Elektrogas VMR Series User manual

elektrogas.com

VMR

VMR-OTN

Safety solenoid valves for gas

Fast opening and fast closing type

DN8 … DN150

EE161 -0108

ELEKTROGAS – TECHNICAL MANUAL

2-13

VMR

VMR-OTN

Safety solenoid valves for gas

Fast opening and fast closing type

Contents

Description ………………………………………….. 2

Features …………………………………………….. 2

Functioning and application ………………………. 3

Accessories and optionals ………………………… 4

Technical specifications …………………………… 4

Gas flow chart (pressure drop) …………………… 6

Ordering information ………………………………. 8

Standards and approvals …………………………. 9

Installation, adjustment and servicing ……………..10

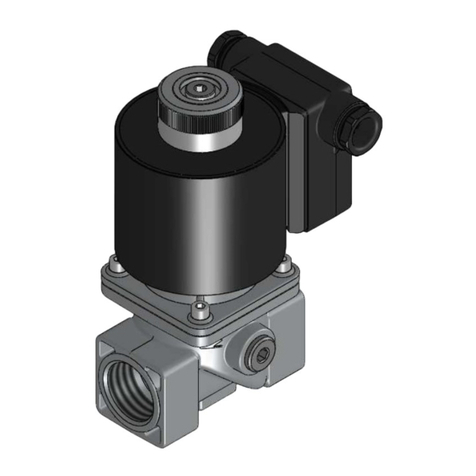

Description The VMR type valve is a fast opening single-stage solenoid valve, normally closed (open when

energized). This type of device is suitable for air or gas blocking and releasing controls, required

in gas power burners, atmospheric gas boilers, industrial kilns and others gas consuming

appliances.

Features The valves are made of aluminum alloy die-cast (or hot-pressed brass for OTN versions), with a

wide range for inlet/outlet connections from DN 8 up to DN 150.

Suitable for use with air and non-aggressive gases included in the 1, 2 and 3 families (EN 437).

This valve is open only when energized: if, for any reason, power supply goes down, the valve

closes immediately (intrinsic safe).

Qualified for continuous service (100% ED).

An incorporated fine mesh filter protects the valve seat and disc as well as downstream

components and prevents dirty contamination (except brass models).

Provided with G1/4 pressure gauge on two sides in the inlet chamber (except brass models).

Flanged models are provided with gauges in the outlet chamber too. Other gauge points on

request.

Provided with G1/8 connection on the bottom for closed position indicator micro switch from

DN65 to DN150 (on request from 3/4" to 2").

The coils are provided with ISO 4400 plug or with terminal box. Both systems are provided with

suitable cable gland to avoid water and dirty contamination.

Pipe connections meet group 2 and backpressure sealing is compliant with class A, according

to EN161 requirements.

All components are designed to withstand any mechanical, chemical and thermal condition

occurring during typical service. Effective impregnation and surface treatments have been used

to improve mechanical sturdiness, sealing and resistance to corrosion of the components.

Valves are 100% tested by computerized testing machineries and are fully warranted.

WARNING

This control must be installed in compliance with the rules in force.

ELEKTROGAS – TECHNICAL MANUAL

3-13

Functioning and

application The VMR type valve is a safety shutting device using auxiliary power supply.

When it is de-energized, the spring pushes on the seal disc, keeping the gas passage closed.

Now, the inlet chamber is under the gas line pressure, and it forces on the disc too, improving

the seal.

When the coil is powered the valve opens rapidly, against the strength of the spring and gas

pressure. The flow may be adjusted using the regulating screw on the top (see the Installation,

adjustment and servicing section).

If the power supply is shut off, the valve rapidly closes, interrupting the gas flow.

