Elektrogas VMM User manual

Printed in Italy - EE163/0704

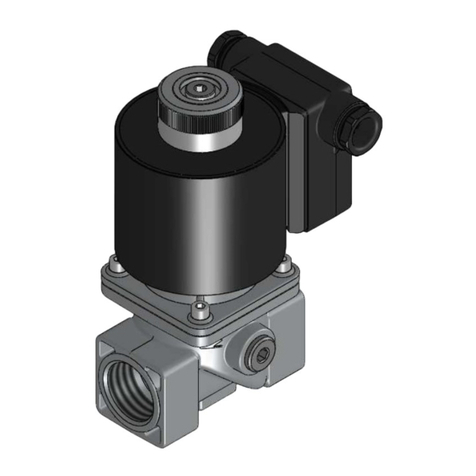

VMM

Multiple safety solenoid valve

for Gas regulating trains

DN32 … DN50

VMM402AS30

Certified Quality System

www.elektrogas.com

2Printed in Italy - EE163/0704

VMM

Multiple safety solenoid valve

for gas regulating trains

Class A - Group 2

The VMM type valve is a combination of two solenoid

valves in an only compact and versatile valve housing.

This device is suitable for air or gas blocking and

releasing controls (with one or two stages operation),

required in gas power burners, atmospheric gas boiler,

furnaces and others gas consuming appliances.

The VMM type valve is made in accordance with EN161

standard (EC type examination certificate no.

0063AQ1350).

1- Features

Inlet/outlet connection flanges are easy detachable

to simplify the installation.

Provided with bilateral G1/4” pressure gauges in all

pressure chambers.

Optional G1/8” connection for closed position

indicator micro switch.

Fine mesh filter incorporated prevents dirty

contamination of the seal seat.

Maximum operating pressure 200 mbar or 360

mbar.

Suitable for air and non-aggressive gases (EN 437,

1, 2 and 3 families).

Easy adjustable flow rate, fast stroke and slow

opening time.

Qualified for continuous service (100% ED) and

endless ON/OFF cycles.

Coil insulation is class H (180°C).

Terminal box with PG connector.

Provided with a power saving electronic device, to

reduce power consumption and working

temperature.

Valves are 100% tested by computerized testing

machineries and are fully warranted.

For valve identification see the following charts.

WARNING

- This control must be installed in compliance with

the laws in force.

- Read instructions before use.

- Elettromeccanica Delta S.p.a. reserves the right

to update or make technical changes without

prior notice.

Fig. 1

2- Technical specifications

Connections ………………. Gas threaded ISO 7/1

Rp1¼, Rp1½ and Rp2

Flanged PN16 - ISO 7005

with optional kit for

DN40 and DN50

By-pass size ………………. 1/2" and 1"

Voltage rating ………………230 VAC 50/60 Hz

Voltage on request …………110 VAC 50/60 Hz

Voltage tolerance …………. -15% / +10%

Power consumption ………. 90W (working)

by-pass 1/2" 25W

by-pass 1" 45W

Max. opening current ……...2A for 1sec.

Environment temperature …-15°C / +60°C

Max. working pressure …… 200 / 360 mbar

Flow capacity ……………… see charts

Disc sealing ……..………… NBR

Closing time ……………….. < 1 sec.

Protection class …………… IP 54 (EN60529)

Cable gland ………………...PG9

Overall dimensions ……….. see charts

3Printed in Italy - EE163/0704

3- Operation

The VMM type valve is a safety shutting device using

auxiliary power supply.

The first valve (A) is a fast opening solenoid valve that is

safety. When it is de-energized, the spring pushes on

the seal disc, keeping the gas passage closed. Now, the

inlet chamber is under the gas line pressure, and it

forces on the disc too, improving the seal.

When the coil is powered the valve opens rapidly,

against the strength of the spring and gas pressure.

If the power supply is shut off, the valve rapidly closes,

interrupting the gas flow.

Equally, the second valve (B) may be a fast opening or a

slow opening solenoid valve to adjust the gas flow, with

a first adjustable fast stroke and a second adjustable

slow stroke (see the Service Instruction Section).

