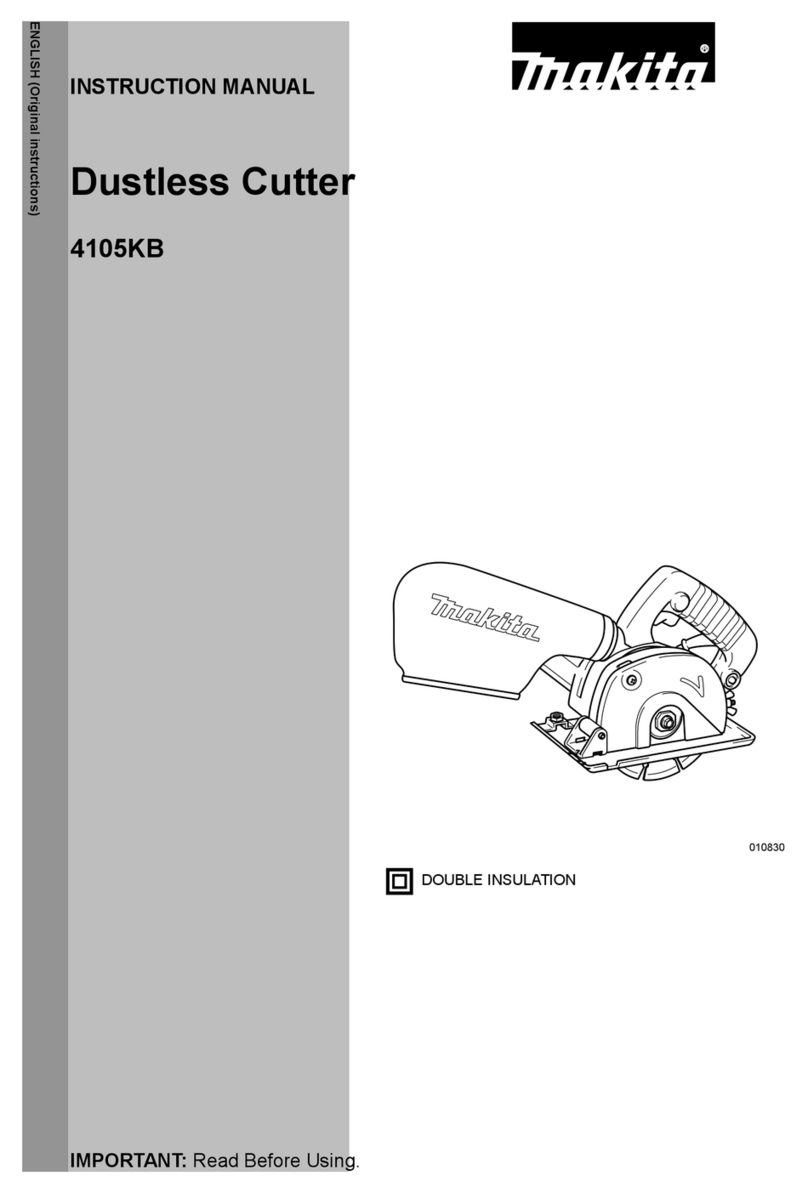

A.4 Exploded diagram, Z27/ Z27S

Schmid & Wezel

D 75433 Maulbronn

Seite/ Page

12/ 12

12

Ausführung/ Execution

05.2004

B. Declaration of Conformity

EG-K O N F O R MI T Ä T S E R K L Ä R U N G

EC D E C L A R A T I O N O F C O N F O R MI T Y

Hiermit erklären wir, dass die nachfolgend bezeichneten vollständigen Maschinen aufgrund ihrer Konzipierung und Bauart der

EG-Maschinenrichtlinie 2006/42/EG und den grundlegenden Sicherheits- und Gesundheitsanforderungen entsprechen.

Bei einer nicht mit uns abgestimmten Änderung der Maschine verliert diese Erklärung ihre Gültigkeit.

We hereby declare that the following designated complete machines comply with the ECmachine directive 2006/42/ECand

meet the essential demands on health and safety on account of their conception and design.

The validity of this declaration expires when a modification to the machine is made without being coordinated with us.

CE

Bezeichnung der Maschine: Zangen

Typ EFAZ ..: 05,06,07,08,10,12,,13

14,27,27S, 28,28S, 078, 079, 080,085, 090, 140,ZR27

Antrieb Hydraulikantrieb

Angewandte Vorschriften/Richtlinien: 2006/42/EG

Angewandte A- Normen: DINEN1050

Angewandte B- Normen: DINEN294, DINEN954-1, DINEN954-2(Entwurf)

Angewandte C- Normen: EN12 984

Angewandte nationaleNormen: ---------

Machineidentification: Cutter

Type EFAZ ..: 05,06,07,08,10,12,,13

14,27,27S, 28,28S, 078, 079, 080,085, 090, 140,ZR27

Actuation Hydraulicdrive

Applied regulations/directives: 2006/42/CE

Applied A- standards: DINEN1050

Applied B- standards: DINEN294, DINEN954-1, DINEN954-2(draft)

Applied C- standards: EN12 984

Appliednational standards: ---------

Hersteller Name - Anschrift: Schmid &Wezel GmbH&Co

Manufacturer Name - Address: Maybachstrasse 2 , 75433 Maulbronn

Unterschrift: Signature: ________________________ __________________

Firma: Firma: UlrichMerkle Dr. Norbert Lay

Angaben zumUnterzeichner: Geschäftsführer Leiter Technik und Entwickelung

Details of the undersi

g

ned: Mana

g

in

g

directo

r

Head of en

g

ineerin

g

and develo

p

men

t

This manual suits for next models

1

Table of contents

Other EFA Cutter manuals