1592002231 XT130-131C-D GB R.1.0 25.05.2015 XT130C –XT131C - XT130D –XT131D 2/4

In “Pr2” when a parameter is present in “Pr1” the LED is on.

5.7 HOW TO CHANGE A PARAMETER

To change a parameter value operates as follows:

1. Enter the Programming mode

2. Select the required parameter.

3. Press the “SET” key to display its value.

4. Use “UP” or “DOWN” to change its value.

5. Press “SET” to store the new value and move to the following parameter.

TO EXIT: Press SET + UP or wait 15s without pressing a key.

NOTE: the set value is stored even when the procedure is exited by waiting the time-out to expire.

5.8 HOW TO LOCK THE KEYBOARD

1. Keep pressed for more than 3 s the the o and nkeys.

2. The “POF” message will be displayed and the keyboard will be locked. At this point it will be

possible only to see the set point or the MAX o Min temperature stored

3. If a key is pressed more than 3s the “POF” message will be displayed.

5.9 TO UNLOCK THE KEYBOARD

Keep pressed together for more than 3s the the o and nkeys, till the “Pon” message will be

displayed.

5.10 ON/OFF FUNCTION

TO SWITCH THE INSTRUMENT ON/OFF: If the function is enabled (par. onF=yES), by pressing

the SET key for more than 4s the controller is switched OFF. To switch the instrument on again

press the SET key.

6. PROBES AND MEASURING RANGE

7. LIST OF PARAMETERS

REGULATION

db dead band width: (0.1÷Full Scale) this is the band below and above the set point beyond

which the relay 1 respectively relay 2 are enabled. Once a output is enabled, it remains ON

until the set point is reached.

LS1 Minimum set point: (Down Sc.÷ Set) Sets the minimum acceptable value for the set point.

US1 Maximum set point: (Set÷ Full Sc.) Sets the maximum acceptable value for set point.

AC Anti-short cycle delay: (0÷250 sec) Minimum time between the switching off and the

following switching on

on Minimum time a stage stays switched ON (0÷250 sec)

ono:Minimum time between 2 following switching ON of the same load (0÷120 min).

ALARMS

ALC Temperature alarms configuration: it determines if alarms are relative to set point or

referred to absolute values.

rE relative to set point; Ab absolute temperature

ALL Minimum alarm:

with ALC=rE: relative to set point, (0÷|Down Sc.-Set|) this value is subtracted from the set

point. The alarm signal is enabled when the probe values goes below the “SET-ALL” value.

with ALC=Ab absolute value, minimum alarm is enabled when the probe values goes below

the “ALL” value.

ALU Maximum alarm:

with ALC=rE: alarm relative to set point, (0÷|Full Sc.-Set|) Maximum alarm is enabled when

the probe values exceeds the “SET+ALU” value.

with ALC=Ab: absolute alarm, (Set÷Full Sc.) Maximum alarm is enabled when the probe

values exceeds the “ALU” value.

ALH Differential for alarm recovery: (0,1÷Full scale) the alarm recovers when probe value is

higher than Alarm value + ALH.

ALd Alarm delay:(0÷999 min) time interval between the detection of an alarm condition and

alarm signalling.

dAO Delay of alarm at start-up: (0÷23.5h) time interval between the detection of the alarm

condition after instrument power on and alarm signalling.

So1 Relay status with faulty probe: So1=oFF open; So1=on closed.

So2 Output 2 status with faulty probe: So1=oFF open; So1=on closed.

tbA Status of alarm relay after pushing a key. (XT131C/ XT131D only): oFF = relay disabled;

on = relay enabled.

AS Alarm relay configuration (XT131C only): cL = 4-6 terminals open with alarm; oP = 4-6

terminals closed with alarm.

PROBES AND DISPLAY

LCI Start of scale, only with current or voltage input: (with rES = in, dE, cE: -99.00÷199.00,

with rES=irE -999÷1999) Adjustment of read out corresponding to 4mA or 0V input signal.

