PURELAB Pulse 1/2 US Operator Manual ELGA

Page 4 PURELAB Pulse 1/2 US MANU40563 Version 2 02/16

3.2 Process Description

The PURELAB Pulse process links three purification technologies,

Reverse Osmosis, Electro-Deionization and Photo Oxidation and

incorporates a re-circulation pump and an optional RO feed water boost

pump.

The unit is designed to operate from a good quality potable water supply,

and produces up to 10 or 20 liters per hour of purified reverse osmosis

grade water which is further purified and circulated through a reservoir.

A graphics screen displays the system status and provides control by

means of three function buttons.

The water is processed and treated by the PURELAB Pulse unit as

follows:

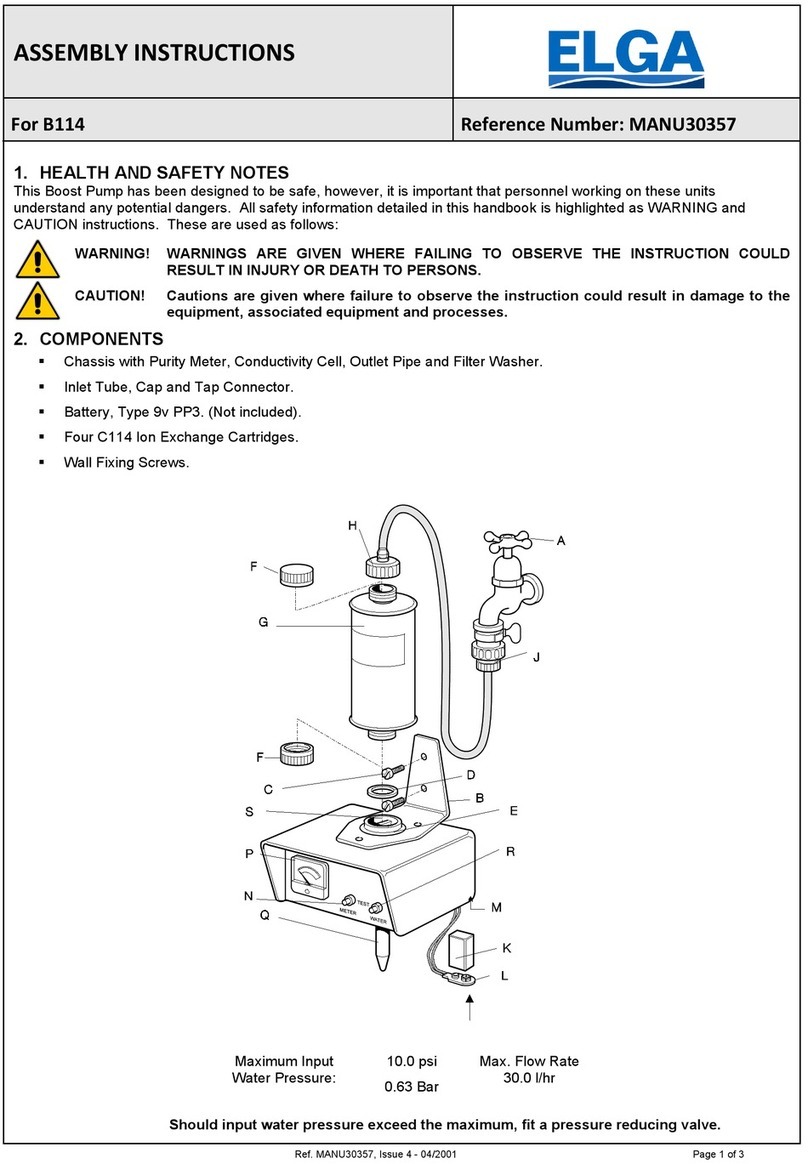

Potable water enters through a strainer and inlet solenoid valve,

at either regulated mains water pressure, or is pumped by

means of a feed water pump (optional), and passes through the

pre-treatment cartridge. The pre-treatment cartridge has been

designed to protect the reverse osmosis cartridges from

particulate/colloidal matter and excessive free chlorine, which

may be present in the incoming feedwater.

The pre-treated water then passes the sanitization port and

through one or two reverse osmosis cartridges, set up in series,

which split the flow into permeate and concentrate streams. The

permeate water is further purified whilst the waste concentrate

stream is passed to drain.

The permeate water then passes though a line cell which

measures the conductivity of the water.

The permeate water passes through the conditioning cartridge

which removes traces of hardness remaining in the water.

The permeate water is drawn into the main re-circulation stream

by the re-circulation pump together with water from the

reservoir and passes through the re-circulation purification loop.

This water is pumped directly through the UV chamber where it

is exposed to intense UV radiation to provide continuous

bacterial control by photo oxidation and to promote the

cleavage of organic molecules.

The water then passes through the Pulse electrical

ion-exchange module which removes inorganic and organic

impurities.

Waste water from the Pulse module is passed to the drain.

Finally the water is passed through a:

Water quality sensor which measures the resistivity of the

water.

Temperature sensor which provides accurate temperature

measurement.

The deionised water is either dispensed through a dispense

tap, or continues within the re-circulation circuit to the reservoir.

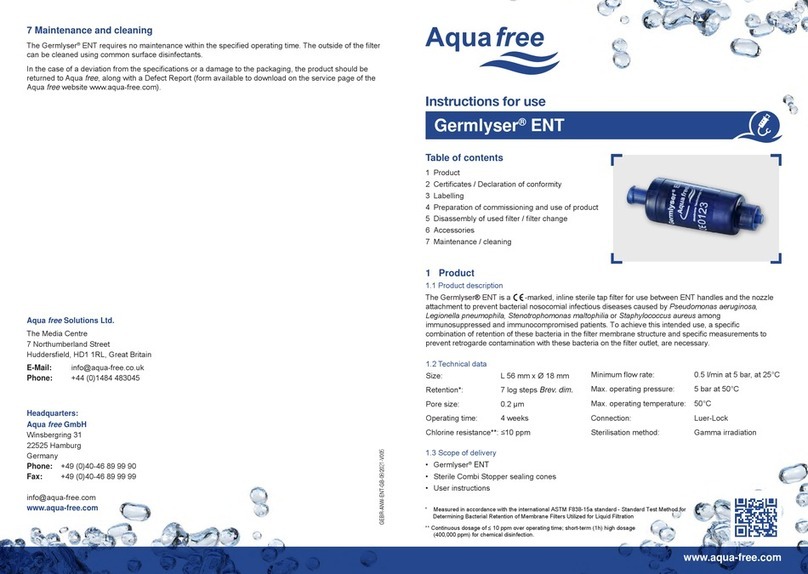

An optional point of use 0.2µm bacterial filter can be fitted to the

dispense tap for added protection.

During periods of non-use the unit will automatically operate in

intermittent re-circulation mode to maintain water purity with

maximum efficiency.

If the level of water in the reservoir is below 10% (or 40% on

start up) the re-circulation mode will be disabled until a level of

70% is reached. The re-circulation will restart automatically.

When the make-up starts, there is an initial 15 minute flush

period prior to water being passed to the recirculation circuit.