effeff 309X User manual

309X/409X/709X

D0035302

Sicherheitsschlösser

Serrature di sicurezza

Security locks

Cerraduras de seguridad

Serrures de sécuritéSerrures de sécurité

Max 45

Max 45

Max 7

EL560 - EL563

EL360, EL362

EL160, EL162

EL460 - EL463

EL260, EL262

EL060, EL062

X

Y

Ø10.5

Ø10.5

Ø5.5

Ø8.5

Ø5.5

Ø8

Ø8

Ø4.5

20

15

21.8

16.9

92 (PZ) / 94 (RZ) 91

76

25

21.5 25

254

30

3

300

35

20

6

8

22

10

9

8 /

45 / 50 / 55 / 60

20.5

30 / 35 / 40 / 45

24

/ 28

7R

10

8

20

3

20 / 24

22

6

35

63

72(PZ) / 74(RZ)

35

55 /60 /65/80/100

8

Ø8

Ø6

Ø6

235

88 /93 /98/113/133

16.5

38

3

168.5

21.5

66.5

8/ 9

X Y max.

30 40

35 45

40 50

45 55

50 70

55 75

60 80

65 85

80 90

100 110

2

Contents

Technical Data............................................................................................................4

Standards ...................................................................................................................4

Wiring Diagram ...........................................................................................................5

Emergency Exit Devices – Installation According to EN 179......................................7

Panic Exit Devices – Installation According to EN 1125 .............................................7

Settable Functions of 709X (narrow style)..................................................................8

Settable Functions of 709X (wooden door).................................................................9

Drilling Scheme (Locks)............................................................................................17

Drilling Scheme (Strike Plates for Wooden Door).....................................................18

Installation Schematic...............................................................................................20

Inhalt

Technische Daten..................................................................................................... 10

Prüfungen ................................................................................................................. 10

Anschlussschema..................................................................................................... 11

Installation für Notausgang entsprechend EN 179 ................................................... 13

Installation für Anti-Panik-Ausgänge entsprechend EN 1125 ................................... 13

Einstellbare Funktionen 709X (Rohrrahmen)............................................................ 14

Einstellbare Funktionen 709X (Vollblatt)................................................................... 15

Bohrschema für Türdrückersteuerungen ...................................................................17

Bohrschema für Schließbleche................................................................................. 18

Installationsskizzen....................................................................................................20

3

Operating voltage *) **): 12 – 24V DC STAB (-10%, +15%)

Current **): Max. 0.40 A

Idle 0.13 A (12V DC)

0.065 A (24V DC)

Micro switches **): Max. 0.5 A 30V AC/DC resist.10 W

Operating temperature: -20°C - +60°C

Bolt throw: 20 mm (deadbolt), 10mm (double action bolt)

Backset:

55, 60, 65 mm (wooden style)

30, 35, 40, 45 mm (narrow style)

Forend:

20, 24 mm (wooden style)

24, 28 mm (narrow style)

Spindle: 9 mm (8 mm with snap spindle adapter)

Connection cable:

Z09XKAB (10 m) 16 x 0.14 mm2

Door clearance: 2 - 5.5 mm

Settable functions: Mechanical functions:

- Opening direction of trigger bolt

- Exit handle side (709X)

Electrical function: *) **)

- Fail locked / Fail unlocked

Monitoring outputs **): Bolt deadlocked

Lock open

Trigger bolt in

Handle down

Cylinder used

Sabotage

Strike plate:

Z09XSBL-01 ... Z09XSBL-04

*) Not micro switch locks

**) Not mechanical locks

TECHNICAL DETAILS

TESTED ACCORDING TO THE STANDARDS

EN 179 3 7 6 1 1 3 4 2 A Exit

EN 1125 3 7 6 0 1 3 2 1/2 A Panic exit

EN 1634-1 Fire

EN 61000-6-1:2001 EMC

EN 61000-6-3:2001 EMC

EN STANDARDS

ENGLISH

TIP!

Remove exit handle Allen screw of split spindle lock case to enable electrical

controlling of both handles (through spindle lock function). In this case, remove or

cover also the CE mark label.

4

409X/709X

c

c

nc

no

no

no

c

nc

11

**) Potential free loop is closed when

connection cable is connected

to lockcase.