It is possible connect a third by-pass valve (C), which

performs by driver stage or to obtain a second fast

(slow) stroke or both.

4- Accessories

A fine mesh filter is provided, to prevent dirty

contamination of the seal seat. However, an external

strainer must be installed upstream of the unit.

Each pressure chamber is provided with bilateral G1/4"

gauges, to connect min/max adjustable pressure

switches, leakage tester or other gas equipments.

On request, valves are supplied with a G1/8” connection

on the bottom, to installed a closed position indicator

micro switch. An adapting rod is provided too.

WARNING

The assemblage of any accessories could exclude

the fitting of other devices.

5- Coil features

The continuous service (100% ED) causes inevitable coil

heating, depending of working environment. This

situation is absolutely normal and has not to worry. To

improve the coil cooling, install the unit allowing free air

circulation.

Valve is provided with a power saving electronic device.

It has two stages of operation: full power is supplied to

the coil while the valve is opening; low power is supplied

while the valve is open.

Coil and terminal box are provided with suitable gaskets,

to avoid water and dirty contamination (see the Service

Instruction Section).

Fig. 2

6- General information

Backpressure sealing is compliant with the Class A:

the maximum backpressure admitted, with leakage

within the EN161 requirements, is 150mbar.

Maximum torsional stresses admitted are compliant

with the Group 2 of the EN161 standard.

Recommended testing pressure is 1500 mbar Max.

All components are design to withstand any

mechanical, chemical and thermal condition

occurring during typical service.

Effective impregnation and surface treatments has

been used to improve mechanical sturdiness,

sealing and resistance to corrosion of the

components.

Valves are suitable for use with air and non-

aggressive gases included in the 1, 2 and 3 families

(EN 437).

Materials in contact with gas:

•Aluminium

•Brass

•Stainless steel

•Plated steel

•Anaerobic adhesive

•Nitrile rubber (NBR)

•Polytetrafluoroethylene (PTFE)

