6FormC-1601

Shear Plate Adjustment

Afterreplacingshearplate,adjustangleofspringsocarbide

contactsknife edgeata 3degreeangle.Refer todiagrams

forexplanationofproperangle.

Top

View Front

View

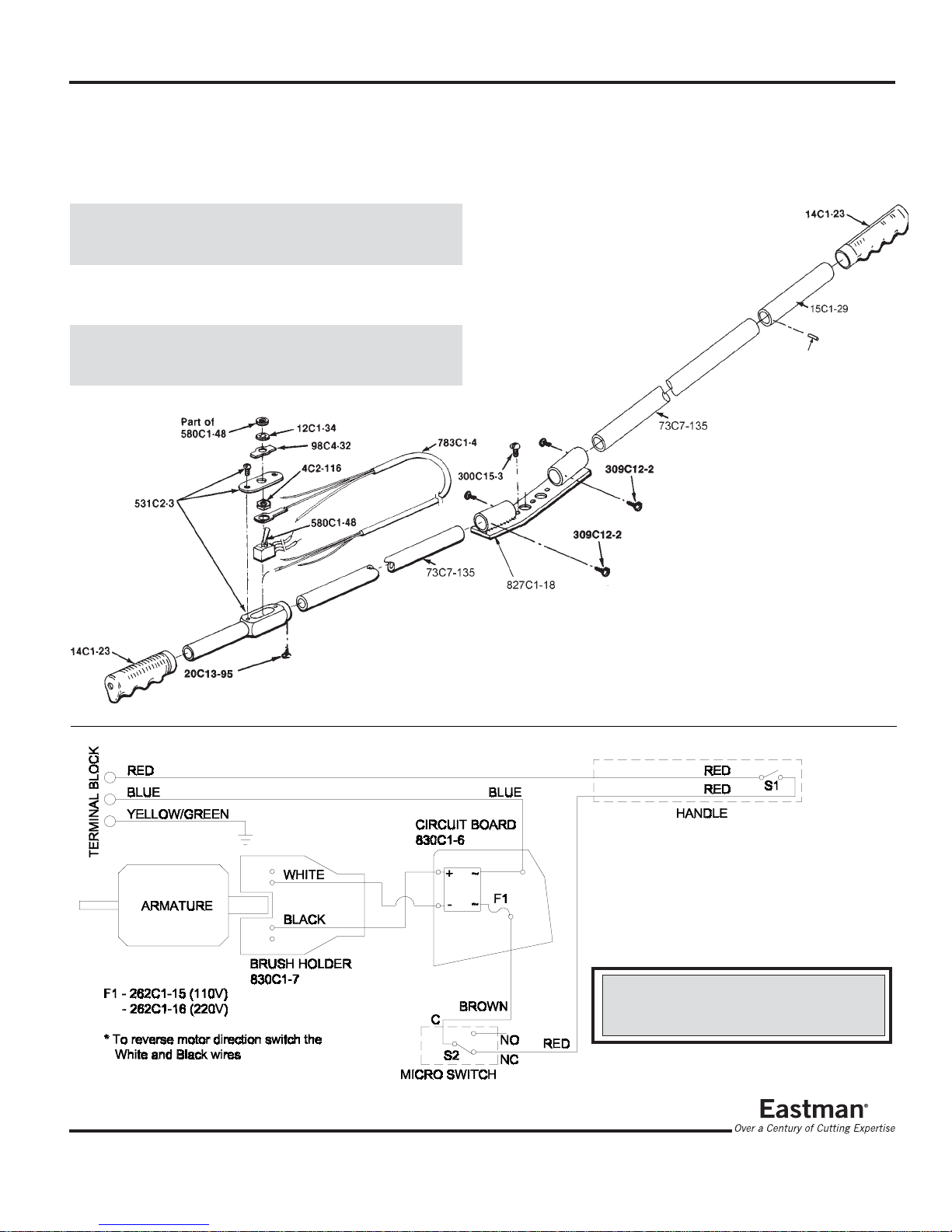

MicroSwitchReplacement

Remove cover plate and cover insulation. Remove (2) two

switch screws and lift out microswitch being careful not to

loseswitch spacers. Remove leadsandre-solder the leads

ofthe new switch. Replace partsin reverseorder.

CAUTION

Excessivesolderingheat will damage switch.

FuseReplacement

With cover plate and cover insulation removed, fuse is vis-

ible. Liftburned out fuse out offuseholderand replace with

identicalfuse. Replacecover plate and insulation.

CAUTION

Replace only with identically rated fuse. Use of different

fusemaycauseelectricalhazardordamageelectronicparts.

