P a g e | 3

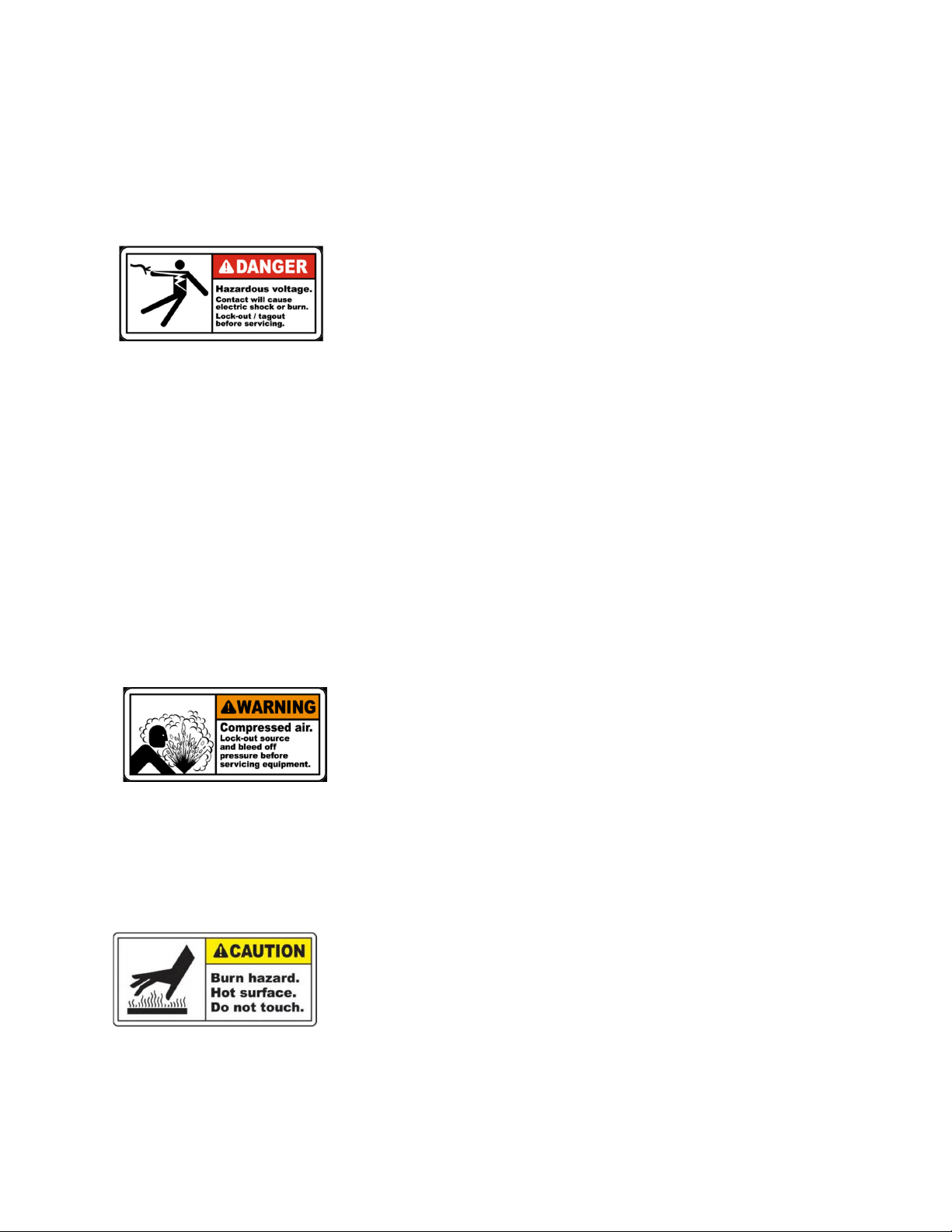

WARNINGS AND SAFETY INSTRUCTIONS

GENERAL WARNING

This instruction contain general caution information for use in Pool and SPA pump installation application.

Specified Pump model function should be refer to particular manual. Components such as the filtration

system, pumps and heater must be positioned so as to prevent their being used as means of access to the

pool by young children.

RISK OF ELECTRICAL S OCK

This appliance should be installed by qualified electrical personnel in

accordance with National Electrical Code and all applicable local codes and

ordinances. Hazardous voltage can shock, burn, and cause death or serious

property damage. DO NOT use an extension cord to connect unit to electric

supply to reduce the risk of electric shock.