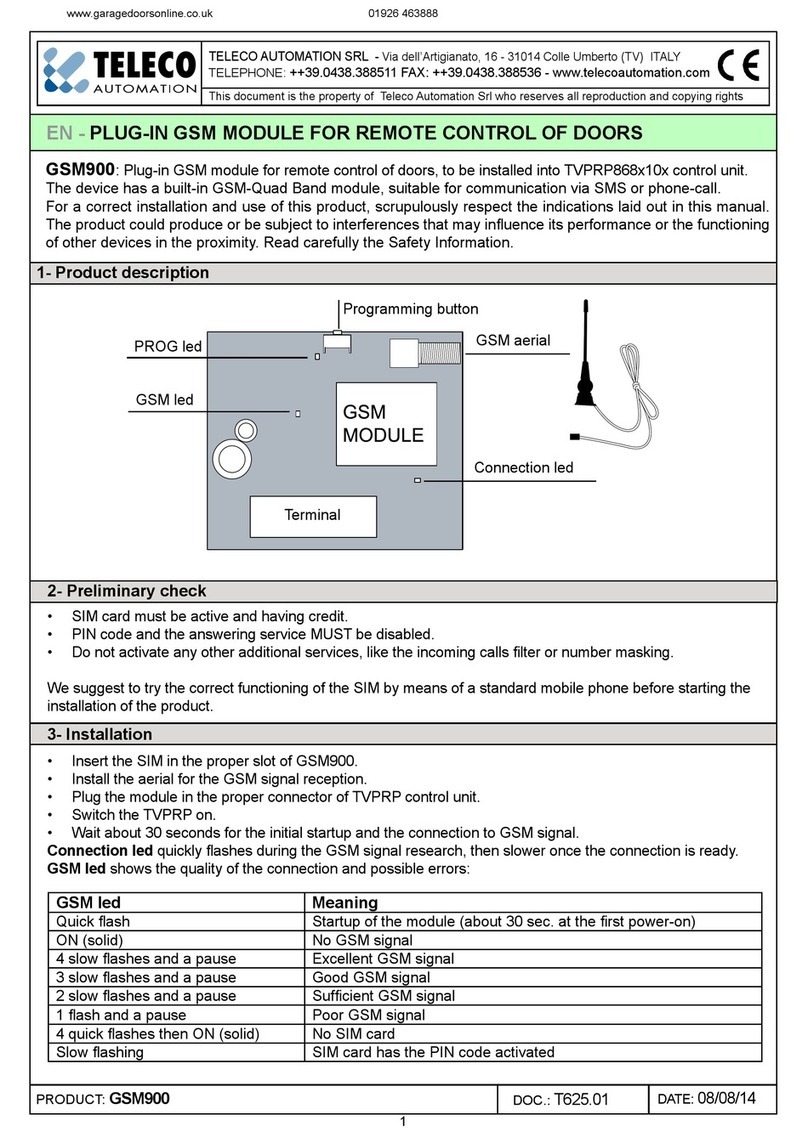

Fig.1

This kind of valve is normally installed as safety and regulating device in gas trains, for industrial

applications and gas firing systems.

Figure 2 shows an example of installation.

Fig.2

WARNING

Location and mode of installation must be in compliance with local rules in force.

Fast opening

solenoid valve

Gas

network

Consumer

Slow opening

solenoid valve

Ball

valve

Valve

leak

teste

r

Gas

filter

Pressure

regulator

Pressure

switch

Pressure

gauge

ELEKTROGAS – TECHNICAL MANUAL

4-13

Accessories and

optionals A fine mesh filter is provided, to prevent dirty contamination of the seal seat. However, an

external strainer must be installed upstream of the valve. Brass models are available without

internal filter only.

Inlet pressure chamber is provided with bilateral G1/4 gauges, to connect manometers,

pressure switches, leakage tester or other gas equipments. Flanged models are provided with

gauges in the outlet chamber too. Brass models are available without gauges only.

Models from DN65 to DN150 are provided with G1/8 connection on the bottom for closed

position indicator micro-switch (on request from 3/4" to 2"). To install the micro-switch the

installing kit must be required.

The threaded models Rp11/2 and Rp2 can be provided with flanged connections using an

optional kit.

