1.0 – HINTS AND WARNINGS

Please read the warning notices given in this secti on very carefully, because they provide important

information regarding safety in installation, use and maintenance of the unit.

•Keep this manual in a safe place, so that it will always be available for further consultation.

•The unit has been manufactured in accordance with best practice. Both its lifetime and electrical and

mechanical reliability will be enhanced if it is correctly used and subjected to regular maintenance.

1.1 - WARNING: any intervention or repair for the unit must be carried out by qualified and authorised

personnel: manufacturer declines any responsibility for consequences in case this rule is not complied.

1.2 - SHIPPING AND TRANSPORTING: shipment is always at the purchaser's ri sk. Claims for any

missing materials must be made within 15 (fifteen) days of goods arrival, while claims for defective

materials will be considered within 30 (thirty) days from the same date. Return of equipment or other

materials to EMAUX or to authorized distributor must be previously agreed with EMAUX authorised personnel.

1.3 - PROPER USE OF DOSING PUMP

•Dosing pumps are not designed to dose additives in gaseous or solids form.

•Any different use is to be considered improper and therefore dangerous.

•Always ensure the right compatibility with dosed liquid and pumps wetted parts. In case of doubt, please

contact our offices for further information and suggestions.

•All other applications or modifications are prohibited.

•The pump is not designed for use in explosion-hazardous locations.

•When using flammable chemicals, observe relevant rules concerning transport and storage of these liquids.

•Do not use these pumps with radioactive chemicals !!!!!!

•When using aggressive chemicals ensure that materials forming wetted parts are compatible with those

chemicals (ask for EMAUX Chemical Compatibility Resistance Chart).

