2

Index

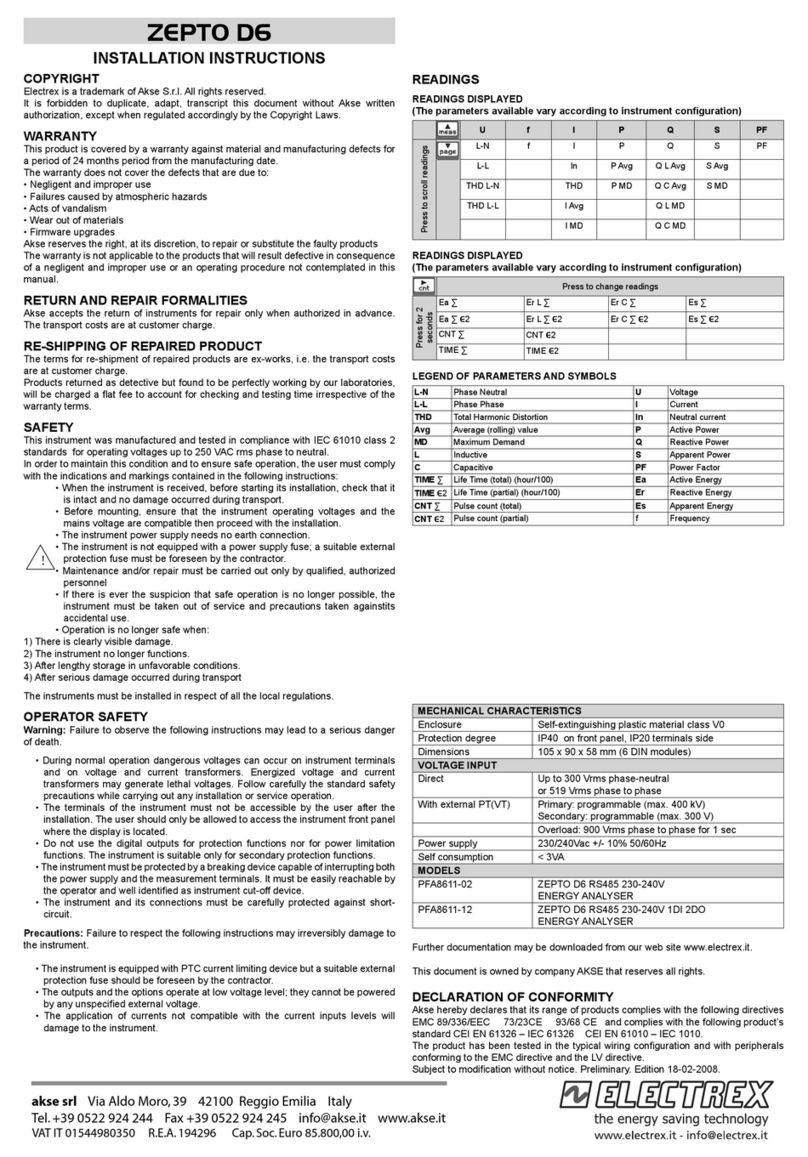

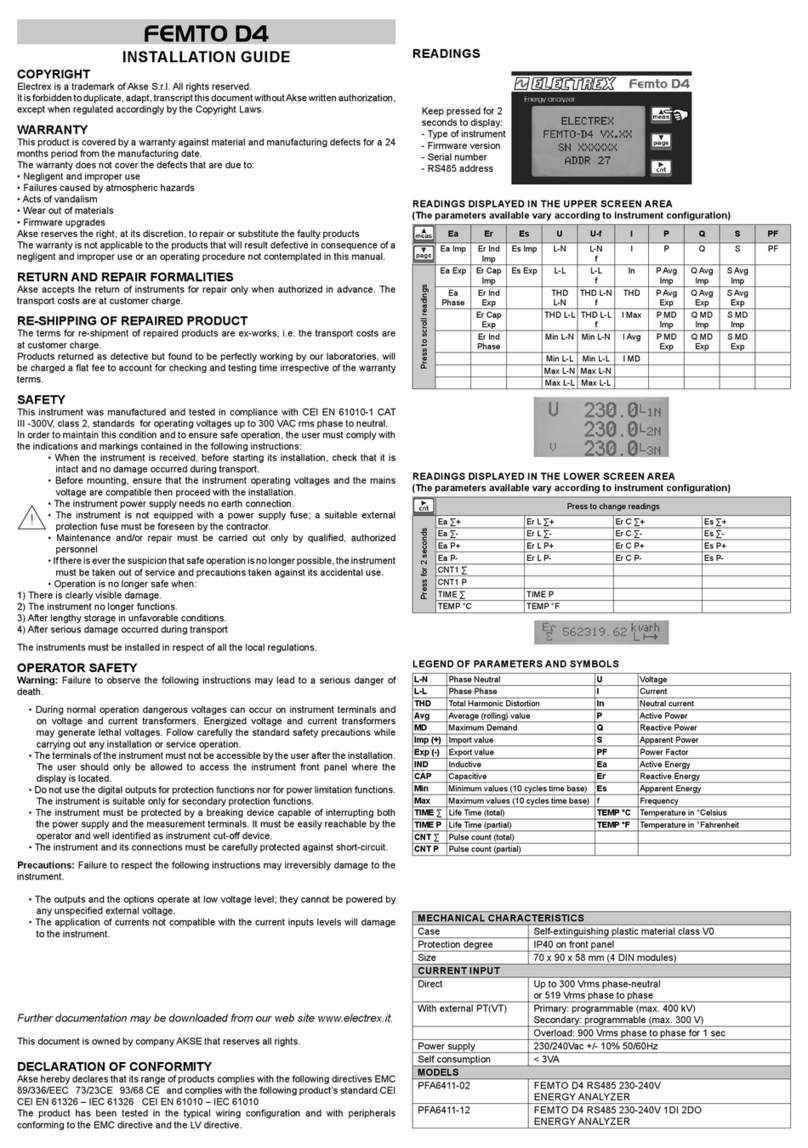

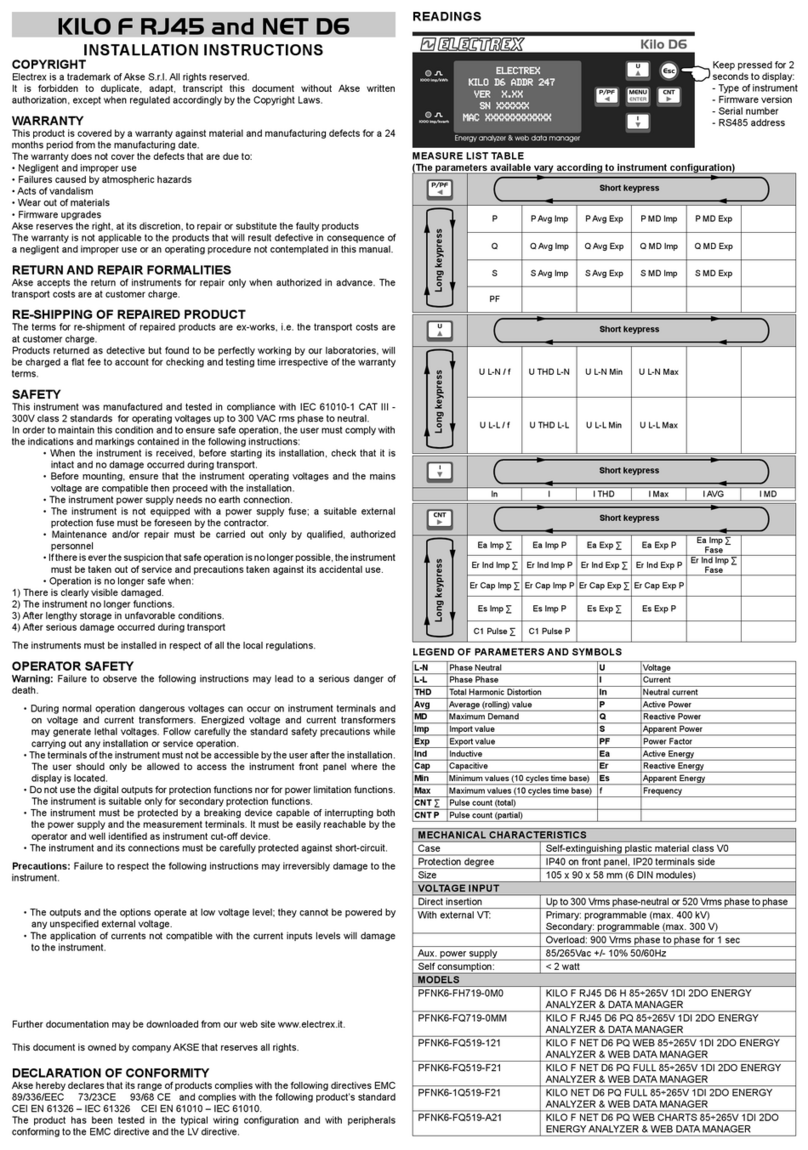

INTRODUCTION .............................................................................................................................. 3

1.1 COPYRIGHT........................................................................................................................ 3

1.2 WARRANTY ........................................................................................................................3