Technical

specifications Tab. 1

Connections Gas threaded ISO 7/1 from Rp1/4 to Rp2

Flanged PN16 – ISO 7005 from DN40 to DN150

Voltage rating 230 VAC 50/60 Hz

110 VAC 50/60 Hz

24 VAC/DC

12 VAC/DC

Voltage tolerance -15% / +10%

Power consumption see charts

Ambient temperature -15°C / +60°C

Max. operating pressure 200 mbar (20 kPa)

360 mbar (36 kPa)

Flow capacity see charts

Closing time < 1 second

Opening time < 1 second

Filter (except brass models) 600 µm, metal mesh

Protection class IP54 (EN 60529)

Cable gland ISO 16 (EN 50262) for terminal box

PG 9 for standard plug

Coil winding insulation Class H (200°C)

Coil thermal resistance Class F (155°C)

Materials in contact with gas Aluminium alloy

Brass

Stainless steel

Plated steel

Anaerobic adhesive

Nitrile rubber (NBR)

Polytetrafluoroethylene (PTFE)

ELEKTROGAS – TECHNICAL MANUAL

5-13

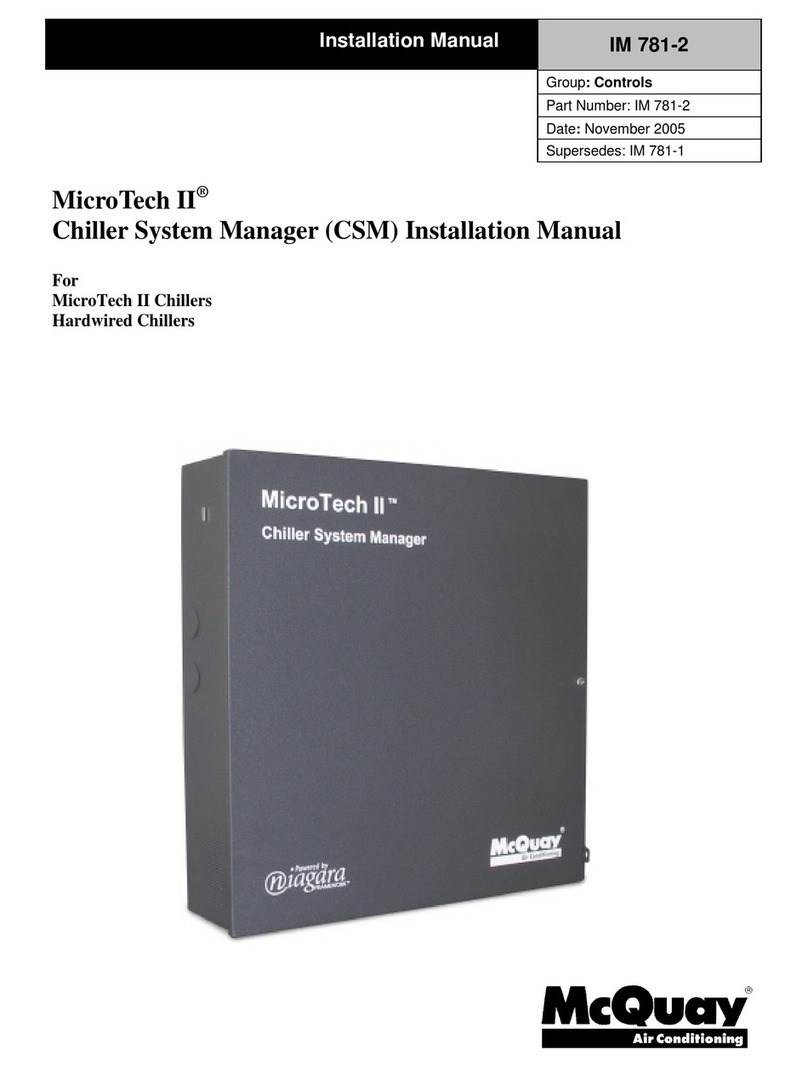

Fig.3

Tab. 2

Material and

connections

Overall dimensions

[mm]

CuZn AlSi

Power

consumption

@230VAC

[W]

Flow factor

Kvs

[m³/h] A B C D Int h

Weight

[Kg]