*) not micro switch locks

COMMON FOR HANDLE DOWN

KEY CYLINDER USED

12V DC (-10%) - 24V DC (+15%) STAB. *)

LOCKED / OPEN *)

HANDLE DOWN

BOLT OUT

BOLT IN

COMMON FOR BOLT IN /

TRIGGER BOLT IN

SABOTAGE LOOP **)

MONITORING OUTPUTS

White

Red

Blue

Turquoise

Violet

Orange

Yellow

Grey

Pink

Brown

Yellow/Red

TRIGGER BOLT IN

COMMON FOR BOLT OUT

KEY CYLINDER USED

Green/Red

Connection cable Z09XKAB

Length 10m 16 x 0.14 mm

2

Micro switches of lock case when:

- Key cylinder not used

- Handle not used

- Bolt out

- Trigger bolt in

- Bolt not in

(POTENTIAL FREE CONTROL)

Lock case

Control

Unit

Solenoid Red

White

GND / Control

Orange

Yellow

Brown

Grey

Pink

Yellow/Red

Violet

Turquoise

Green/red

Blue

KEY CYLINDER USED

WIRING DIAGRAM New wiring“ from 2007-03

Marking:

„NEW WIRING“ on the product label

HANDLE DOWN

BOLT OUT

TRIGGER BOLT IN

BOLT IN

SABOTAGE LOOP

5

Copyright©Abloy Oy Joensuu Factory 2005

**) Potential free loop is closed when

connection cable is connected

to lockcase.

*) not micro switch locks

COMMON FOR BOLT OUT /

HANDLE DOWN /

KEY CYLINDER USED

12V DC (-10%) - 24V DC (+15%) STAB.

*)

+

–

LOCKED / OPEN *)

HANDLE DOWN

BOLT OUT

BOLT IN

COMMON FOR BOLT IN /

TRIGGER BOLT IN

SABOTAGE LOOP **)

MONITORING OUTPUTS

White

Red

Blue

Turquoise

Violet

Orange

Yellow

Grey

Pink

Brown TRIGGER BOLT IN

KEY CYLINDER USED

Green/Red

Connection cable Z09XKAB

Length 10m 16 x 0.14 mm2

Micro switches of lock case when:

- Key cylinder not used

- Handle not used

- Bolt out

- Trigger bolt in

- Bolt not in

(POTENTIAL FREE CONTROL)

Lock case

Control

Unit

Solenoid Red

White

+12 - 24V DC

GND / Control

Orange

Yellow

Brown

Grey

Pink

Violet

Turquoise

Green/red

Blue

COMMON

KEY CYLINDER USED

HANDLE DOWN

BOLT OUT

TRIGGER BOLT IN

BOLT IN

COMMON

SABOTAGE LOOP

„Old wiring“ until 2007-02

WIRING DIAGRAM

409X/709X

6

EMERGENCY EXIT DEVICES INSTALLATION ACCORDING TO EN 179

The following lock cases and handles are approved to be installed together in an emergency

exit door. Strike plate Z09XSBL-01 ... Z09XSBL-04 must be used in the installation.

EN 179

PANIC EXIT DEVICES INSTALLATION ACCORDING TO EN 1125

The following lock cases and push bars are approved to be installed together in a panic exit door.

Strike plate Z09XSBL-01 ... Z09XSBL-04 must be used in the installation.

Recommended distance from a floor to a handle or to a push bar is between

900mm - 1100mm.

Lubricate the bolts of the lock case at least once a year. Use vaseline type lubrication.

Note! ASSA ABLOY will not be liable for products in case these instructions are not followed.

EN 1125

Functional check after installation:

Emergency exit (active) side and functional sensitivity tests:

- Use the handle of exit side. Exit side is correctly set if the bolt goes inside the lock case

irrespective of the electrical control.

- In the profile door locks the force of handle is about 15 N (approximately 1.5 kg weight

at a 100 mm distance from the pivot of the handle opens the lock).

- In the wooden door locks the force of handle is about 25 N (approximately 2.5 kg weight

at a 100 mm distance from the pivot of the handle opens the lock). According to EN 179

the force of handle must be less than 70 N.

- Close the door slowly and check that the lock deadlocks.

- Check that the bolts slide freely into the strike plate.