1.3 RETURN AND REPAIR FORMALITIES .............................................................................. 3

1.3.1 RE-SHIPPING OF REPAIRED PRODUCT .................................................................. 3

1.3.2 Return Material Authorization (RMA form) ................................................................... 4

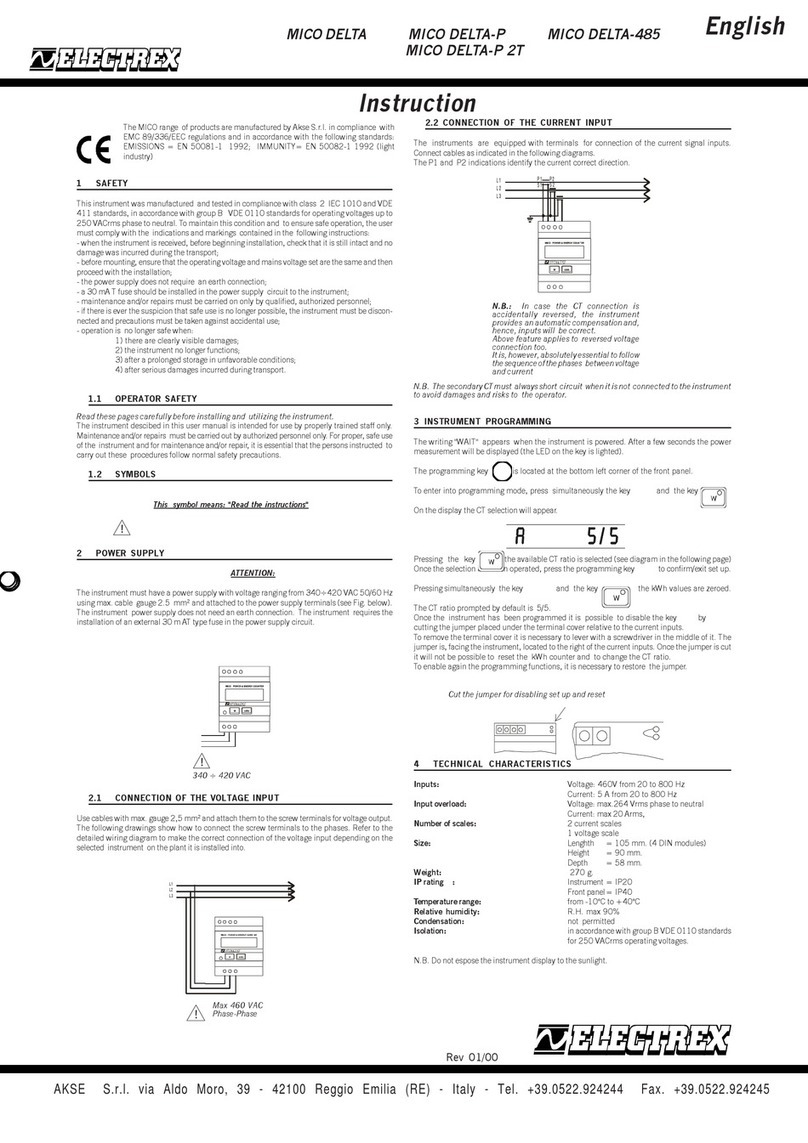

2Safety......................................................................................................................................... 5

2.1 Operator safety .................................................................................................................... 5

