GB

5

Do not leave the room closed

for long. Periodically open

the windows to ensure proper

ventilation.

This instruction booklet is an

integral part of the appliance

and, therefore, it must be kept

with care and must ALWAYS

accompany the appliance, even

when the latter is transferred

to another owner or user or

transferred to another system. If

it gets damaged or lost, please

request another copy from

the local Technical Assistance

Service.

Repairs or maintenance must

be performed by the Technical

Assistance Department or by

skilled personnel in accordance

with this manual.

Do not modify or tamper with the

applianceashazardoussituations

may be generated and the

appliance manufacturer shall not

be held liable for any damage

caused.

BASIC

SAFETY RULES

The use of products that use

electricity and water requires the

observation ofsome fundamental

safety rules such as:

Use of the appliance by children

and unassisted disabled persons

is prohibited.

It is forbidden to touch the

appliance if you are barefoot or

when parts of the body are wet

or damp.

Any cleaning operation is

prohibited before disconnecting

the appliance from the mains

power supply by placing the main

system switch on "off".

It is forbidden to modify the safety

or adjustment devices without

the authorization and the

manufacturer's directions

unit.

It is forbidden to pull, disconnect

or twist the electrical cables

coming out of the appliance,

even if it is disconnected from

the mains.

It is forbidden to introduce objects

and substances through the air

intake and delivery grilles..

OVERVIEW

GENERAL INFORMATION

Thank you for choosing an EMMETI

Thin fan coil unit to air condition

your rooms. Please read this user

and installation manual carefully

before installing and operating

the appliance. By following the

suggestions below you will be able

to maintain the performance of the

appliance over time. In compliance

withEuropeanregulation99/44/EEC,

the manufacturer guarantees the

machine for 24 months from

the date of purchase (without

prejudice to any commercial

warranty extensions), for any

manufacturing defects. Any

other problem related to incorrect

installation, extraordinary

weathering, non-conforming

sizing and unauthorised

tampering is excluded.

Conformity

EMMETI Thin fan coil units conform

to European Directives:

• Low Voltage Directive

(LVD) 2014/35/EU;

• Electromagnetic compatibility Direc-

tive (EMC) 2014/30/EU;

• RoHS Directive 2011/65/EC

• WEEE Directive 2012/19/EU

Symbols

The pictograms shown in the

following chapter allow you to

provide information, quickly and

unequivocally, which is necessary

for the machine to be used correctly

and safely.

Index

- The paragraphs preceded by

this symbol contain crucial

information and prescriptions,

regarding safety in particular.

Failure to comply may result in:

- risks for operator safety

- loss of the warranty

- disclaimed liability by the

manufacturer.

General hazard

- if the operation described is not

performed in compliance with

safety regulations, there may

be a risk of suffering physical

damage.

Electrical hazard

- if the operation described is

not performed in compliance

with the safety regulations,

there lies the risk of suffering

physical damage due to

contact with live elements.

GENERAL

WARNINGS

After unpacking, check that the

contents are intact and that all

parts are included. If not, contact

EMMETI who sold the appliance

to you.