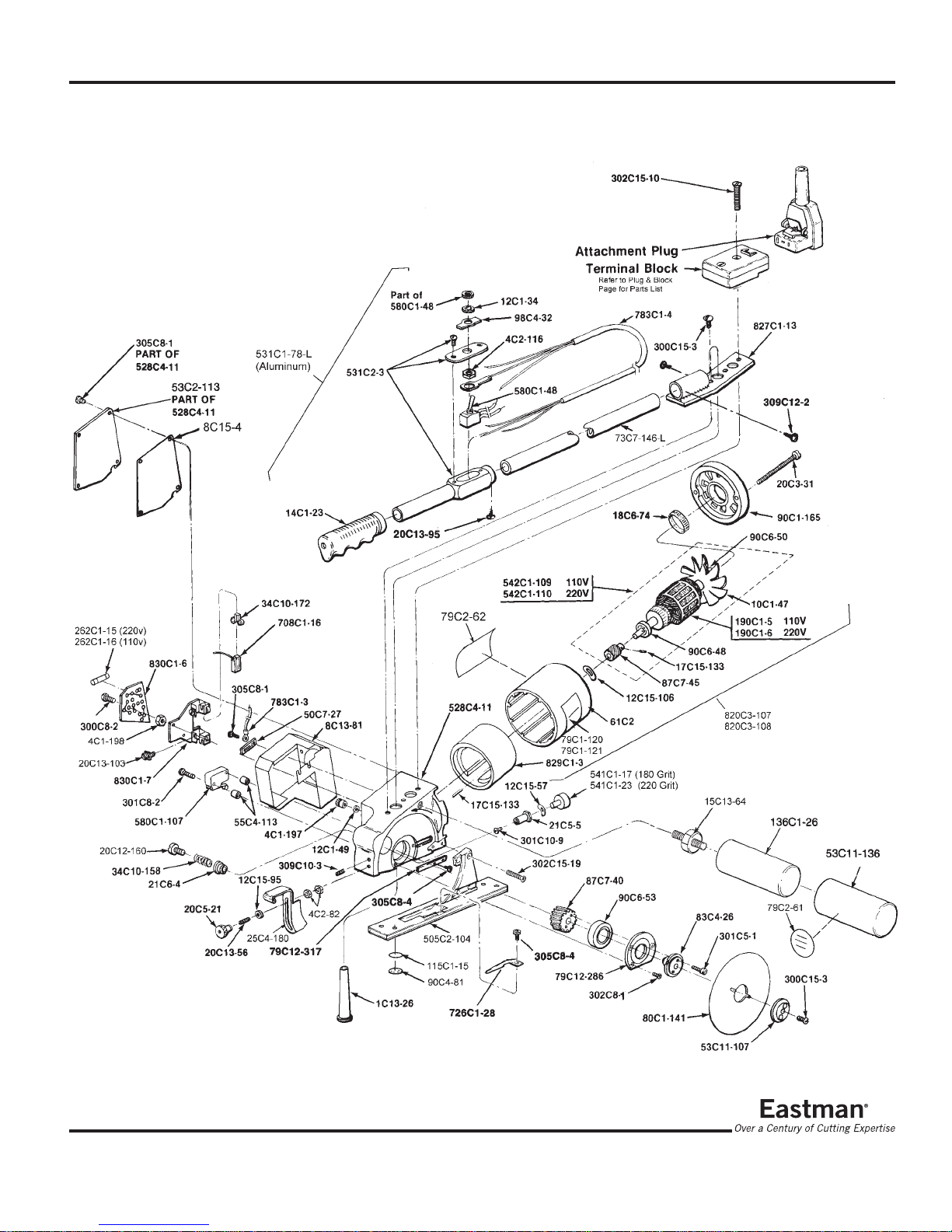

Lubrication of Knife Gear

Knifegear“Z”shouldberemovedandreplacedifnecessary

orrepackedwithgreaseeverythreemonths.

Removeknifeasdescribedabove,toexposebearingretainer

plate79C12-286.Inserta#10-32x11/2"screwintocenter

ofknifeflange“X”sothatgear,bearingandknifeflangecan

beremovedasoneunit.Removethree(3)screws“W”andlift

outgearassembly.Inspectandreplacegear“Z”ifnecessary

or repack gear teeth ONLY with grease. Reassemble in

reverseordermakingsurethatbearing“Y”isseatedsquarely

beforesecuringknifeflange“X”andretainerplate.

IMPORTANT: Use of too much grease when repacking

knifegear“Z”mayresultinunduestrainon

knifemotor.

Service

Daily:

-Cleanworkarea.

-Clean track assembly.

-Cleanand lubricate guide tubeswith lightmachine oil.

-Checkbladeandsharpeningstoneforwear.

Weekly:

-Checkforanyunusualwearanddeterminewhy.

-Check entire machine for loose nuts and bolts.