Rp 1/4 8 0,55 30 46 66,5 75 - - 0,27

Rp 3/8 16 0,7 30 58 95 110 - - 0,4

Rp 1/2 16 1,0 30 58 95 110 - - 0,4

Rp 3/8 20/25 (2) 2,9 88 77 124 140 - - 1,4

Rp 1/2 20/25 (2) 4,0 88 77 124 140 - - 1,4

Rp 3/4 45 9,5 88 96 150 164 - - 2,5

Rp 1 45 12,0 88 96 150 164 - - 2,5

Rp 11/4 20/80 (3) 20,0 120 153 188 220 - - 5,7

Rp 11/2 20/80 (3) 26,0 120 153 188 220 - - 5,7

Rp 2 20/80 (3) 40,0 106 156 192 230 - - 6

DN 40 (1) 20/80 (3) 26,0 150 193 188 262 110 4x18 7,4

DN 50 (1) 20/80 (3) 40,0 165 196 192 274 125 4x18 8

DN 65 60/240 (3) 63,0 200 305 266 355 145 4x18 14

DN 80 60/240 (3) 80,0 200 305 266 355 160 8x18 14

DN 100 80/320 (3) 148,0 252 350 352 492 180 8x18 36

DN 125 90/360 (3) 250,0 310 460 430 600 210 8x18 58

DN 150 90/360 (3) 315,0 310 460 430 600 240 8x23 60

(1) Optional Kit (2) 360/200mbar (3) Working/Opening

ELEKTROGAS – TECHNICAL MANUAL

6-13

AIRGAS VkV ⋅=

1

0.1

0.5

0.3

0.4

0.2

0.6

0.7

0.8

1

5

2

3

4

10

6

7

8

0.2

50

30

40

20

100

60

70

80

200

0.2

0.3

0.2

0.3

0.3

0.4

0.4

0.5

0.6

0.5

0.4

0.7

0.8

0.8

0.7

0.6

0.5

0.7

0.6

0.8

1

1

DN 125

DN 80

DN 65

DN 100

DN 150

1

100

80

108

3

2

2

2

34

3

5

4

7

6

6

5

4

6

7

5

8

78

10

30

10

20

20

20

30

40

30

60

50

60

50

40

40

50

70

60 70

80

800

200

100

80

70

100

200

300

400

500

600

300

200

400

500

300

400

500

600

700

700

800

1000

600

800

700

1000

1000

2000

5000

4000

3000

2000

2000

4000

3000

3000

5000

4000

5

2

3

4

10

8

7

6

50

20

40

30

80

70

60

100

200

300

800

700

1000

2000

5000

Rp 1/2-OTN

Rp 3/8-OTN

Rp 1½

Rp 1/2

Rp 3/8

Rp 1

Rp 3/4

Rp 1¼

Rp 2

Air

dP [mmH O]

2

dP [mbar]

V [Nm³/h]

