Electrex FEMTO D4 DC User manual

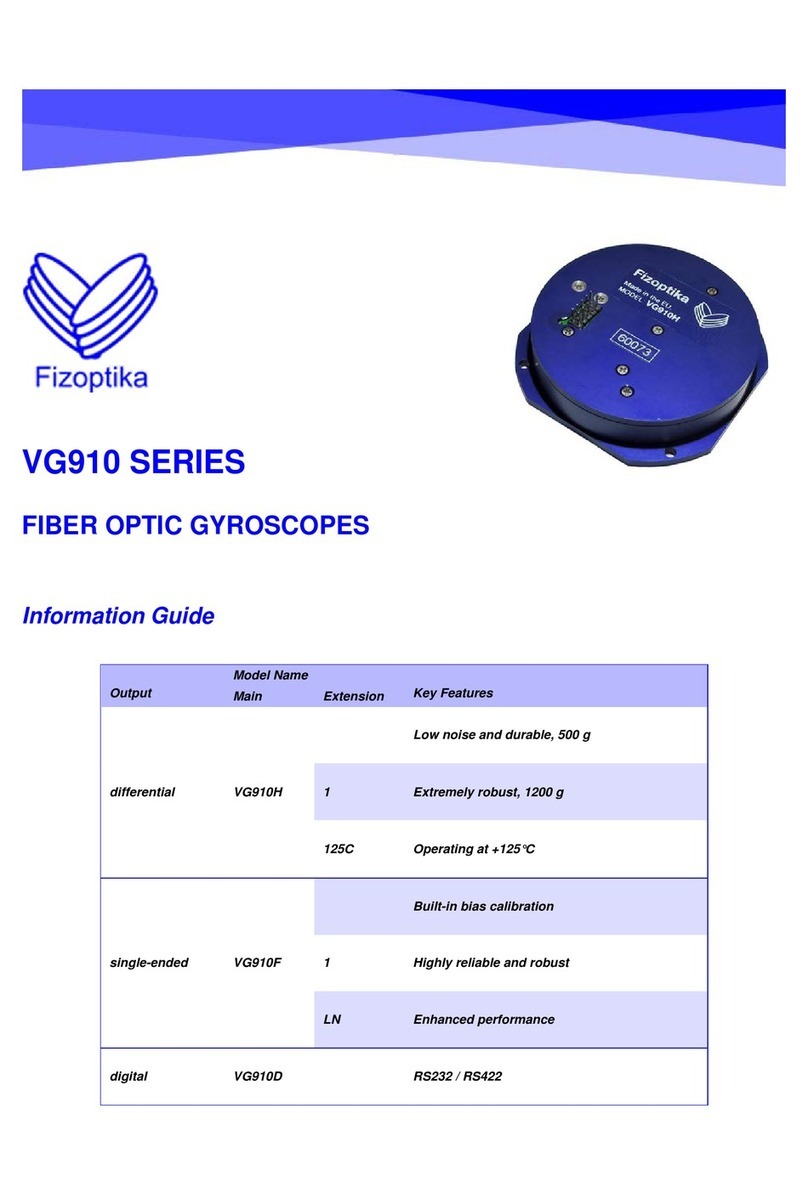

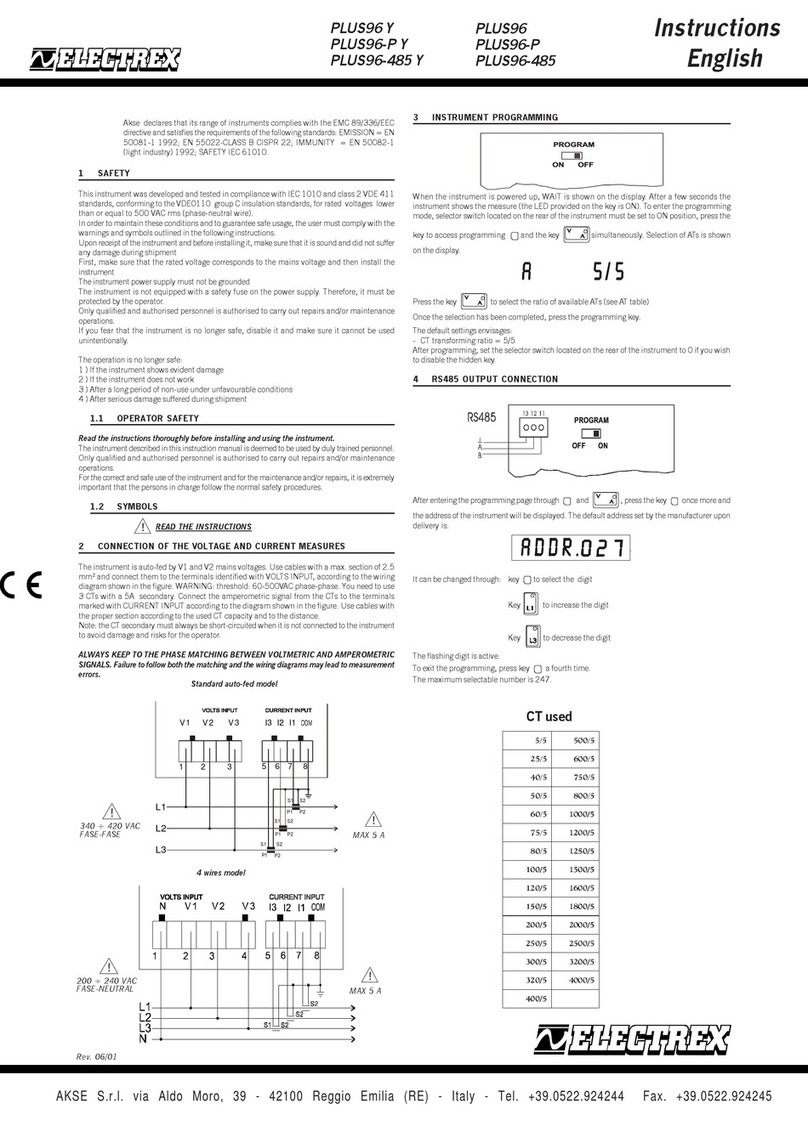

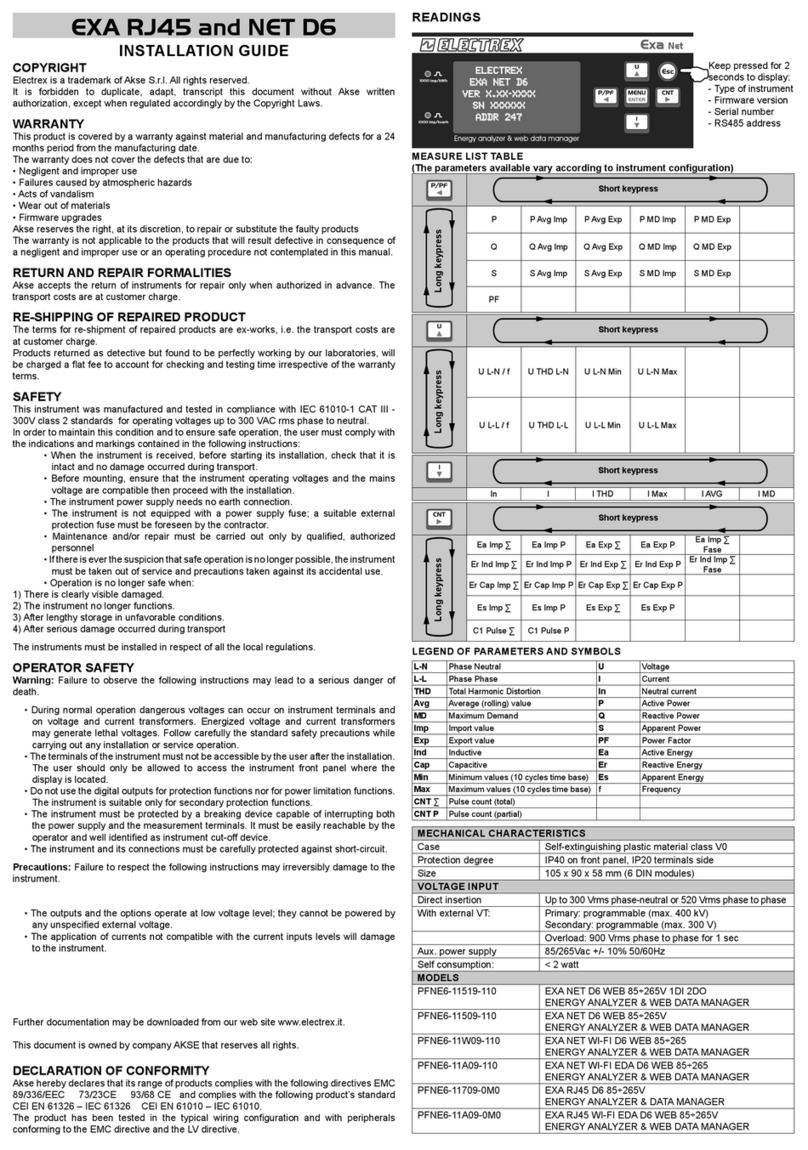

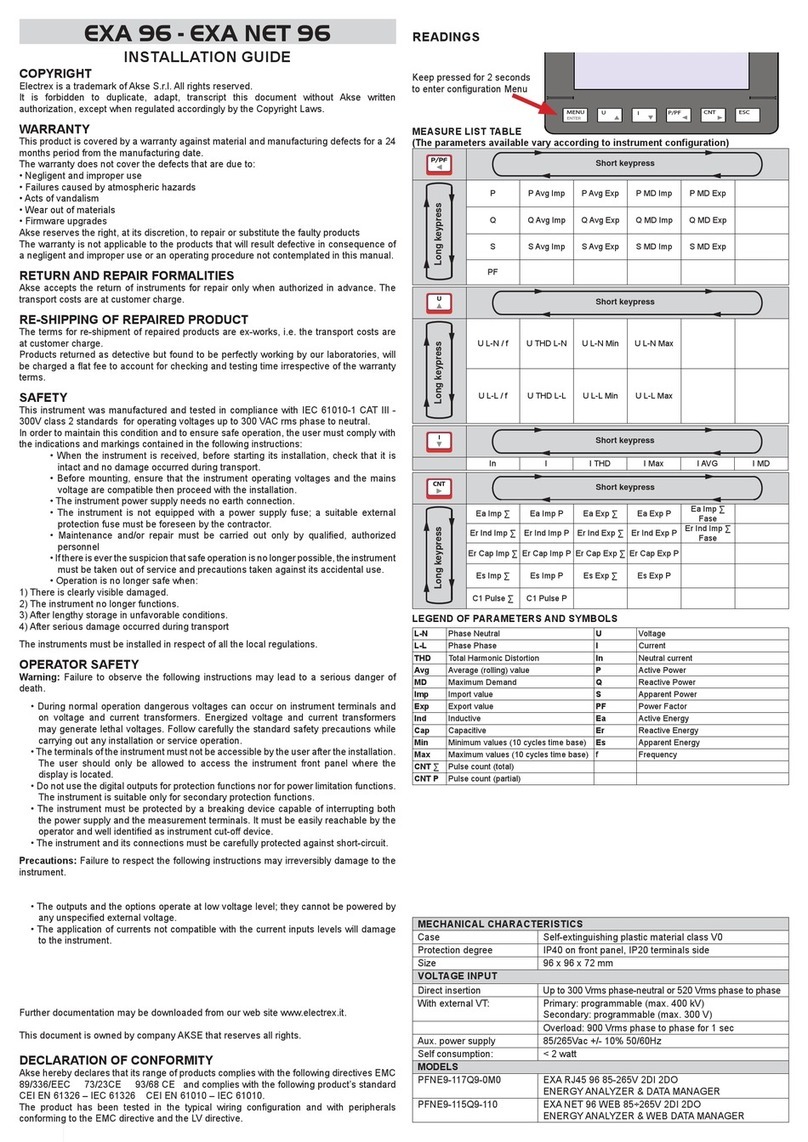

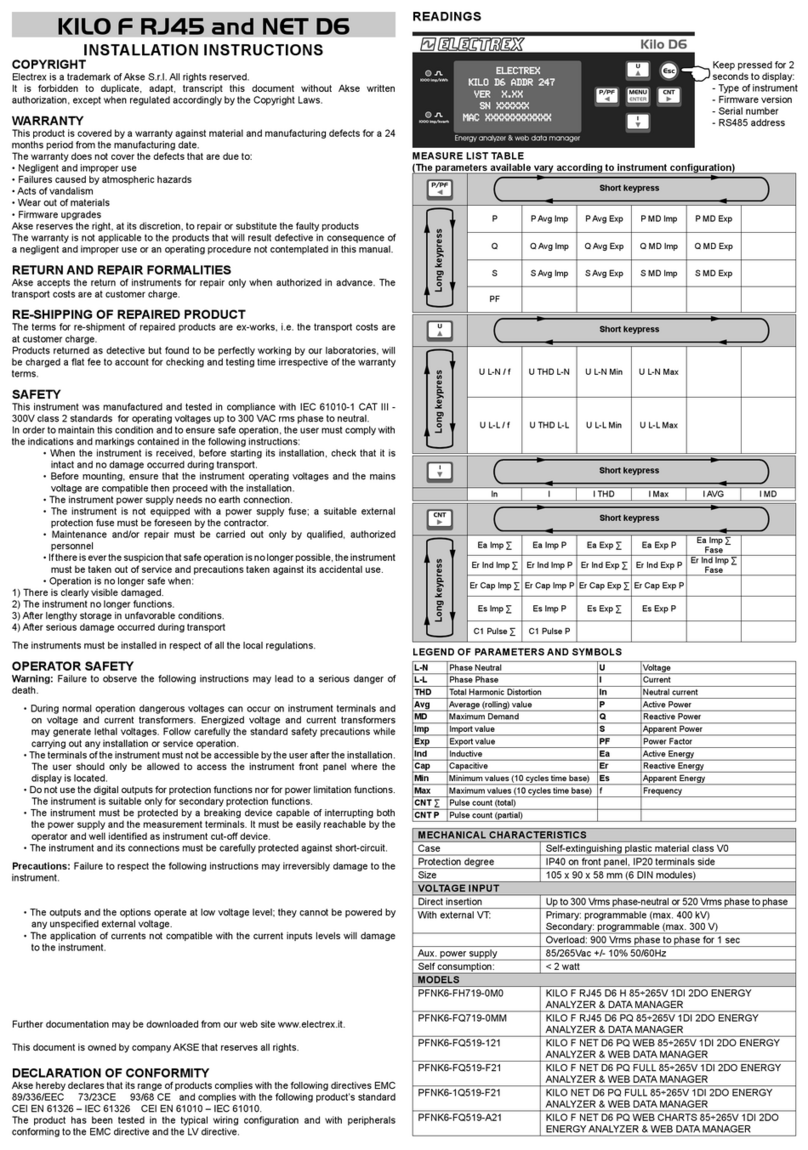

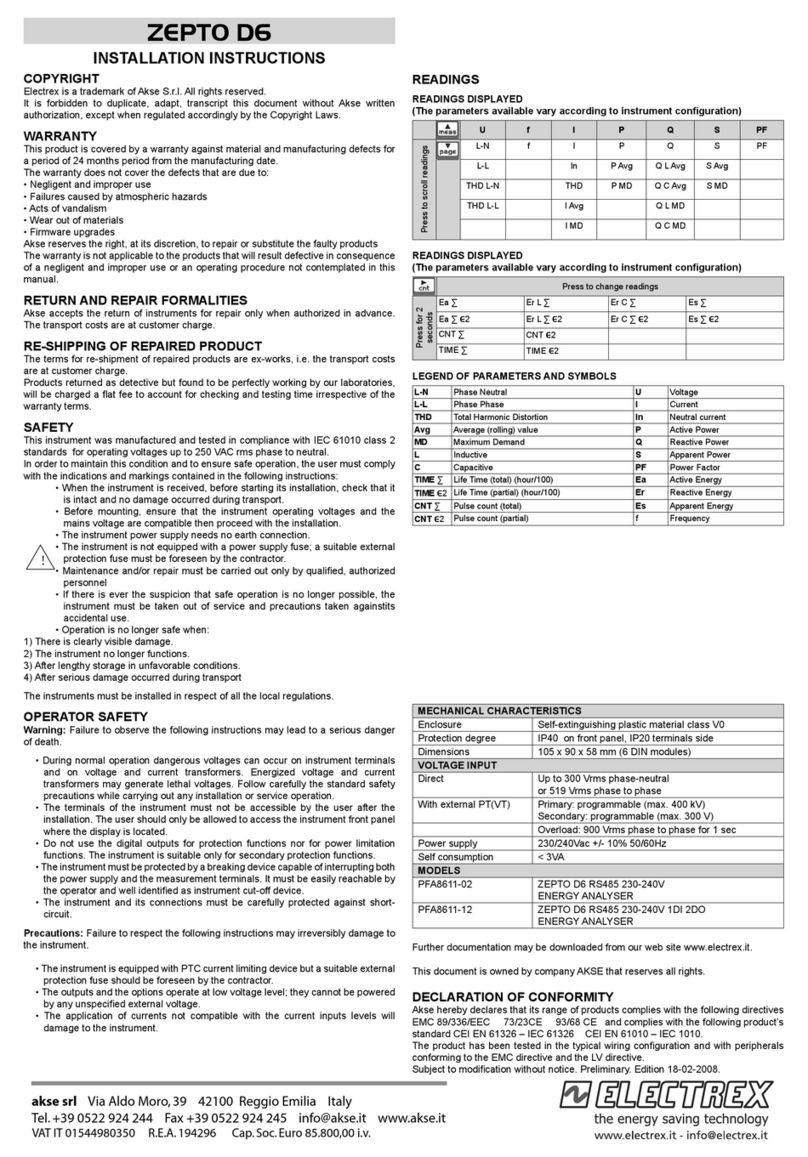

READINGS

READINGS DISPLAYED IN THE UPPER AREA OF THE DISPLAY

(The parameters available may change according to instrument configuration)

Ea U I P

Ea Imp U I P

Press to scroll read-

ings

Ea Exp Min U I Max P Avg Imp

Max U I Avg P Avg Exp

I MD P MD Imp

P MD Exp

READINGS DISPLAYED IN THE LOWER AREA OF THE DISPLAY

(The parameters available may change according to instrument configuration)

Press to change readings

Press for 2 seconds

Ea ∑+

Ea ∑-

Ea P+

Ea P-

CNT1 ∑

CNT1 P

TIME ∑TIME P

TEMP °C TEMP °F

LEGEND OF PARAMETERS AND SYMBOLS

Avg Average (rolling) value UVoltage

MD Maximum Demand ICurrent

Imp (+) Import value PActive Power

Exp (-) Export value Ea Active Energy

Min Minimum values (10 cycles time base)

Max Maximum values (10 cycles time base)

TIME ∑Life Time (total) TEMP °C Temperature in °Celsius

TIME P Life Time (partial) TEMP °F Temperature in °Fahrenheit

CNT ∑Pulse count (total)

CNT P Pulse count (partial)

Push for 2 seconds to

display:

- Type of instrument

- Firmware version

- Serial number

- RS485 address

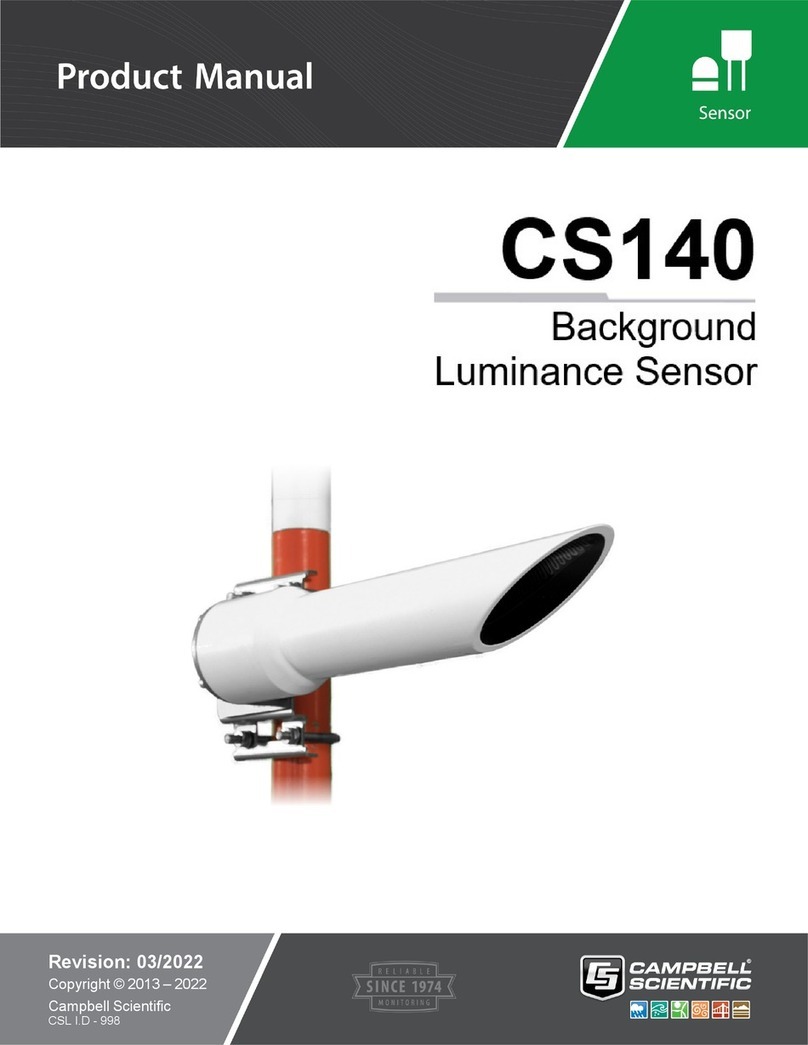

MECHANICAL CHARACTERISTICS

Case self extingush plastic class V0

Protection degree IP40 (front)

Size 70 x 90 x 58 mm (4 DIN modules)

VOLTAGE INPUT

Direct up to 300 V

max 360 V

Power supply 230/240Vac +/- 10% 50/60Hz

Self consumption < 3VA

MODEL

PFA6471-12 FEMTO D4 DC RS485 230-240V 1DI 2DO

ENERGY ANALYZER

INSTALLATION GUIDE

!

FEMTO D4 DC

COPYRIGHT

Electrex is a trademark of Akse S.r.l. All rights reserved.

It is forbidden to duplicate, adapt, transcript this document withoutAkse written authorization,

except when regulated accordingly by the Copyright Laws.

WARRANTY

This product is covered by a warranty against material and manufacturing defects for a 24

months period from the manufacturing date.

The warranty does not cover the defects that are due to:

• Negligent and improper use

• Failures caused by atmospheric hazards

• Acts of vandalism

• Wear out of materials

• Firmware upgrades

Akse reserves the right, at its discretion, to repair or substitute the faulty products

The warranty is not applicable to the products that will result defective in consequence of a

negligent and improper use or an operating procedure not contemplated in this manual.

RETURN AND REPAIR FORMALITIES

Akse accepts the return of instruments for repair only when authorized in advance. The

transport costs are at customer charge.

RE-SHIPPING OF REPAIRED PRODUCT

The terms for re-shipment of repaired products are ex-works, i.e. the transport costs are

at customer charge.

Products returned as detective but found to be perfectly working by our laboratories, will

be charged a flat fee to account for checking and testing time irrespective of the warranty

terms.

SAFETY

This instrument was manufactured and tested in compliance with IEC 61010-1 CAT III-

300V class 2 standards for exercise voltages up to 300 Vac rms phase to neutral.

In order to maintain this condition and to ensure safe operation, the user must comply with

the indications and markings contained in the following instructions:

• When the instrument is received, before starting its installation, check that it is

intact and no damage occurred during transport.

• Before mounting, ensure that the instrument operating voltages and the mains

voltage are compatible then proceed with the installation.

• The instrument power supply needs no earth connection.

• The instrument is not equipped with a power supply fuse; a suitable external

protection fuse must be foreseen by the contractor.

• Maintenance and/or repair must be carried out only by qualified, authorized

personnel

• If there is ever the suspicion that safe operation is no longer possible, the instrument

must be taken out of service and precautions taken againstits accidental use.

• Operation is no longer safe when:

1) There is clearly visible damage.

2) The instrument no longer functions.

3) After lengthy storage in unfavorable conditions.

4) After serious damage occurred during transport

The instruments must be installed in respect of all the local regulations.

OPERATOR SAFETY

Warning: Failure to observe the following instructions may lead to a serious danger of

death.

• During normal operation dangerous voltages can occur on instrument terminals and

on voltage and current transformers. Energized voltage and current transformers

may generate lethal voltages. Follow carefully the standard safety precautions while

carrying out any installation or service operation.

• The terminals of the instrument must not be accessible by the user after the installation.

The user should only be allowed to access the instrument front panel where the

display is located.

• Do not use the digital outputs for protection functions nor for power limitation functions.

The instrument is suitable only for secondary protection functions.

• The instrument must be protected by a breaking device capable of interrupting both

the power supply and the measurement terminals. It must be easily reachable by the

operator and well identified as instrument cut-off device.

• The instrument and its connections must be carefully protected against short-circuit.

Precautions: Failure to respect the following instructions may irreversibly damage to the

instrument.

• The instrument is equipped with PTC current limiting device but a suitable external

protection fuse should be foreseen by the contractor.

• The outputs and the options operate at low voltage level; they cannot be powered by

any unspecified external voltage.

• The application of currents not compatible with the current inputs levels will damage

to the instrument.

Further documentation may be downloaded from our web site www.electrex.it.

This document is owned by the company AKSE that reserves all rights.

DECLARATION OF CONFORMITY

Akse hereby declares that its range of products complies with the following directives EMC

89/336/EEC 73/23CE 93/68 CE and complies with the following product’s standard

CEI EN 61326 – IEC 61326 CEI EN 61010 – IEC 61010.