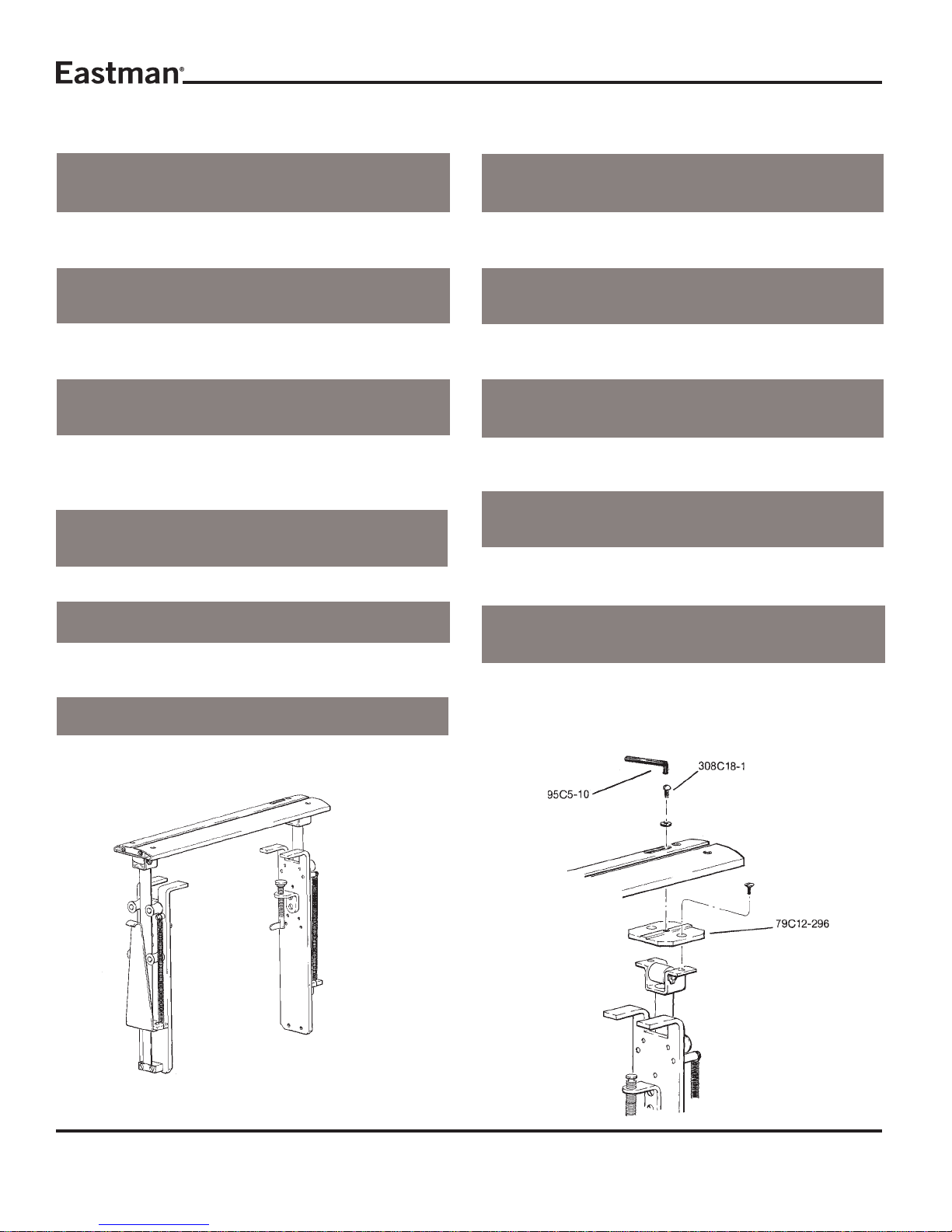

Ordering Replacement Parts

Your Eastman Falcon lV has been carefully designed to

provide many hours of trouble free operation. The

comprehensiveexplodedpartillustrationshavebeencarefully

preparedtoenableyoutoeasilyorderreplacementparts,as

required.Replacementpartsforthismachinemaybeordered

throughyournearestEastmanrepresentativeordirectlyfrom

the Eastman factory.

Sharpener Replacement

To replace sharpener stone, first remove knife blade (see

knife replacement). Insert screwdriver into slotted head of

sharpenerbutton"P"andholdhexbushing“Q”inplace. Turn

counterclockwiseandremovesharpenerbuttonandspring

“S”. Set these parts aside for later reassembly. Remove

screw “T” to separate hex bushing, spring washer “U” and

emerywheel“V”. Replaceemerywheelandreassemblein

reverseorder.Check that screw “P” is tightenedsecurely.

MotorBrushReplacement

Remove (4) four screws, cover plate and cover insulation,

being careful not to damage insulation material. Loosen

and disengage (2) two screws holding down micro switch

andliftoutswitch beingcarefulto retainthetwoswitchspac-

ers. Remove (2) two screws and carefully lift out the com-

binedassemblyofthemotorbrushcardcircuitboard. Move-

ment of the parts will be restricted by wires but have ad-

equate length to work without disconnecting. Loosen (2)

twobrush screws and remove the motorbrushpigtailsfrom

underthefasteners. Turnbrushcardoverandslidebrushes

outofguides.

When inserting new brushes, bevel corner at wire pigtail

must face slot in brush holder. Pigtail runs through slot to

screw fastener. Wrap pigtails around screw fasteners and

tighten. Turn assembly back to its original position. With

yourfingers,separatebrushes enoughtofitaroundcommu-

tatorbarsand begin working the assembly inside cavityin-

sulation. Continue working assembly down until it is flat to

inside of standard and brushes snap into position around

commutator. Replace (2) two screws holding down circuit

board and motor brush card. Replace switch spacers and

switchand secure with(2)twoscrews. Replace cover insu-

lationandcoverandfasten with (4) four screws.