0.1

0.3

0.2

0.6

0.5

0.4

0.7

0.8

1

2

4

3

8

7

5

6

10

3000

60

30

20

50

40

100

70

80

200

800

400

300

700

500

600

1000

2000

Natural gas

Town gas

LPG

Rp 1/4-OTN

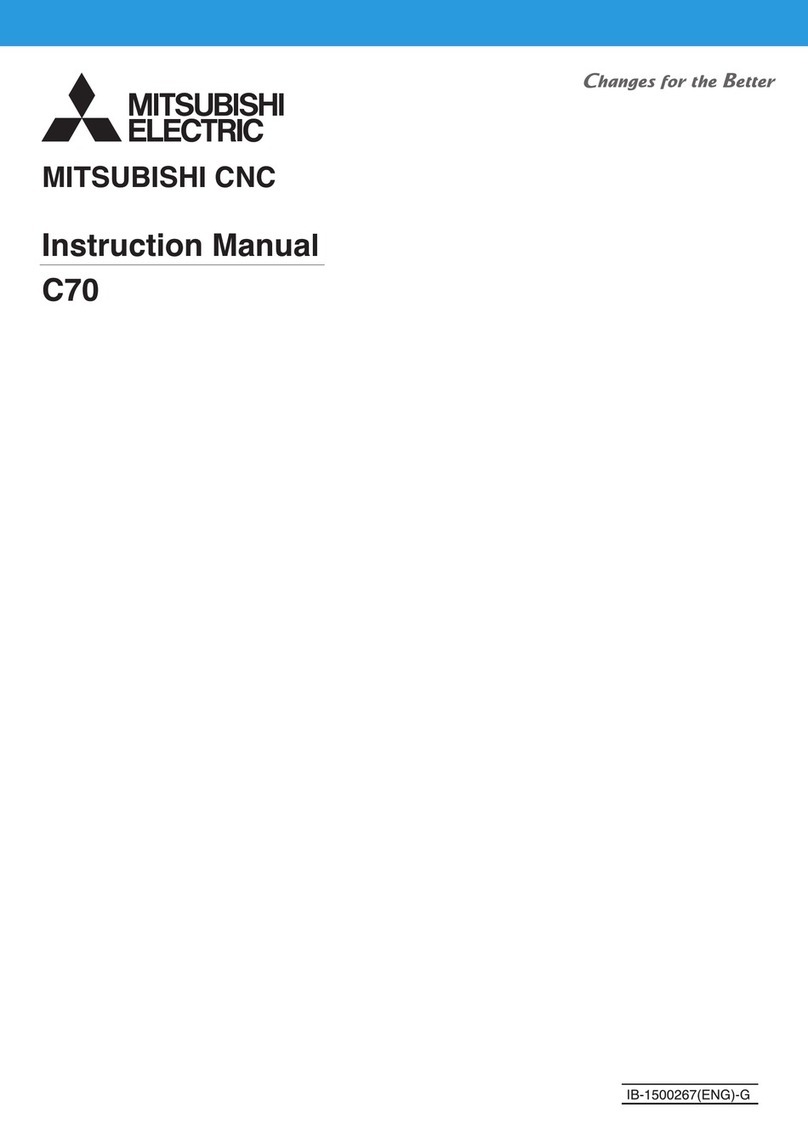

Gas flow chart

(Pressure drop)

Fig. 4

Formula of conversion

from air to other gases Tab. 3

15°C, 1013 mbar, dry

Gas type Specific gravity

ρ

[Kg/m³] GAS

.

k

ρ

251

=

Air 1,25 1,00

Natural gas 0,80 1,25

Town gas 0,57 1,48

LPG 2,08 0,77

ELEKTROGAS – TECHNICAL MANUAL

7-13

When the flow read on the diagram is referred to operating pressure instead of standard

conditions, the pressure drop ∆p read on the diagram must be multiplied for the factor:

(1+ relative pressure in bar)

Example:

In the 2” solenoid valve with an air flow of 80 Nm3/h there is a pressure drop ∆p = 5 mbar.

If we consider that 80 m3/h is the flow at 200 mbar of inlet pressure, then the pressure drop to

be consider is:

∆p = 5x(1+0,2) = 6 mbar

Normally, pressure drop and flow rate for the valves are read from the gas flow diagram.

However, the valves can also be chosen in accordance with the characteristic ”Kvs value” which

is shown in table 2.

The selection of the valve requires the calculation of the Kv under the operating conditions.

Considering only subcritical pressure drops:

2

1

p

p<∆

Kv can be calculated with the formula:

()

2

273

514 pp

tV

Kv ⋅∆

+

=

ρ

where

V = flow rate [Nm3/h]

Kv = flow factor [m3/h]

ρ= density [Kg/m3]

p1= absolute inlet pressure [bar]

p2= absolute outlet pressure [bar]

∆p = differential pressure p1-p2[bar]

t = media temperature [°C]

To the Kv value calculated from operating conditions we add an allowance of 20%, to obtain the

minimum Kvs value which the valve should have:

Kvs > 1,2 Kv

Valve must be selected considering the following:

- Pressure drops ∆p ≤0,1p1are recommended and ∆p > p1/2 are always unadvisable

- Flow velocities w ≤15 m/s are recommended and w > 50 m/s are always unadvisable.