3Mounting .................................................................................................................................... 6

3.1 Instruments size (mm) ......................................................................................................... 6

3.2 Optional modules size (mm) ................................................................................................ 6

3.3 Fixing and blocking .............................................................................................................. 6

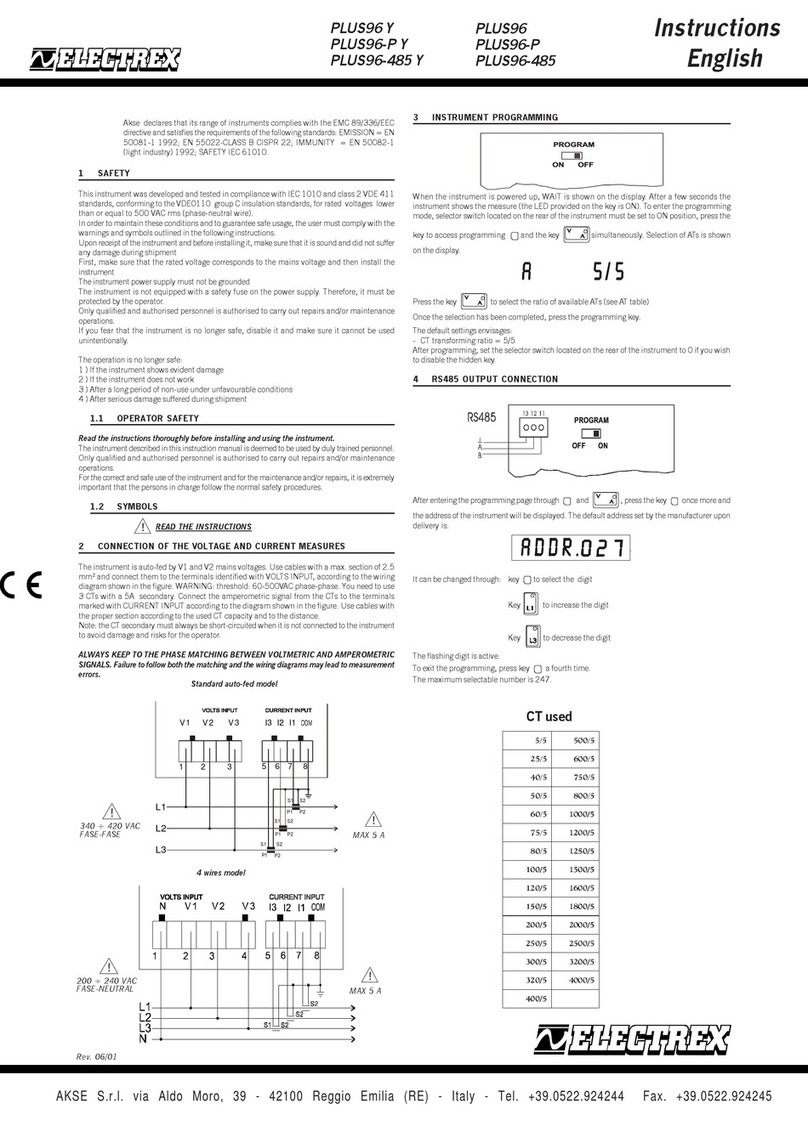

4Wiring diagrams......................................................................................................................... 7