The safety features of this product are essential to its compliance with EN 179. No

modification of any kind, other than those described in these instrictions, are permitted.

Functional check after installation:

Panic exit (active)side and functional sensitivity tests:

- Push the push bar towards the door on the exit side. Exit side is correctly set if the bolt goes

inside the lock case irrespective of the electrical control.

- Force to open the lock by pushing the push bar is about 60 N (approximately 6kg). According

to EN 1125 it must be less than 80 N.

- Close the door slowly and check that the lock deadlocks.

- Check that the bolts slide freely into the strike plate.

Note! The length of the push bar must be at least 60 % of the width of the door.

The safety features of this product are essential to its compliance with EN 1125. No

modification of any kind, other than those described in these instrictions, are permitted.

1016, 1023, 1056, 1070,

1080, 1088, 1090, 1117,

1118, 1119, 1137, 1146,

1155, 1160, 1161, 1162,

1177, 1178, 1191, 0612,

0616, 0617, 0619, 0625,

0627, 0628, 0646, 0662,

0665, 0680, 0681, 0682,

0688

309X / 409X

IKON

DO 20.15.02 FSB

DO 20.03.01, DO 20.03.02 HEWI

DO 20.13.01, DO 20.13.02

Wooden style

111, 111.23,

114.23GK, 131, 132,

111X, 113X, 114X,

161X, 163X, 171X,

112X, 165X, 166X

IKON

DO 20.15.01

Narrow style

309X / 409X

S6B3, S6B6

S6B8

S326, S426, S4K3

S4K6

709X

709X

ENGLISH

309X / 409X / 709X

309X / 409X / 709X 8000-00-1100 (-), 8000-20-1100 (PZ)

8000-00-1100 (-), 8000-21-1100 (RZ)

effeff

DO 30.04

8000-00-1100 (-), 8000-10-1100 (PZ)

8000-00-1100 (-), 8000-11-1100 (RZ)

Narrow style

Wooden style effeff

DO 30.04

TESA

DO 30.06

UNIVERSAL SERIE

19709G9xx

JPM

DO 30.05

DORMA

990000-XX-0A, 990100-XX-0A,

990001-XX-0A, 990101-XX-0A,

991000-XX-0A, 991100-XX-0A,

991001-XX-0A, 991101-XX-0A

(870000-30-0A, 870000-31-0A,

870000-32-0A, 870000-33-0A)