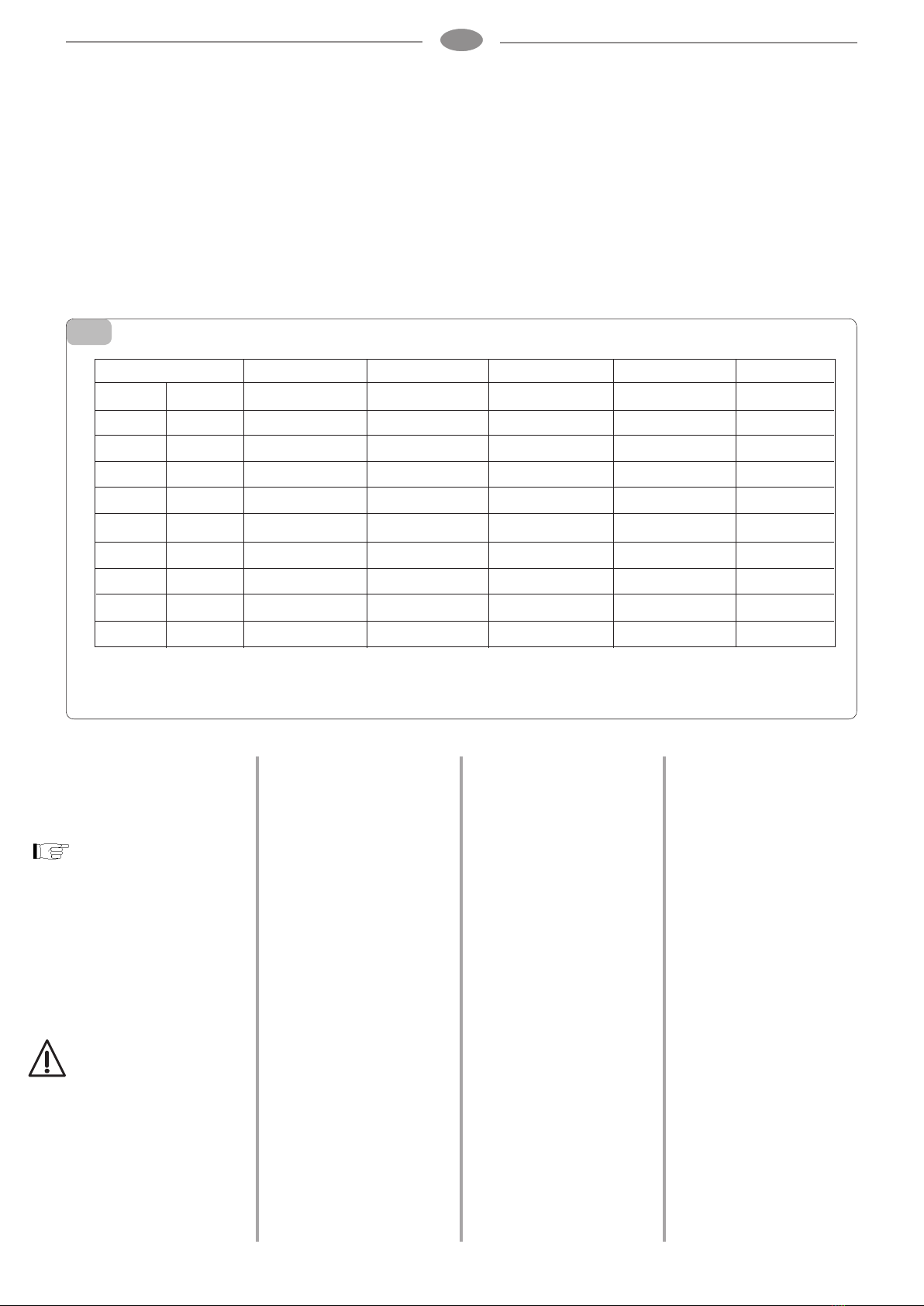

The packaging contains:

- fan coil unit

- thermal insulation for valve

and retainer

- 2 brackets

- user and installation manual

- paper template.

The appliance must be installed

by an authorised EMMETI. Once

the work is done, it must issue

a declaration of conformity

to the client in compliance

with current regulations and

with the indications in the

instruction manual supplied y the

manufacturer with the appliance.

These appliances have been

designed for conditioning and/

or heating rooms and they

must be destined solely for this

purpose, in accordance with their

performance characteristics.

The manufacturer refuses any

contractual or extra-contractual

liability for damage caused to

people, animals or property

resulting from incorrect

installation, adjustment,

maintenance or improper use.

In the event of water leaks, turn

off the main switch and close the

water taps.

Immediately call the Technical

Assistance Service EMMETI or

other qualied personnel and do

not intervene personally on the

appliance.

The recessed ETI series THIN

have no grids or a cover cabinet.

Provide protective elements

and air supply/return grids to

prevent accidental contact with

the appliance.

The following steps must be

carried out if the appliance is

not to be used for a long period:

- Set the master switch of the

system to “off”

- Close the water valves

- If there is a risk of frost,

make surethat antifreeze liquid

has been added to the system,

otherwise empty the system.

A temperature that is too high or

too low is harmful to health and is

an unnecessary waste of energy.

Avoid prolonged direct contact

with the air ow.

It is forbidden to open the access

doors to the internal parts

of the appliance, without having

rst placed the main system

switch on “off”.