ELEKTROGAS – TECHNICAL MANUAL

8-13

Ordering

information

Tab.4

Material and Connections 230V 110V 24V 12V

CuZn AlSi 200 mbar 360 mbar 200 mbar 360 mbar 200 mbar 200 mbar

Rp 1/4 VMR01OTN 1VMR01OTN.B1VMR01OTN.C1VMR01OTN.D1

Rp 3/8 VMR02OTN 1VMR02OTN.B1VMR02OTN.C1VMR02OTN.D1

Rp 1/2 VMR12OTN 1VMR12OTN.B1VMR12OTN.C1VMR12OTN.D1

Rp 3/8 VMR02A

1VMR0 VMR02A.B

1VMR0.B VMR02.C VMR02.D

Rp 1/2 VMR12A

1VMR1 VMR12A.B

1VMR1.B VMR12.C VMR12.D

Rp 3/4 VMR2 VMR2.B VMR22.C VMR22.D

Rp 1 VMR3 VMR3.B VMR32.C VMR32.D

Rp 1¼ VMR35 VMR35.B VMR352.C VMR352.D

Rp 1½ VMR4 VMR4.B VMR42.C VMR42.D

Threaded

Rp 2 VMR6 VMR6.B VMR62.C VMR62.D

DN 40

2VMR4F VMR4F.B VMR42F.C VMR42F.D

DN 50

2VMR6F VMR6F.B VMR62F.C VMR62F.D

DN 65 VMR72 VMR7 VMR72.B VMR7.B VMR72.C

DN 80 VMR82 VMR8 VMR82.B VMR8.B VMR82.C

DN 100 VMR92 VMR9 VMR92.B VMR9.B VMR92.C

3

DN 125 VMR932 VMR93 VMR932.B VMR93.B

Flanged

DN 150 VMR952 VMR95 VMR952.B VMR95.B

(1) Provided with DIN plug (2) Optional kit (3) Class B

The versions with inlet pressure p1≤200 mbar (20 kPa) may be order inserting the digit “2” in to

the designation.

Different voltage than 230V may be order adding to the standard designation the additional

code as shown above.

Example:

VMR72.B for a valve with DN65 flanged connections, 110VAC, 200 mbar

Manufacturer reserves the right to update or make technical changes without prior notice.

ELEKTROGAS – TECHNICAL MANUAL

9-13

Standards and

approvals The valve design meets current European approval requirements regarding safety shut-off

functions on gaseous fuels.

These products conform with the Gas Appliances Directive (90/396/EEC) and the certification

has been issued by the notified body:

GASTEC CERTIFICATION B.V.

Wilmersdorf, 50

NL-7323 AC Apeldoorn

CE Reg.-Nr. 0063AQ1350

The following standards/technical specifications have been fulfilled:

- Electromagnetic Compatibility (2004/108/EC)

- Low Voltage Directive (2006/95/EC)

Quality Management System is certified according to UNI EN ISO 9001 and the monitoring is

carried out by the notified body:

Kiwa Gastec Italia Spa

Via Treviso, 32/34

I- 31020 San Vendemiano (TV)

ELEKTROGAS – TECHNICAL MANUAL

10-13

Installation,

adjustment

and servicing To assure a proper and safe operation, as well as a long life of the valve, the installation

procedure and a periodical servicing are very important topics and the following instructions

should be always fulfilled.

IMPORTANT: before proceeding with the installation, ensure that all the features of your system

are comply with the specifications of the valve (gas type, operating pressure, flow rate, ambient

temperature, electrical voltage, etc.).

CAUTION

Shut off the gas supply at the main manual shut-off valve and disconnect electrical

power to the valve before proceeding installation or servicing.

PIPING CONNECTION

- Check correspondence of flow direction with arrow printed on valve body.

- Check correct alignment of connecting pipes.

- Ensure that installing area is protected from rain and water splashes or drops.

- Remove the end caps and make sure no foreign body is entered into the valve during

handling.

THREADED MODELS

- Put sealing agent onto the pipe thread. Avoid excessive quantities which could enter in the

valve and damage the seal seat.

- Screw the pipes using proper tools only. Do not use unit as lever because damage to the

valve stem could result.

FLANGED MODELS

- Position the gasket or sealing agent on the flanges and insert the bolts with washers.

- Screw the nuts tightening them crosswise and using proper tools only. Avoid overtightening

and mount tension free.

Following chart shows the maximum values of bending moment (Fmax), torque (Tmax) and

screws driving torque (Cmax), according to EN161.