7

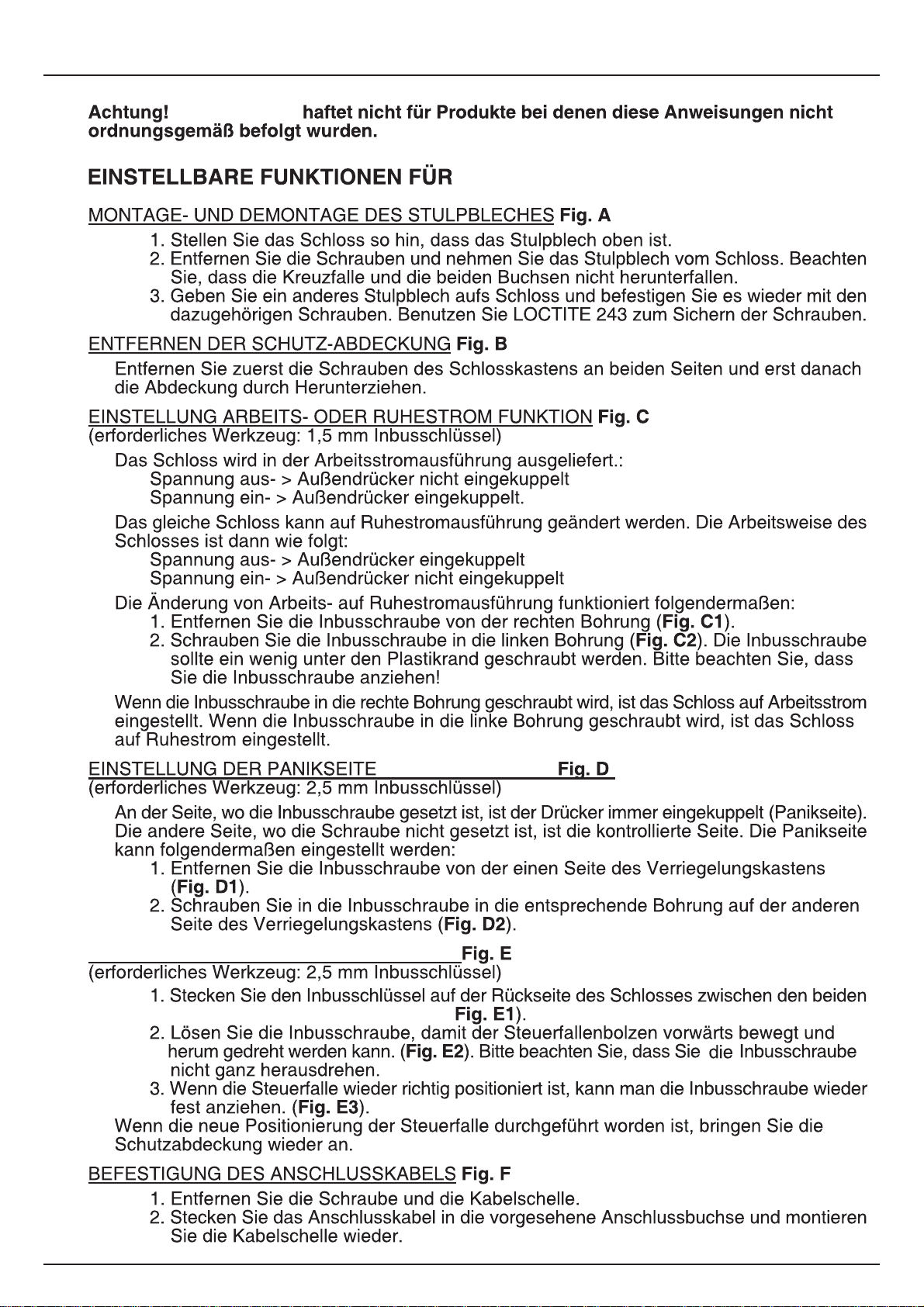

SETTABLE FUNCTIONS OF 709X (narrow style)

CHANGING THE FOREND Fig. A

1. Set the lock case forend up on the table.

2. Unscrew the fixing screws and remove the forend. Please note that the double action

bolt and its two bushings do not fall off.

3. Set another forend and screw in the screws. Use LOCTITE 243 on each fixing screw.

REMOVING THE MANIPULATION PROTECTION COVER Fig. B

SETTING THE ELECTRICAL FUNCTION: FAIL LOCKED -> FAIL UNLOCKED Fig. C

(Needed tool: 1.5 mm Allen key)

The lock case is delivered in Fail locked mode:

Power off -> Handle does not open the lock.

Power on -> Handle opens the lock.

The lock case can be changed in Fail unlocked mode. Then the lock works electrically in the

following way:

Power off -> Handle opens the lock.

Power on -> Handle does not open the lock.

The electrical function is changed from Fail locked into Fail unlocked mode in the following way:

1. Remove the Allen screw from the right-hand hole (Fig. C1).

2. Screw in the Allen screw in the left-hand hole (Fig. C2). The Allen screw should settle

a little under the plastic edge, but please note not to use strength.

When the Allen screw is fixed in the right-hand hole, the electrical function is Fail locked.

When the Allen screw is fixed in the left-hand hole, the electrical function is Fail unlocked.

SETTING THE EXIT HANDLE SIDE Fig. D (Needed tool: 2.5 mm Allen key)

Exit side of the lock case is set with an Allen screw. The handle, of which side the Allen screw

is fixed, always opens the lock, while the handle of the other side is controlled electrically.

The lock case is delivered so, that the Allen screw is fixed on the caser side of the lock case.

Exit handle side can be changed in the following way:

1. Remove the Allen screw from the caser side of the lock case (Fig. D1).

2. Screw in the Allen screw in the corresponding hole on the other side of the lock case

(Fig. D2).

CHANGING THE HANDING OF THE TRIGGER BOLT Fig. E (Needed tool: 2.5 mm Allen key)

1. Locate the Allen key between the two springs in the back of the lock case in the Allen

screw-head of the trigger bolt (Fig. E1).

2. Loosen the Allen screw, so that the trigger bolt moves forward and can be turned around

(Fig. E2). Please note not to unscrew the Allen screw.