UCI End of scale, only with current or voltage input (with rES = in, dE, cE: -99.00÷199.00,

with rES=irE -999÷1999) Adjustment of read out corresponding to 20mA or 1V or 10V input

signal.

oPb Probe calibration: (-999÷999) allows to adjust possible offset of the probe.

rES Resolution: select the resolution of the controller.

in= integer (-99÷199);

dEC= 1 decimal point (-99.0÷199.0),

cE = 2 digits after the decimal point (-99.00÷199.00) only for current or voltage input,

irE = integer, large scale (–999÷1999) only for current or voltage input.

WARNING: if rES is changed from “irE” to another value, all the parameters values

expressed in degrees: SET, db, LS1, uS1, ALL, ALu, ALH, LCi, uCi, LAo, uAo, HES, have to

be checked and set.

NOTE: the decimal point selection is not available on models with thermocouple input.

UdM Measurement unit: it depends on models:

for temperature:°C = Celsius; °F = Fahrenheit.

with 4÷20mA, 0÷1V, 0÷10V input : 0= °C; 1= °F, 2= %RH, 3=bar, 4=PSI, 5=no

measurement unit.

PbC Probe selection: it sets the kind of probe. It depends on models

for temperature NTC/PTC: Ptc = PTC; ntc = ntc.

for temperature standard: Pt= Pt100, J = J thermocouple, c= K thermocouple, S = S

thermocouple; Ptc = PTC; ntc = ntc.

with 4÷20mA, 0÷1V, 0÷10V input : cur=4÷20mA, 0-1= 0÷1V, 10= 0÷10V.

P3F Third wire presence for Pt100 probe: for using 2 or 3 wires Pt100 probes: no = 2 wires

probe; yES = 3 wires probe.

ANALOG OUTPUT - ONLY FOR XT130D, XT131D - OPTIONAL

AOC Analog output configuration: (only for models with analog output)

AOC=Pb Probe reading. The analog output parameters LAO and UAO are indipendent and

correspond to the absolute read-out probe signal.

AOC=Er Probe - Set Point1. The analog output parameters LAO and UAO are related to

the difference between measurement of the probe and Set Point .

LAO Lower analog output limit: (only for models with analog output) minimum value of

temperature associated to the 4mA analog output. This value can be absolute or relative to

the Set Point by setting the AOC parameter.

UAO Upper analog output limit: (only for models with analog output) maximum value of

temperature associated to the 20mA analog output. This value can be absolute or relative to

the Set Point by setting the AOC parameter.

SAO Analog output safety with probe fault: (only for models with analog output)

determines what state the analog output should assume when the probe is faulty:

SAO = oFF; analog output = 4mA

SAO = on; analog output = 20mA.

DIGITAL INPUT

HES Set point change during during the Energy Saving cycle : (Down Sc./Full Sc.) sets the

variation of the set point during the Energy Saving cycle.

i1F Digital input operating mode: configure the digital input function: c-H = NOT USED;

oFF = to switch the controller off.; AUS = Not used; HES = Energy Saving; EAL = generic

external alarm; bAL = serious external alarm: it switches off the loads.

i1P Digital input polarity:

CL : the digital input is activated by closing the contact;

OP : the digital input is activated by opening the contact

did Digital input alarm delay:(0255 min) delay between the detection of the external alarm

condition (i1F= EAL or i1F = bAL) and its signalling.

OTHER

Adr RS485 serial address (0÷247) identifies the instrument within a control or supervising

system.

onF Swithching ON/OFF enabling from keyboard: (no = disabled; yES=enabled) It permits

the switching OFF of the instrument by pressing the SET key for more than 4s.

Ptb Parameters table: (read only) Shows the code of the parameters map.

rEL Software release: (read only)

Pr2 To access the Pr2 parameter programming menu.