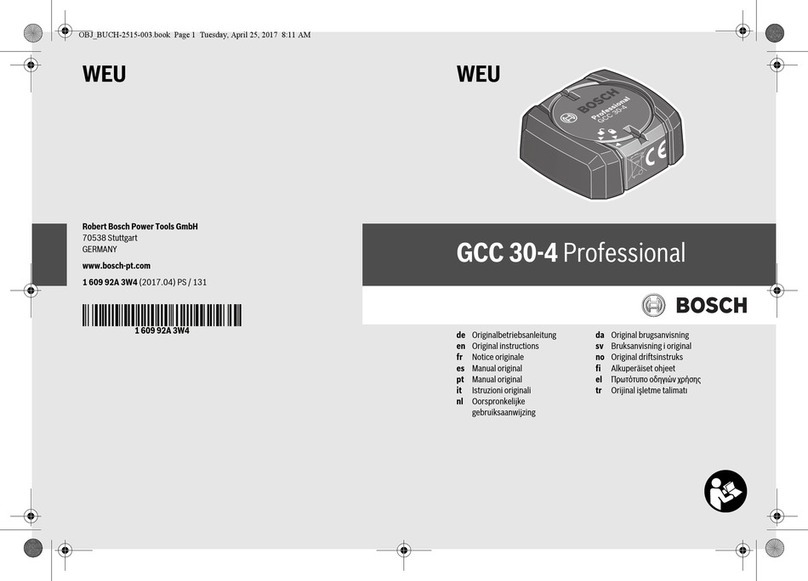

Tab. 5

Fig. 5

Valve may be mounted with coil in horizontal or vertical position. Coil may be oriented 360

degrees in any direction.

Connections Fmax

(Nm) t<10 s

Tmax

(Nm)

Cmax

(Nm)

Rp1/4 35 20 -

Rp3/8 70 35 -

Rp1/2 105 50 -

Rp3/4 225 85 -

Rp1 340 125 -

Rp1¼ 475 160 -

Rp1½ DN40 610 200 50

Rp2 DN50 1100 250 50

DN65 1600 - 50

DN80 2400 - 50

DN100 5000 - 80

DN125 6000 - 160

DN150 7600 - 160

Maximum 90°

from vertical

ELEKTROGAS – TECHNICAL MANUAL

11-13

ELECTRICAL CONNECTION (IEC 730-1)

Valve is provided with terminal box or standard plug (see tab. 4) for the electrical connections.

To connect the valve do the following:

Terminal box version:

- Using a screwdriver remove the box cover.

- Unscrew the gland-nut (7) and remove the retaining ring

(9) and conical grommet (5).

- Insert the cable in to the gland-nut, retaining ring, grommet

and then into its housing in the box cover.

- Connect power cables to the rectifier terminals (1)

according to printed designation.

- Pull the cable and screw back the box cover, make sure

the gasket (2) is properly used.

- Screw back the gland-nut, make sure that the grommet is

locked on the cable.

Should cables pass through originally closed opening, use

the rubber capsule placed underneath the cap to close any

other opening.

Fig. 6 Standard plug version:

- Using a screwdriver remove the plug from the coil.

- Unscrew the gland-nut (7) and remove the washer (6) and

grommet (5).

- To remove the rectifier unit (1) from the plug housing (3),

remove the gasket (2) and extract the screw (4) completely,

then insert a flat screwdriver into the slot located on edge

and pull it.

- Insert the cable in to the gland-nut, washer, grommet and

then into the plug housing.

- Connect power cables to the rectifier terminals according

to printed designation.

- Pull back the cable and insert the rectifier unit into the

housing.

- Screw back the gland-nut, make sure that the grommet is

locked on the cable.

- Insert the screw and gasket into the housing and screw

back the plug on the coil.

Fig. 7

The continuous service (100% ED) causes inevitable coil heating, depending of working

environment. This situation is absolutely normal and has not to worry. To improve the

coil cooling, install the valve allowing free air circulation.

WARNING

Make sure all gaskets are used properly.

Perform leak and functional tests after mounting (max. testing pressure 1500 mbar).

All works must be executed by qualified technicians only and in compliance with local

and national codes.