The product has been tested in the typical wiring configuration and with peripherals

conforming to the EMC directive and the LV directive.

Subject to modification without notice. Edition 20-05-2010

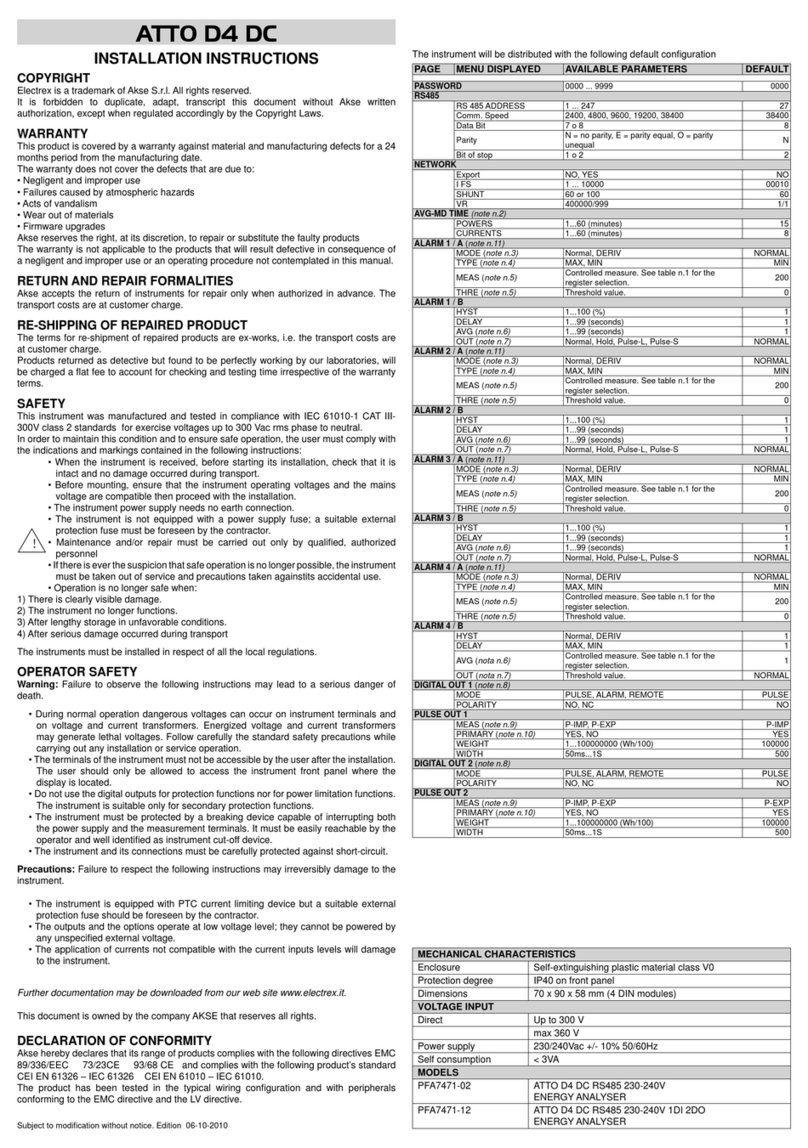

DEVICE SETUP

SETUP LIST

PAGE PARAMETERS VALUES AVAILABLE DEFAULT

PASSWORD REQUEST 0000 ... 9999 0000

RS485

RS485 Address 1 ... 247 27

Rate 2400, 4800, 9600, 19200, 38400 38400

Data Bit 7 or 8 8

Parity N = no parity, E =even parity, O = odd parity N

Stop Bit 1 or 2 2

RS-485

ADDR 027

COM 38400-8-N-2

NETWORK

Export NO, YES NO

I FS 1 ... 10000 00010

SHUNT 60 o 100 60

VR 400000/999 1/1

NETWORK

EXPORT

I FS

SHUNT

VR

NO

00010

60

000900/300

AVG-MD TIME (note n.1)

POWERS 1...60 (minutes) 15

CURRENTS 1...60 (minutes) 8

AVG-MD TIME

POWERS 15

CURRENTS 08

ALARM 1 / A (note n.10)

MODE (note n.2) NORMAL, DERIV NORMAL

TYPE (note n.3) MAX, MIN MIN

MEAS (note n.4) Controlled measure. See table n.1 for register

selection 344

THRE (note n.4) Threshold value 0

ALARM 1/A

MODE NORMAL

TYPE MAX

MEAS 344

THRE 000.00

ALARM 1 / B

HYST 1...100 (%) 1

DELAY 1...99 (seconds) 1

AVG (note n.5) 1...99 (seconds) 1

OUT (note n.6) Normal, Hold, Pulse-L, Pulse-S NORMAL

ALARM 1/B

HYST 01

DELAY 01

AVG 01

OUT NORMAL

ALARM 2 / A (note n.10)

MODE (note n.2) NORMAL, DERIV NORMAL

TYPE (note n.3) MAX, MIN MIN

MEAS (note n.4) Controlled measure. See table n.1 for register

selection 344

THRE (note n.4) Threshold value 0

ALARM 2 / B

HYST 1...100 (%) 1

DELAY 1...99 (seconds) 1

AVG (note n.5) 1...99 (seconds) 1

OUT (note n.6) Normal, Hold, Pulse-L, Pulse-S NORMAL

ALARM 3 / A (note n.10)

MODE (note n.2) NORMAL, DERIV NORMAL

TYPE (note n.3) MAX, MIN MIN

MEAS (note n.4) Controlled measure. See table n.1 for register

selection 344

THRE (note n.4) Threshold value 0

ALARM 3 / B

HYST 1...100 (%) 1

DELAY 1...99 (seconds) 1

AVG (note n.5) 1...99 (seconds) 1

OUT (note n.6) Normal, Hold, Pulse-L, Pulse-S NORMAL

ALARM 4 / A (note n.10)

MODE (note n.2) NORMAL, DERIV NORMAL

TYPE (note n.3) MAX, MIN MIN

MEAS (note n.4) Controlled measure. See table n.1 for register

selection 344

THRE (note n.4) Threshold value 0

ALARM 4 / B

HYST 1...100 (%) 1

DELAY 1...99 (seconds) 1

AVG (note n.5) 1...99 (seconds) 1

OUT (note n.6) Normal, Hold, Pulse-L, Pulse-S NORMAL

EXIT SETUP

(push for 2 seconds)

DIGITAL OUT 1 (note n.7)

