2

2 x 3 18 24

3 x 4 18 24

4 x 6 18 24

6 x 8 32 43

8 x 10 32 43

10 x 12 51 69

12 x 16 51 69

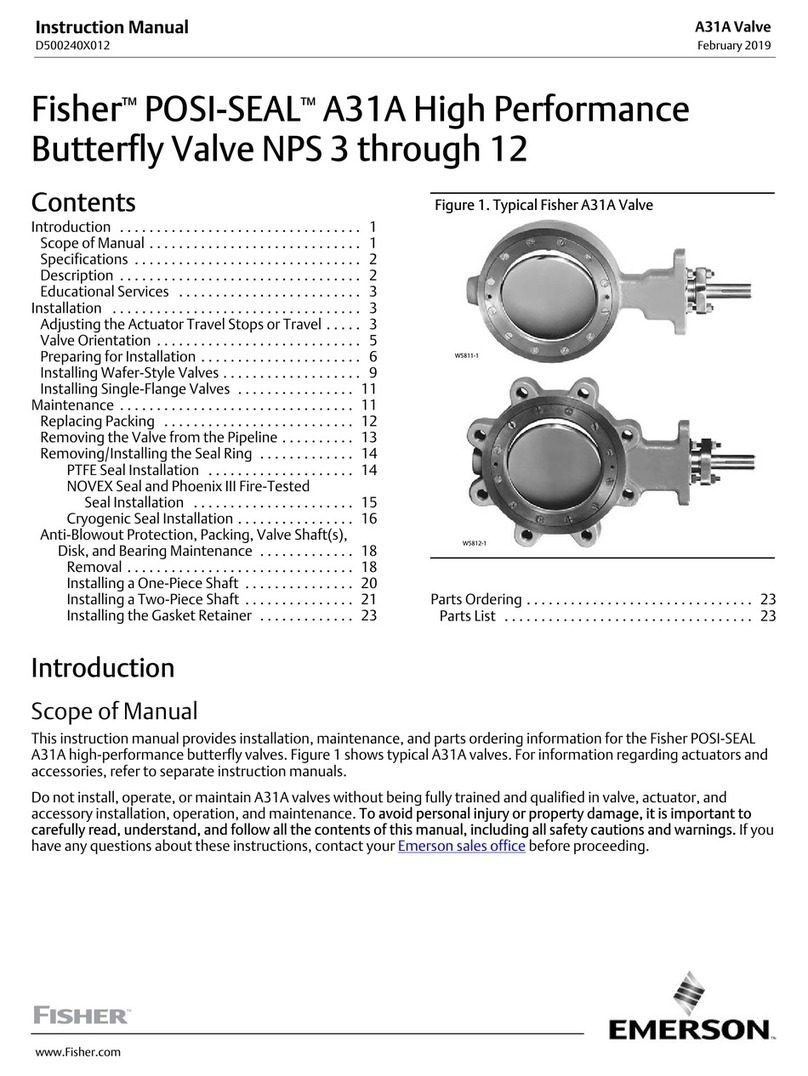

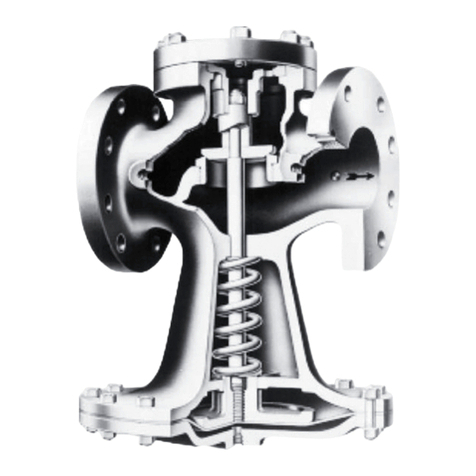

3 INSTALLATION

Many valves are damaged when first placed

in service because of failure to clean the

connection properly when installed. Before

installation flange faces or threaded

connections on both the valve inlet and

the vessel and/or line on which the valve is

mounted must be thoroughly cleaned of all dirt

and foreign material.

