Table of Contents

MAN-G-SOLWHIIG-EC (Ver. 1.509)

4

Chapter 1: This Installation Guide .....................................................................................6

Chapter 2: Safety Information ..........................................................................................6

2.1. Warnings ........................................................................................................................ 7

2.2. Cautions.......................................................................................................................... 7

2.3. CE Marking Conformance............................................................................................... 7

2.4. Warranty Information .................................................................................................... 7

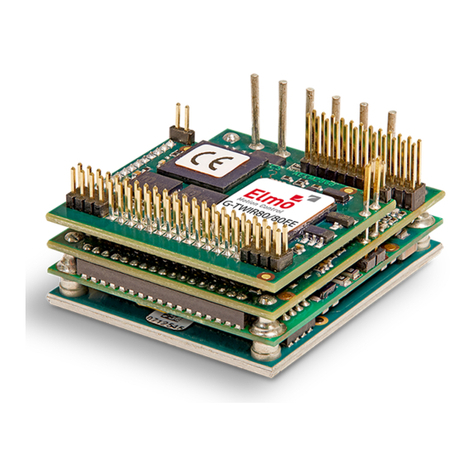

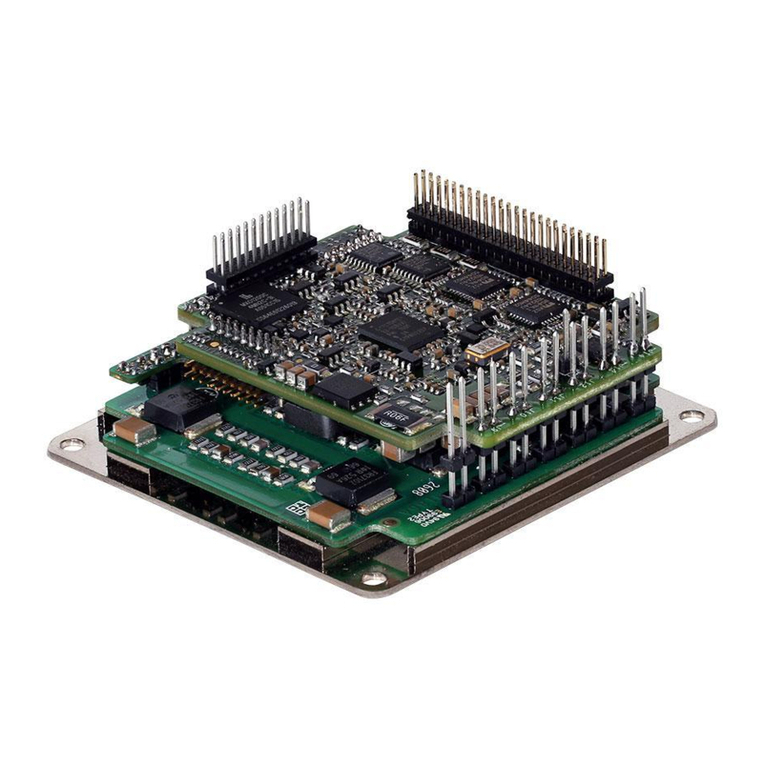

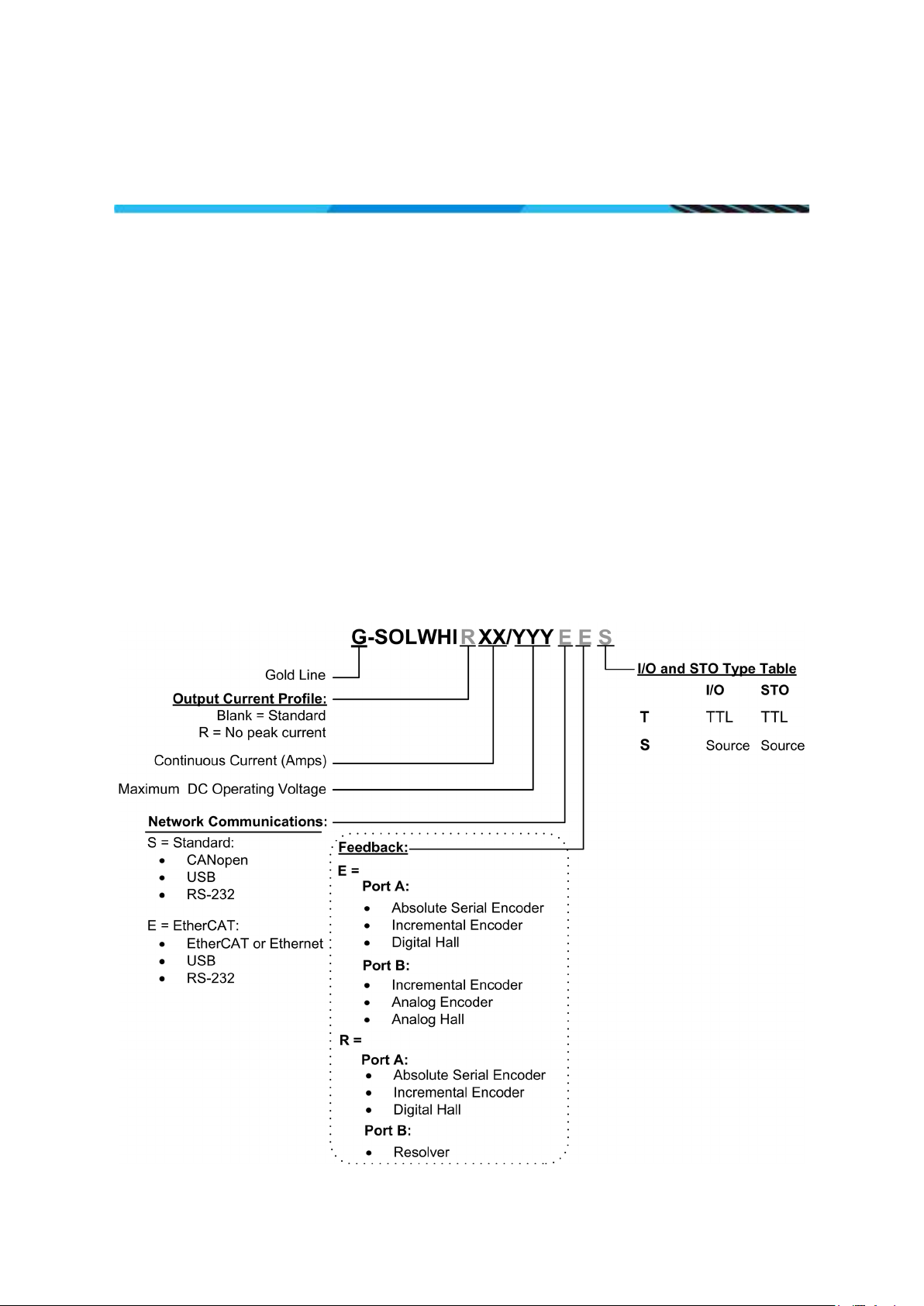

Chapter 3: Product Description.........................................................................................8

3.1.1. Accessories ...................................................................................................... 8