ELEKTROGAS – TECHNICAL MANUAL

12-13

FLOW RATE ADJUSTMENT (Vmax)

Flow rate may be adjusted from 0 cubic meters/h to the maximum (excepting 4", 5", 6" and

brass models).

To perform regulation do the following:

1. Remove coil fastener cap.

2. Using a 4 mm Allen wrench, remove the locking dowel.

3. Located under the locking dowel is the flow regulation screw. Use the Allen wrench to set it.

4. Turn wrench clockwise to decrease or counter-clockwise to increase flow rate (factory

setting is max. flow rate).

5. When adjustment is completed, screw back the locking dowel and cap.

WARNING

Make sure that capacity adjustments are made while burner is operating.

Check the regulation is not changed during reassembly.

Adjustments below 40% of capacity are unadvisable because they may cause

turbulence.

Fig. 8

COIL REPLACEMENT

Before to start with coil replacement, make sure it is the cause of failure.

To perform coil replacement do the following:

1. Make sure an identical one spare part is available.

2. Switch off power supply and remove the box cover.

3. Disconnect the wires from terminal board.

4. Remove coil fastener cap and replace the coil.

5. Reassemble following the inverse sequence.

To maintain a good performance of the system, almost once a year, an external inspection

of the valve is recommended.

Fig. 9

ELEKTROGAS – TECHNICAL MANUAL

13-13

EXTERNAL INSPECTION

- Turn off all power before servicing any part of the system.

- Check the conditions of the plug/box gasket. If gasket is deteriorated, replace it with a

new one.

- Check the electrical connections are clean, dry and correctly tightened.

- Check the conditions of pipe connections: cover them with a soap solution and check

for leakages.

- Check the proper operation of the valve: power the coil and verify that valve opens,

then, turn off power and check the closing function.

INTERNAL INSPECTION

Make this inspection when the valve does not work properly only.

To make an internal inspection of the valve, do the following:

- Shut ball valve upstream the system and make sure no pressure is inside the valve.

- Unscrew coil fastener cap (15) and remove the coil (13).

- Using an Allen key, remove the screws (10) on the upper flange (9), in cross way. The

gas in the valve will come out during this step.

- Check the main O-ring (8). If it’s necessary, replace it with an identical one.

- Clean the internal side of the stem (11) with a clean cloth and compressed air.

- Remove the spring (7) and blow it with compressed air. Check the spring is corrosion

free. Take attention to the assembly direction of the spring.

- Check the wear conditions of the sliding rings (6) and, if it’s necessary, replace them.

- Clean the plunger assembly (4, 5, 6) with a clean cloth and compressed air.

- Check the conditions of the sealing gasket (4). If gasket is deteriorated, replace it with a

new one.

- Clean the sealing lip with a clean cloth. Do not use tools, because a lip damage could

result.

- Remove the filter (3) and blow it with compressed air.

- Reassemble the valve following the inverse sequence.

When reassembling, take attention to the correct position of the spring.

When the reassembly is finished, verify the correct sealing between the upper flange and

the valve body:

- Open ball valve to restore pressure into the valve.

- Apply a soap solution between the upper flange and the valve body and check for

leakages.

- Remove the soap solution with a clean cloth, before to reassemble the coil.

WARNING

To prevent product damage and dangerous situations, read the Installation and

Service Instructions carefully.

Turn off all power before servicing any part of the system.

Perform leak and functional tests after mounting.

Use all gaskets properly (void warranty).

All wiring must be in compliance with local and national codes.

Make sure all works are performed by qualified technicians only.

Fig. 10

This manual suits for next models

76

Table of contents

Other Elektrogas Control Unit manuals

Elektrogas

Elektrogas VMRNA User manual

Elektrogas

Elektrogas EVRM-NC User manual

Elektrogas

Elektrogas EVRM-NA User manual

Elektrogas

Elektrogas EVRM-NA User manual

Elektrogas

Elektrogas VMM User manual

Elektrogas

Elektrogas VMR01OTN User manual

Elektrogas

Elektrogas VML Series User manual

Elektrogas

Elektrogas VMRNA User manual

Elektrogas

Elektrogas VMM User manual

Elektrogas

Elektrogas EVRM-NA User manual