MODE PULSE, ALARM, REMOTE PULSE

POLARITY NO, NC NO

DIGITAL OUT 1

MODE PULSE

POLATITY NO

PULSE OUT 1

MEAS (note n.8) P-IMP, P-EXP P-IMP

PRIMARY (note n.9) YES, NO YES

WEIGHT 1...100000000 (Wh/100) 100000

WIDTH 50ms...1S 500

PULSE OUT 1

MEAS P-IMP

PRIMARY YES

WEIGHT 100.00k

WIDTH 0500

DIGITAL OUT 2 (note n.7)

MODE PULSE, ALARM, REMOTE PULSE

POLARITY NO, NC NO

PULSE OUT 2

MEAS (note n.8) P-IMP, P-EXP P-EXP

PRIMARY (note n.9) YES, NO YES

WEIGHT 1...100000000 (Wh/100) 100000

WIDTH 50ms...1S 500

DISPLAY

CONTRAST 20 - 45 36

CLEAR TOTAL COUNTERS NO, YES NO

CLEAR PARTIAL COUNTERS NO, YES NO

CLEAR MIN-MAX NO, YES NO

CLEAR MAX DEMAND NO, YES NO

RESTORE FACTORY SETTINGS NO, YES NO

ENTER NEW PASSWORD 0000 ... 9999 0000

TABLE n.1 (ModBus Registers for alarm configuration)

REGISTER DESCRIPTION SYMBOL UNITS

220 Voltage Amplitude U [V]

232 Current Amplitude I [A]

240 Active Power ( Imp/ Exp) P [W]

332 Current AVG I AVG [A]

344 Total imported active power, AVG P Imp AVG [W]

352 Total exported active power, AVG P Exp AVG [W]

376 External Pulse Counter, With Weight, Total counter

or Tariff T1

CNT1 S

384 External Pulse Counter, With Weight, Partial

Counter or Tariff T2

CNT1 P

OPERATING KEYS

Click Change selected field

value

Change selected field value Go to next field

Click

2 sec

Go to next window Back to initial entry field Exits setup

ENTERS INTO SET UP MODE

(Push together for 2 seconds)

Subject to modification without notice. Edition 20-05-2010

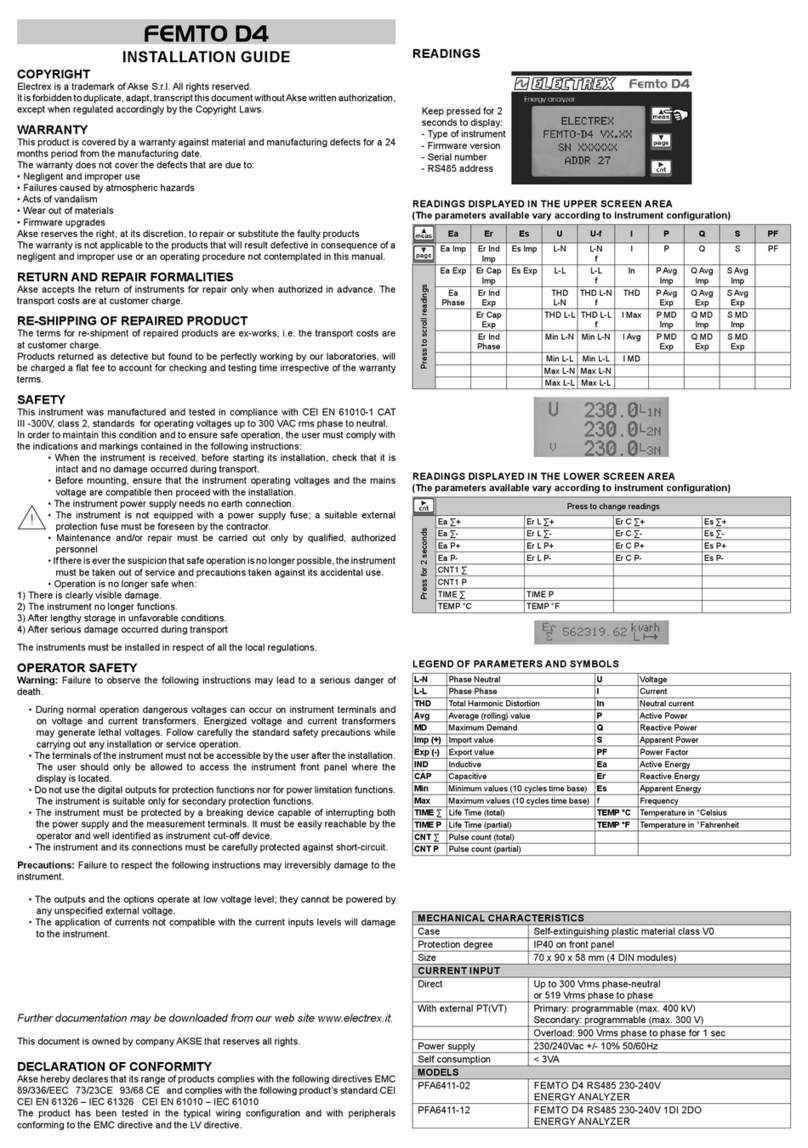

INPUT & OUTPUTS CONNECTION EXAMPLE

U

30.0

V

Ea Σ+

319.62

kWh

+-3456AB

T

10 11 12

17 18 19 20+1415-

RS-485 AUX

AUXVOLTAGE INPUT POWER

CURRENT INPUT

NO

C

NC

NO

C

NC

Max

27 Vdc

27 mA

(-) (+)

230 Vac

DA:

- TRASDUTTORE CON

CONTATTO PULITO

- GME

- STATO INTERRUTTORE

- STATO ALLARMI

R

e

l

a

y

R

e

l

a

y

Power

Supply

Digital Inputs

Supply voltage (external): from 10 to 30

Vdc

Current consumption: from 2 to 10mA

Max. count frequency 10 or 100Hz

N.B. For gas meters a galvanic separation is

needed per ATEX standards

Digital outputs (optocoupled NPN

transistor type for DIN 43864)

Maximum applicable voltage: 27 Vdc

Maximum switchable current: 27 mA

U

30.0

V

Ea Σ+

319.62

kWh

+ - 3456AB

T

10 11 12

17 18 19 20+1415-

RS-485 AUX

AUXVOLTAGE INPUT POWER

CURRENT INPUT

Es.

Input M8 Supervisor

12C C34

(-)(+)

(-) (+) (+)

Es. PLC

Out PLC

Comune

Note n.1

POWERS Integration time of the average value (AVG) and peak value (MD) for

power (from 1 to 60 minutes)

CURRENTS Integration time of the average value (AVG) and peak value (MD) for

current (from 1 to 60 minutes)

Note n.2

NORMALE Classic Alarm with reference to a fixed threshold or to maximum and

minimum delay and applicable hysteresis. “AVG” parameter is not used.