It is forbidden to disperse and

leave the packaging material

within the reach of children as

it can be

potential source of danger.

It is forbidden to stand on the

appliance and / or lean against it

any type of object.

The appliance can reach

temperatures on external

components above 70 ° C

BE VERY CAREFUL

TO ANY CONTACT MADE,

RISK OF BURNS.

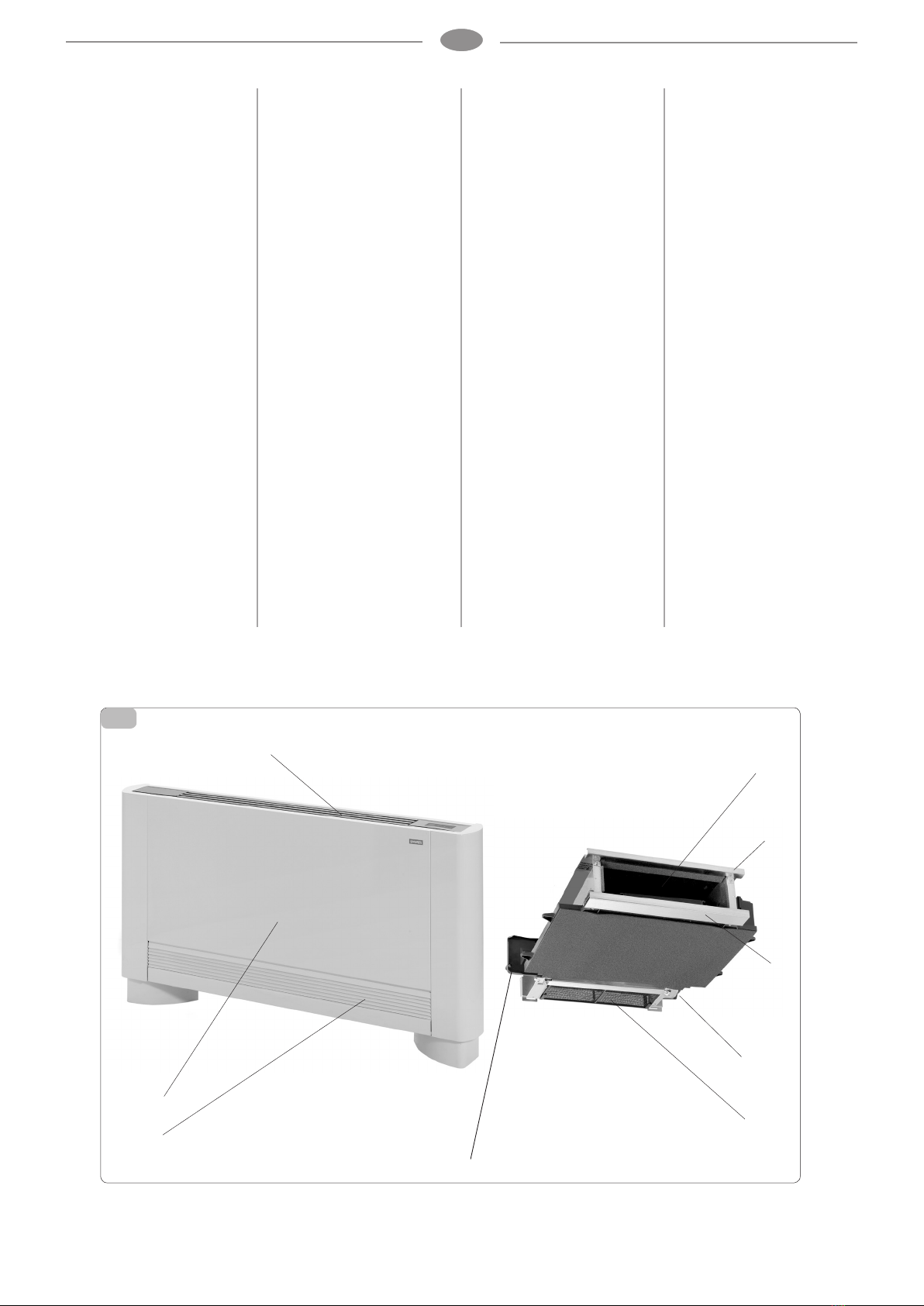

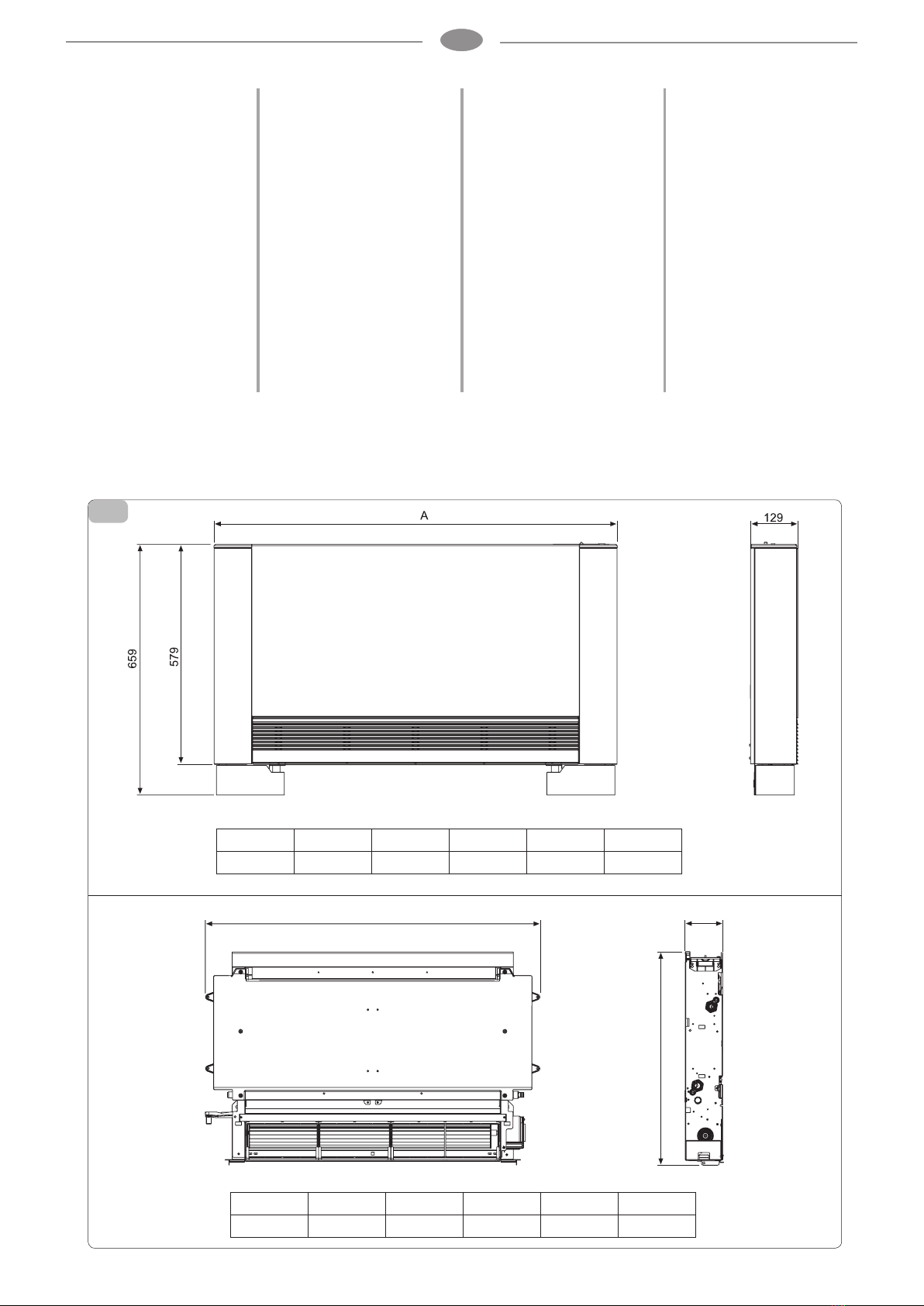

