Table 3. Main Valve Body Sizes, End Connection Styles and Body Pressure Ratings

MAIN VALVE BODY SIZE

MAIN VALVE BODY MATERIAL END CONNECTION STYLE(1)

STRUCTURAL DESIGN RATING(2)

NPS DN psig bar

1

2

3

4

6

25

50

80

100

150

Cast iron

NPT(3) 400 27.6

CL125 FF 200 13.8

CL250 RF 500 34.5

1

2

3

4

6

25

50

80

100

150

WCC Steel

NPT(3) 1500 103

CL150 RF 290 20.0

CL300 RF 750 51.7

CL600 RF 1500 103

8

10

200

250 LCC Steel

CL150 RF 290 20.0

CL300 RF 750 51.7

CL600 RF 1500 103

1.RatingsandendconnectionsforotherthanASMEstandardcanusuallybeprovided.ContactyourlocalSalesOfceforassistance.

2.SeeSpecicationsandTable2foradditionalpressureratings.

3. Available with NPS 1 and 2 / DN 25 and 50 only.

*For further instructions on Types EZR, EZH and EZL, refer to the corresponding instruction manual of these products.

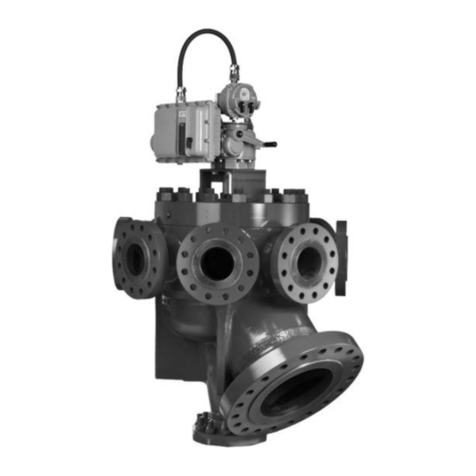

Clean out all pipelines before installation and check to be

sure the valve has not been damaged or collected foreign

material during shipment. Use suitable line gaskets and

good bolting practices with a flanged body. The Type OSE

must be installed in a horizontal position with the mechanism

box above the body (see Figure 2). The Types EZHOSX,

EZROSX and EZLOSX are installed with the mechanism

box typically below the pipe. Type OS2 slam-shut device can

also be installed in a pit that is subject to flooding by venting

the mechanism box above the maximum possible flood

level. When used below ground, the vent must be relocated

(piped) to keep the mechanism box from collecting moisture

and/or other foreign material. Install obstruction-free tubing

or piping into the 1/4 NPT vent tapping. Provide protection

on the relocated vent by installing a screened vent cap into

the end of the vent pipe.

Type OS2 can be used along with a token relief valve to

minimize unnecessary shutoff. The relief valve is set to

open before the Type OS2 slam-shut device activates.

This arrangement allows the relief valve to handle minor

overpressure problems such as gas thermal expansion or

seat leakage due to dirt moving through the system which

may move out of the regulator during the next operating

cycle. The slam-shut device does activate if the regulator

has a major malfunction with excessive gas flow that

exceeds the token relief capacity.

The manometric device requires an external sensing line

which should be tapped into a straight run of pipe 8 to

10 pipe diameters downstream or upstream of the slam-shut

device. If impossible to comply with this recommendation

due to the pipe arrangement, it may be better to position

the sensing line tap nearer the regulator or slam-shut outlet

rather than downstream of a block valve. Do not position

the tap near any elbow, swage or nipple which might cause

turbulence. It is recommended to install an isolation valve

and a vent valve on the sensing line, which can be useful for

tripping and verifications.

Startup*

!

WARNING

To avoid personal injury or property

damage due to explosion or damage to

regulator or downstream components during

startup, release downstream pressure to

prevent an overpressure condition on the

diaphragm of the regulator. In order to avoid

an overpressure condition and possible

equipment damage, pressure gauges

should always be used to monitor pressures

during startup.

These startup procedures are for the Type OSE/OS2 only.

1. Make sure the upstream and downstream shutoff valves

are closed.

2. Slowly open the upstream shutoff valve.

3. For NPS 8 and 10 / DN 200 and 250 body sizes, slowly

open the bypass valve.

4. The slam-shut valve is shipped with the slam-shut

device in the tripped position. To reset the slam-shut,

follow the procedure under Resetting the Trip

Mechanism in the Adjustment section.

5. For NPS 8 and 10 / DN 200 and 250 body sizes, close

the slam-shut valve bypass.

6. Slowly open the downstream shutoff valve.

7. Check all connections for leaks.

8. Adjust the slam-shut pressure setting by following the

appropriate procedures in the Adjustment section.

7

Type OS2

North America Only