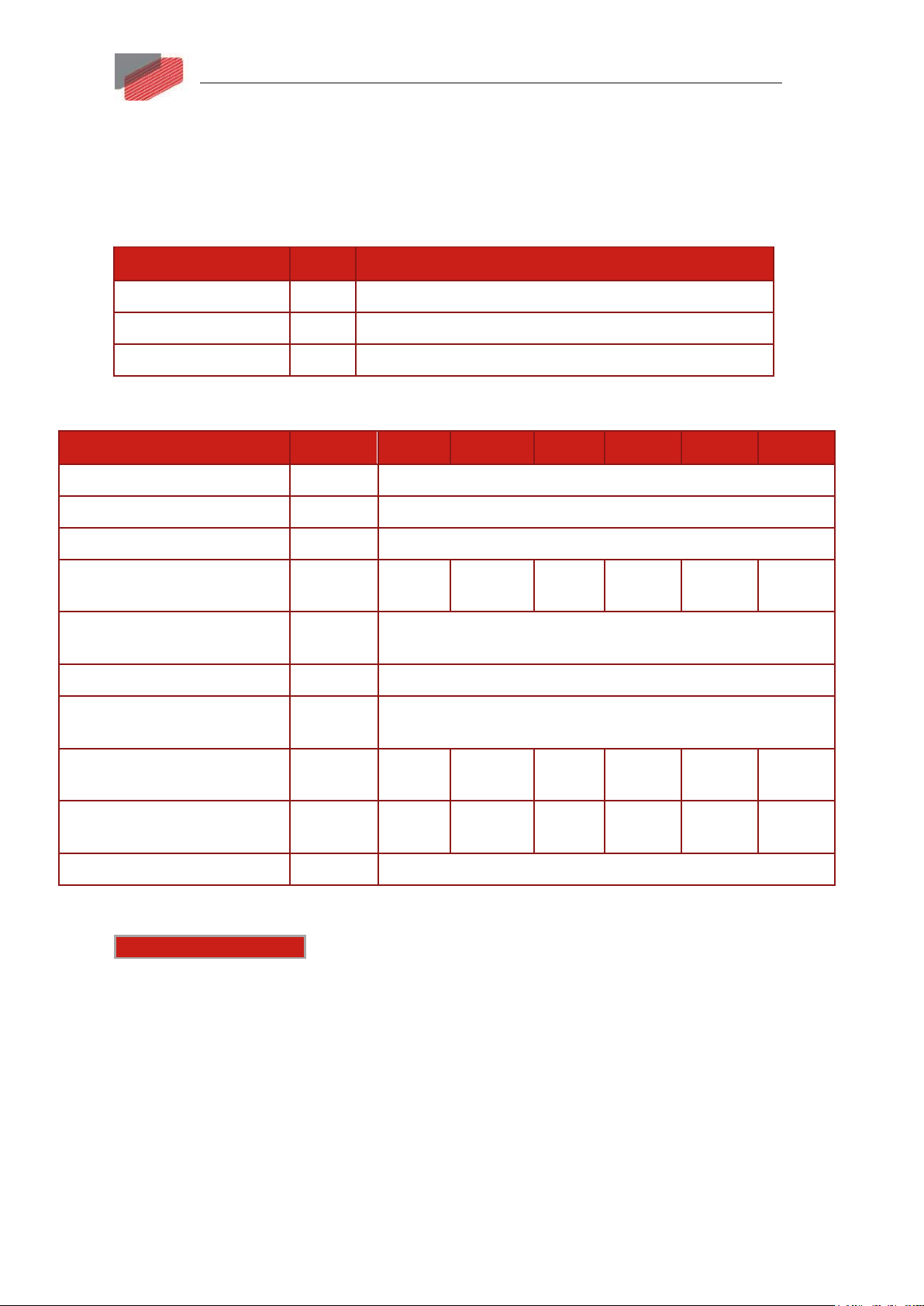

Chapter 4: Technical Information......................................................................................9

