Prothermo NMT539

Endress+Hauser 7

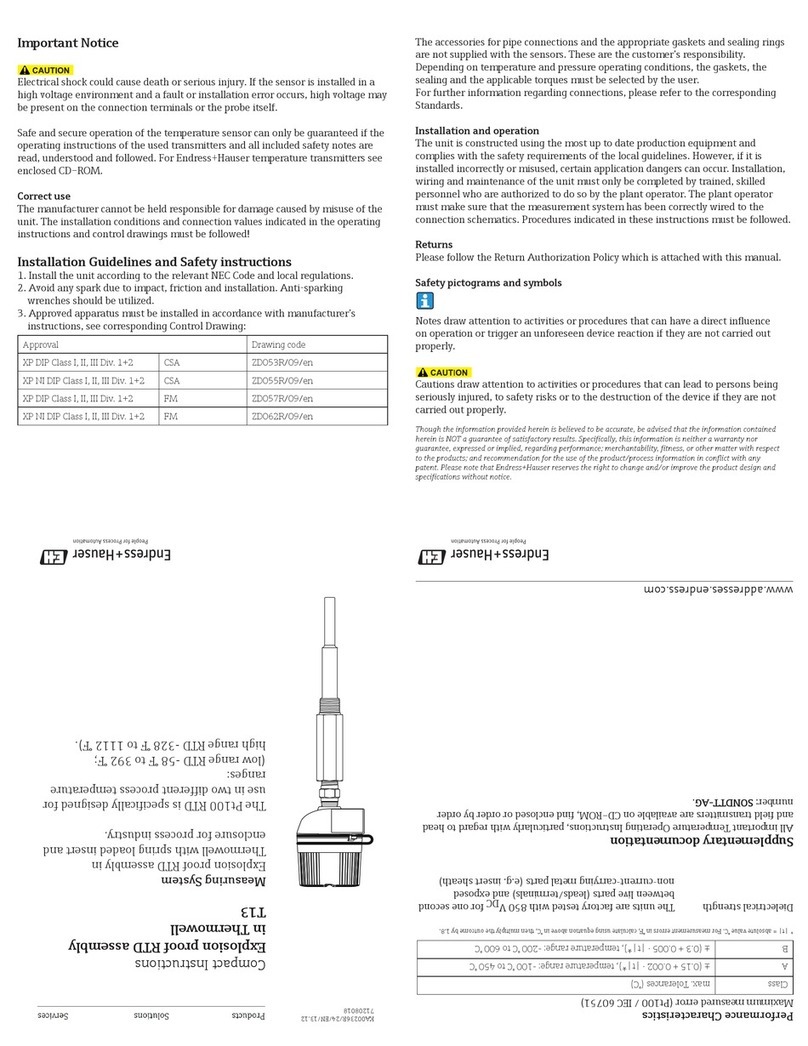

Figure 6: FM C/US approval nameplate

AConverter

B Average temperature and water bottom sensor

1. Temperature class

2. Maximum ambient temperature

3. XA revision number

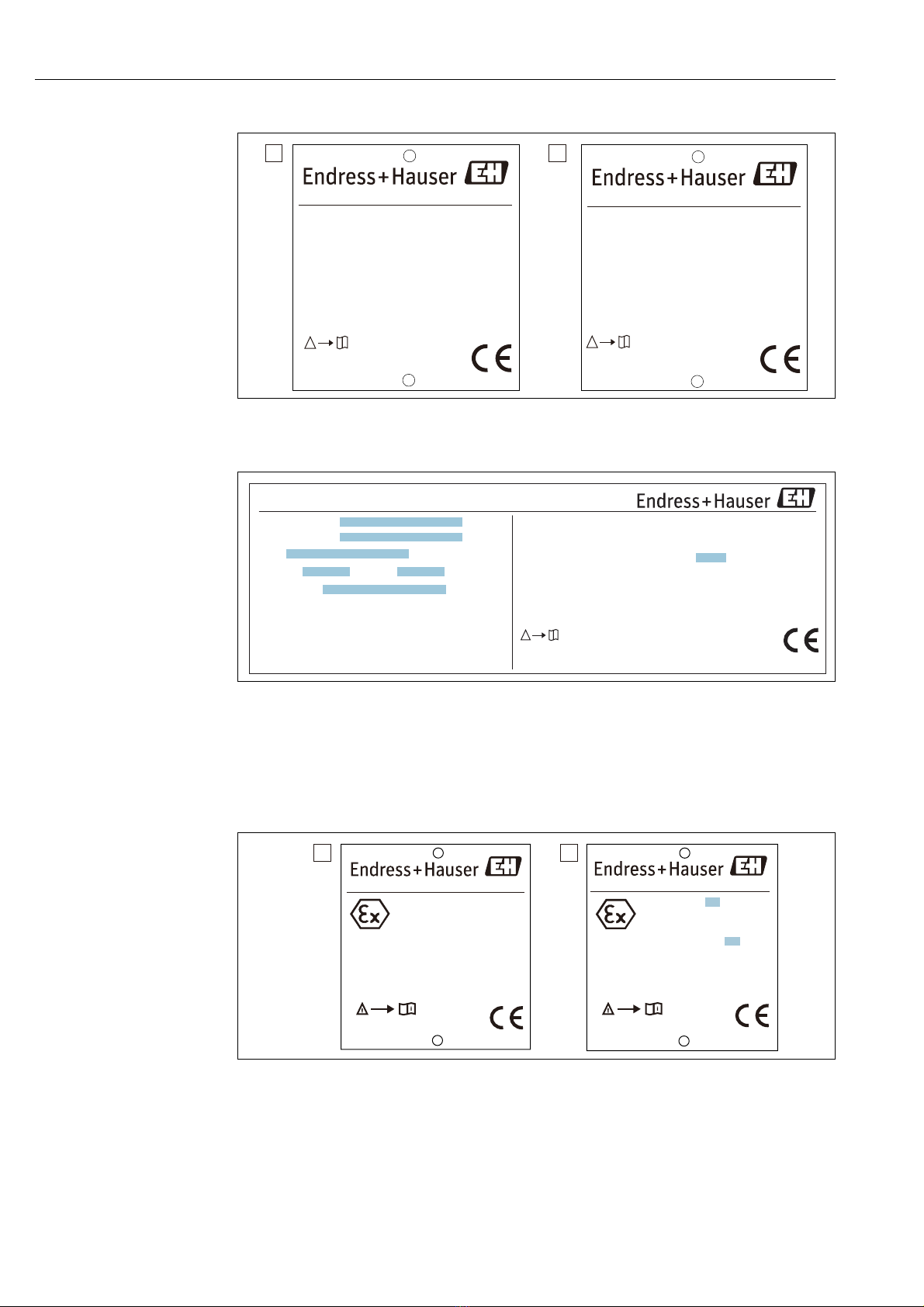

Figure 7: cFMus approval nameplate (Converter + Temperature + WB)

A cFMus approval nameplate (English)

B cFMus approval nameplate (France)

1. Range of measured temperature

2. Maximum ambient temperature

Figure 8: cFMus approval nameplate (Converter only)

Ambient temperature: -40 ~ Υ

NP-2527-2

Warning:

- Don't modify parts and circuits of this instrument.

Supply circuit; Ui < 30 V Ii < 120 mA Pi < 1 W

Temperature measurement circuit;

Uo = 8.6 V Io = 71 mA Po = 153 mW

&R ȝ)/R P+

&L Q)

/L ȝ+

IS Cl. I, Div. 1, Gp. C,D

Cl. I, Zone0, AEx ia IIB T4

NI Cl. I, Div. 2, Gp. C,D

Install per control drawing

No. Ex461-851

Ambient temperature: -40 ~ +85Υ

NEMA 4X, IP65

3527+(502107

Yamanashi 406-0846

Made in Japan

(QGUHVV+DXVHU<DPDQDVKL&R/WG

Ui< 30 V ࠉIi < 120 mA ࠉPi < 1 W

&L Q)/L ȝ+

Warning:

- Don't modify parts and circuits of this instrument.

- Avoid electrostatic charge at the plastic surface.