4.1 Power supply ....................................................................................................................... 7

4.2 Measurement connections................................................................................................... 7

4.2.1 Voltage connection........................................................................................................ 7

4.2.2 Current connection ........................................................................................................ 7

4.2.3 4W Star connection (4 wire) .......................................................................................... 8

4.2.4 3W Delta connection (3 wire) ........................................................................................ 9

4.2.4.1 Connection with 2 CTs on L1 and L3 ................................................................... 9

4.2.4.2 Connection with 2 CTs on L1 and L2 ................................................................. 10

4.2.5 2 Wire connection (single phase) ................................................................................ 10

4.2.6 2 Wire connection (bi-phase) ...................................................................................... 11

4.3 Outputs connection............................................................................................................ 11

4.4 Optional modules connection............................................................................................. 12

4.4.1 RS485 Option.............................................................................................................. 12

4.4.2 RS232 Option.............................................................................................................. 13

4.4.3 Dual 4-20 mA analog output option............................................................................. 13

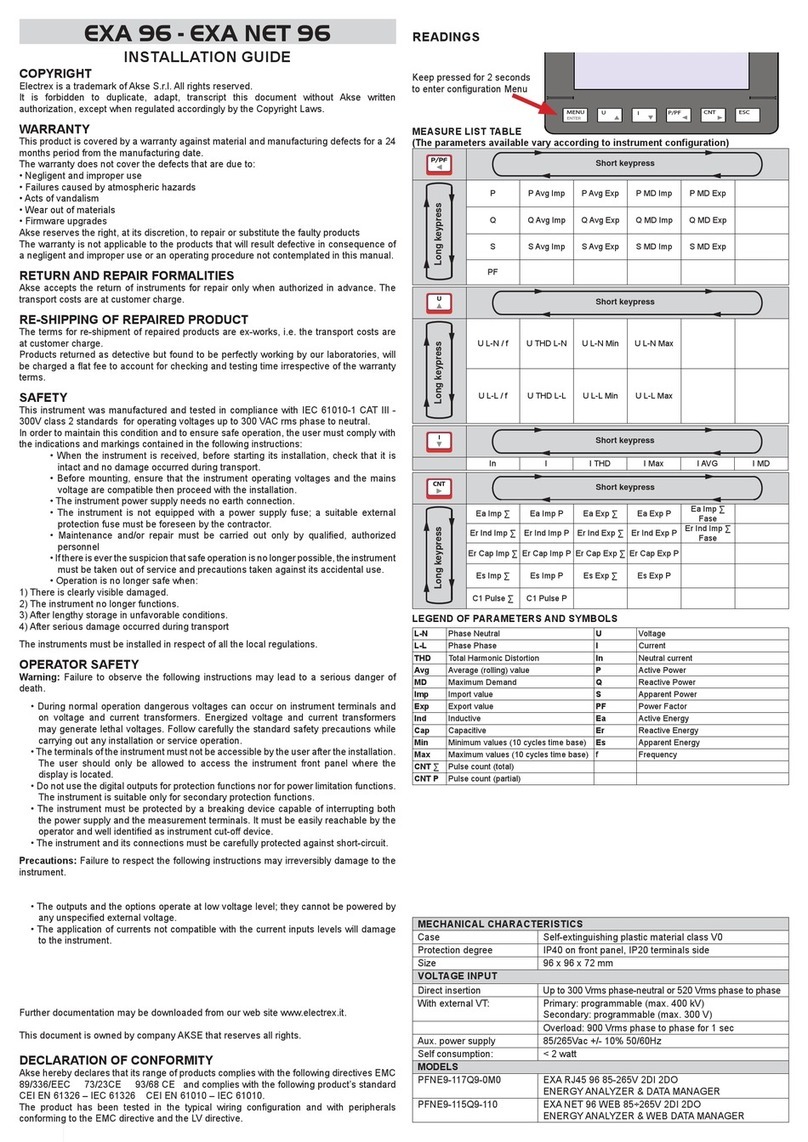

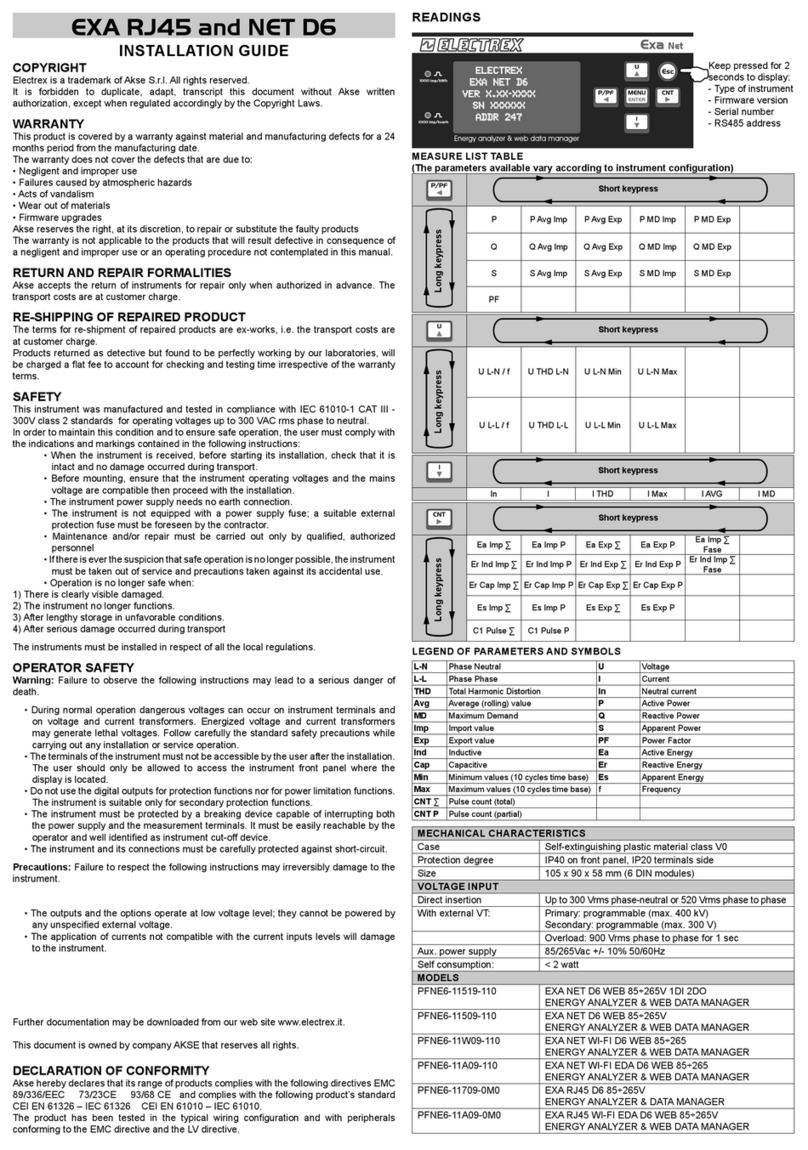

5Instrument use ......................................................................................................................... 14