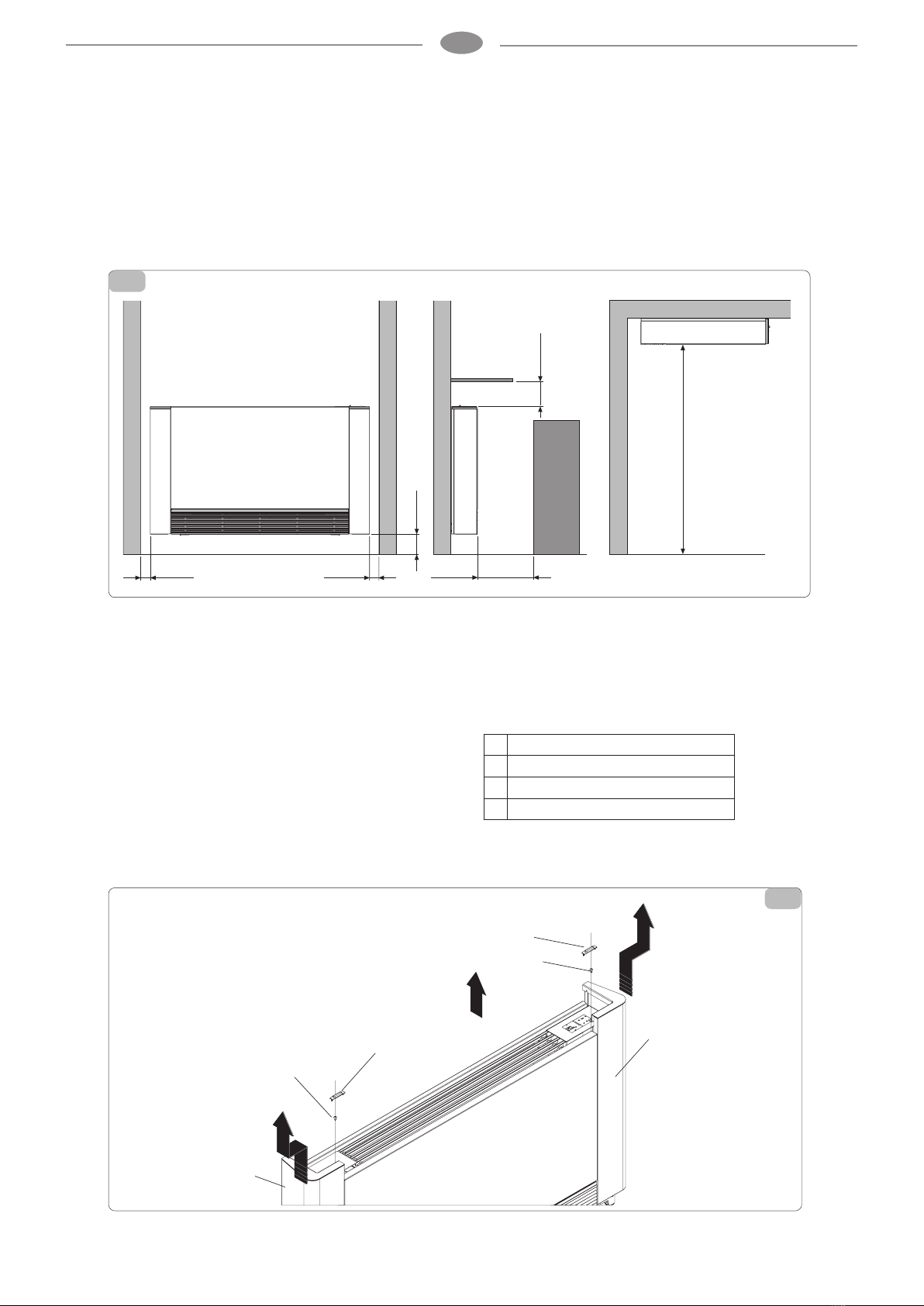

PRODUCT RANGE

Fan coil units of the Thin range

care are divided into 2 basic

types: ETM and ETI – each of

which has different performance

and dimensions

ETM

fan coil unit (suitable for

horizontal or vertical installa-

tions). The horizontal conden-

sate drain pan kit accessories

are available to install the

ETM versions

ETM BRC20 BRC40 BRC60

BRC80

ETI

recessed fan coil unit with no

panelling (suitable for horizontal

or vertical installations).

ATTENTION

It is understood that this equip-

ment is not intended for use

by persons (including children)

with reduced physical, sensory

or mental abilities and must

not be used by people with no

knowledge and experience of the

product. They must be instructed

and monitored while using the

equipment by a person who is

responsible for their safety.