V260 Valve

Instruction Manual

May 2010

7

from the valve body cavity. If

necessary, disassemble the valve in a

safe area for cleaning.

See the WARNING at the beginning of

the Maintenance section for more

information before removing the valve

from the pipeline.

Disassemble the valve only to the extent necessary

to accomplish the needed inspection and repairs.

For some repairs (for example, the trim parts only)

complete disassembly of the valve is not necessary.

Follow the disassembly procedures to the point

necessary to accomplish the repair, then skip to the

appropriate assembly steps to complete the

reassembly of the valve. Always clean and protect

sealing surfaces from damage.

Mark parts as necessary to allow them to be

returned to the same position as removed. For

example: Be sure to return the tailpiece to the same

end of the valve from which it was removed. Also,

the seal assembly within the tailpiece should be

returned to the same tailpiece from which it was

removed. The bearing plates should be marked and

reinstalled on the ball in the same position as they

were, when removed.

1. Isolate the control valve from the line pressure,

release pressure from both sides of the valve body,

and drain the process media from both sides of the

valve. If using a power actuator, shut off all pressure

lines to the power actuator, release pressure from

the actuator, and disconnect the pressure lines from

the actuator. Use lock-out procedures to be sure that

the above measures stay in effect while you work on

the equipment.

2. Remove line bolting, remove the control valve

from the pipeline, and clean all valve surfaces. Place

the actuator/valve assembly on a flat working

surface.

3. Mark parts as necessary to allow them to be

returned to the same position during re-assembly.

4. Perform the procedure in the Packing

Maintenance section to remove the actuator from the

valve. When valve maintenance is complete, refer to

the Mounting Actuator procedure at the end of the

Maintenance section to re-install the actuator on the

valve.

5. Provide a clean soft working surface to protect

the tailpiece-flange sealing surface.

a. If the valve does not have an attenuator dome,

lift the valve and place it on its side with either

tailpiece flange resting on the flat surface. Be

sure the valve is in a stable, upright position

before releasing the hoist connection.

b. If the valve has a single attenuator dome, it is

best to position the valve body so the tailpiece

with the dome is in the down position. Be sure the

valve is stable, in an upward position before

releasing the hoist connection.

Note

If the packing is in good condition, it is

possible to remove and replace the

seal assembly, or dome assembly

without removing the packing box

assembly. However, the packing

assembly must be removed to remove

the ball (key 11) from the valve body.

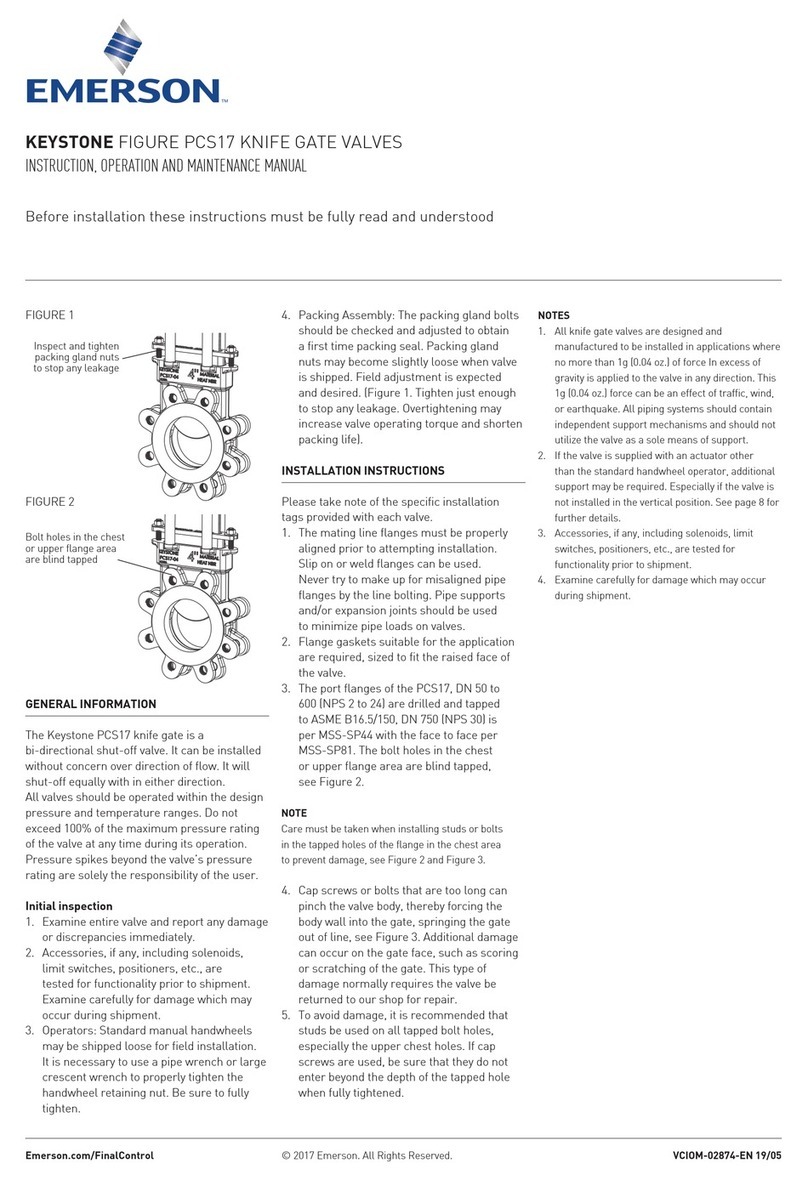

6. Remove the packing housing nuts (key 23).

Remove the packing housing assembly from the

valve. The assembly includes all the packing box

parts, drive shaft, O-ring seals, bearing, and other

parts.

7. Remove the nuts from the studs (keys 19 and 3)

to remove the tailpiece/valve connection. (Refer to

figure 6).

Note

While lifting the tailpiece (key 2 or 6)

from the valve body, check to see if

the seal assembly is lifting with the

tailpiece. (Note: Some valve

constructions do not have a seal

assembly installed in the tailpiece.) If it

is, slide something between the ball

and tailpiece to protect the ball in case

the seal assembly falls out of the

tailpiece.

8. If the valve has dual attenuator domes, tap the

dome to loosen it from the top tailpiece before the

top tailpiece is lifted from the valve body.

9. Turn the tailpiece over so the seal assembly is

facing up, and place it on a clean soft surface with

the flange face down.

10. From the tailpiece assembly or from the valve,

remove the seal assembly, wave spring, and O-ring

seal (keys 8 and 7). Clean and protect all sealing

surfaces.