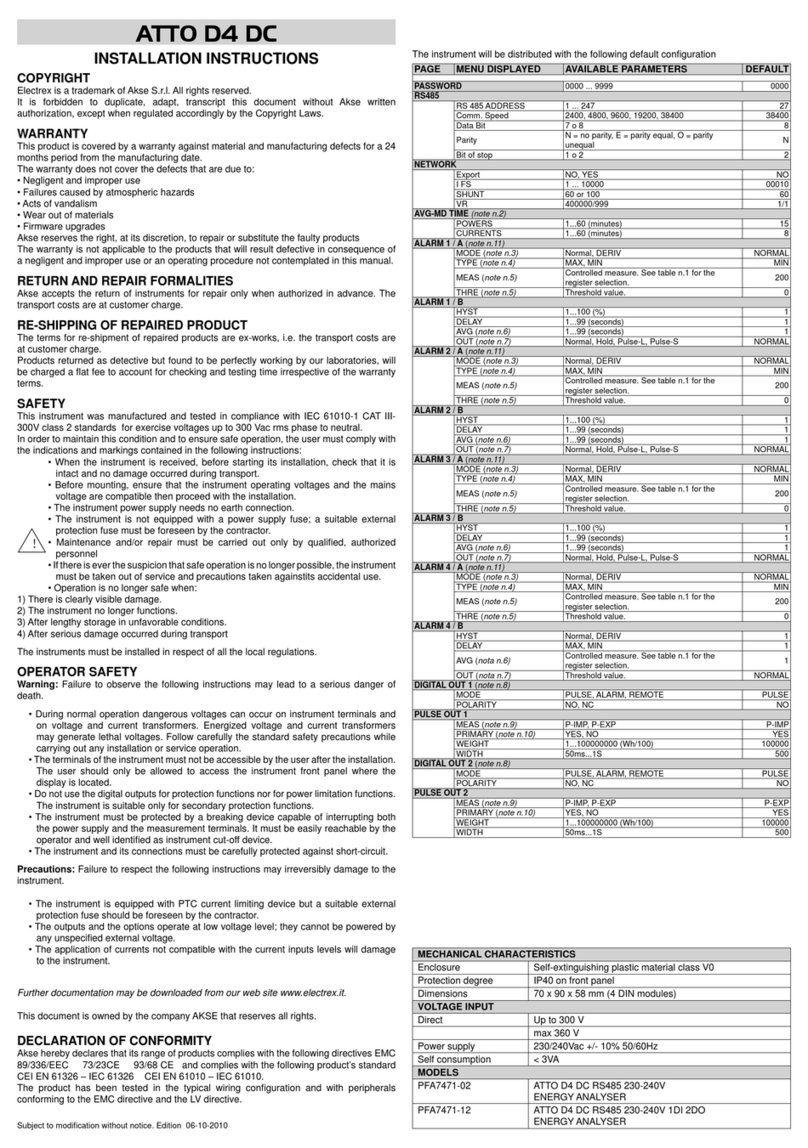

5.1 Instrument set up ...............................................................................................................14

5.1.1 Set up sequence ......................................................................................................... 15

5.1.2 Configuration procedure.............................................................................................. 16

5.1.2.1 Electrical system configuration........................................................................... 16

5.1.2.2 Communication characteristics configuration..................................................... 18

5.1.2.3 Digital Outputs configuration .............................................................................. 18

5.1.2.4 Pulse characteristics configuration..................................................................... 19

5.1.2.5 Alarm configuration ............................................................................................ 20

5.1.2.6 4-20 mA Analog Outputs configuration. ............................................................. 22

5.1.2.6.1 Alarms and 4-20 mA output configuration for the average (AVG) parameters .............. 23

5.1.2.7 Clock calendar configuration (for X3M-D only) .................................................. 24

5.1.2.8 Contrast adjustment ........................................................................................... 25

5.1.2.8.1 Time zones ..................................................................................................................... 26

5.1.3 Reset Procedure ......................................................................................................... 30

5.2 Readings............................................................................................................................ 31

5.2.1 Readings selection keys.............................................................................................. 31

5.2.1.1 Voltage and Frequency readings ....................................................................... 31

5.2.1.2 Current readings ................................................................................................ 31

5.2.1.3 Powers ............................................................................................................... 32

5.2.1.4 Power Factor...................................................................................................... 34

5.2.1.5 Energies ............................................................................................................. 34

5.2.1.6 Tariff Energies and Tariff Maximum Demand (for X3M-D only) ........................ 35

5.2.1.7 Calendar Clock (for X3M-D only) and Life Time................................................. 36