August 2020

L231040 Rev AD

7

Calibration routines are included in the software to the 0%

and 00% points for any distance desired. Even reverse

calibration is a simple task using the software routines.

Reverse calibration is desirable if ullage instead of level is

required, or when the probe is installed with bottom mount

electronics.

Level Transmitter. This transmitter computes the distance

between the float and the detector from the elapsed time

measurement. A specific time window becomes active only

for a short time after the interrogation pulse is applied to

the waveguide. Any feedback signal, received before and

after this window, is rejected as noise. Even signals received

during the active window are evaluated and filtered so that

only high integrity data is accepted.

The conditioned signal is converted to a percent of full-scale

number and written to the D/A Converter. The scale is

defined by the calibration procedure and it corresponds to

the output span (0%- 00%).

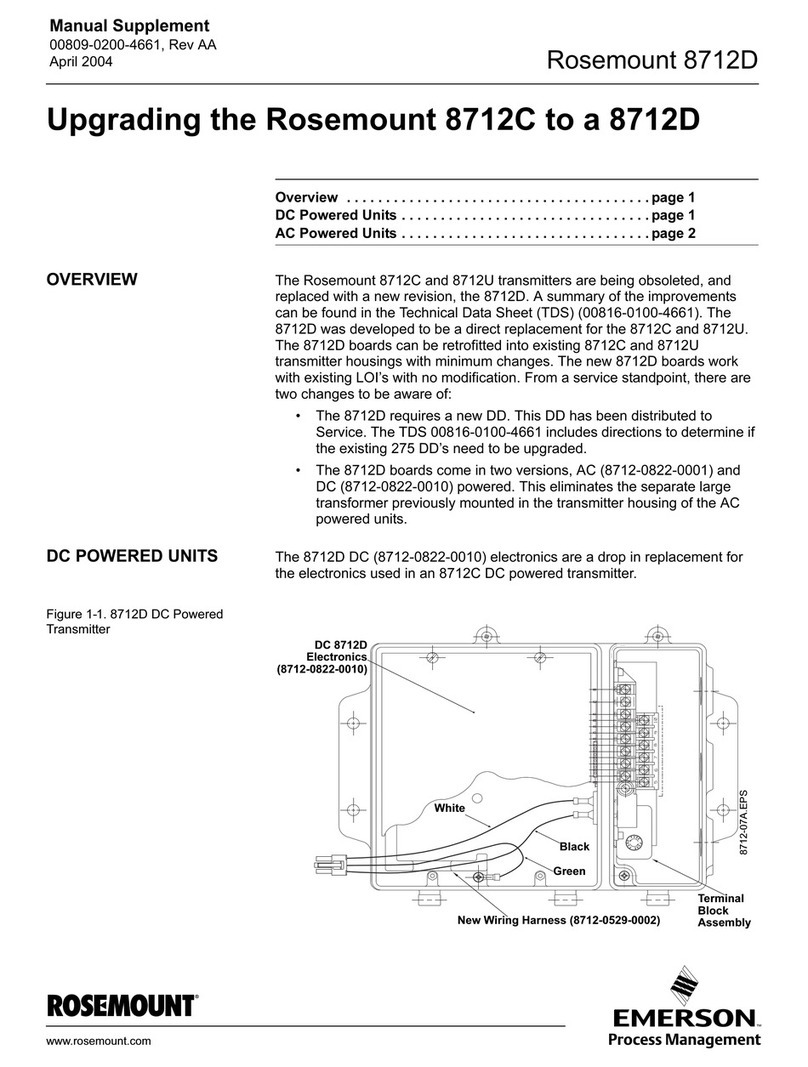

Basic Level Transmitter Simplified Block Diagram

The LTM-350 transmitter has four output configurations.

. Primary Level: The most basic version of this

transmitter is that it computes the distance between

the float and the detector from the elapsed time

measurement. A specific interrogation pulse is

applied to the waveguide. Any feedback signal

received before and after this window is rejected as

noise. Even signals received during the active

window are evaluated and filtered so that only high

integrity data is accepted. The conditioned signal is

converted to a percent of full-scale number and a

number representing the distance and output as an

analog and digital HART signal.

2. Primary Level and Interface Level: A second float

may be added below the first, and the second

output will be calibrated automatically. The second

time interval is timed in the same manner as the

first one to derive the position of the heavier float.

The two floats require a separation of

approximately three inches. The float size,

geometry, and magnetic strength all play a factor in

how close the two floats can be without interfering

with each other. (Only via HART Protocol)

3. Primary Level and Temperature: An optional

temperature sensor is embedded inside the bottom

tip of the probe, and it is configured to be the third

digital output of the transmitter, and comes factory

calibrated for the operating range of -50 °C to 49

°C (-58 °F to 300 °F). (Only via HART Protocol)

4. Primary Level, Interface Level, and Temperature:

This options is called a ‘full- blown” unit and offers

all three possible outputs. (Only via HART Protocol)

A deadband of approximately three inches, next to the

detector, is fixed in the software and the float is not

permitted to enter this area. If this happens output

readings maybe erratic or go to fail mode.

Section 3: Installation and iring

3.0 MLI Mount Transmitter Installation

The LTM-350 can be mounted to the side of a Magtech MLI

series level indicator using a special mounting bracket and

stainless steel hose clamps. When mounting the transmitter

to a MLI the active sensor region of the probe should fall

within the centerline of the process connections on the MLI.

If the transmitter deadband region is inside the centerline of

the process connections the transmitter will not output an

Please Note:

Configuration options must be chosen at quot

•During Insta ation, do not attempt to twist or turn the

head of the transmitter. Damage to the detector

assemb y can occur if the head is rotated. If head is

oose, contact factory immediate y.

Warning:

•

If the instrument is used as an exp osion proof (exp)

device then exp conduit must be sea ed within 18

inches of the termination point