Table of Contents

MAN-G-WHI (Ver. 1.400)3

Chapter 1: This Installation Guide ................................................................................ 5

Chapter 2: Safety Information ..................................................................................... 5

2.1. Warnings ....................................................................................................................6

2.2. Cautions......................................................................................................................6

2.3. CE Marking Conformance...........................................................................................6

2.4. Warranty Information ................................................................................................6

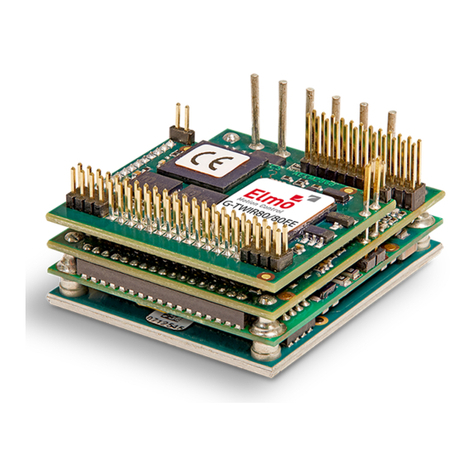

Chapter 3: Product Description .................................................................................... 7

Chapter 4: Technical Information................................................................................. 8

4.1. Physical Specifications................................................................................................8

4.2. Technical Data ............................................................................................................8

4.2.1. Control Supply .............................................................................................9

4.2.2. Product Features .......................................................................................10

4.2.3. Environmental Conditions.........................................................................11

4.2.4. Gold Line Standards...................................................................................12

Chapter 5: Installation................................................................................................13

5.1. Unpacking the Drive Components ...........................................................................13

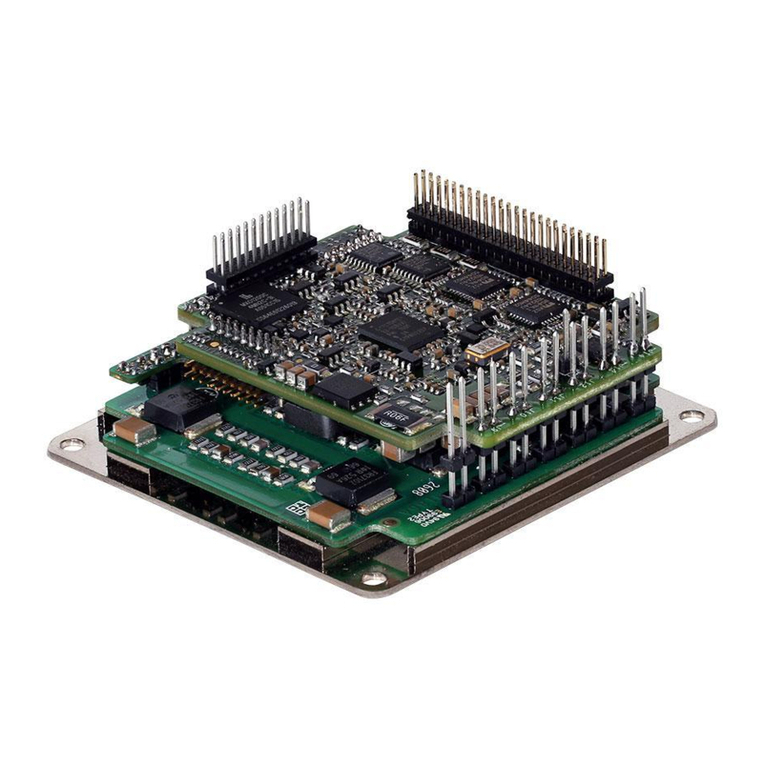

Chapter 6: Mounting the Gold Whistle........................................................................14

Chapter 7: Integrating the Gold Whistle on a PCB........................................................16

7.1. Power Returns (PR) ..................................................................................................16

7.2. COMRET....................................................................................................................16

7.3. Earth Connection (PE) ..............................................................................................16

7.4. Power Return (PR), Common Return (COMRET) and Earth Connections (PE).........17

7.5. Power Conductors PCB layout..................................................................................18

Chapter 8: The Gold Whistle Connection Diagram .......................................................19

Chapter 9: PCB Connections........................................................................................20

9.1. Wiring legend ...........................................................................................................20

9.2. Connector Types.......................................................................................................22

9.2.1. Connector Types........................................................................................22

9.3. Drive Status Indicator...............................................................................................22

9.4. Motor Power Connector Pinouts .............................................................................23

9.5. Main Power and Control Connector ........................................................................25

9.5.1. Main Power ...............................................................................................25

9.5.2. Control Supply ...........................................................................................26

9.5.3. Power Supply for the Power Rating 200 V ................................................27

9.5.4. Power Supply for power rating 100 V .......................................................28

9.5.4.1. Single Power Supply .................................................................28