3Printed in Italy - EE162/0704

3- Operation

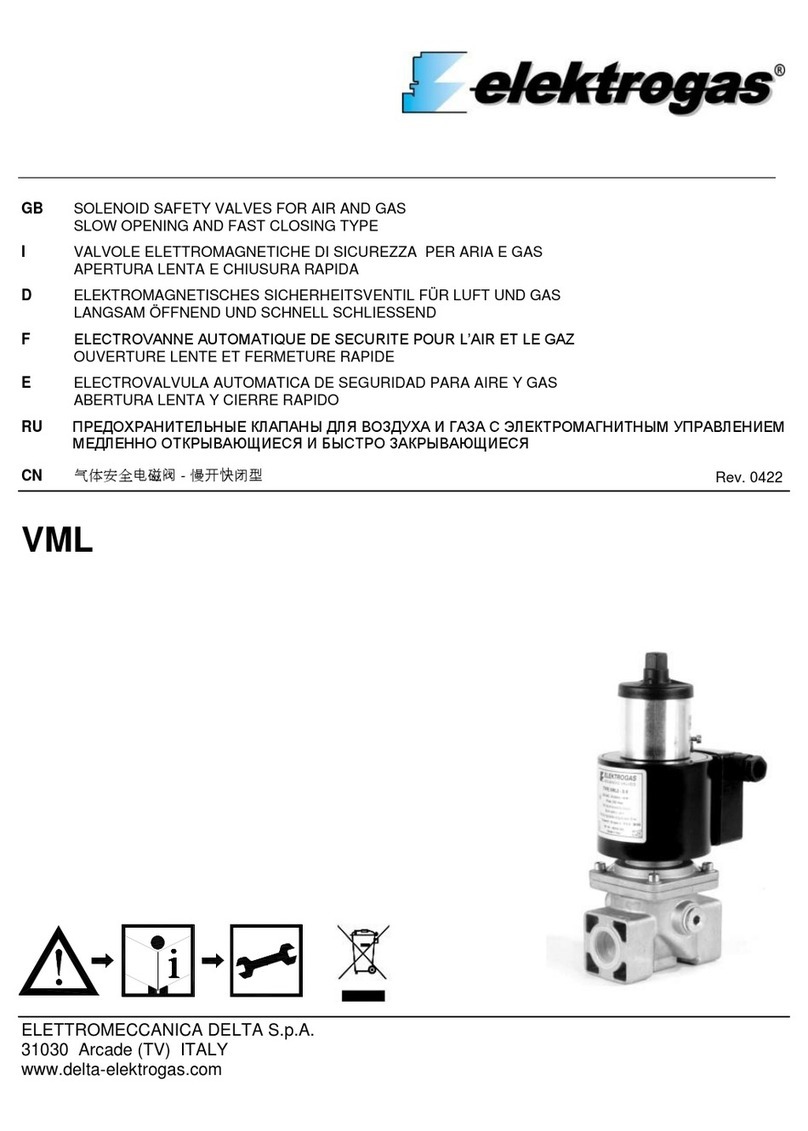

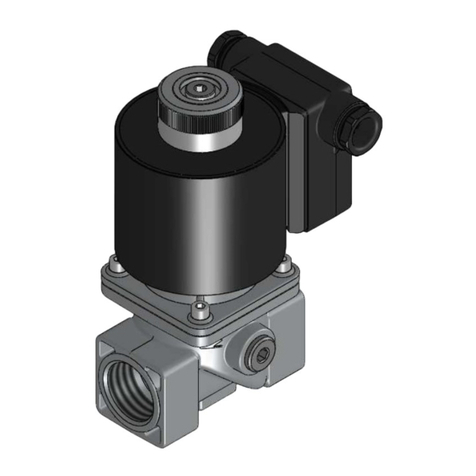

The VML type valve is a safety shutting device using

auxiliary power supply.

When it is de-energized, the spring pushes on the seal

disc, keeping the gas passage closed. Now, the inlet

chamber is under the gas line pressure, and it forces on

the disc too, improving the seal.

When the coil is powered the valve opens rapidly or

slowly, against the strength of the spring and gas

pressure. The rapid stroke may be adjusted using the

regulating screw on the top (see the Service Instruction

Section), to adjust the initial gas flow. Main flow and

opening time can be adjusted also.

If the power supply is shut off, the valve rapidly closes,

interrupting the gas flow.

4- Accessories

A fine mesh filter is provided, to prevent dirty

contamination of the seal seat. However, an external

strainer must be installed upstream of the valve.

Inlet pressure area is provided with bilateral G1/4"

gauges, to connect min/max adjustable pressure

switches, leakage tester or other gas equipments.

Flanged models are provided with gauges in the outlet

chamber too

On request, valves are supplied with a G1/8” connection

on the bottom, to installed a closed position indicator

micro switch (from 3/4" to 3"). An adapting rod is

provided too.

5- Coil features

The continuous service (100% ED) causes inevitable coil

heating, depending of working environment. This

situation is absolutely normal and has not to worry. To

improve the coil cooling, install the valve allowing free air

circulation.

The models from 1"¼ up to 3" are provided with a power

saving electronic device. It has two stages of operation:

full power is supplied to the coil while the valve is

opening; low power is supplied while the valve is

opened.

Coil and terminal box are provided with suitable gaskets,

to avoid water and dirty contamination (see the Service

Instruction Section).

Fig. 2

6- General information

Backpressure sealing is compliant with the Class A:

the maximum backpressure admitted, with leakage

within the EN161 requirements, is 150mbar.

Maximum torsional stresses admitted are compliant

with the Group 2 of the EN161 standard.

Recommended testing pressure is 1500 mbar Max.

All components are design to withstand any

mechanical, chemical and thermal condition

occurring during typical service.

Effective impregnation and surface treatments has

been used to improve mechanical sturdiness,

sealing and resistance to corrosion of the

components.

Valves are suitable for use with air and non-

aggressive gases included in the 1, 2 and 3 families

(EN 437).

Materials in contact with gas:

•Aluminium

•Brass

•Stainless steel

•Plated steel

•Anaerobic adhesive

•Nitrile rubber (NBR)

•Polytetrafluoroethylene (PTFE)