3. When the handing of the trigger bolt is set, tighten the Allen screw (Fig. E3).

When the needed settings have been done, attach the manipulation protection cover.

ATTACHING THE CABLE Fig. F

1. Unscrew the fixing screw and remove the cable clamp.

2. Connect the cable into the connector. Fix the cable clamp.

SETTING 8/9 SNAP SPINDLE ADAPTERS Fig. M

8/9 snap spindle adapters are set if the lock case is installed with 8mm spindle. The adapters

must be set on the both sides of the lock case.

There are two flat sides and two sides with a cup in a adapter. The round markings on the

handle follower of a lock case denote the direction, in which the adapter is set. With 309X

and 409X the direction of the adapter has to be noticed. With 709X the direction

has no significance.

ENGLISH

8

SETTABLE FUNCTIONS OF 709X (wooden style)

CHANGING THE FOREND Fig. G

1.Unscrew the fixing screws and remove the forend.

2.Set another forend and screw in the fixing screws. Please note that a screw below the

dead bolt is longer than the other screws. Use LOCTITE 243 on each fixing screw.

SETTING THE ELECTRICAL FUNCTION: FAIL LOCKED FAIL UNLOCKED Fig. H

The lock case is delivered in Fail locked mode:

Power off -> Handle does not open the lock.

Power on -> Handle opens the lock.

The lock case can be changed in Fail unlocked mode. Then the lock works electrically in the

following way:

Power off -> Handle opens the lock.

Power on -> Handle does not open the lock.

The electrical function is changed from Fail locked into Fail unlocked mode by turning the

changer, which is located on the case side of the lock case, in the following way:

1. Unscrew the fixing screw and pull out the changer.

2. Turn the changer around.

3. Put the changer back and screw in the fixing screw. Please make sure that the changer

is straight and it fits tightly in the lock case.

When the arrows on the changer and the lock case are positioned as shown in the figure,

the electrical function is Fail locked (Fig. H1).

When the arrows on the changer and the lock case are positioned as shown in the figure,

the electrical function is Fail unlocked (Fig. H2).

SETTING THE EXIT HANDLE SIDE Fig. I (Needed tool: 2.5 mm Allen key)

Exit side of the lock case is set with an Allen screw. The handle, of which side the Allen screw

is fixed, always opens the lock, while the handle of the other side is controlled electrically.

The lock case is delivered so, that the Allen screw is fixed on the case side of the lock case.

Exit handle side can be changed in the following way:

1. Remove the Allen screw from the case side of the lock case (Fig. I1).

2. Fix the Allen screw in the corresponding hole on the other side of the lock case

(Fig. I2).

CHANGING THE HANDING OF THE TRIGGER BOLT Fig. J (Needed tool: 2 mm Allen key)

1. Press the trigger bolt inside the lock case until the Allen screw of the trigger bolt is

shown on the cover side of the lock case.

2. Unscrew the Allen screw.

3. Pull out the trigger bolt and turn it around.

4. Put the trigger bolt back in its place and press it inside the lock case.

5. Screw in the Allen screw.

SETTING MANIPULATION PROTECTION PLUG Fig. K

Set the brass plug on the outside of the lock case as shown in the figure.

ATTACHING THE CABLE Fig. L

1. Connect the cable into the connector.

2. Use a cable tie to fix the cable to the lock case. Cut the cable tie short.

SETTING 8/9 SNAP SPINDLE ADAPTERS Fig. M

8/9 snap spindle adapters are set if the lock case is installed with 8mm spindle. The adapters

must be set on the both sides of the lock case.

There are two flat sides and two sides with a cup in the adapter. The round markings on the

handle follower of a lock case denote the direction, in which the adapter is set. With 309X

and 409X the direction of the adapter has to be noticed. With 709X the direction

has no significance.