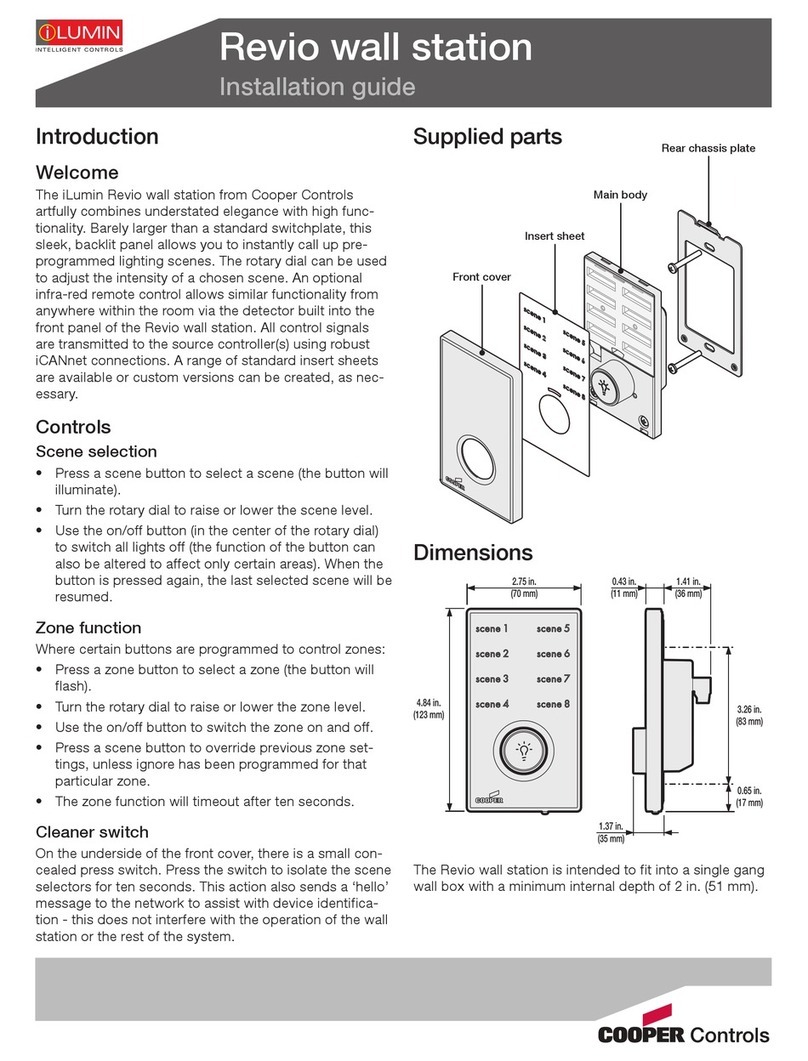

1 = Adjustable pressure switch (Min)

2 = Adjustable pressure switch (Max)

3 = Valve leakage tester

4 = Limit switch

5 = Limit switch

6 = Burner pressure gauge

A = First valve

B = Second valve

C = By-pass valve

X = Inlet chamber

Y = Middle chamber

Z = Outlet chamber

4Printed in Italy - EE163/0704

7- Valve identification

VMM 50 2 A S 1 0

Valve type

Connections size

32 = Rp1¼

40 = Rp1½ DN40 (1)

50 = Rp2 DN50 (1)

Max working pressure

2 = 200 mbar

3 = 360 mbar

Supply voltage

A = 230V 50/60Hz

B = 110V 50/60Hz

Second valve type

F = fast

S = slow

By-pass valve on the Right side

(seen from the inlet)

0 = none

1 = ½” (DN15) Fast

2 = ½” (DN15) Slow

3 = 1” (DN25) Fast

4 = 1” (DN25) Slow

By-pass valve on the Left side

(seen from the inlet)