NP-2528-2

IS Cl. I, Div. 1, Gp. C,D

Cl. I, Zone0, AEx ia IIB T

NI Cl. I, Div. 2, Gp. C,D

Install per control drawing

No. Ex461-850

NEMA 4X, IP65

3527+(502107

Yamanashi 406-0846

Made in Japan

(QGUHVV+DXVHU<DPDQDVKL&R/WG

A B

NP-2528-3

Type 4X

PROTHERMO NMT539

0044

Supply circuit; Ui = 30 V Ii = 120 mA Pi = 1 W

Ci = 6.6 nF

/L ȝ+

Warning:

- Don't modify parts and circuits of this instrument.

- Avoid electrostatic charge at the plastic surface.

Endress+Hauser Yamanashi Co.,Ltd.

Yamanashi 406-0846

Made in Japan

Install per control drawing

C: Ex462-711-3

US: Ex461-850-2

Ambient temperature: -40 ~ Υ

C : IS Cl. I, Div. 1, Gp. C,D T*

IS Cl. I, Zone 0, Ex ia IIB T* Ga

US: IS Cl. I, Div. 1, Gp. C,D T*

Cl. I, Zone 0, AEx ia IIB T* Ga

NI Cl. I, Div. 2, Gp. C,D T*

T* = T

C : FM17CA0088

US: FM17US0168

21

NP-2730

Type 4X

PROTHERMO NMT539

0044

Circuit d'alimentation; Ui = 30 V Ii = 120 mA Pi = 1 W

Ci = 6.6 nF /L ȝ+

Attention:

- Ne modifiez pas les pièces et les circuits de cet instrument.

- Évitez la charge électrostatique sur la surface plastique.

Endress+Hauser Yamanashi Co.,Ltd.

Yamanashi 406-0846

Fabriqué au Japon

Installation par dessin de contrôle

C: Ex462-711-3

US: Ex461-850-2

Température ambiante : -40 ~ Υ

C : IS Cl. I, Div. 1, Gp. C,D T*

IS Cl. I, Zone 0, Ex ia IIB T* Ga

US: IS Cl. I, Div. 1, Gp. C,D T*

Cl. I, Zone 0, AEx ia IIB T* Ga

NI Cl. I, Div. 2, Gp. C,D T*

T* = T

C : FM17CA0088

US: FM17US0168

1

2

A B

NP-2527-3

Type 4X

PROTHERMO NMT539

0044

Ambient temperature: -40 ~ +85Υ

Supply circuit; Ui = 30 V Ii = 120 mA Pi = 1 W

Ci = 6.6 nF

/L ȝ+

Temperature measurement circuit;

8R 9,R P$3R P:&R ȝ)/R P+

Warning:

- Don't modify parts and circuits of this instrument.

Endress+Hauser Yamanashi Co.,Ltd.

Yamanashi 406-0846

Made in Japan

Install per control drawing

C: Ex462-712-3

US: Ex461-851-2

C : IS Cl. I, Div. 1, Gp. C,D T4

IS Cl. I, Zone1, Ex ia IIB T4 Ga

US: IS Cl. I, Div. 1, Gp. C,D T4

Cl. I, Zone1, AEx ia IIB T4 Ga

NI Cl. I, Div. 2, Gp. C,D T4

C : FM17CA0088

US: FM17US0168

A

B

NP-2731

Type 4X

PROTHERMO NMT539

0044

Température ambiante: -40 ~ +85Υ

Circuit d'alimentation; Ui = 30 V Ii = 120 mA Pi = 1 W

Ci = 6.6 nF /L ȝ+

Circuit de mesure de la température;

8R 9,R P$3R P:&R ȝ)/R P+

Attention:

- Ne modifiez pas les pièces et les circuits de cet instrument.

Endress+Hauser Yamanashi Co.,Ltd.

Yamanashi 406-0846

Fabriqué au Japon

Installation par dessin de contrôle

C: Ex462-712-3

US: Ex461-851-2

C : IS Cl. I, Div. 1, Gp. C,D T4

IS Cl. I, Zone1, Ex ia IIB T4 Ga

US: IS Cl. I, Div. 1, Gp. C,D

Cl. I, Zone1, AEx ia IIB T4 Ga

NI Cl. I, Div. 2, Gp. C,D

C : FM17CA0088

US: FM17US0168

2 Identification