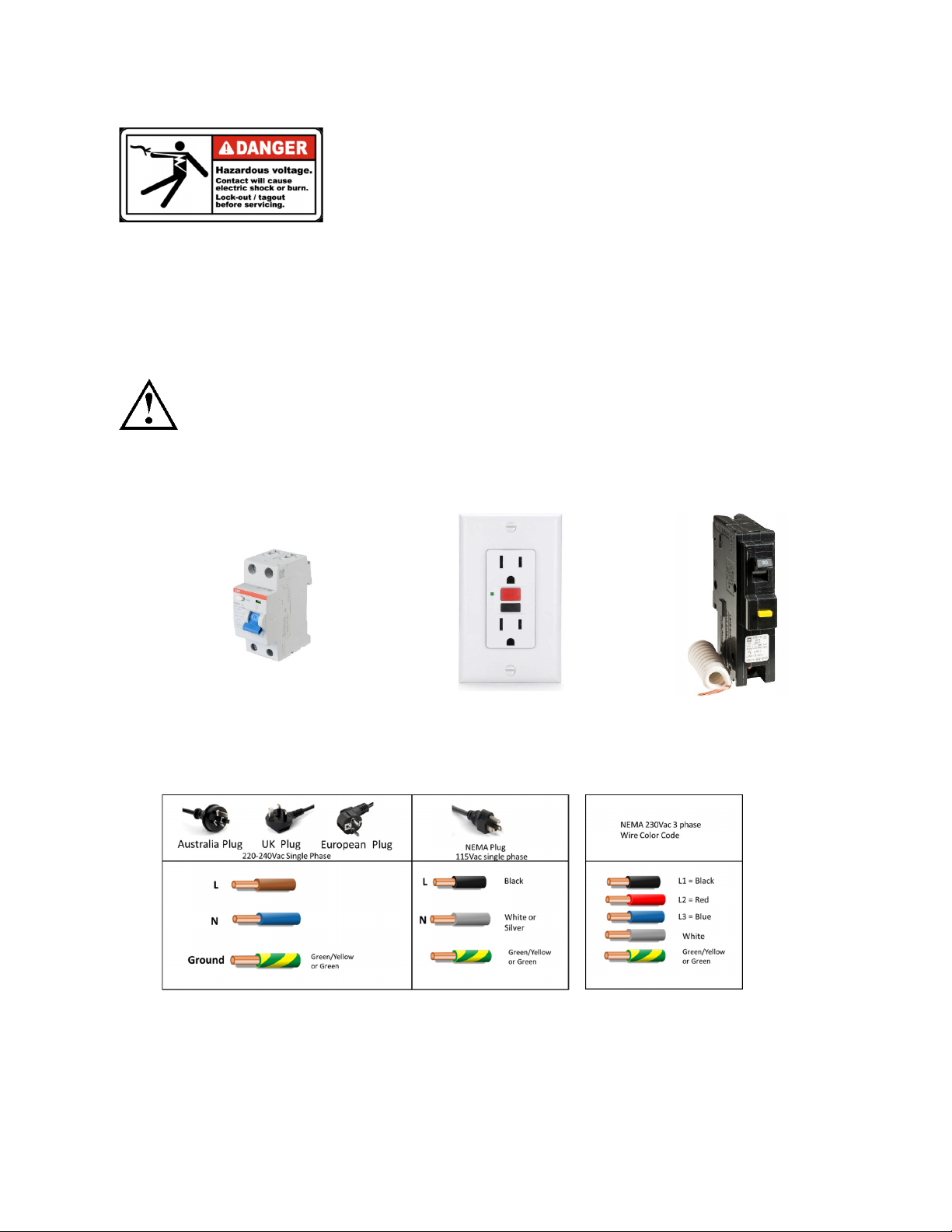

•The pump should be permanently connected to an individual circuit breaker.

•Pump must be connected to a residual current device (RCD) having a rated residual operating current

not exceeding 30 mA or receptacle with ground fault circuit interrupt (GCFI).

•Electrical grounding must be connected before connecting to electrical power. Failure to ground all

electrical equipment can cause serious or fatal electrical shock hazard.

•Bonding: Use at least #8 AWG (# AWG for Canada) a solid copper conductor, run a continuous wire

from external bonding lug (if available) to the pressure wire connector provided on the electrical

equipment and to all metal parts of swimming pool, spa, or hot tub, and metal piping (except gas piping),

and conduit within 1.5 m (5 ft) of inside walls of swimming pool, spa, or hot tub.