DERIV “THRE” parameter becomes a % value, “AVG” parameter is used. The

instant value applied to the alarm on “MEAS” is compared with its value

mediated obtained on the basis of the time set on “AVG”. When the

instantaneous value combined alarm differs in more (setting “Max”) or less

(setting “MIN”) from the average value (“ AVG “) of the percentage set on

“THRE” the alarm goes on. With delay and applicable hysteresis.

Note n.3

MAX Alarm setting in excess compared with the established conditions.

MIN Alarm setting in decrease compared with the established conditions.

Note n.4

MEAS indicates which register (and thus measure) the alarm is related.

See table n.1 input register.

THRE Alarm threshold in absolute value, with the exception made for “DERIV”

in which the value inserted becomes a percentage.

Note n.5

AVG Parameter to be used only in “DERIV” mode. Is the duration of the refe-

rence (in seconds) used to create a reference value for the istantaneous

readings.

Note n.6

NORMAL Physical output of the alarm excited during the duration of the alarm. It

restores automatically

HOLD Output remains excited until manual reset made via Modbus

PULSE-L Output generate a 500ms impulse when the alarm goes on.

PULSE-S Output generate a 100ms impulse when the alarm goes on.

Note n.7

PULSE Enables exit function as impulsive

ALARM Enables exit function as alarm

REMOTE Enables function output via protocol Modbus

NO Normally open

NC Normally closed

Note n.8

P-IMP Imported Active Power (Energy)

P-EXP Exported Active Power (Energy)

Note n.9

YES Referred to SHUNT primary

NO Referred to SHUNT secondary

Note n.10

ALLARME 1 Alarm related to the physical output: DIGITAL OUT 1 (DO1, terminal 8)

ALLARME 2 Alarm related to the physical output: DIGITAL OUT 2 (DO2, terminal 9)

ALLARME 3 Only MODBUS alarm

ALLARME 4 Only MODBUS alarm

ALARM SET UP EXAMPLE

To ensure that the exit “digital out 1” remain excited for the alarm duration (latching) when

average active power (MEAS 344) exceeds the value of 100 kW, hysteresis, 5% and

latency of 5 seconds set the parameters such as table:

ALARM 1 / A

MODE (note n.1) NORMAL, DERIV NORMAL

TYPE (note n.2) MAX, MIN MAX

MEAS (note n.3) Controlled measure. See table n.1 for register

selection 344

THRE (note n.3) Threshold value 100000

ALARM 1 / B

HYST 1...100 (%) 5

DELAY 1...99 (seconds) 5

AVG (note n.4) 1...99 (seconds) 1

OUT (note n.5) Normal, Hold, Pulse-L, Pulse-S NORMAL

DIGITAL OUT 1 MODE PULSE, ALARM, REMOTE ALARM

POLARITY NO, NC NO

To ensure that the exit “digital out 2” remain excited for the alarm duration (latching) when

average active power (MEAS 344) goes down the value of 90 kW, hysteresis, 5% and

latency of 5 seconds set the parameters such as table:

ALARM 2 / A

MODE (note n.1) NORMAL, DERIV NORMAL

TYPE (note n.2) MAX, MIN MIN

MEAS (note n.3) Controlled measure. See table n.1 for register

selection 344

THRE (note n.3) Threshold value 90000

ALARM 2 / B

HYST 1...100 (%) 5

DELAY 1...99 (seconds) 5

AVG (note n.4) 1...99 (seconds) 1

OUT (note n.5) Normal, Hold, Pulse-L, Pulse-S NORMAL

DIGITAL OUT 2 MODE PULSE, ALARM, REMOTE ALARM

POLARITY NO, NC NO

C

10

1

11

2

12

AUX

IN/OUT

!

Common

12

11

10

DO2

DO1

DI (+)

20

19

DI (-)

+

19

-

20

AUX

IN/OUT

!

DIGITAL INPUTS AND OUTPUTS CONNECTION

(only for the version PFA6471-12)

MESSAGE “CFG ERROR”

During the set up operation a “CFG ERROR” message could appear. This means

that some wrong parameters are typed. To restore the factory default settings use the

following procedure (RESTORE FACTORY SETTING) seguire la seguente procedura:

CFG ERROR

RESTORE

FACTORY SETTINGS

YES

Once this procedure is done the meter is configured with its factory default settings.

Stored data will remain after the restore operation.