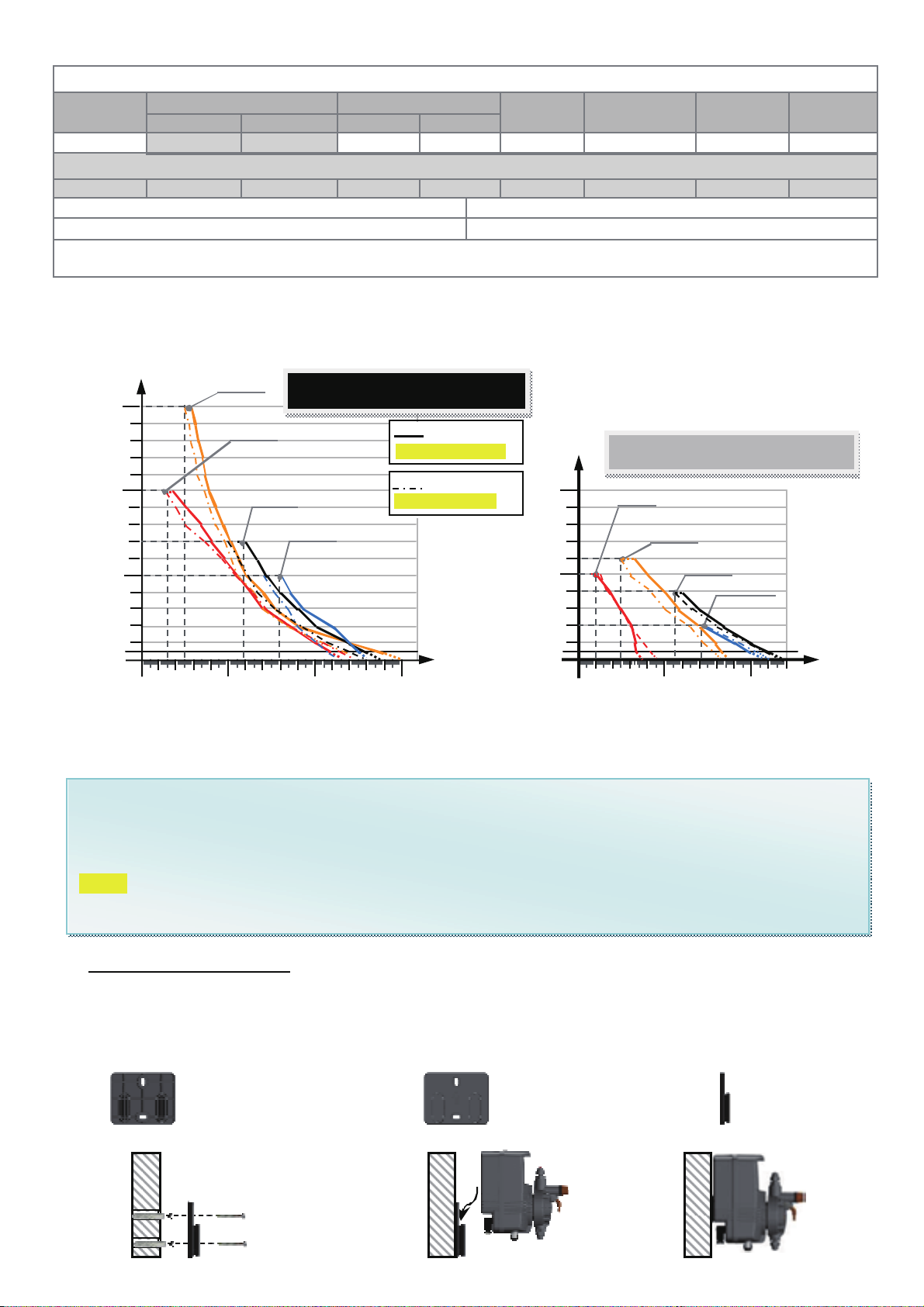

•The pump can only be used for applications duties which technical requirements meet with CTRL - 2 technical

characteristics and specifics data shown in the present operating instructions booklet.

•The vendor is not liable for damages deriving from improper and/or unreasonable use of the pump.

1.4 - RISKS

•After unpacking the equipment, ensure it’s in good shape. In case of doubt, do not use it and contact

qualified personnel. Packing materials (plastics bags, polystyrene, etc.) should be kept out of reach of

children being potential sources of danger. However, save packaging: it can be used for future shipments.

•Before connecting the equipment ensure voltage ratings corresponds to local power supply. You will find

these characteristics in the product label placed on the equipment and packing.

•The electrical installation must comply with the standards and rules in force in the country where i t’s utilised.

•Use of electrical equipment always implies observance of some basic rules:

1 - do not touch the equipment with wet or damp hands or feet;

2 - do not operate the equipment with bare feet (example: swimming pool equipment);

3 - do not leave the equipment exposed to the action of the atmospheric agents;

4 - do not allow the equipment to be touched by children or used by unskilled individuals without supervision;

•In case of emergencies or improper functioning, the pump should be sw itched off immediately

Disconnect the power cable from the main pow er supply !

Contact our technical assistance for any necessary repairs, use only original spares ! Failure to respect this

condition could render the equipment unsafe to use.

•When there is no longer use requirement of installed equipment, ensure to disconnect it from power supply:

1. Disconnect power from mains or from the single-pole switch-contact.

2. Relieve all pressure from discharge hose. In case of liquid ends losse s (rupture of the hoses) the unit

should be immediately switched OFF, emptying and depressurizing discharge hose.

Take all due safety precautions during unit service (gloves, goggles, overalls, etc.).

1.5 - DOSING TOXIC AND/OR DANGEROUS LIQUIDS HANDLING

To avoid risk from contact with hazardous liquids or toxic fumes, always adhere to this instruction manual:

•Follow the instructions of the chemical liquid manufacturer.

•Frequently check the hydraulic part of the pump and use it only if it is in perfect condition.

•Use only correct materials for hoses, valves, seals to suit dosing liquid; if possible shield it with PVC pipe.

•Before handling the pump, ensure to flush out and neutralize the pump head with proper reagent liqui d.

PUMPS USED WITH RADIOACTIVE MATERIALS CANNOT BE RETURNED FOR REPAIRS OR

REPLACEMENTS AND WILL NO T BE ACCEPTED BY EMAUX.