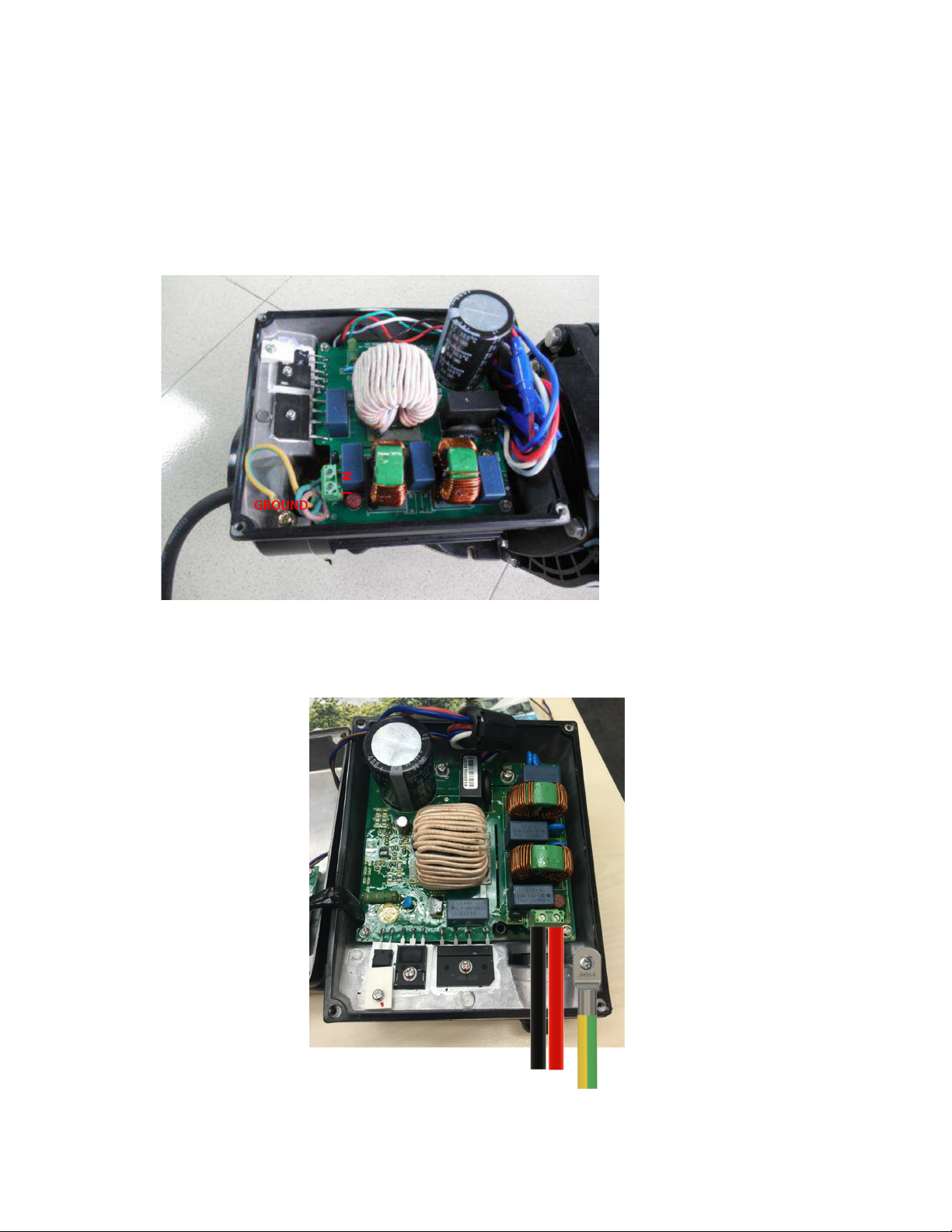

•Never open the inside of the drive motor enclosure. There is a capacitor bank that holds a mains supply

voltage charge even when there is no power to the unit. The voltage should be referred to the individual

pump operation voltage.

•The pump is capable of high flow rates; use caution when installing and programming to limit pumps

performance only.

•Switch OFF pump power before servicing and disconnecting the main circuit to the pump.

•Never change the filter control valve position while the pump is running

COMPRESS AIR AZARDOUS

This system enclosed pre-filter / filter and become pressurized. Pressurized

air can cause the Lid to separate which can result in serious injury or

death.

STAND CLEAR OF PUMP DURING START-UP

Pool and spa circulation systems operate under high pressure. When any part of the circulating system (i.e.

lock ring, pump, filter, valves, etc.) is serviced, air can enter the system and become pressurized. Filter tank

Lid and pre-filter cover must be properly secured to prevent violent separation. Place pre-filter / filter air

relief valve in the open position and wait for all pressure in the system to be relieved before remove the lib

to access the basket for cleaning.

YPERT ERMIA

SPA water temperature excess 38°C (104°F) may be injurious to health.

Measure water temperature before entering SPA.

Hyperthermia occurs when the internal temperature of the body reaches a level several degrees above the

normal body temperature of 98. °F (37 °C). The symptoms of hyperthermia include drowsiness, lethargy,

and an increase in the internal temperature of the body.