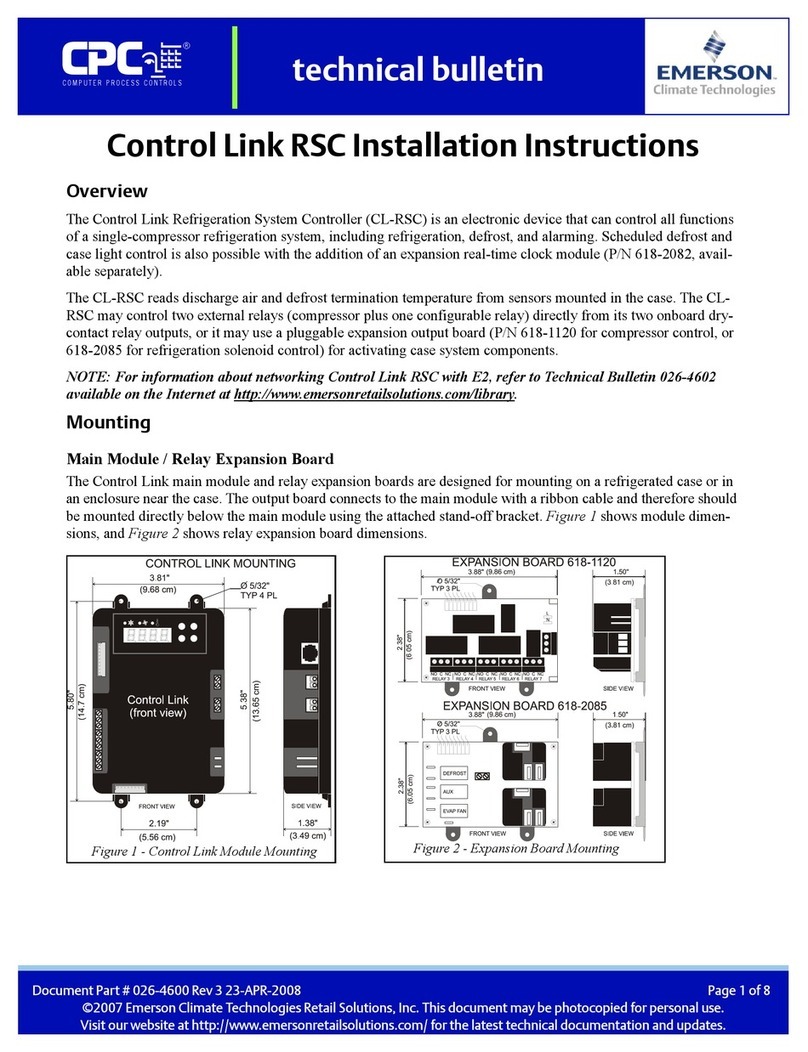

8. INSTALLATION AND MOUNTING

Instrument XT130C and XT131C shall be mounted on vertical

panel, in a 29x71 mm hole, and fixed using the special brackets

supplied.

To obtain an IP65 protection grade use the front panel rubber

gasket (mod. RG-C). Instruments XT130D, XT131D, shall be

mounted on an omega DIN rail .

The temperature range allowed for correct operation is 060 °C.

Avoid places subject to strong vibrations, corrosive gases,

excessive dirt or humidity. The same recommendations apply to

probes. Let air circulate by the cooling holes.

9. ELECTRICAL CONNECTIONS

The instruments are provided with screw terminal block to connect cables with a cross section up

to 2,5 mm2. Before connecting cables make sure the power supply complies with the instrument’s

requirements. Separate the input connection cables from the power supply cables, from the

outputs and the power connections. Do not exceed the maximum current allowed on each relay, in

case of heavier loads use a suitable external relay.

10. SERIAL CONNECTIONS

All models can be connected to the monitoring and supervising system XJ500 using the serial

port. The external XJ485 serial module to interface the instrument with the monitoring and

supervising system XJ500 is required.

The standard ModBus RTU protocol it is used.

NOTE: XT130C or XT131C instruments with current or voltage input and 230V or 115V

supply, cannot be connected to the XJ485 serial module.