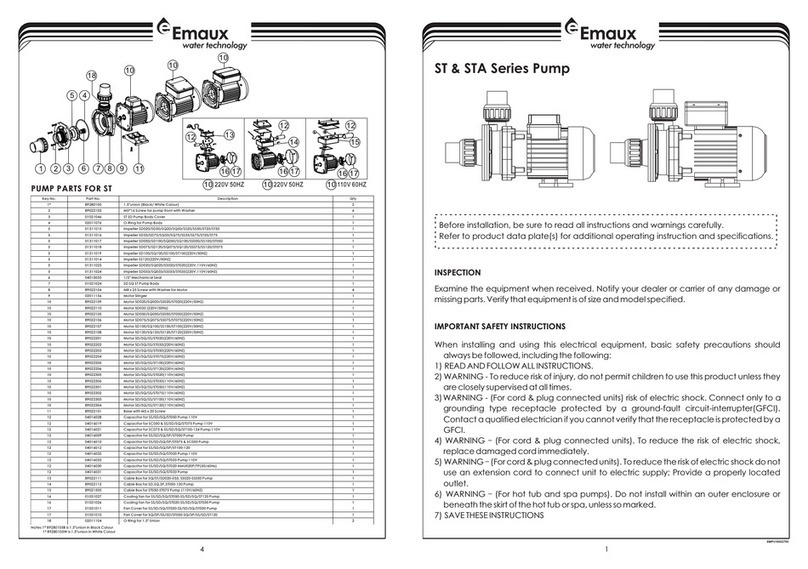

1

INSTALLATION

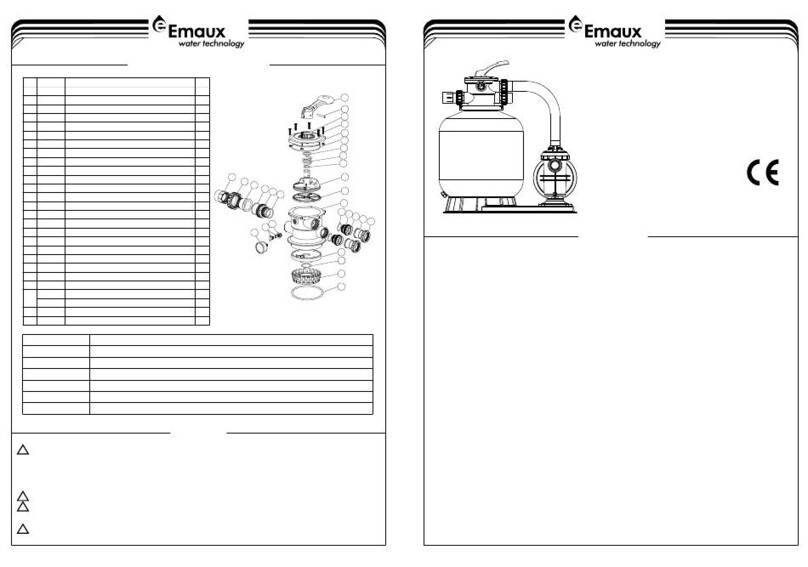

FSP300-4W

FILTER & PUMP COMBO

INSTALL/START-UP OF FILTRATION

* Install filtration system including pump, filter tank and excessiveshock.

multiportvalve. d.Carefully pour in correct amount and grade of filter sand. Be

* The filter system should be installed as close as possibie to sure center pipe remains centered in opening.

the swimming pool and preferably at a level of 0.50 Sand surface should be leveled and should come to about

metres below the surface of the water in the swimming the middle of the filter tank. Remove plastic cap from internal

pool. Make sure there is drainage available at the place pipe.

wherethefilteristobeinstalled. 2.Assemblefiltercontrolvalvetofiltertank.

*PUMP a.Insert filter control valve(with O'ring in place)into the tank

1.Only qualified, licensed personnel should install pump neck, taking care that the center pipe slips into the hole in the

andwiring. bottomofthevalve.

2.Electrical Contractors Please Note: All 220V/60Hz pump b.Placetwoplasticclampsaroundvalveflangeandtankneck

must be wired to the main power supply trough an and tighten just enough so that the valve may Be rotated on

approvedandcorrectlyratedcontractor. tankforfinalpositioning.

3.Allowforgatevalveinsuctionpiping. c.Carefully screw pressure gauge(with O'ring in place)into

4.Pumpsuctionanddischargeconnectionshavemoulded tappedholeinvalvebody.Donotover-tighten.

in thread stops, do not try to screw pipe in beyond these d.ConnectpumptocontrolvalveopeningmarkedINwithhose.

stops. After connections are made, tighten clamps with screwdrive,

*FILTERTANKandMULTIPORTVALVE tapping around clamp with screwdrive handle to help seat

1.Loading the sand media. Filter sand media is loaded valveflangeclamp.

throughthetopopeningofthefilter. 3.Makereturntopoolpipeconnectiontocontrolvalveopening

A.Loosentheplasticclampsfromtankneck. marked OUT and complete other necessary plumbing

b.Cap internal pipe with plastic cap to prevent sand from connections,suctionlinestopump,waste,etc.

enteringit. 4.To prevent water leakage, be sure all pipe connections are

c.We recommend filling tank approximately 1/2 way with tight.

water to provide a cushion effect when the filter sand is

poured in. This helps protect the under-drain laterals from

1. Be sure correct amount of filter media sand is in tank FILTERpositionandrestartpump.Thefilterisnowoperating

and that all connections have been made and are in the normal filter mode, filtering dirt particles from the

secure. poolwater.

2.DepresscontrolvalvehandleandrotatetoBACKWASH 5. Adjust pool suction and return valves to achieve desired

position. (To prevent damage to control valve seal, flow. Check system and filter for water leaks and tighten

alwaysdepresshandlebeforeturning.) connections,bolts,nuts,asrequired.

3. Prime and start pump. Never run pump dry! Running 6. Note the initial pressure gauge reading when the filter is

pump dry may damage seals, causing leakage and clean. (It will vary from pool to pool depending upon the

flooding! Fill pump with water before starting motor. pump and general piping system.) As the filter removes

(be sure all suction and return lines are open), allowing dirt and impurities from the pool water, the accumulation

the filter tank to fill with water. Once water is flowing in the filter will cause the pressure to rise and flow to

outof the waste line,run the pump forat least 1 minute. diminish. When the pressure gauge reading is 1.5 bar,

Theinitial back-washingofthefilter isrecommended higher than the initial "clean" pressure you noted, it is time

to remove any impurities or fine sand particles in the to backwash the filter (see BACKWASH under filter and

sandmedia. controlvalvefunctions).

4. Turn pump off and set valve to RINSE position. Start NOTE: During initial clean-up of the pool water it may be

pump and operate until water in sight glass is clear, necessary to backwash frequently due to the unusually

about 1/2 to 1 minute. Turn pump off and set valve to heavyinitialdirtloadinthewater.

名 称

版 本 编 号

规 格

比 例

颜 色

产品负责人

更改日期

更改内容

版本 制图/设计

A

意万仕(中山)泳池设备有限公司

EMAUX ZhongShan)Swimming Pool Equipment Co., Ltd(

审核 批准

80g印尼蓝

普通印刷

2020.12

1 : 1

210X297(mm)

EMFS20120902

PANTONE Process Black C

材料

工 艺

日 期

EMAUX FSP300-4W 胶缸连泵(220V 60Hz) 英文说明书

EMFS20120902