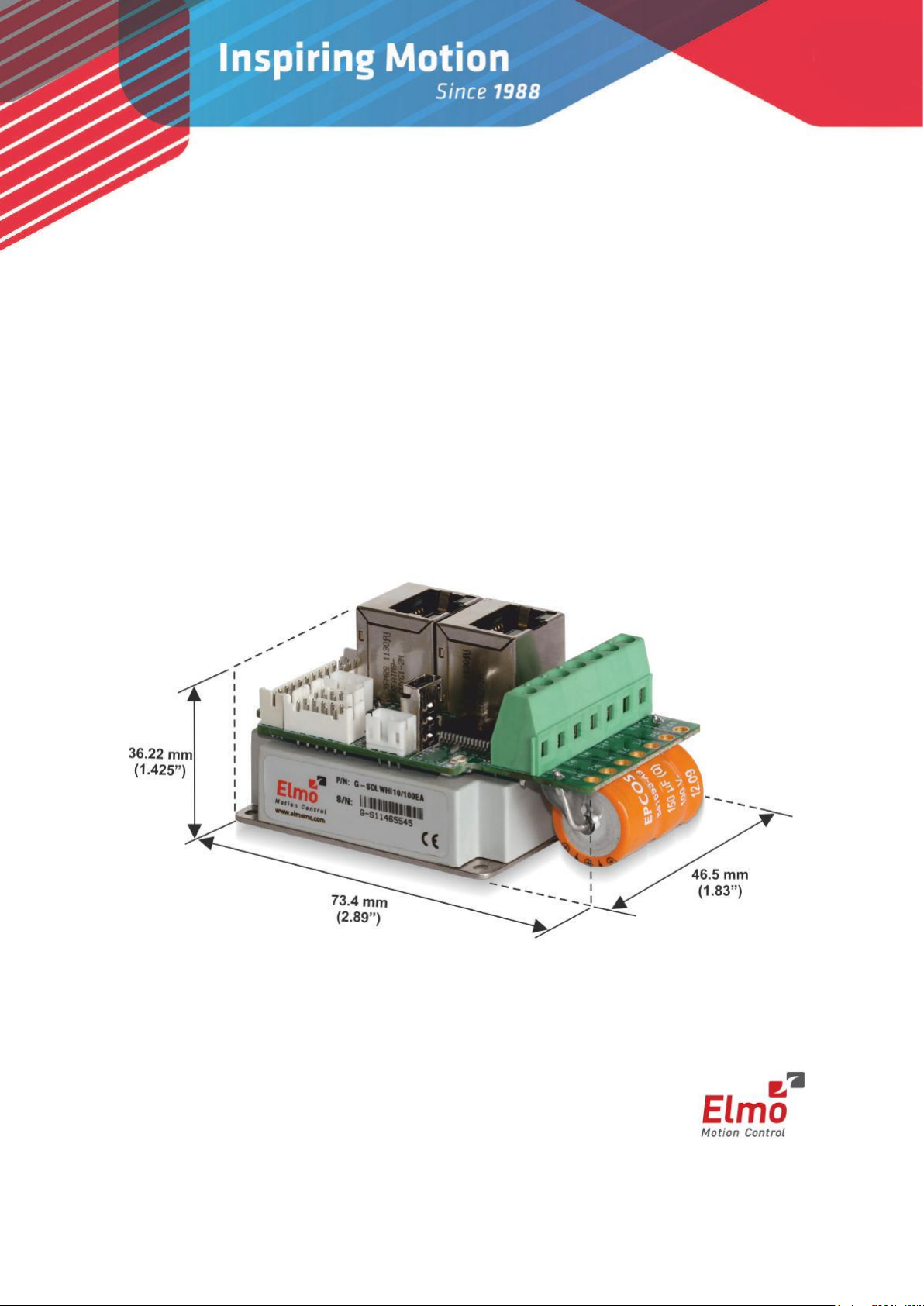

4.1. Physical Specification ..................................................................................................... 9

4.2. Technical Data ................................................................................................................ 9

4.2.1. Auxiliary Supply ............................................................................................. 10

4.2.2. Product Features ........................................................................................... 11

4.3. Environmental Conditions............................................................................................ 12

4.3.1. Gold Line........................................................................................................ 12

4.4. Gold Line Standards...................................................................................................... 13

Chapter 5: Installation....................................................................................................14