Subject to modification without notice. Edition 20-05-2010

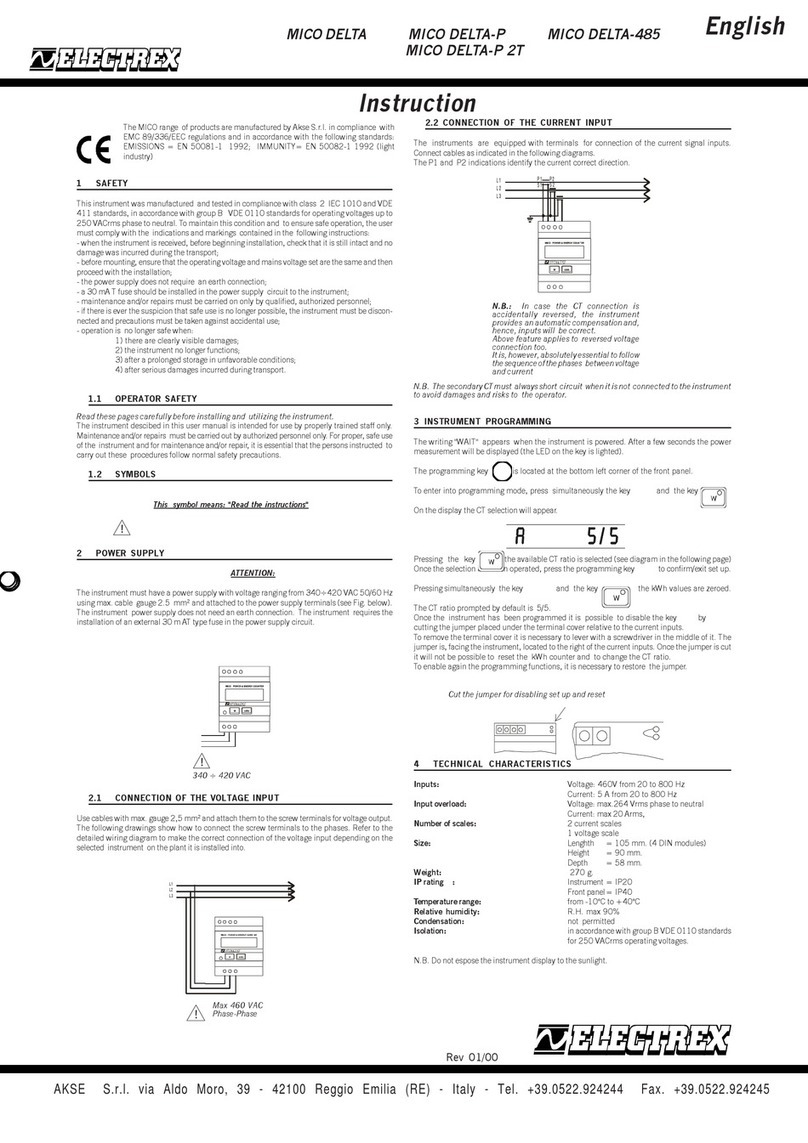

SHUNT CONNECTED BEFORE SHUNT CONNECTED AFTER

The instrument is fitted with a separate power supply. The power supply terminals are

numbered (17) and (18). Use cables with max cross-section of 2,5 mm2if stranded, 4

mm2if rigid.

POWER SUPPLY AND SERIAL LINE CONNECTION

akse srl Via Aldo Moro, 39 42124 Reggio Emilia Italy

P.I. 01544980350 R.E.A. 194296 Cap. Soc. Euro 85.800,00 i.v.

Voltage connection:

Use cables with max cross-section of 2,5 mm2if stranded 4 mm2if rigid and connect them to the terminals marked VOLTAGE INPUT on the instrument according to the applicable

diagrams that follow.

Connessioni amperometriche

Use SHUNT with adequate primary and 60 o 100 mV as secondary rate. Connect the SHUNT to the terminals marked I1 (S1 e S2) (current input) according to the applicable diagrams

that follow.

WIRING FOR VOLTAGE AND CURRENT

U

30.0

V

Ea Σ+

319.62

kWh

+ - 3456AB

T

10 11 12

17 18 19 20+1415-

RS-485 AUX

AUXVOLTAGE INPUT POWER

CURRENT INPUT

LN

FUSE

(50mA T)

230 ÷ 240 V ±10%

Serial RS485 port

AB

T

U

30.0

V

Ea Σ+

319.62

kWh

+-3456AB

T

10 11 12

17 18 19 20+1415-

RS-485 AUX

AUXVOLTAGE INPUT POWER

CURRENT INPUT

+

-SHUNT

U

30.0

V

Ea Σ+

319.62

kWh

+ - 3456AB

T

10 11 12

17 18 19 20+1415-

RS-485 AUX

AUXVOLTAGE INPUT POWER

CURRENT INPUT

+

-SHUNT

Subject to modification without notice.

Edition 20-05-2010

Made

in Italy

Pensato, progettato e prodotto in Italia

Engineered and manufactured in Italy

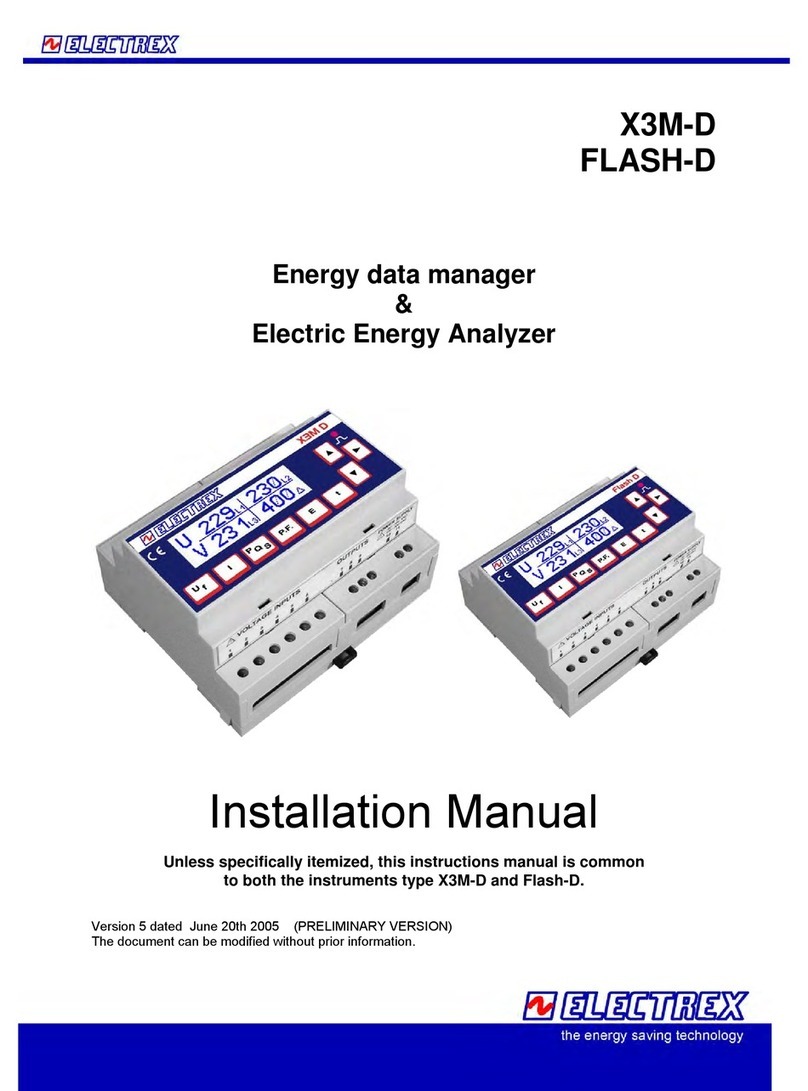

This manual suits for next models

1

Other Electrex Measuring Instrument manuals

Electrex

Electrex Femto D4 User manual

Electrex

Electrex PLUS96 Y User manual

Electrex

Electrex ETTO D2 User manual

Electrex

Electrex KILO User manual

Electrex

Electrex MICO User manual

Electrex

Electrex ZEPTO D6 User manual

Electrex

Electrex MICO DELTA User manual

Electrex

Electrex NET D6 User manual

Electrex

Electrex x3m-D User manual

Electrex

Electrex EXA 96 User manual

Electrex

Electrex ATTO D4 DC User manual

Electrex

Electrex KILO F RJ45 User manual

Electrex

Electrex EXA 96 User manual

Electrex

Electrex Zepto D6 User manual

Electrex

Electrex FEMTO 96 User manual

Electrex

Electrex FEMTO D4 User manual

Electrex

Electrex EXA TR D6 User manual

Electrex

Electrex FEMTO D4 70A User manual