0 = none

1 = ½” (DN15) Fast 3 = 1” (DN25) Fast

2 = ½” (DN15) Slow 4 = 1” (DN25) Slow

(1) Optional kit

Fig. 3

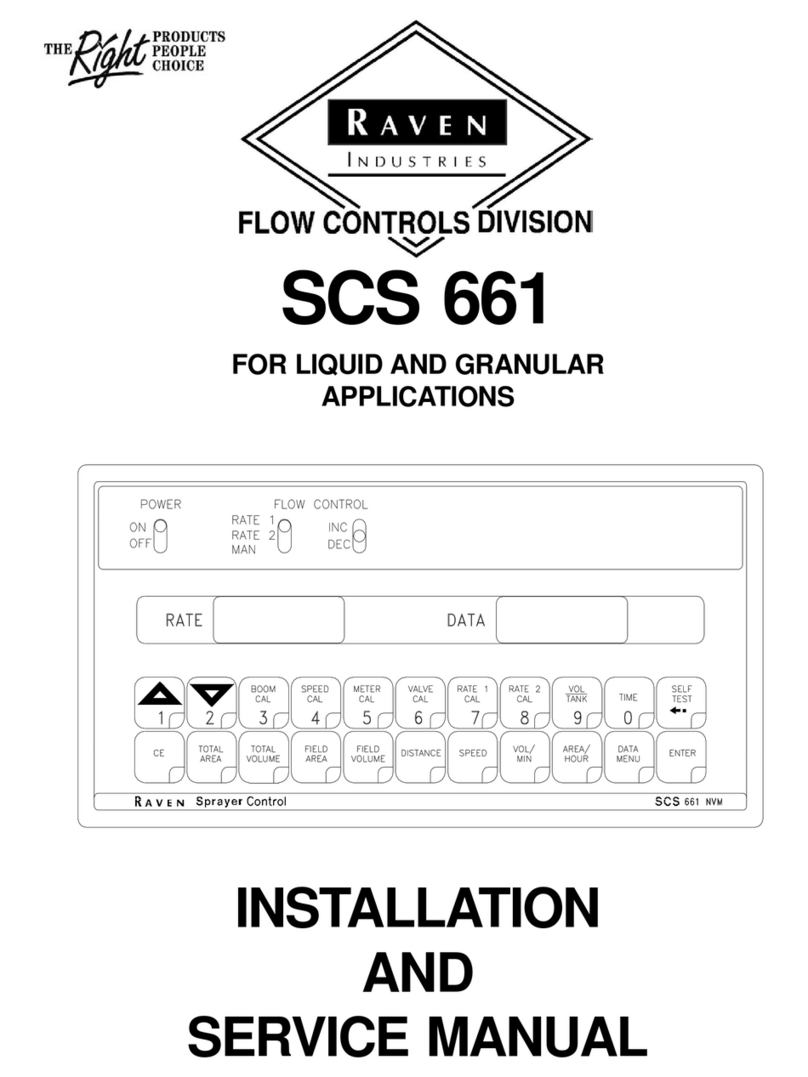

Model Overall dimensions (mm)

A B C D E F G H Weight

(Kg)

VMM….F00 211 280 105 138 170 230 148 13,0

VMM….S00 211 280 105 138 245 305 148 13,7

VMM….S10 211 280 105 138 245 305 200 15,3

VMM….S20 211 280 105 138 245 305 200 15,5

VMM….S30 211 280 105 138 245 305 220 16,3

VMM….S40

Gas threaded

according to

ISO 7/1

211 280 105 138 245 305 220 16,5

5Printed in Italy - EE163/0704

mbar

2

mmH O

NaturalGas

TownGas

Air

m³/h

1"¼

1"½

2"

8- Loss of pressure

Formula of conversion from air

to other gases

Gas type Specific gravity

(Kg/m³) K

Natural Gas 0.80 1.25

Town Gas 0.57 1.48

LPG 2.08 0.77

Air 1.25 1.00

+15°C, 1013 mbar, dry

6Printed in Italy - EE163/0704

9- Valve installation

Verify the line pressure is lower of the maximum working

pressure admitted to the valve.

Check correspondence of flow direction with arrow

printed on valve body.

Check correct alignment of connecting pipes and allow

enough space from the walls to allow free air circulation.

Remove the end caps and make sure no foreign

body is entered into the valve during handling.

Install in an area that is protected from rain and

water splashes or drops.

1. Put sealing agent onto the pipe thread (avoid

excessive quantities of fittings glue which could

enter in the valve and damage the seal seat).

2. Screw the pipes using proper tools only. Do not use

unit as lever because damage to the valve stem

could result. Remove connection flanges to simply

installation.

Avoid overtightening and mount tension free.

Following chart shows the maximum values of bending

moment (Fmax), torque (Tmax) and screws driving torque

(Cmax), according to EN13611.

Connection Fmax

(Nm) t<10 s Tmax

(Nm) Cmax

(Nm)

Rp1¼ 475 160 -

Rp1½ 610 200 50

Rp2 1100 250 50

Fig. 4

Valve may be mounted with coil in horizontal or vertical

position. Coil may be oriented 360 degrees in any

direction.

10- Electrical connections (IEC 730-1)

Check correspondence between valve voltage rating and

line power supply, before making any electrical

connections.

1. Switch off power supply and remove protection

cover.

2. Connect power cables to rectifier circuit terminal

board.

3. Should cables pass through originally closed

opening, use the rubber disc placed underneath the

box plug to close any other opening.

4. Screw back the box cover, taking care to use all

gaskets properly, because this could condition the

valve life duration.

Fig. 5

WARNING

•To prevent product damage and dangerous

situations, read the Installation and Service

Instructions carefully.

•Turn off all power before servicing any part of

the system.

•Perform leak and functional tests after mounting.

A gas leak detection spray may be used also.

•Coil and terminal box must be replaced with

identical spare parts only.

•If the coil is turned, make sure the cap (brake) is

properly tightened and the coil is locked.

•Use all gaskets properly (void warranty).

•All wiring must be in compliance with local and

national codes.

•Make sure all works are performed by qualified

technicians only.

Tmax

Fmax

7Printed in Italy - EE163/0704

11- Flow rate adjustment (Vmax)

Flow rate may be adjusted from 0 cubic meters/h up to

the maximum admitted:

Fast valve type

1. Remove coil fastener cap.

2. Using a 4 mm Allen wrench, remove the locking

dowel.