Because foreign materials that pass into and

through safety valves can damage the valve,

the systems on which the valves are tested and

finally installed must also be inspected and

cleaned. New systems in particular are prone

to contain foreign objects that inadvertently get

trapped during construction and will destroy

the seating surface when the valve opens.

Thesystem should be thoroughly cleaned

before the safety valve is installed.

Foam padding is sometimes used to protect the

main valve seat during shipping. Check for any

foam padding inside the main valve and remove

before installation.

The gaskets used must be dimensionally

correct for the specific flanges. The inside

diameters must fully clear the safety valve inlet

and outlet openings so that the gasket does not

restrict flow.

For flanged valves, draw down all connection

studs or bolts evenly to avoid possible distortion

of the valve body.

The maximum torque for flange bolting for

valves with aluminum bodies should not exceed

the values shown in the following table.

4 INLET PIPING

Connect this valve as direct and close as

possible to the vessel being protected.

The valve should be mounted vertically in an

upright position either directly on a nozzle from

the pressure vessel or on a short connection

fitting that provides a direct, unobstructed flow

between the vessel and the valve. Installing a

safety valve in other than this recommended

position will adversely affect its operation.

The valve should never be installed on a fitting

having a smaller inside diameter than the inlet

connection of the valve.

5 DISCHARGE PIPING

Discharge piping should be simple and direct.

A ‘broken’ connection near the valve outlet is

preferred wherever possible. All discharge

piping should be run as direct as is practicable

to the point of final release for disposal. The

valve must discharge to a safe disposal area.

The pilot exhaust is often vented to the

atmosphere under operating conditions,

since the discharge during operation is small.

When pilot discharge to the atmosphere is

not permissible, the pilot exhaust should

be connected either to the discharge piping

or through a supplementary piping system

to a safe location. When discharge piping is

designed, avoid the possibility of back pressure

on the pilot unless the pilot is a balanced

design.

Discharge piping must be drained properly

to prevent the accumulation of liquids on the

downstream side of the main valve or pilot.

The weight of the discharge piping should be

carried by a separate support and be properly

braced to withstand reactive thrust forces when

the valve relieves. The valve should also be

supported to withstand any swaying or system

vibrations.

ANDERSON GREENWOOD PILOT OPERATED SAFETY RELIEF VALVES

Operating and Safety inStructiOnS

Threaded valves have flats on the body inlet

neck to aid in installation. Use a back-up

wrench on the body outlet neck during the

installation of discharge piping.

Safety valves are intended to open and

close within a narrow pressure range. Valve

installations require accurate design both

as to inlet and discharge piping. Refer to

International, National and Industry Standards

for guidelines.

If the pilot valve is discharging into a

pressurized system be sure the valve is a

‘balanced’ design. Pressure on the discharge of

an ‘unbalanced’ design will adversely affect the

valve performance and set pressure.

Fittings or pipe having a smaller inside

diameter than the valve outlet connections

must not be used.

2 STORAGE AND HANDLING

Because cleanliness is essential to the

satisfactory operation and tightness of a safety

valve, precautions should be taken during

storage to keep out all foreign materials.

Inlet and outlet protectors should remain in

place until the valve is ready to be installed

in the system. Take care to keep the valve

inlet absolutely clean. It is recommended that

thevalve be stored indoors in the original

shipping container away from dirt and other

forms of contamination.

Safety valves must be handled carefully and

never subjected to shocks. Rough handling may

alter the pressure setting, deform valve parts

and adversely affect seat tightness and valve

performance.

The valve should never be lifted or handled

using the tubing, piping, pilot or pilot brackets.

When it is necessary to use a hoist, use the

lifting eye(s) on the main valve body. If there are

no lifting eyes a chain or sling should be placed

around the main valve body in a manner that

will ensure that the valve is in a vertical position

to facilitate installation.

ft·lb Nm