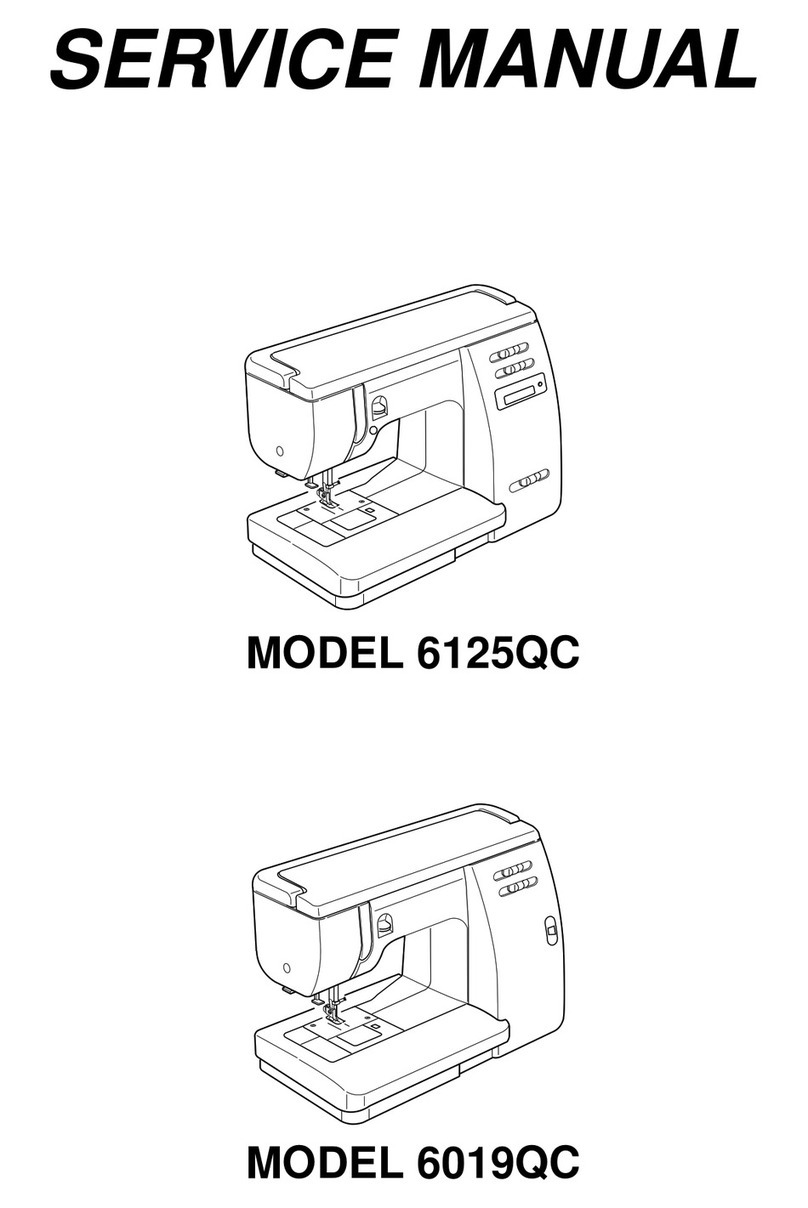

Replacing the External Parts

1. Belt Cover........................................................................................ 1

2. Looper Cover................................................................................... 2

3. Rear Cover ...................................................................................... 3

4. Front Cover...................................................................................... 4

5. Free Arm Cover ............................................................................... 5

Mechanical Adjustment

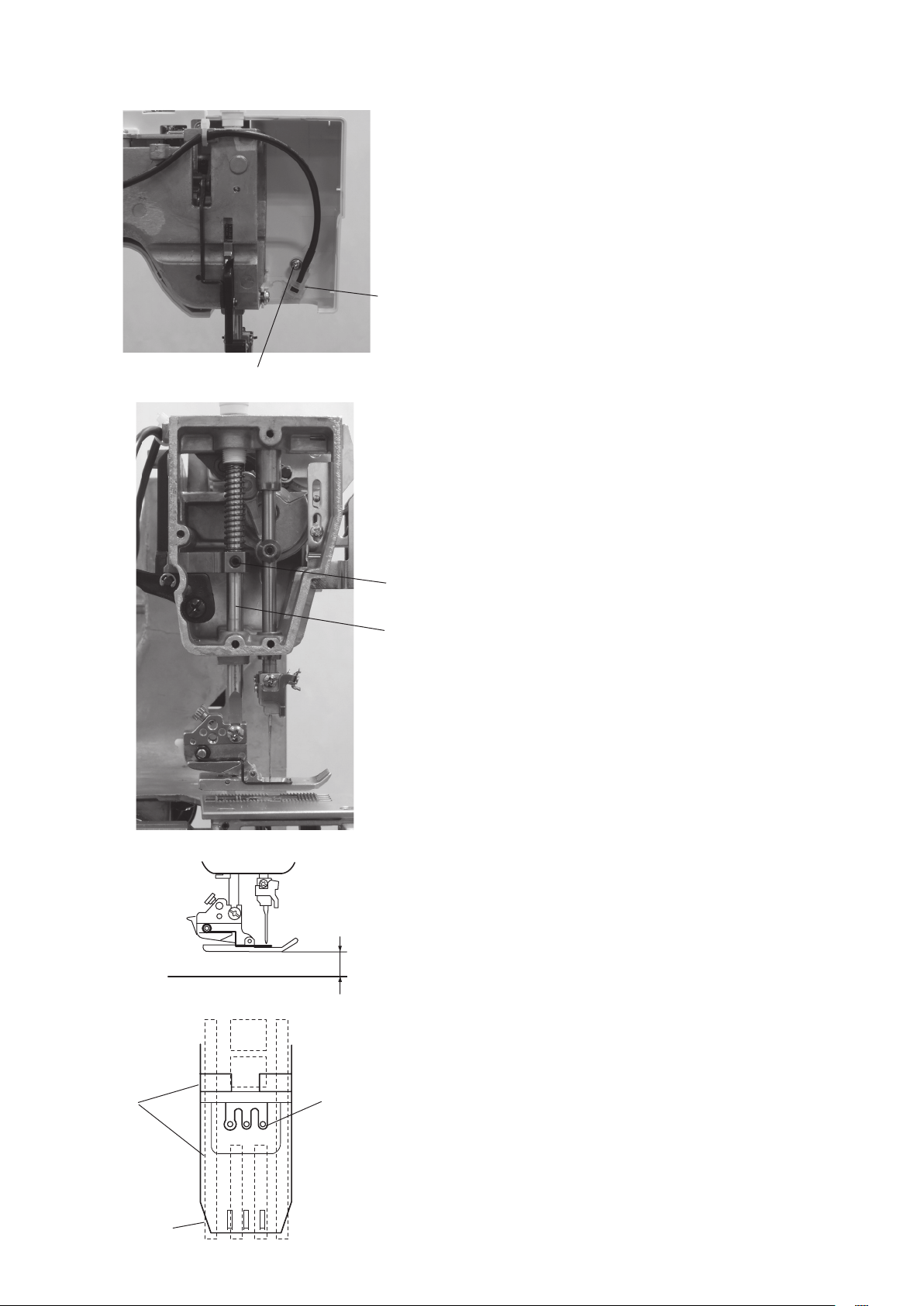

1. Presser Bar Height .......................................................................... 6

2. Foot Pressure .................................................................................. 7

3. Needle Bar Heihgt ........................................................................... 8

4. Feed Dog Height ............................................................................. 9

5. Looper Height................................................................................ 10

6. Looper Postion .............................................................................. 11

7. Needle to Looper Timing ............................................................... 12

8. Clearance between the Needle and Looper.................................. 13

9. Back Needle Guard Height............................................................ 14

10. Needle to Feed Dogs Timing ......................................................... 15

11. Stitch Length ................................................................................. 16

12. Differential Feed Ratio................................................................... 17

13. Thread Tension.............................................................................. 18

14. Motor ............................................................................................. 19

Parts List ........................................................................................... 20-37

Table of Contents