3. Located under the locking dowel is the flow

regulation screw. Use the Allen wrench to set it.

4. Turn wrench clockwise to decrease or counter-

clockwise to increase flow rate (factory setting is

max. flow rate).

5. When adjustment is completed, screw back the

locking dowel and cap.

Slow valve type

1. Remove plastic cap.

2. Keeping the outer screw fixed, use a screw driver to

turn the internal screw clockwise to decrease or

counter-clockwise to increase flow rate (factory

setting is max. flow rate).

3. When adjustment is completed, screw back the

plastic cap.

12- Fast stroke adjustment (Vstart)

Fast flow section may be adjusted:

1. Remove plastic cap.

2. Using a 7 mm wrench, turn the outer screw

clockwise to decrease or counter-clockwise to

increase the initial fast stroke.

3. When adjustment is completed, screw back the

plastic cap.

NOTE: the flow rate regulation can not be lower than the

fast flow section.

13- Opening time adjustment (T)

To regulate opening time, turn the screw located on the

side of the brake. One fourth of a turn clockwise

increases opening time by 2÷3 s, up to a maximum of

about 25 s (slow run).

Factory setting is about 12÷14 s.

WARNING

•In the slow valve type, perform the fast stroke

adjustment before of the flow rate adjustment.

•Make sure that capacity adjustments are made

while burner is working.

•Check the regulation is not changed during

reassembly.

•Adjustments below 40% of capacity are

unadvisable because they may cause

turbulence.