ENGLISH

9

(Vollblatt)

(Rohrrahmen)

(Vollblatt)

(Rohrrahmen)

Anschlusskabel:

(Z09XKAB)

Abstand Türe/Zarge:

Einstellbare Funktionen:

(709X)

Z09XSBL-01 ... Z09XSBL-04

10

409X/709X

c

c

nc

no

no

no

c

nc

11

Anschlusskabel: Z09KAB

Sabotageschleife

Gelb/Rot

Gelb/Rot

„Neuer Anschluss“ ab 03/2007

Kennzeichnung:

„NEW WIRING“ auf Produkt-Etikett

ANSCHLUSS

409X/709X

**) Der potenzialfreie Kontakt ist geschlossen

(POTENZIALFREIER KONTAKT)

SABOTAGE SCHLEIFE **)

wenn der Anschlussstecker am Schloss

11

Anschlusskabel: Z09KAB

c

nc

no

c

**) Der potenzialfreie Kontakt ist geschlossen

(POTENZIALFREIER KONTAKT)

Sabotageschleife

nc

„Alter Anschluss“ bis 02/2007

ANSCHLUSS

409X/709X

12

Z09XSBL-01 ...

Z09XSBL-04

309X/409X/709X

(Rohrrahmen)

309X/409X/709X

(Vollblatt)

Z09XSBL-01 ... Z09XSBL-04) müssen

309X/409X

309X/409X

(Rohrrahmen)

709X (Rohrrahmen)

709X (Vollblatt)

12

DORMA

(Rohrrahmen)

13

709X Rohrrahmen

(709X, Rohrrahmen)

ÄNDERN DER STEUERFALLENPOSITION

Federn in den Steuerfallenbolzen (

ASSA ABLOY

14

(709X, Rohrrahmen)

EINSTELLUNG ARBEITS- ODER RUHESTROMFUNKTION

ÄNDERN DER STEUERFALLENPOSITION (rechte/linke Türe)

Bei Verwendung der Adapter mit 309X/409X muss die Richtung beachtet werden.

Bei Verwendung des Schlosses 709X muss keine Richtung beachtet werden.

EINSTELLBARE FUNKTIONEN FÜR 709X (VOLLBLATT)

15

Bei Verwendung der Adapter mit 309X/409X muss die Richtung beachtet werden.

Bei Verwendung des Schlosses 709X muss keine Richtung beachtet werden.

16

Copyright©Abloy Oy Joensuu Factory 2005

309X / 409X / 709X

DRILLING SCHEME

Perçage approprié selon

les installations

130

132 70,2

75,2 91 76

21,5

25 25

RZ94

7

116,5

17

208

87

27 / 32 / 37 / 42

17

0,50

+0

21,5

52 35 52

PZ92

276

18

245

Select suitable drillings

according to fittings.

FREES EN BOOR TEKENINGEN

SCHEMA

Selecteer de juiste boren

conform de diameter van

de gaten in het slot.

17

Copyright©Abloy Oy Joensuu Factory 2005

309X / 409X / 709X

Perçage approprié selon

les installations

DRILLING SCHEME

- 0

+0.5

24mm

Forend

20mm right

Forend

20mm left

Forend

1) 1)

0,50+ 0

9R

(RZ)13

0,50+ 0

20.2

0,50+ 0

9R

(RZ)

23

(PZ)

18

0,50

+0

24

90, 95, 100,115, 135

130, 135, 140, 155, 175

3

(PZ)18

(PZ)72 (RZ)74

1+ 0

167

21.5

80

38

38

0,50+ 0

20.2

1+ 0

18

1+ 0

18

98

51 52

64

55, 60, 65, 80, 100

235

Select suitable drillings

according to fittings.

FREES EN BOOR

TEKENINGEN

SCHEMA Selecteer de juiste boren

conform de diameter van

de gaten in het slot.

18

Copyright©Abloy Oy Joensuu Factory 2005

Z09XSBL-01 ... Z09XSBL-04

Z09XSBL-03

+0.5

-0

+0.5

-0

Z09XSBL-01

Z09XSBL-02/ -04

6R

6R

24

0,50

+0

250

23

6R

6R

15

2

11

0,50

+0

170

2

11

15

17

2

0,50

+0

20

0,50

+0

25

54

38 25

24

2

0,50

+0

20

0,50

+0

9

20

54

38 25

0,50

+0

24

3

51

30

41

176

16

10

107

67

10

17

232

98

17

16

28 / 20*)

10

1)

*) EA324

DRILLING SCHEME

FREES EN BOOR TEKENINGEN

SCHEMA

19

A

BC

C1 C2

20

Other manuals for 309X

1

This manual suits for next models

14

Table of contents

Other effeff Lock manuals