5.1. Unpacking the Drive Components ............................................................................... 14

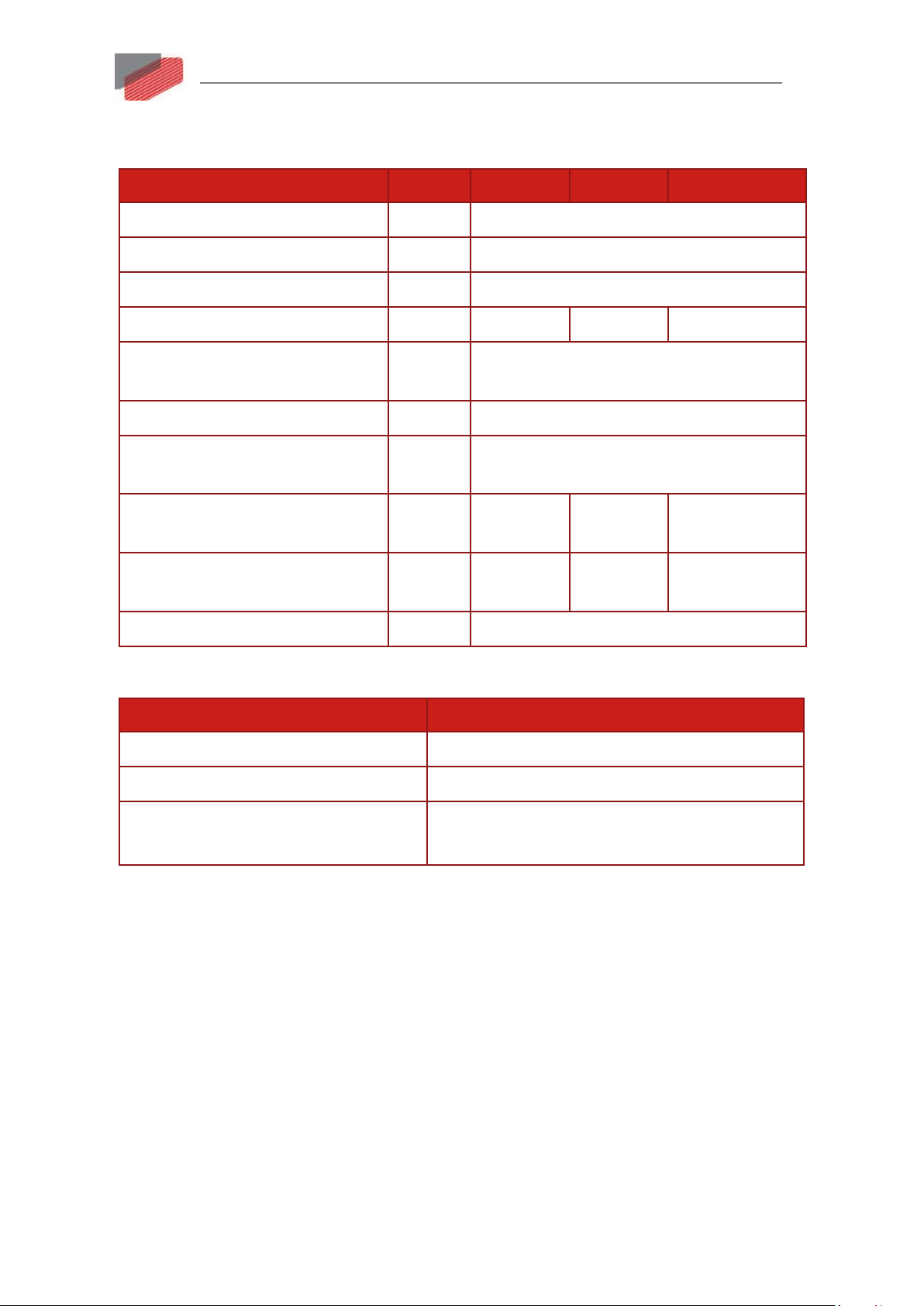

5.2. Connector Types........................................................................................................... 15

5.2.1. Connector Types............................................................................................ 15

5.3. Mounting the Gold Solo Whistle .................................................................................. 17

5.4. The Gold Solo Whistle Connection Diagrams............................................................... 18

Chapter 6: Wiring...........................................................................................................20

6.1. Basic Recommendations .............................................................................................. 22

6.1.1. General .......................................................................................................... 22

6.1.2. Feedback Cable Port A and Port B Connector............................................... 23

6.1.3. Feedback Cable Port C Connector ................................................................. 24

6.1.4. IO Cable Connector........................................................................................ 24

6.1.5. STO (Port C) Cable Connector........................................................................ 25

6.2. Motor Power Connector Pinouts (J28)......................................................................... 26

6.3. Main and Auxiliary Power ............................................................................................ 28

6.3.1. Description .................................................................................................... 28

6.3.2. Main Power (J29)........................................................................................... 29

6.3.3. Auxiliary Power Supply (J30) ......................................................................... 30

6.3.4. Connectivity................................................................................................... 31

6.3.4.1. Power Rating 200 V ...................................................................... 31

6.3.4.2. Power Rating 100 V ...................................................................... 32

6.4. Drive Status Indicator................................................................................................... 34