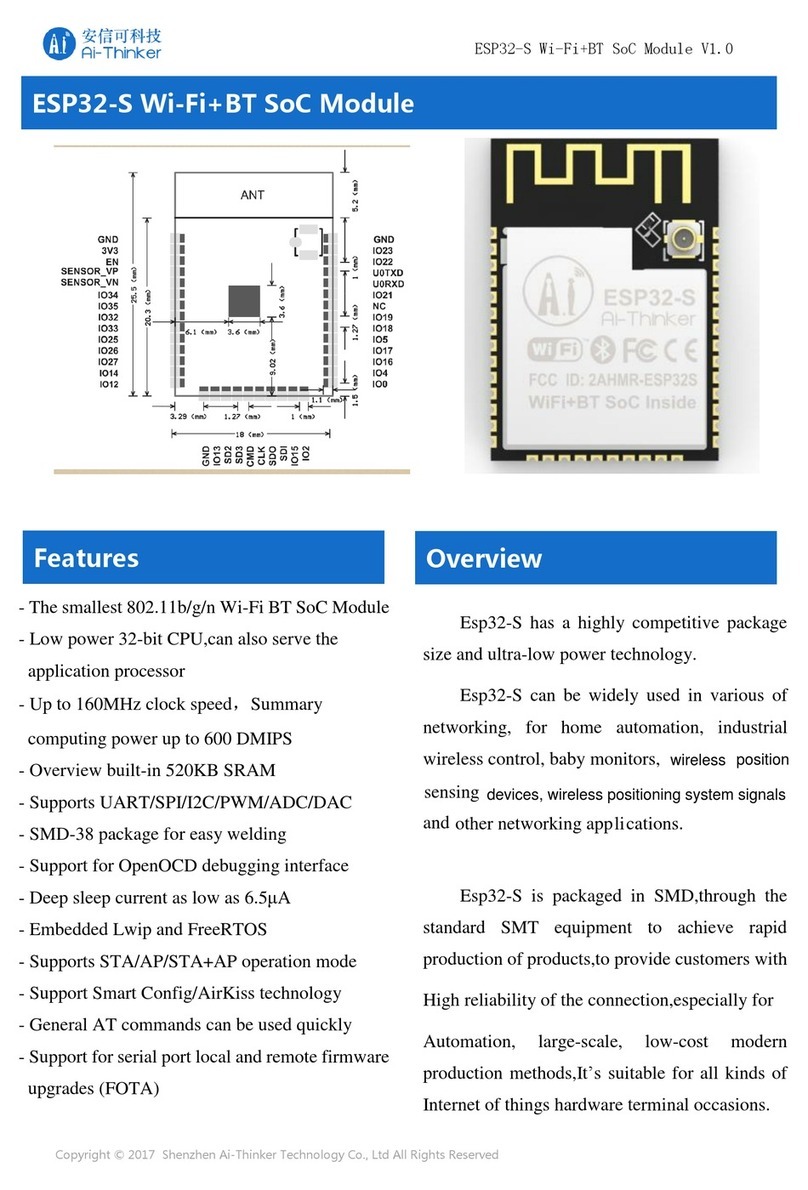

Fig. 6

1 = Connection flange

2 = G1/4" pressure gauge

3 = Filter

4 = Electrical connections

5 = By-pass flow adjustment

6 = Opening time adjustment (T)

7 = Rapid stroke adjustment (Vstart)

8 = Flow adjustment (Vmax)

A = First valve

B = Second valve

C = By-pass valve

X = Inlet chamber

Y = Middle chamber

Z = Outlet chamber

8Printed in Italy - EE163/0704

13- Maintenance

To maintain a good performance of the system, almost

once a year, an inspection of the valve is recommended.

External inspection

Turn off all power before servicing any part of the

system.

Check the conditions of the terminal board gasket. If

gasket is deteriorated, replace it with a new one.

Check the electrical connections are clean, dry and

correctly tightened.

Check the conditions of pipe connections: cover them

with a soap solution and check for leakages.

Internal inspection

To make an internal inspection of the valve, do the

following:

1. Close ball valve upstream the system.

2. Unscrew the fastening cup (or brake) and remove

the coil.

3. Using an Allen key, remove the screws on the upper

flange, in cross way. The gas in the valve will come

out during this step.

4. Check the hydraulic brake is free of oil leakages

(small leakages are admitted). If it’s necessary,

replace it with a new one.

5. Check the main gasket and, if it’s necessary,

replace it with a new one.

6. Clean the internal side of the stem with a clean cloth

and compressed air.

7. Remove the spring and blow it with compressed air.

Check the spring is corrosion free. Take attention to

the assembly direction of the spring.

8. Check the wear conditions of the sliding rings and, if

it’s necessary, replace them.

9. Clean the plunger assembly with a clean cloth and

compressed air.

10. Check the conditions of the sealing gasket. If gasket

is deteriorated, replace it with a new one.

11. Clean the sealing lip with a clean cloth. Do not use

tools, because a lip damage could result.

12. Reassemble the valve following the inverse

sequence.

To assemble the sliding rings, wind them onto a lower

diameter (ex. Screw driver), then insert them from the

top.

When reassembling, take attention to the correct

position of the sliding rings and spring.

To clean the filter disconnect the valve body from

connection flanges.

Fig. 7

When the reassembly is finished, verify the correct

sealing between the upper flange and the valve body:

1. Open ball valve to restore pressure into the valve.

2. Apply a soap solution between the upper flange and

the valve body and check for leakages.

3. Remove the soap solution with a clean cloth, before

to reassemble the coils.

WARNING

•When reassemble, use all gaskets properly.

•Perform functional test after mounting.

•All works must be executed by qualified

technicians only and in compliance with local

and national codes.

Cap

O-ring

Stem

Scre

w

Upper flange

Spring

Sliding ring

Plunge

r

Disc + gasket

Coil assembly

Brake

O-ring

This manual suits for next models

1

Table of contents

Other Elektrogas Control Unit manuals

Elektrogas

Elektrogas VMM User manual

Elektrogas

Elektrogas VML Series User manual

Elektrogas

Elektrogas VML2 User manual

Elektrogas

Elektrogas EVRM-NA User manual

Elektrogas

Elektrogas EVRM-NC User manual

Elektrogas

Elektrogas VMRNA User manual

Elektrogas

Elektrogas EVRM-NA Series User manual

Elektrogas

Elektrogas VML0 User manual

Elektrogas

Elektrogas VMR01OTN User manual

Elektrogas

Elektrogas VMH DN Series User manual