2

VCIOM-13643-EN © 2019, 2022 Emerson Electric Co. All rights reserved 01/22. Cash Valve is a mark owned by one of the companies in the Emerson Automation

Solutions business unit of Emerson Electric Co. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their

prospective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed

by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time

without notice.

Emerson Electric Co. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance

of any Emerson Electric Co. product remains solely with the purchaser.

Emerson.com

OPERATIONS

1. Maintain a system operating pressure at

least 5 psig or 10% below the set pressure

of the valve, whichever is greater. Operating

too close to the valve set pressure will cause

seat leakage and will shorten the time

between valve maintenance.

2. Do not use the safety valve as a control valve

to regulate system operating pressure.

Excessive operation will cause the seat

to leak and will require more frequent

valve maintenance.

MAINTENANCE

Maintenance should be performed on a

regular basis. An initial inspection interval of

12 months is recommended. Depending on

the service conditions and the condition of the

valve, the inspection interval may be decreased

or increased. Use only Cash Valve parts for

repair. Depending on the local jurisdictional

requirements where the valve is installed,

repairs may have to be made by a repair facility

holding a VR stamp.

WARNING

Removal of the seal wires or any attempt to

adjust, repair or modify this product by non-VR

Certified personnel voids the product guarantee

and may cause serious damage to equipment,

personal injury, and death. Emerson is not liable

for any damage resulting from misuse or

misapplication of its products.

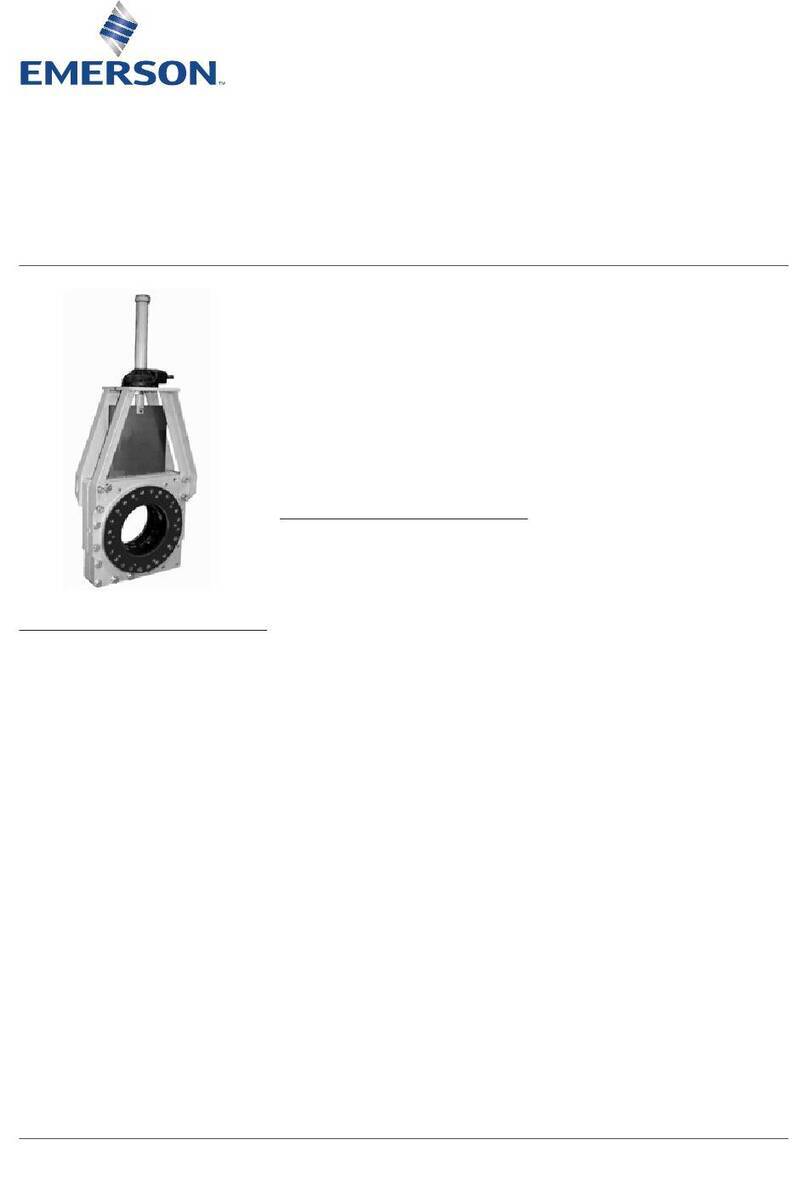

CASH VALVE™ TYPE C776 PRESSURE RELIEF VALVES FOR CRYOGENIC SERVICE

INSTALLATION AND OPERATING INSTRUCTIONS

INSTALLATION

Always wear proper safety equipment, including

safety glasses and ear protection.

1. Mount the valve in a vertical position so that

the valve body is self-draining. If a body drain

port is provided, make sure it is open when

required by the ASME code. Do not plug any

bonnet vent openings. The inlet piping should

be as short as possible, with no elbows,

and equal to or greater than the size of the

pressure relief valve inlet connection. This

will help to limit the inlet pressure drop to

3% or less when the valve is relieving.

2. When discharge piping is connected to valve

outlet, make sure it is self-draining if a body

drain port is not used. The valve should not

be connected to any discharge pipe that

contains pressure before the valve opens or

to any pipe where the pressure build-up is

greater than 10% of the set pressure when

the valve is open and relieving.

Discharge piping, other than a short tailpipe,

must be supported.

3. For threaded valves, to prevent sealing

compound from entering and damaging the

valve, apply a small amount of pipe thread

sealing compound to external threads only.

Do not put any sealing compound on the first

thread or on any internal threads. To do so

may cause the sealing compound to enter

the valve and cause seat leakage.

Do not use the valve body or bonnet for

installing the valve in threaded connections.

Use the wrench flats provided to tighten the

valve to the connecting pipe. Torque valve

enough to ensure a pressure-tight seal

and do not overtighten. To do so may cause

valve leakage.

4. Do not paint, lubricate or allow contaminates

to enter or cover the interior or any working

parts of the valve.