1.6 - ASSEMBLING AND DISMANTLING THE EQUIPMENT

1.6.1 - ASSEMBLY

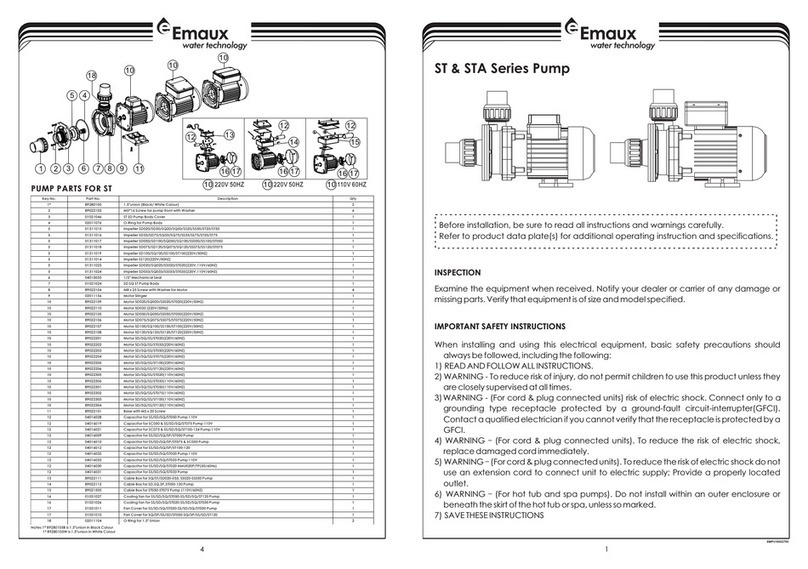

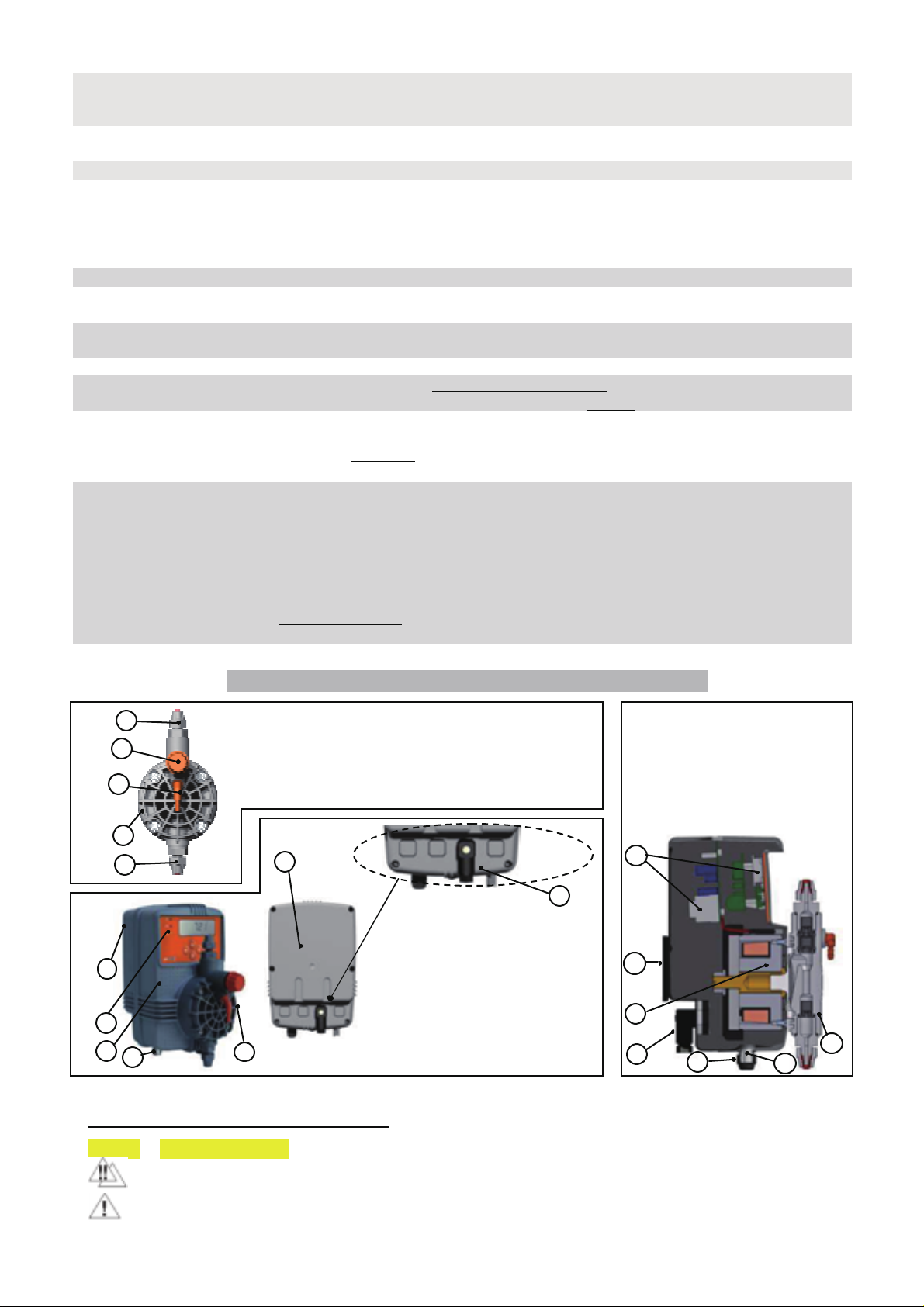

All EMAUX equipments are supplied fully assembled. Please refer to exploded view drawings shown in the

present booklet, showing all details and a complete overview of all components. These drawings are in any

case useful whenever spare parts are needed.

1.6.2 - DISMANTLEMENT

Before dismantling the unit or before carrying any operation, proceed as follows:

1. disconnect power.

2. relieve all pressure from discharge hose.